Future Directions in High-Tech Manufacturing: Trends to Watch

In 2024, the significance of high-tech manufacturing is paramount as industries gear up for a technological revolution. The landscape is evolving rapidly, with emerging trends shaping the future of production processes. This blog aims to shed light on the key trends driving innovation and transformation in the high-tech manufacturing sector. By exploring these trends, manufacturers can stay ahead of the curve and adapt to the dynamic industry landscape.

Federal Investments and Regulations

New Federal Investments

The 2021 Infrastructure Investment and Jobs Act (IIJA), the 2022 Creating Helpful Incentives to Produce Semiconductors (CHIPS) and Science Act, and the 2022 Inflation Reduction Act (IRA) have significantly influenced high-tech manufacturing through their promotion and funding of infrastructure, clean energy, and semiconductor production. These investments are driving innovation and economic growth in the industry.

Key Points:

Infrastructure Advancements: The IIJA focuses on enhancing infrastructure across various sectors, providing a solid foundation for technological advancements in high-tech manufacturing.

Clean Energy Initiatives: With a focus on sustainability, these investments encourage the adoption of eco-friendly practices within manufacturing processes.

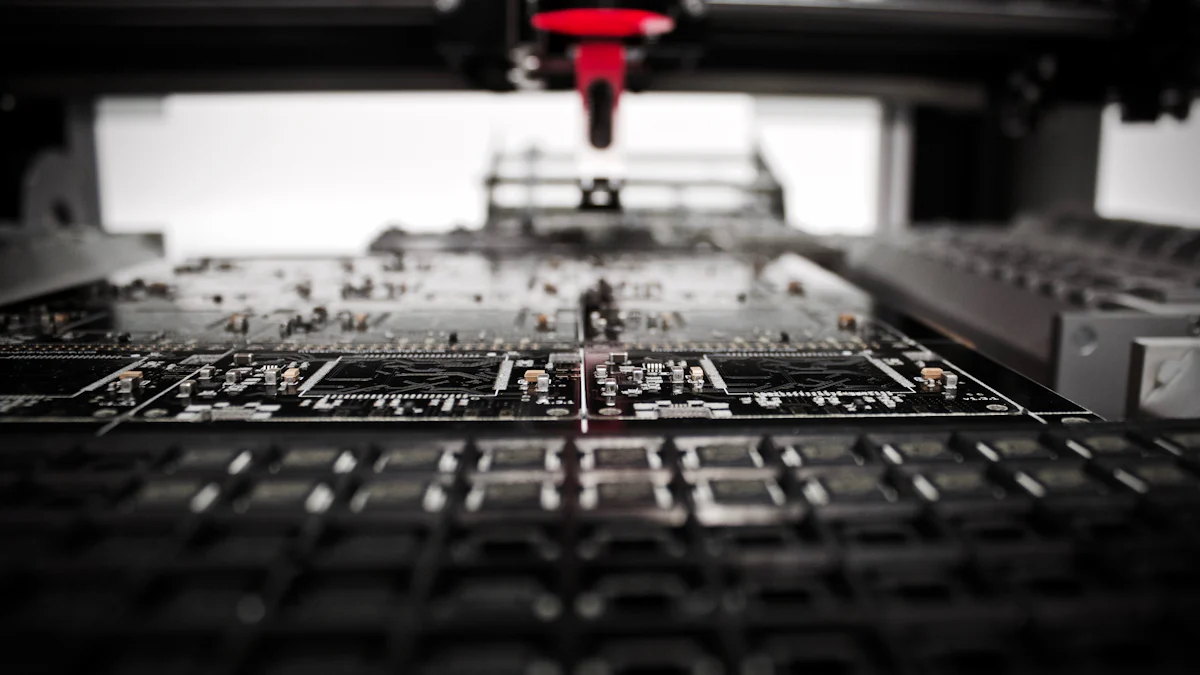

Semiconductor Production Boost: The CHIPS and Science Act aims to strengthen U.S. supply chains, create employment opportunities, and enhance competitiveness in semiconductor technologies.

Impact on Innovation

The infusion of funds from these federal investments is catalyzing innovation within the high-tech manufacturing sector. Manufacturers are leveraging these resources to develop cutting-edge technologies, streamline production processes, and enhance product quality. By investing in research and development initiatives, companies are pushing the boundaries of what is possible in modern manufacturing.

Key Innovations:

Advanced Machinery: High-tech manufacturers are investing in state-of-the-art equipment that improves precision, efficiency, and output capacity.

Smart Manufacturing Solutions: The integration of smart technologies enables real-time monitoring, data analysis, and predictive maintenance for optimized operations.

Collaborative Research: Partnerships between industry players and research institutions foster collaborative innovation that drives technological breakthroughs.

Economic Implications

The economic landscape of high-tech manufacturing is experiencing a positive shift due to these federal investments. By injecting capital into key areas of development, such as automation, digitalization, and sustainability efforts, the government is paving the way for sustainable growth and global competitiveness in the industry.

