2024 Robotics Trends in Supply Chain Management

In the realm of supply chain management, the integration of robotics technology has become paramount. The upcoming year 2024 holds significant promise for advancements in this field. Embracing the latest trends will be crucial for businesses aiming to stay competitive and efficient. The impact of robotics technology on supply chains is poised to revolutionize operations, enhance productivity, and streamline processes like never before.

Advanced Robotics Technology

In the realm of supply chain management, the integration of robotics technology is at the forefront of innovation. The upcoming year 2024 holds promises of significant advancements in this field. Embracing the latest trends will be crucial for businesses aiming to stay competitive and efficient.

AI Integration

Enhanced Decision Making

Artificial Intelligence (AI) integration into robotics technology revolutionizes decision-making processes within supply chains. By analyzing vast amounts of data swiftly, AI enhances decision-making accuracy, leading to optimized operations and improved efficiency.

Predictive Maintenance

Predictive maintenance is a key application of AI in robotics technology for supply chain management. By leveraging AI algorithms, robots can predict maintenance needs accurately, reducing downtime and ensuring continuous operations without disruptions.

Machine Learning Applications

Demand Forecasting

Machine learning applications play a vital role in demand forecasting within supply chains. Through sophisticated algorithms, robots equipped with machine learning capabilities can predict demand patterns accurately, enabling businesses to optimize inventory levels and meet customer needs efficiently.

Inventory Optimization

Inventory optimization is another crucial aspect where machine learning applications shine. Robots integrated with machine learning technologies can analyze inventory data in real-time, identifying trends and optimizing stock levels to prevent overstocking or shortages.

The role of robotics technology in supply chain management continues to evolve rapidly, driven by advancements in AI integration and machine learning applications. These technological innovations are reshaping how businesses operate within their supply chains, enhancing productivity and efficiency like never before.

Collaborative Robots (Cobots)

In the landscape of supply chain management, the integration of robotics technology is reshaping operational efficiency. Collaborative Robots, commonly known as Cobots, are at the forefront of this transformation. These innovative machines are designed to work alongside human counterparts, enhancing productivity and safety within warehouse settings.

Increased Efficiency

Human-Robot Collaboration

The concept of Human-Robot Collaboration represents a paradigm shift in supply chain operations. By working together seamlessly, humans and Cobots can achieve tasks with precision and speed. This collaboration streamlines processes, reduces errors, and boosts overall efficiency in warehouse environments.

Safety Enhancements

Safety is a top priority in any workplace, especially in dynamic settings like warehouses. Cobots are equipped with advanced sensors and safety features that mitigate risks associated with human-machine interactions. These safety enhancements not only protect human workers but also ensure uninterrupted workflow within the supply chain.

Flexibility in Operations

Adaptability to Tasks

One of the key advantages of Cobots is their adaptability to a wide range of tasks. Whether it's picking items from shelves or assisting in packaging processes, these robots can swiftly adjust to varying demands within the supply chain. Their versatility enables businesses to optimize workflows and respond efficiently to changing market dynamics.

Ease of Programming

Unlike traditional industrial robots that require complex programming by experts, Cobots offer a user-friendly interface for programming tasks. With intuitive controls and interactive software, operators can easily teach Cobots new functions without extensive training. This ease of programming empowers businesses to deploy robotics technology swiftly and cost-effectively.

Collaborative Robots are revolutionizing supply chain management by combining the strengths of human workers with the precision and reliability of automation. As businesses embrace these intelligent machines, they unlock new levels of efficiency, safety, and adaptability within their operations.

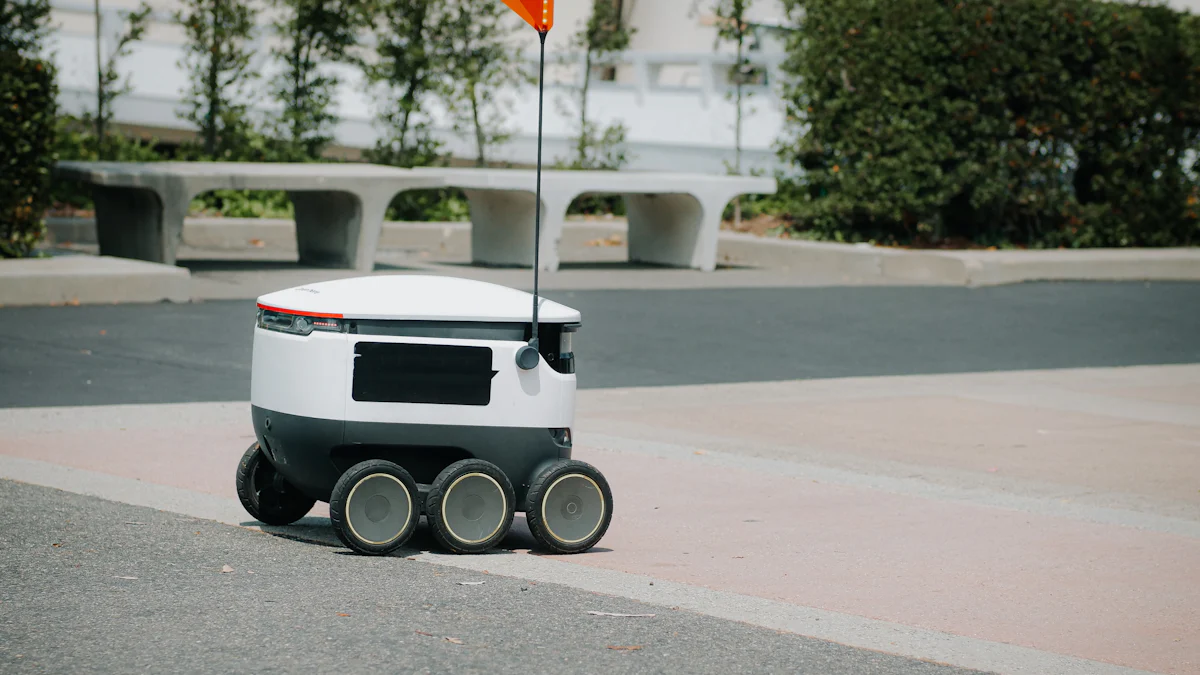

Autonomous Mobile Robots (AMRs)

The integration of robotics technology in supply chain management has paved the way for the rise of Autonomous Mobile Robots (AMRs). These cutting-edge robots are transforming warehouse operations and revolutionizing logistics processes to meet the evolving demands of modern businesses. AMRs offer a myriad of benefits, including increased productivity, enhanced operational efficiency, and cost reduction strategies that are reshaping the industry landscape.

Warehouse Automation

Picking and Sorting

AMRs excel in streamlining warehouse operations through efficient picking and sorting capabilities. With their advanced sensors and intelligent navigation systems, these robots can autonomously navigate warehouse environments, identify items for picking, and accurately sort them for distribution. By automating these tasks, companies can significantly reduce manual labor costs and improve order fulfillment speed.

Transportation within Warehouses

One of the key strengths of AMRs lies in their ability to transport goods within warehouses seamlessly. These robots can navigate through complex warehouse layouts, transport goods between different locations, and optimize inventory management processes. By leveraging AMRs for transportation tasks, businesses can enhance operational agility, minimize errors in handling goods, and ensure timely deliveries to customers.

Last-Mile Delivery

Urban Logistics

In urban settings where last-mile delivery poses significant challenges, AMRs offer innovative solutions for efficient urban logistics. These robots can navigate crowded city streets, deliver packages to customers' doorsteps, and overcome logistical hurdles associated with urban environments. By incorporating AMRs into last-mile delivery services, companies can improve delivery times, reduce carbon emissions from traditional vehicles, and enhance customer satisfaction with reliable service.

Cost Reduction

Cost reduction is a primary driver behind the adoption of AMRs in supply chain management. These robots streamline warehouse operations by optimizing workflows, reducing labor costs associated with manual tasks, and minimizing errors in inventory management. The implementation of AMRs leads to overall cost savings for businesses through increased efficiency, reduced operational downtime, and improved resource utilization.

LexxPluss, a leading provider of autonomous mobile robots (AMRs), offers cutting-edge solutions designed to enhance warehouse automation and intralogistics operations. Their smart interconnectivity features enable total control over fleets of AMRs while ensuring seamless integration into existing warehouse systems. By leveraging LexxPluss' expertise in robotics technology, businesses can achieve unparalleled efficiency gains and operational excellence in supply chain management.

MiR, another prominent player in the robotics industry specializing in internal logistics automation solutions for manufacturing facilities and warehouses. Their range of AMRs combines mobility with collaborative capabilities to optimize workflow processes across various workstations efficiently. By integrating MiR's mobile collaborative robots into existing operations alongside cobots from Universal Robots, businesses can achieve a harmonious blend of automation that enhances productivity levels significantly.

The adoption of Autonomous Mobile Robots (AMRs) represents a pivotal shift towards intelligent automation within supply chains globally. As these advanced robotic systems continue to evolve and adapt to diverse industry needs...

The growth potential of the robotics industry in supply chain management is significant, with the global market projected to reach $117.89 billion by 2027.

Companies can optimize operations, maximize efficiency, and achieve high returns on investment by deploying AMRs in supply chain management.

Robots are redefining the landscape of supply chain management, ushering in an era of unparalleled efficiency, flexibility, and safety.

Implementing autonomous robots can provide significant improvements in productivity and efficiency while reducing labor costs and improving customer satisfaction.

Using robotics, businesses can mitigate workforce shortages, increase throughput, and improve overall warehouse efficiency.

See Also

Robotic Innovations: Exploring Sustainable Supply Chain Trends

Revolutionizing Supply Chains with Robotics Technology

Tomorrow's Logistics Revolution: AI in the Supply Chain