Comprehensive Guide to IoT Supply Chain Solutions and Their Benefits

Supply chain management plays a pivotal role in the success of businesses worldwide. Embracing IoT supply chain solutions has become imperative for companies looking to streamline operations and enhance efficiency. The integration of IoT technology revolutionizes traditional supply chains by providing real-time insights and predictive maintenance capabilities. This blog aims to delve into the transformative power of IoT in optimizing supply chain processes, from procurement to delivery, offering a comprehensive guide on its benefits and future trends.

IoT Supply Chain Overview

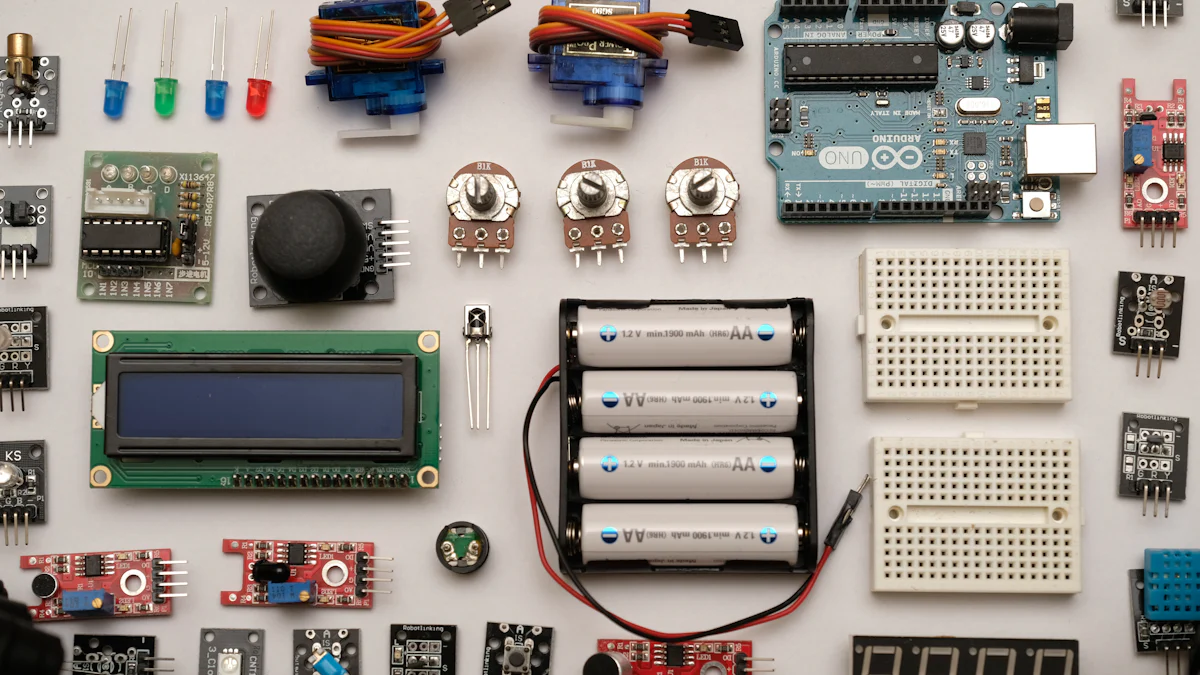

In the realm of supply chain management, the integration of IoT devices has emerged as a game-changer, offering unparalleled insights and optimization opportunities. These devices play a crucial role in enhancing operational efficiency and streamlining processes across various industries. The demand for IoT devices continues to rise steadily due to their multifaceted benefits and their ability to revolutionize traditional supply chains.

Definition and Components

IoT Devices

IoT devices are instrumental components that facilitate real-time data collection and analysis throughout the supply chain. Their versatility allows them to be deployed in diverse applications, from warehouse management to transportation logistics. The widespread adoption of IoT devices underscores their pivotal role in modernizing supply chain operations.

Connectivity

The seamless connectivity enabled by IoT devices ensures a continuous flow of information across different nodes within the supply chain network. This interconnectedness enhances communication channels, enabling swift decision-making processes and proactive problem-solving strategies.

Data Analytics

Data analytics powered by IoT devices provide valuable insights into supply chain performance metrics. By leveraging advanced analytics tools, companies can extract actionable intelligence from the vast amounts of data generated by these devices. This data-driven approach empowers organizations to make informed decisions and optimize their supply chain processes effectively.

Implementation Process

Planning

Effective planning is essential for the successful integration of IoT devices into existing supply chain frameworks. Companies need to strategize meticulously, identifying key areas where IoT technology can drive significant improvements. A well-defined implementation plan ensures a smooth transition towards a more connected and efficient supply chain ecosystem.

Integration

The seamless integration of IoT devices involves aligning these technologies with existing infrastructure seamlessly. Compatibility testing and system configurations are critical steps in ensuring that IoT solutions operate harmoniously with pre-existing systems. Through meticulous integration efforts, companies can maximize the potential benefits offered by IoT in enhancing supply chain visibility and performance.

