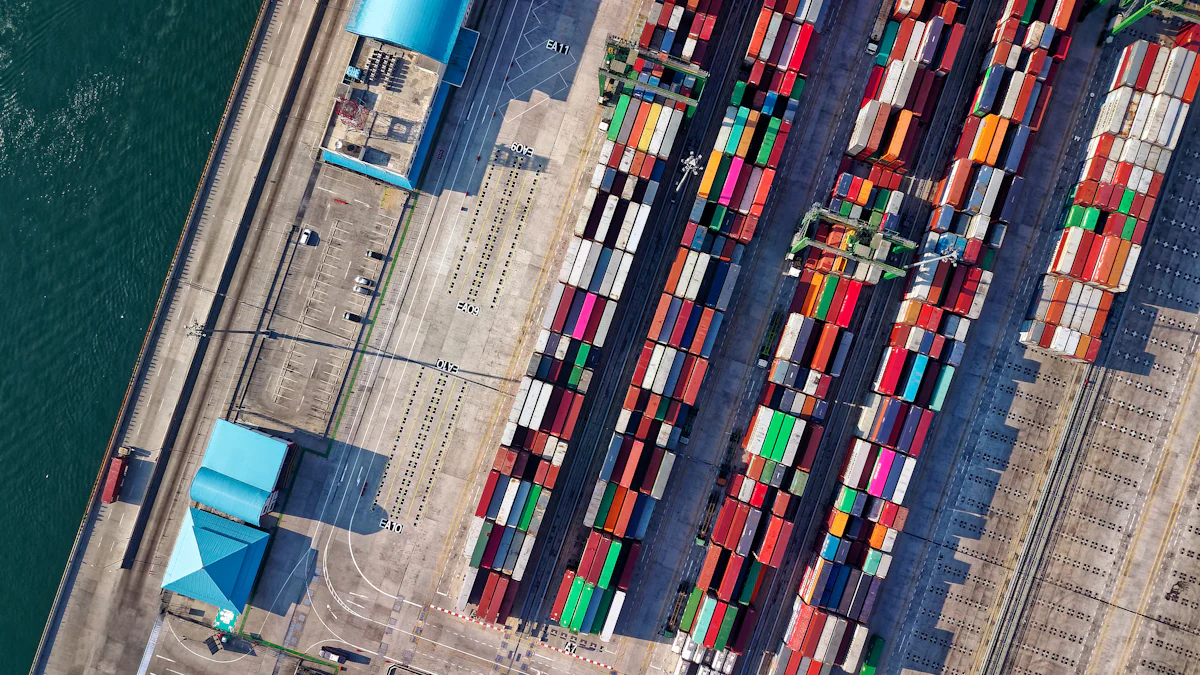

Supply Chain Optimization: Definition, Benefits, and Strategies

Supply chain optimization is the strategic process of maximizing efficiency and minimizing costs within the flow of goods and services. Organizations that prioritize supply chain optimization gain a competitive edge by enhancing performance and accelerating product delivery. This blog delves into the significance of supply chain optimization, its benefits, and effective strategies to achieve operational excellence.

Definition of Supply Chain Optimization

Supply Chain Optimization involves fine-tuning the processes within a supply network to maximize efficiency and minimize costs. By focusing on supply chain optimization, organizations aim to achieve peak performance and expedite the delivery of products. Let's delve deeper into what constitutes supply chain optimization and why it holds immense importance in today's competitive business landscape.

What is Supply Chain Optimization?

Key Components

Efficient Processes: Ensuring that each step in the supply chain operates seamlessly to avoid delays.

Effective Inventory Management: Maintaining optimal stock levels to meet demand without excess or shortages.

Collaborative Relationships: Establishing strong partnerships with suppliers and distributors for smooth operations.

Data-Driven Insights: Leveraging analytics to make informed decisions and identify areas for improvement.

Objectives

Enhanced Efficiency: Streamlining operations to reduce lead times and enhance overall productivity.

Cost Minimization: Identifying cost-saving opportunities across the supply chain without compromising quality.

Customer Satisfaction: Meeting customer demands promptly through timely deliveries and reliable service.

Importance of Supply Chain Optimization

Competitive Advantage

To stay ahead in the market, companies must continuously seek ways to improve their operations. Through supply chain optimization, organizations can outperform competitors by delivering products faster, more efficiently, and at a lower cost.

Cost Reduction

By optimizing their supply chains, businesses can significantly reduce operational expenses associated with inventory management, transportation, and warehousing. This leads to improved profitability and financial sustainability.

Benefits of Supply Chain Optimization

Enhanced Efficiency

Streamlined Operations

Implementing supply chain optimization strategies leads to streamlined operations, ensuring that each process flows seamlessly from start to finish. By analyzing different transportation modes, carrier contracts, and delivery schedules, organizations can reduce costs and improve delivery times. This optimization results in a more efficient supply chain network, enhancing overall productivity.

Improved Collaboration

Another key benefit of supply chain optimization is improved collaboration among partners. Establishing strong partnerships with suppliers and distributors is crucial for smooth operations. By optimizing inventory levels based on historical demand patterns, supplier lead times, and storage costs, organizations can minimize stockouts and reduce excess inventory. This collaborative approach fosters better communication and coordination within the supply chain.

Cost Savings

Reduced Waste

One significant advantage of supply chain optimization is the reduction of waste throughout the supply network. Analyzing data-driven insights helps identify areas where waste can be minimized or eliminated. For instance, by developing a transportation optimization strategy for a logistics company, costs can be reduced while improving delivery times. This reduction in waste contributes to cost savings and enhances operational efficiency.

Optimized Inventory

Optimizing inventory levels is essential for cost savings and operational effectiveness. By analyzing historical demand patterns and supplier lead times, organizations can ensure optimal stock levels to meet customer demands efficiently. Case studies have shown that developing a demand forecasting model for a manufacturing company improves production planning accuracy while minimizing excess inventory. This optimization strategy not only reduces costs but also enhances customer satisfaction through timely deliveries.

Faster Delivery

Accelerated Processes

Supply chain optimization accelerates processes within the network, leading to faster delivery times and improved customer satisfaction. Through process refinement techniques like lean manufacturing principles and just-in-time inventory management, organizations can streamline their operations for quicker order fulfillment. By leveraging technology such as blockchain and artificial intelligence (AI), businesses can enhance their delivery processes further.

Improved Customer Satisfaction

Ultimately, the goal of supply chain optimization is to enhance customer satisfaction by meeting demands promptly and reliably. Faster delivery times achieved through accelerated processes contribute significantly to improved customer experiences. By utilizing data-driven decision-making tools like analytics and predictive modeling, organizations can ensure timely deliveries while maintaining high service quality standards.

Strategies for Supply Chain Optimization

Technology Integration

In the realm of supply chain optimization, technology plays a pivotal role in enhancing operational efficiency and performance. Blockchain, artificial intelligence (AI), and the Internet of Things (IoT) are key components that organizations leverage to streamline their supply networks.

Blockchain

Blockchain technology revolutionizes supply chain transparency by creating an immutable ledger of transactions. Through decentralized record-keeping, companies can track products from their origin to final destination seamlessly. This ensures authenticity, reduces fraud risks, and enhances trust among stakeholders.

Artificial Intelligence

Artificial intelligence (AI) drives predictive analytics and automation in supply chain operations. By analyzing vast datasets, AI algorithms forecast demand patterns, optimize inventory levels, and identify potential disruptions proactively. This enables businesses to make data-driven decisions swiftly and adapt to dynamic market conditions effectively.

Internet of Things

The Internet of Things (IoT) empowers real-time monitoring and visibility across the supply chain. IoT sensors collect data on product location, condition, and movement, enabling precise tracking throughout the logistics process. By harnessing IoT capabilities, organizations can improve asset utilization, minimize delays, and enhance overall operational efficiency.

Process Refinement

Efficiency in supply chain management is not solely dependent on technology but also on streamlined processes that eliminate bottlenecks and enhance productivity.

Lean Manufacturing

Lean manufacturing principles focus on waste reduction and continuous improvement. By optimizing production processes to deliver value with minimal resources, organizations can achieve greater efficiency and responsiveness to customer demands. Implementing lean practices results in shorter lead times, reduced costs, and improved quality control.

Just-In-Time Inventory

Just-in-time inventory strategies aim to minimize excess stock while ensuring timely availability of materials for production. By synchronizing inventory levels with demand fluctuations, companies reduce storage costs and enhance cash flow management. JIT systems promote leaner operations by facilitating a more agile response to market changes.

Data-Driven Decision Making

Data serves as the cornerstone of effective supply chain optimization strategies, enabling informed decision-making and strategic planning based on actionable insights.

Analytics

Utilizing advanced analytics tools allows organizations to extract valuable information from complex datasets. By analyzing historical trends, performance metrics, and customer preferences, businesses can identify optimization opportunities across the supply chain. Analytics drive continuous improvement initiatives by providing visibility into operational inefficiencies and areas for enhancement.

Predictive Modeling

Predictive modeling leverages machine learning algorithms to forecast future scenarios based on historical data patterns. By simulating various what-if scenarios and predicting outcomes with accuracy, companies can mitigate risks, optimize resource allocation, and enhance demand forecasting accuracy. Predictive modeling empowers proactive decision-making that aligns supply chain activities with business objectives effectively.

Optimizing supply chains is crucial for organizations seeking increased profitability, waste reduction, and enhanced customer satisfaction. Manufacturers benefit from this optimization by lowering costs, increasing profits, and improving product quality. Ultimately, supply chain optimization contributes to customer satisfaction, business success, and provides a competitive advantage in the market. Organizations can leverage these benefits by implementing effective strategies and embracing future developments in supply chain management technologies.