The Role of AI and Automation in Logistics Transformation

AI and automation are reshaping how logistics companies operate. These technologies streamline processes, reduce costs, and enhance customer satisfaction. For example, machine learning improves decision-making, while predictive analytics ensures accurate inventory tracking. By addressing challenges like supply chain disruptions and last-mile delivery, AI drives efficiency and aligns with logistics industry trends.

Key Takeaways

AI and automation make logistics faster and cheaper. Use them to stay ahead in business.

Live data helps make better choices and track supplies. Tools like RFID and IoT sensors help check inventory easily.

Companies like JUSDA improve logistics with AI and eco-friendly methods. Learn from them to make your work better.

AI and Automation in the Context of Logistics

Defining AI and its applications in logistics

Artificial intelligence is revolutionizing logistics by enabling smarter and faster decision-making. You can see its impact in various areas, such as automating data entry to reduce errors and providing real-time tracking for shipment visibility. AI also enhances predictive analytics, helping you forecast demand and optimize inventory levels. For example, it improves predictive maintenance, preventing equipment failures that could disrupt operations. Additionally, AI-powered tools streamline repetitive tasks, saving time and boosting efficiency.

In logistics, artificial intelligence plays a critical role in route optimization, ensuring transportation efficiency and fuel savings. It also supports warehouse management by automating picking and packing processes. With AI, you can achieve better order accuracy, reducing errors in fulfillment and improving customer satisfaction. This technology empowers you to monitor shipments in real-time, identify potential issues, and take proactive measures to resolve them.

Understanding automation in supply chain operations

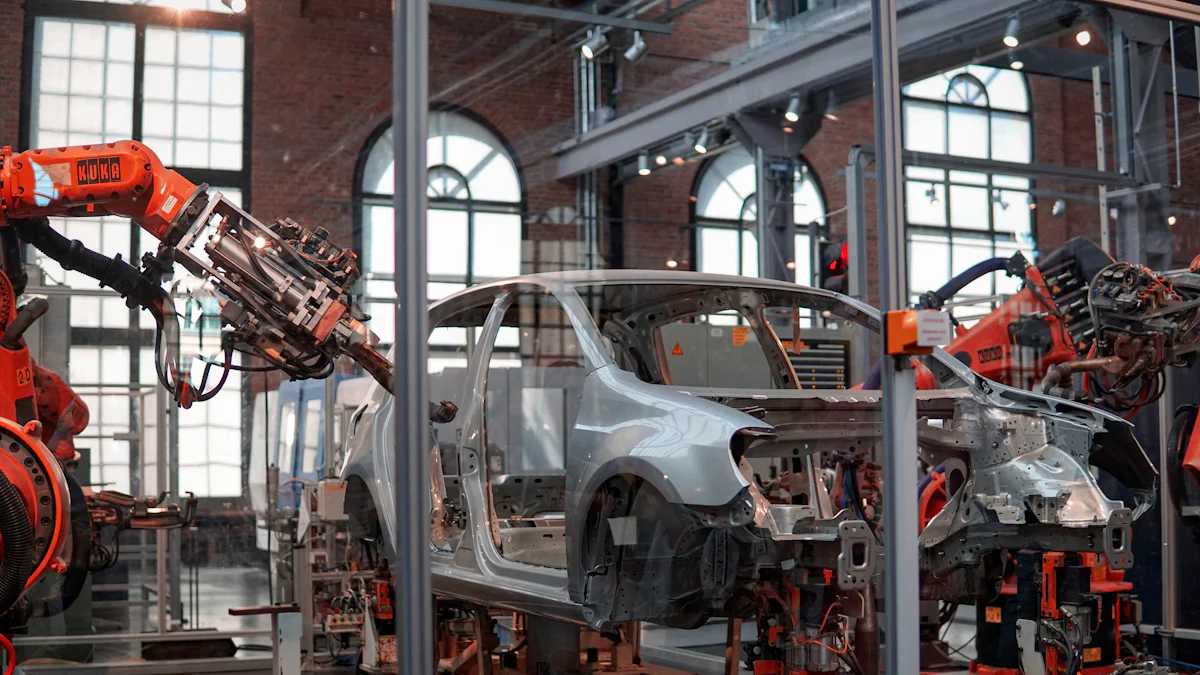

Automation simplifies complex supply chain operations by using advanced tools and systems. For instance, warehouse automation enhances accuracy and productivity in storage and retrieval. Automated Storage and Retrieval Systems (AS/RS) and robotics are common examples, helping you manage inventory efficiently. Transportation automation, including self-driving vehicles and drones, ensures faster and more reliable deliveries.

Type of Automation | Description |

|---|---|

Warehouse Automation | Technologies that enhance accuracy, productivity, and efficiency in storage and retrieval. |

Automated Storage and Retrieval Systems (AS/RS) | Computer-controlled machinery for storing and retrieving goods. |

Robotics | AI-equipped robots for navigating warehouses and picking/packing items. |

Transportation Automation | Use of self-driving vehicles and robotics for moving goods and last-mile delivery. |

Automated Guided Vehicles (AGVs) | Mobile robots that autonomously move goods using sensors. |

Drones | Used for last-mile delivery of small packages, improving speed and reducing road traffic. |

Order Processing Automation | Technologies that automate various stages of order fulfillment. |

Automated Order Fulfillment Systems | Systems that automate sorting, packing, and shipping tasks. |

Robotic Process Automation (RPA) | Software and robots that automate repetitive order-processing tasks, minimizing human errors. |

By adopting these systems, you can reduce manual labor, minimize errors, and improve overall operational efficiency.

How AI and automation work together to optimize logistics

AI and automation complement each other to transform logistics operations. AI-powered solutions provide real-time visibility, allowing you to monitor shipments and address delays proactively. By automating data entry, AI minimizes errors in inventory and shipment information. It also aids in quality control, identifying potential issues before delivery.

When combined with automation, artificial intelligence optimizes inventory management and route planning. This integration reduces costs and enhances efficiency. For example, AI-driven automation in warehouses streamlines picking and packing, ensuring faster order fulfillment. Additionally, AI improves transportation management by predicting shipment ETAs, helping you plan better and meet customer expectations.

Together, AI and automation foster digital transformation in logistics. They enable you to manage demand effectively, reduce risks, and achieve operational excellence. By leveraging these technologies, you can stay ahead in the competitive logistics landscape.

Current Applications of AI and Automation in Logistics Companies

Predictive analytics for smarter supply chain management

Predictive analytics is transforming how you manage supply chains by providing actionable insights. It uses machine learning to analyze historical data and predict future trends. For example, demand forecasting becomes more accurate, helping you prepare for seasonal fluctuations and market changes. Predictive analytics also optimizes inventory levels, ensuring you stock the right amount of goods at the right time. This reduces overstocking and minimizes shortages.

Example Type | Description |

|---|---|

Inventory Optimization | Uses predictive analytics to manage stock levels by forecasting demand and determining optimal inventory levels, reorder points, and order quantities. |

Demand Forecasting | Transforms demand predictions from guesswork to a strategic tool by integrating data from various sources to create accurate forecasts, considering factors like seasonality and market conditions. |

Risk Assessment Modeling | Employs predictive modeling to identify and mitigate risks in supply chains, allowing companies to make informed decisions and develop strategies to enhance resilience and adaptability in a volatile market. |

By leveraging predictive analytics, you can improve supply chain visibility and make smarter decisions, ensuring your logistics operations run smoothly.

Autonomous vehicles and drones in delivery operations

Autonomous vehicles and drones are revolutionizing logistics innovations by making deliveries faster and more efficient. These technologies reduce fuel and labor costs while improving accessibility to remote areas. For instance:

Amazon’s MK30 drone delivers medicine within 60 minutes, showcasing the potential for rapid delivery.

Kodiak’s autonomous trucks enhance logistics efficiency and lower operational expenses.

Drones assist in warehouse inventory management, streamlining stocktaking processes.

Real-time tracking further enhances customer satisfaction by providing transparency. These advancements demonstrate how logistics companies can achieve cost savings and improve delivery reliability.

Robotic process automation (RPA) in warehouse management

RPA is reshaping warehouse management by automating repetitive tasks. It streamlines order processing, from receipt to delivery confirmation, ensuring faster and more accurate fulfillment. RPA also assigns picking and packing tasks based on item location and worker availability, speeding up operations.

Evidence Description | Impact |

|---|---|

RPA streamlines order processing and tracking, automating the entire process from order receipt to delivery confirmation. | Increases speed and accuracy in order fulfillment. |

RPA significantly speeds up the picking and packing processes, assigning tasks based on item location and worker availability. | Enhances timely order fulfillment. |

RPA provides real-time updates on stock levels. | Improves inventory management efficiency. |

By reducing human error and labor costs, RPA allows you to focus on complex challenges, ultimately improving customer satisfaction.

AI-powered route optimization and fleet management

AI-powered route optimization enhances fleet management by reducing costs and improving efficiency. It minimizes fuel consumption and vehicle wear through optimized routes. Real-time dynamic routing adapts to traffic and weather conditions, ensuring timely deliveries.

You can improve employee productivity by optimizing technician schedules.

Customers benefit from accurate estimated arrival times, enhancing their experience.

Optimized routes reduce carbon emissions, promoting sustainability in logistics operations.

By integrating AI into fleet management, logistics companies can achieve operational excellence while contributing to environmental goals.

Benefits of AI and Automation for Logistics Companies

Cost efficiency and operational improvements

AI and automation technology significantly reduce costs and improve operational efficiency in logistics. By automating repetitive tasks, you can lower manual labor expenses and minimize errors. AI implementation also optimizes transportation and inventory management, leading to substantial cost savings.

Metric | Cost Savings |

|---|---|

Transportation Costs | |

Inventory Holding Costs | 30% lower |

Manual Labor Costs | 35% reduction |

Overall Productivity Increase | 12% increase |

These savings allow you to allocate resources more effectively, ensuring your logistics operations remain competitive and efficient.

Enhancing customer experience with faster deliveries

AI ensures faster and more accurate deliveries, which directly enhances customer satisfaction. By streamlining processes, you can provide consistent and timely service. AI-powered systems also reduce wait times by offering instant updates and personalized responses. This efficiency allows your team to focus on complex customer queries, improving overall service quality. Customers appreciate the reliability and speed, which fosters trust and loyalty toward your brand.

Real-time data insights for better decision-making

Real-time data empowers you to make informed decisions quickly. Continuous monitoring of inventory levels helps prevent stockouts and overstock situations. RFID tags and IoT sensors provide instant updates on stock quantities and locations. Additionally, real-time monitoring acts as an early warning system for potential disruptions, such as adverse weather or traffic congestion. This visibility ensures you can adapt to changes and maintain smooth operations.

Real-time data enhances supply chain visibility.

It allows you to monitor processes and anticipate problems.

You can address issues proactively, ensuring operational efficiency.

Promoting sustainability in logistics operations

AI promotes sustainability by optimizing delivery routes and improving resource utilization. Streamlined operations reduce fuel consumption and emissions, aligning with environmentally responsible practices. For example, AI selects the most efficient paths for deliveries, minimizing travel time and fuel usage. These sustainable logistics practices not only meet regulatory demands but also appeal to eco-conscious consumers. By adopting AI-driven solutions, you contribute to a greener future while maintaining operational excellence.

Sustainability is no longer optional in logistics. AI helps you achieve it by integrating efficiency with environmentally responsible practices.

Challenges in Adopting AI and Automation in Logistics

High implementation costs and ROI concerns

Adopting AI and automation in logistics often requires significant financial investment. You may face high costs when replacing outdated equipment or upgrading systems. These expenses can increase overhead, especially during the initial implementation phase. