AI Adoption and Low-Cost Implementation Strategies for Supply Chain Optimization

AI Adoption is now within your reach for supply chain optimization. Over the past five years, the market for intelligent, cost-effective solutions has grown quickly. Many businesses, both large and small, now use smart tools to handle complex supply chains. Companies see benefits like faster delivery, better inventory management, and lower costs. You can take advantage of these new technologies to stay ahead in a fast-changing world.

Key Takeaways

AI helps simplify complex supply chains by improving decision-making and reducing errors.

Using AI can cut costs, speed up operations, and improve inventory management.

Start AI adoption with small projects that deliver quick results to build confidence.

Good data quality and clear goals are essential for successful AI implementation.

Overcoming budget, skills, and change challenges is possible with smart planning and training.

Supply Chain Challenges

Rising Complexity

You face a supply chain landscape that grows more complex every year. Modern supply chains stretch across continents, involve many suppliers, and handle a wide range of products. This complexity comes from several sources:

Structural complexity: You manage many suppliers, products, and locations.

Dynamic complexity: You deal with constant changes in demand and external conditions like weather.

Demand complexity: Customer needs shift quickly and often.

Product and supply complexity: Products become more sophisticated and diverse.

Process complexity: Operations involve many steps that can create bottlenecks.

Environmental and social complexity: You must meet sustainability goals and follow new regulations.

Information and technological complexity: Large data volumes and cybersecurity risks challenge your systems.

Globalization and localization: You balance global reach with local needs and rising customer expectations.

These factors combine to make your supply chain harder to manage. Unpredictable shipping schedules, port congestion, and limited tracking can cause delays and inefficiencies. You may see disruptions that increase freight costs and damage customer relationships. Relying on a single supplier raises risk, while diversifying suppliers helps you stay resilient. Real-time tracking and demand forecasting tools help you manage shipments and prevent disruptions.

Modernizing your supply chain with AI-driven tools lets you analyze many variables at once. You make faster, more accurate decisions, reduce errors, and respond quickly to disruptions.

Cost Pressures

You also face rising costs at every stage of your supply chain. Inflation, higher labor costs, and increased shipping expenses put pressure on your margins. Key cost drivers include:

Shipping and logistics costs, which have surged in recent years.

Raw material prices, which are expected to keep climbing.

Real estate costs, as warehouse space becomes scarce.

Financial pressures from geopolitical instability and regulatory changes.

You must balance labor costs, delivery times, and product quality. Many companies now focus on automation, technology integration, and smarter procurement to control costs. Strategies like consolidating shipments, optimizing routes, and using AI for demand forecasting help you reduce expenses and improve efficiency. As customer expectations for fast delivery grow, you need to adapt quickly to stay competitive.

AI Adoption Benefits

Efficiency Gains

You can achieve remarkable efficiency gains by integrating AI into your supply chain. AI-driven systems help you automate repetitive tasks, optimize warehouse layouts, and improve inventory accuracy. Many organizations report faster operations and fewer errors after adopting AI. For example, Lineage Logistics improved warehouse efficiency by 20% and saved $4 million annually through AI-powered automation and inventory management.

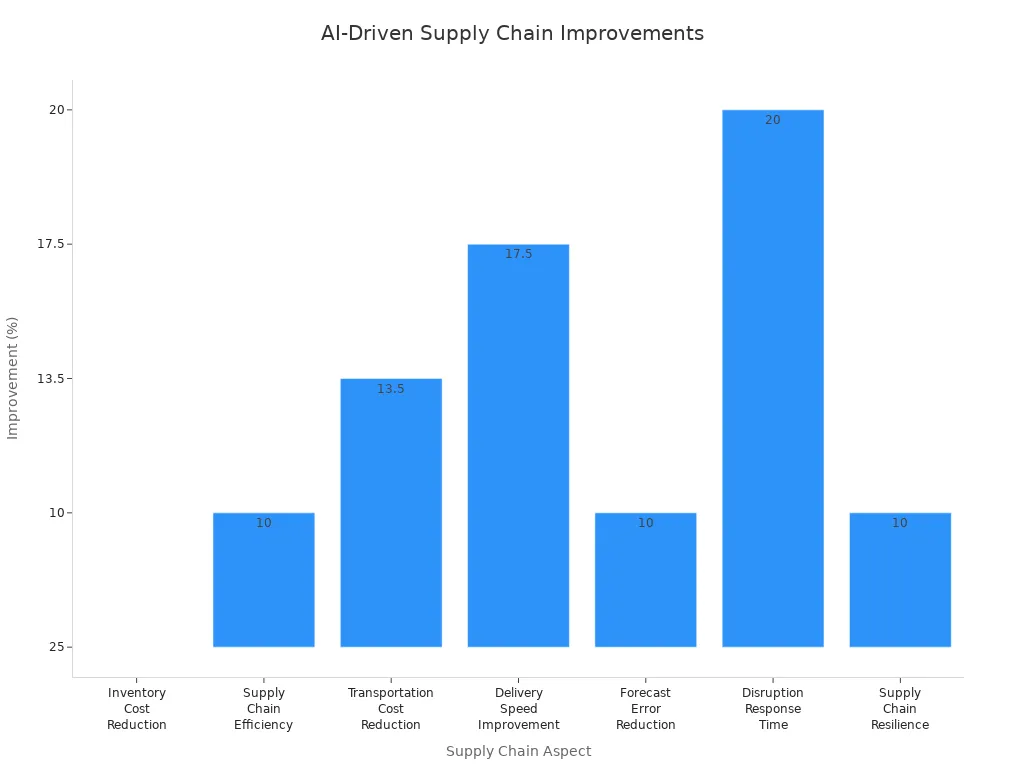

Here is a snapshot of measurable efficiency improvements:

Metric | Reported Efficiency Gain |

|---|---|

Revenue Growth | 74% of users saw increased revenue within 3 months |

Stock Management | 96% reduction in out-of-stock issues |

Operational Efficiency | 89% reduction in future staffing needs |

Time Savings | Up to 50% less time spent on buyer tasks |

Operating Costs | Up to 50% reduction in operating expenses |

AI Adoption also unlocks additional warehouse capacity and reduces supply chain costs by up to 15%. You benefit from more accurate demand forecasting, better routing, and improved worker safety. These improvements help you deliver products faster and with greater reliability.

Cost Reduction

You can lower your supply chain costs significantly with AI. AI-powered forecasting and automation reduce waste, optimize inventory, and cut logistics expenses. Industry reports show that 41% of supply chain professionals experienced cost reductions between 10% and 19% after implementing AI solutions. Companies like Amazon and Walmart have achieved up to 30% inventory cost reduction and 15% lower transportation costs.

You can see that AI-driven optimization outperforms traditional methods by providing real-time insights and dynamic adjustments. This leads to better resource use, less waste, and faster response to market changes.

Resilience

AI Adoption strengthens your supply chain resilience. AI tools analyze data from many sources, such as sales, social media, and logistics networks, to detect disruptions early. You can respond quickly to delays, shortages, or sudden demand spikes. AI also helps you design flexible supply networks and simulate different scenarios, so you stay prepared for unexpected events.

Organizations measure resilience improvements through better on-time delivery, lower inventory costs, and higher visibility. For example, AI reduces forecasting errors by 50% and lost sales by 65%. You gain real-time insights, faster decision-making, and the ability to reroute shipments or adjust production without delay. These capabilities help you maintain steady operations and keep customers satisfied, even during disruptions.

JUSDA’s Approach

JusLink Overview

You want a supply chain partner that understands global complexity and delivers real results. JUSDA stands out as a leader in supply chain innovation, efficiency, and collaboration. With operations in over 155 locations worldwide, JUSDA supports your business across Asia, North America, and Europe. The company works with more than 5,000 component manufacturers and over 1,000 top brand customers. JUSDA’s multicultural team brings together expertise from more than 10 countries, ensuring you benefit from diverse perspectives and local knowledge.