Economic Benefits:

Job Creation: Increased investments lead to job opportunities across various skill levels within the high-tech manufacturing sector.

Revenue Growth: Enhanced productivity resulting from innovative technologies translates into higher revenues for manufacturers.

Global Competitiveness: By fostering a conducive environment for technological advancement, U.S. manufacturers can compete effectively on a global scale.

Emerging Technologies

Digital Twins and Data Analytics

In the realm of high-tech manufacturing, the integration of digital twins and data analytics is revolutionizing traditional production processes. By creating virtual replicas of physical systems, manufacturers can gain unparalleled insights into performance, maintenance, and optimization strategies. These digital representations enable real-time monitoring, simulation of various scenarios, and predictive analytics that drive data-driven decision-making.

Applications in Manufacturing

Enhancing Operational Efficiency: Digital twins allow for continuous monitoring and analysis of manufacturing operations to identify bottlenecks and streamline processes.

Predictive Maintenance: By predicting potential failures before they occur, manufacturers can proactively address maintenance needs, reducing downtime and optimizing productivity.

Product Lifecycle Management: From design to end-of-life stages, digital twins provide valuable data insights that improve product quality and innovation.

Benefits for Efficiency

Improved Decision-Making: Data analytics derived from digital twins empower manufacturers to make informed decisions based on real-time information.

Enhanced Productivity: Optimizing processes through digital twin technology leads to increased efficiency, reduced waste, and higher output levels.

Cost Savings: By identifying areas for improvement and implementing data-driven solutions, manufacturers can achieve cost savings in production.

Cloud Computing and Generative Design

The convergence of cloud computing with generative design is reshaping the landscape of high-tech manufacturing by offering innovative solutions for product development and production optimization. Leveraging cloud-based resources and advanced design algorithms, manufacturers can unlock new possibilities in design creativity, efficiency, and sustainability.

Integration in Production

Scalable Infrastructure: Cloud computing provides a scalable platform for storing large datasets, facilitating collaboration among teams working on complex manufacturing projects.

Real-Time Collaboration: Generative design tools enable real-time collaboration between designers and engineers across different locations, fostering creativity and accelerating product development cycles.

Adaptive Manufacturing Processes: The integration of generative design with cloud computing allows for adaptive manufacturing processes that respond dynamically to changing market demands.

Future Prospects

Sustainable Innovation: Cloud-based generative design promotes sustainable practices by optimizing material usage, reducing energy consumption, and minimizing environmental impact.

Enhanced Product Customization: Manufacturers can offer personalized products through generative design techniques supported by cloud computing resources.

Industry Disruption: The combination of cloud computing infrastructure with generative design capabilities has the potential to disrupt traditional manufacturing paradigms by enabling agile production methods.

Automation and Robotics

Artificial Intelligence in Manufacturing

Artificial intelligence (AI) is revolutionizing the landscape of high-tech manufacturing by enabling predictive machine analytics that optimize production processes and enhance product quality. By harnessing the power of AI, manufacturers can leverage historical and real-time data to predict machine failures and perform maintenance proactively, ensuring uninterrupted operations.

Predictive Machine Analytics

Collecting Data Insights: Manufacturers utilize AI algorithms to gather data on equipment performance and environmental conditions, enabling them to anticipate maintenance needs accurately.

Proactive Maintenance Strategies: By analyzing patterns in machine behavior, predictive analytics help identify potential issues before they escalate, allowing for timely interventions.

Operational Efficiency: Predictive machine analytics streamline maintenance schedules, reduce downtime, and improve overall operational efficiency within manufacturing facilities.

Enhancing Production Quality

Precision Manufacturing: AI-driven analytics ensure consistent product quality by monitoring production parameters and making real-time adjustments for optimal results.

Quality Control Optimization: Through AI-powered quality control systems, manufacturers can detect defects early in the production process, minimizing waste and enhancing product reliability.

Customer Satisfaction: Enhanced production quality translates into customer satisfaction through the delivery of reliable products that meet or exceed expectations.