Monitoring

Continuous monitoring is paramount once IoT devices are integrated into the supply chain environment. Real-time tracking capabilities enable stakeholders to monitor operations proactively, identify bottlenecks, and address issues promptly. By establishing robust monitoring mechanisms, companies can uphold operational excellence and adapt swiftly to dynamic market conditions.

Benefits of IoT in Supply Chain

Enhanced Visibility

Enhancing supply chain operations with IoT devices provides companies with unprecedented visibility into their processes. Through real-time tracking, businesses can monitor the movement of goods from production facilities to end consumers. This level of transparency enables proactive decision-making and efficient resource allocation, ultimately leading to enhanced customer satisfaction.

Transparency

The implementation of IoT solutions in supply chain management fosters a culture of transparency within organizations. By leveraging IoT technology, companies can track product lifecycles accurately and ensure compliance with industry regulations. This heightened level of transparency not only enhances operational efficiency but also builds trust among stakeholders, paving the way for sustainable growth.

Improved Efficiency

Integrating IoT devices into supply chain operations automates repetitive tasks and streamlines processes. Automation reduces human error, accelerates workflows, and minimizes delays in product delivery. By embracing automation through IoT technology, companies can optimize their operations and focus on strategic initiatives that drive business growth.

Efficient resource management is essential for maintaining a competitive edge in today's dynamic market landscape. IoT-enabled supply chains provide real-time insights into resource utilization, enabling companies to allocate resources effectively based on demand fluctuations. By optimizing resource management through IoT solutions, organizations can minimize waste, reduce costs, and enhance overall operational efficiency.

Cost Reduction

Effective inventory management is critical for ensuring seamless supply chain operations and meeting customer demands promptly. IoT technology offers real-time inventory tracking capabilities, enabling companies to maintain optimal stock levels and prevent stockouts or overstock situations. By implementing IoT-driven inventory management systems, businesses can reduce carrying costs, improve order fulfillment rates, and enhance customer satisfaction.

Process Optimization

Optimizing supply chain processes is key to achieving cost savings and operational excellence. With IoT solutions, companies can analyze vast amounts of data generated by connected devices to identify bottlenecks and inefficiencies in their workflows. By leveraging actionable insights from IoT analytics tools, organizations can streamline processes, eliminate redundancies, and drive continuous improvement across the entire supply chain ecosystem.

Future Trends in IoT Supply Chain

Advanced Analytics

In the realm of supply chain management, predictive maintenance stands out as a pivotal trend empowered by IoT technology. By leveraging real-time data insights from connected devices, companies can proactively identify potential equipment failures before they occur. This predictive approach minimizes downtime, reduces maintenance costs, and enhances operational efficiency. Specialized software utilizes IoT data to predict future trends, demand patterns, and potential disruptions in the supply chain ecosystem.

Another significant application of IoT technology in supply chain management is demand forecasting. By analyzing historical data and real-time information collected by IoT devices, organizations can anticipate fluctuations in consumer demand accurately. This proactive forecasting enables companies to optimize inventory levels, streamline production processes, and meet customer needs promptly. Through advanced analytics tools powered by IoT solutions, businesses can enhance their planning strategies and ensure seamless operations.

Blockchain Integration

Security

The integration of blockchain technology into supply chain operations enhances security and transparency across the entire network. Blockchain's decentralized nature ensures that data remains tamper-proof and secure throughout transactions. By leveraging blockchain for supply chain management, companies can mitigate risks related to counterfeit products, unauthorized access, and data breaches. The immutability of blockchain records provides a reliable audit trail for every transaction within the supply chain ecosystem.

Traceability

Blockchain integration offers unparalleled traceability, enabling stakeholders to track the journey of products from their origin to final destination seamlessly. Each transaction recorded on the blockchain creates a transparent and verifiable trail that enhances accountability and trust among participants. Through blockchain-enabled traceability, companies can improve quality control measures, comply with regulatory standards, and build stronger relationships with suppliers and customers.

AI and Machine Learning

Automation

AI-driven automation plays a crucial role in optimizing supply chain processes through predictive analysis and autonomous decision-making capabilities. By integrating AI algorithms with IoT devices, companies can automate routine tasks such as inventory management, order processing, and logistics planning. This level of automation streamlines workflows, reduces human error, and accelerates response times within the supply chain network.

Decision Making

AI and machine learning empower organizations to make data-driven decisions based on real-time insights generated by IoT devices. These technologies analyze vast amounts of data efficiently to identify patterns, trends, and anomalies that impact supply chain performance. By enhancing decision-making processes with AI-driven analytics tools, companies can adapt swiftly to market changes, optimize resource allocation strategies, and drive continuous improvement initiatives across their supply chains.

IoT adoption in supply chains provides numerous advantages for logistics companies. IoT-enabled logistics offer increased data availability and actionability, proactive anomaly event detection, improved planning and workflows, and enhanced quality assurance. By enhancing transparency and collaboration, IoT promotes improved performance and problem-solving capabilities within the supply chain network. Overall, IoT revolutionizes global supply chains by boosting efficiency, transparency, and competitiveness. With IoT devices improving real-time visibility and tracking in supply chain assets, companies can make better decisions and contingency plans effectively.