JUSDA’s reach covers a wide range of industries, including electronics, automotive, FMCG, and healthcare. The company offers a full suite of logistics services—truck, air, ocean, and advanced warehousing. You gain access to specialized solutions like the Vietnam-Europe Rail+ service, which cuts transit times by 50% compared to sea freight and reduces air freight costs by 10%. JUSDA’s commitment to customer-centric solutions and technology-driven processes helps you stay competitive in a fast-changing market.

JusLink, JUSDA’s intelligent supply chain platform, brings all these strengths together. You use JusLink to connect every part of your supply chain, from procurement to delivery. The platform integrates AI, IoT, and cloud computing, giving you real-time visibility and control.

Intelligent Features

JusLink offers you a powerful set of intelligent features designed for modern supply chains. You can use AI-driven sales forecasting to predict demand and plan inventory with confidence. Smart replenishment tools help you avoid stockouts and reduce excess inventory. The Control Tower monitors risks in real time, alerting you to disruptions before they impact your business.

JusLink’s automated management features streamline your daily operations. You track shipments, generate reports, and handle exceptions with ease.

JusLink’s microservices architecture lets you customize the platform for your unique needs. You scale up or down as your business grows. With AI Adoption at the core, JusLink empowers you to make smarter decisions, cut costs, and boost efficiency across your entire supply chain.

AI Adoption Roadmap

Embarking on your AI Adoption journey in supply chain optimization does not have to be overwhelming or expensive. By following a clear, step-by-step roadmap, you can unlock value quickly and build a foundation for long-term success. JusLink’s modular SaaS model makes it easy to start small, scale fast, and adapt to your unique needs.

Quick Wins

You should begin by targeting quick wins—AI projects that deliver high value with minimal effort. These early successes build momentum and confidence across your organization. Common quick wins in supply chain management include predictive maintenance, demand forecasting, robotic process automation, route optimization, warehouse automation, and risk management.

Quick Win Area | Description | Example & Outcome | Key Considerations / Fixes |

|---|---|---|---|

Predictive Maintenance | AI models predict machine failures before they occur, reducing downtime. | Used in manufacturing to reduce unexpected breakdowns. | Requires sensor data and clean inputs. |

Demand Forecasting | AI improves inventory management by predicting supply and demand fluctuations accurately. | Walmart reduced forecasting errors by 30%, saving hundreds of millions on inventory costs. | Needs clean, structured data; data standardization is critical. |

Robotic Process Automation (RPA) | Automates repetitive tasks like invoice processing and inventory tracking. | Widely applicable for back-office supply chain tasks. | Focus on automating low-complexity tasks first for quick ROI. |

Route Optimization | AI dynamically recalculates delivery routes considering fuel prices, traffic, and demand. | UPS’s ORION system saves 10 million gallons of gas annually by optimizing routes. | Incorporate real-time data (traffic, weather); partner with experienced AI providers. |

Warehouse Automation | AI-powered robots speed up fulfillment and reduce errors in warehouses. | DHL’s use of collaborative robots has completed over 500 million picks, improving speed and accuracy. | High upfront costs; smaller firms should start with AI warehouse management software before robotics. |

Risk Management | AI detects supply chain disruptions early using digital twins and real-time visibility. | A Fortune 500 automaker cut inventory by 20% and saved $10M in expedite costs using AI risk management. | Use AI for early warnings but keep humans in control for crisis decisions; build manual overrides. |

You can identify and prioritize these quick wins by focusing on projects that align with your business goals, require available data, and offer manageable risk. For example, Hitachi improved productivity by 8% by starting with AI projects that monitored warehouse routines. Amazon and Walmart began with demand forecasting and recommendation engines, using pilots to prove value before scaling.

Data Readiness

Data is the backbone of every successful AI Adoption. You need high-quality, accurate, and consistent data to power AI models. Many companies face challenges such as data silos, inconsistent formats, and legacy systems. To overcome these, you should:

Leverage internal data from all departments to capture supply chain interdependencies.

Incorporate external data like supplier, distributor, and consumer trends.

Automate data acquisition and cleansing to handle large volumes efficiently.

Use AI tools to adapt to changing conditions and predict future outcomes.

Include unstructured data sources, such as social media, for real-time insights.

You must also ensure strong data governance, compliance, and security. Regularly review and refine your data strategies to maintain agility and accuracy.

Solution Selection

Selecting the right AI solution is critical. Start by mapping your current logistics network and identifying pain points. Clean and structure your data to make it usable for AI. Prioritize supply chain issues based on business needs, then design and select AI solutions that fit your goals.

Key criteria for solution selection include:

Data quality and integration capabilities.

Alignment with specific supply chain challenges (e.g., demand forecasting, inventory management, logistics optimization).

Scalability and cost-effectiveness.

Compliance with data privacy and security standards.

Ease of integration with existing systems.

Employee training and change management support.

JusLink’s AI-driven forecasting, risk management, and automation tools offer practical, scalable solutions for these needs.

Pilot Projects

Pilot projects allow you to test AI solutions on a small scale before full deployment. You can validate effectiveness, minimize risk, and refine models using real-world data. Pilots also help train your team and build a strong business case for broader adoption.

Steps for a successful pilot:

Define clear business objectives.

Gather and integrate relevant data.

Select AI technology aligned with your goals.

Run the pilot and measure outcomes.

Scale up based on results.

Pilots foster a culture of innovation and continuous improvement, making AI Adoption smoother and more effective.

Integration

Integrating AI into your existing supply chain systems requires careful planning. Start with a thorough data audit and upgrade your infrastructure as needed. Choose AI tools with strong integration capabilities and adopt a phased approach—proof of concept, pilot, then full deployment.

You should address challenges like resistance to change, data silos, and system incompatibilities. Continuous monitoring and optimization ensure sustained benefits. Human-AI collaboration remains essential, combining technology with your team’s creativity and expertise.

Change Management

Managing change is vital for successful AI Adoption. Communicate openly with employees, involve them early, and present AI as a tool for empowerment, not replacement. Leadership should set a clear vision and support a people-first approach.

Use structured change management frameworks, such as Prosci ADKAR or Kotter’s 8-Step model, to guide your organization through awareness, desire, knowledge, ability, and reinforcement. Upskill employees with targeted training and digital learning platforms. Establish cross-functional teams and change champions to drive adoption and maintain alignment with business goals.

Continuous Improvement

AI in supply chain optimization is not a one-time project. You need to foster a culture of continuous learning and adaptation. Monitor real-time data, refine algorithms, and create feedback loops for ongoing enhancement. Invest in workforce training and maintain robust data governance.

Regularly review your AI systems, update them to meet new regulations, and measure performance against key metrics. Use insights to optimize inventory, forecasting, and logistics. Strengthen relationships with customers and suppliers through real-time analysis and improved decision-making.

Tip: Start small, measure results, and iterate. JusLink’s modular SaaS model lets you scale your AI Adoption at your own pace, ensuring long-term success.

Real-World Results

Manufacturing Case

You can see the power of AI Adoption in action through real-world examples. Sharp, a leading household appliances manufacturer, partnered with JUSDA to transform its supply chain. By using the JusLink platform, Sharp achieved a 20% reduction in logistics costs. This change did not just save money. It also made Sharp’s order processing cycles much faster. You gain real-time visibility into inventory and shipments with JusLink. This means you can track products at every stage and respond quickly to customer needs.

JusLink helped Sharp streamline global supply chain management. You can ensure timely deliveries and improve customer satisfaction by using similar tools. Sharp’s experience shows that even large, complex supply chains can become more efficient and responsive with the right technology.