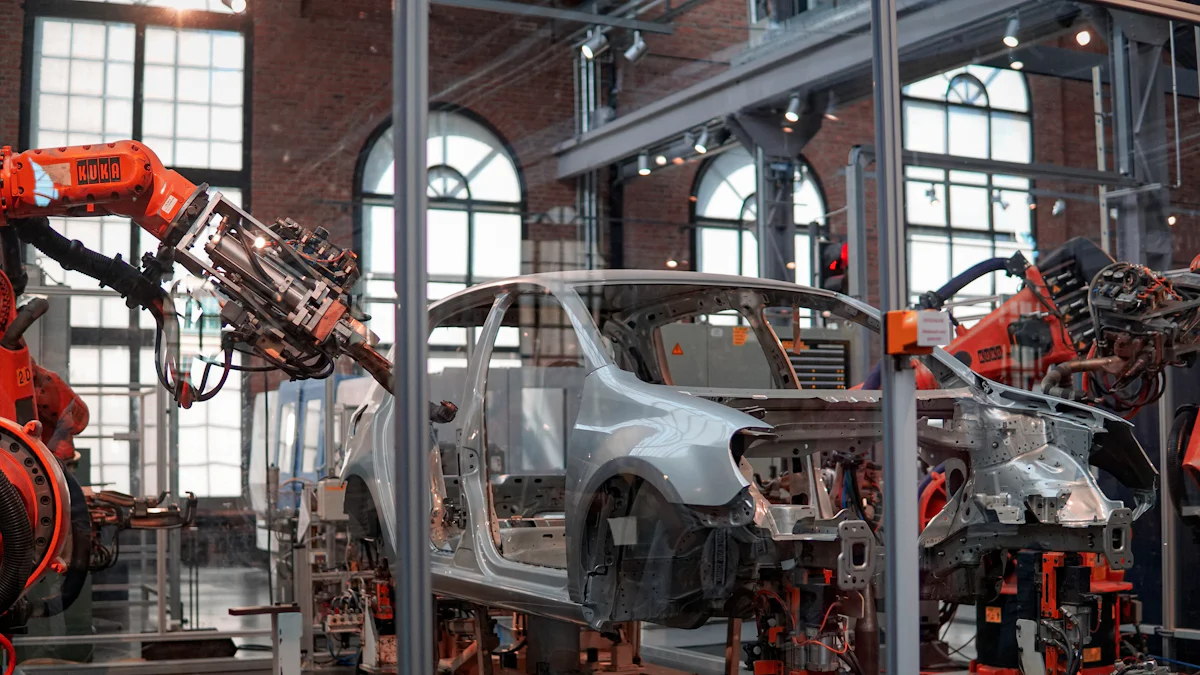

Robotics and Automation

The integration of robotics and automation technologies is reshaping high-tech manufacturing, leading to the development of smart factories that prioritize flexibility and adaptability. By deploying robotic systems and automated processes, manufacturers can achieve higher levels of efficiency, productivity, and operational agility in today's competitive market environment.

Smart Factories

Connected Manufacturing Systems: Smart factories leverage interconnected machines equipped with sensors to collect real-time data for monitoring production activities seamlessly.

Data-Driven Decision-Making: The integration of robotics enables data analysis for predictive insights that drive informed decision-making across all stages of the manufacturing process.

Adaptive Production Environments: Smart factories can adjust workflows dynamically based on changing demand patterns or operational requirements, ensuring optimal resource utilization.

Flexibility and Adaptability

Agile Manufacturing Processes: Robotics enable rapid reconfiguration of production lines to accommodate varying product specifications or volume fluctuations efficiently.

Scalable Operations: Automated systems offer scalability options that allow manufacturers to expand or modify their production capacities without significant disruptions to existing workflows.

Enhanced Agility: The combination of robotics with automation enhances manufacturing agility by facilitating quick responses to market changes or internal optimization needs.

Advanced Manufacturing Techniques

In the realm of high-tech manufacturing, the adoption of 3D printing and additive manufacturing techniques is revolutionizing traditional production processes. These innovative methods offer unparalleled customization capabilities and contribute significantly to waste reduction, driving efficiency and sustainability in manufacturing operations.

3D Printing and Additive Manufacturing

Customization Capabilities

High-tech manufacturers are leveraging 3D printing and additive manufacturing to achieve unprecedented levels of customization in product development. By utilizing advanced design software and additive processes, companies can tailor products to meet specific customer requirements with precision and speed.

Tailored Solutions: Through 3D printing, manufacturers can create bespoke components and prototypes that align perfectly with customer needs, enhancing product functionality and user experience.

Personalized Designs: Additive manufacturing enables the production of unique designs and intricate geometries that were previously unattainable using conventional manufacturing methods.

On-Demand Production: The flexibility of these techniques allows for on-demand production of customized parts, reducing lead times and inventory costs while meeting dynamic market demands.

Reducing Waste

One of the key advantages of 3D printing and additive manufacturing is their ability to minimize waste generation throughout the production process. By adopting these sustainable practices, manufacturers can optimize material usage, reduce scrap, and enhance overall resource efficiency.

Material Optimization: Additive manufacturing processes like 3D printing utilize materials more efficiently by only depositing material where needed, minimizing excess waste compared to subtractive methods.

Eco-Friendly Practices: The reduced material wastage associated with additive techniques contributes to a greener manufacturing environment, aligning with sustainability goals and reducing environmental impact.

Cost-Efficient Production: Waste reduction leads to cost savings for manufacturers by lowering material expenses, improving operational efficiency, and streamlining production workflows.

By embracing advanced manufacturing techniques such as 3D printing and additive manufacturing, high-tech manufacturers can unlock new possibilities for customization, waste reduction, and sustainable production practices. These innovative approaches not only enhance operational efficiency but also position companies at the forefront of technological advancements in the evolving landscape of high-tech manufacturing.

Embracing high-tech manufacturing trends is essential for staying agile, responsive, and competitive in the industry.

Staying updated with high-tech manufacturing trends is crucial for success. Being aware of emerging technologies and market trends can lead to business expansion and increased revenue.