Measurable Impact

You want results you can measure. JusLink delivers clear improvements in logistics, inventory, and risk management. With real-time data, you can spot problems early and fix them before they grow. You reduce delays and avoid costly mistakes. Sharp’s supply chain now runs smoother, with fewer disruptions and better on-time delivery rates.

Here are some key benefits you can expect:

Lower logistics costs

Faster order processing

Better inventory control

Higher customer satisfaction

When you choose AI Adoption with JusLink, you set your business up for long-term success. You gain the tools to adapt, compete, and grow in a changing market.

Overcoming Barriers

Budget Limits

You may worry about the cost of AI Adoption in your supply chain. Many organizations face budget constraints, especially when starting their digital transformation. The initial investment and ongoing expenses for training and upgrades can seem high. However, you can manage these costs with smart strategies:

Start with small-scale AI projects that deliver quick, measurable results.

Use cloud-based AI solutions to avoid large infrastructure expenses and gain flexibility.

Choose pre-built or subscription-based AI models to lower upfront investment.

Build cross-functional teams to share resources and expertise.

Foster collaboration with partners, vendors, or academic institutions to access specialized knowledge and share costs.

Monitor your AI systems and improve them over time to maximize value.

Invest in workforce training and change management to ensure smooth adoption and better budget efficiency.

Tip: Begin with small deployments and expand as you see a return on investment. Prioritize scalable, modular solutions that fit your needs and budget.

Skills Gaps

You might find that your team lacks the skills needed for AI in supply chain operations. Many organizations face this challenge, but you can bridge the gap with a clear plan:

Assess your current workforce skills and technology to find gaps.

Design training programs for different roles, from basic AI literacy to advanced platform management.

Launch pilot projects so employees can learn by doing and build confidence.

Create a culture of continuous learning with in-house academies and micro-credentials.

Communicate openly about how AI supports your team, not replaces it.

Involve HR, operations, and IT to align training with business goals and future needs.

You help your team grow and keep your business competitive by investing in practical, ongoing training.

Change Resistance

Change can feel hard. Some employees may worry about new technology or fear job loss. You can overcome resistance by:

Communicating the benefits of AI Adoption clearly and early.

Involving employees in pilot projects and decision-making.

Providing training and support to build confidence.

Setting up change champions who encourage others and share success stories.

Recognizing and rewarding adaptability and innovation.

Note: When you lead with empathy and clear communication, your team feels valued and ready to embrace new tools.

You can achieve practical and affordable supply chain optimization through AI Adoption, especially with solutions like JusLink from JUSDA. Many companies, including small and medium-sized enterprises, now use cloud-based AI to reduce costs and improve inventory management.

AI-based tools help you optimize stock, boost agility, and enhance customer satisfaction.

Businesses see up to 35% better inventory levels and 15% lower logistics costs.

Start with quick wins and keep improving. Explore JUSDA’s intelligent solutions and take your first step toward a smarter supply chain today.

FAQ

What is the first step to start using AI in my supply chain?

You should identify a small project with clear goals. Focus on quick wins, such as demand forecasting or inventory tracking. This approach helps you build confidence and see results fast.

How does JusLink help reduce supply chain costs?

JusLink uses AI to predict demand, optimize inventory, and automate routine tasks. You can lower logistics expenses, avoid overstocking, and improve delivery speed. These features help you save money and boost efficiency.

Can small businesses use JusLink’s AI tools?

Yes, you can. JusLink’s modular SaaS model lets you start small and scale as your business grows. You do not need a large IT team or big budget to benefit from AI-driven supply chain solutions.

What kind of data do I need for AI adoption?

You need accurate, clean data from your supply chain operations. This includes sales, inventory, and shipment records. Good data helps AI tools make better predictions and decisions.

See Also

Understanding The Financial Impact Of Supply Chain Efficiency

Best Techniques To Ensure Success In Supply Chain Management

Discover Five Cutting-Edge Methods For Supply Chain Improvement

Effective Strategies To Solve Supply Chain Challenges In Tech

Harnessing Artificial Intelligence To Boost Supply Chain Efficiency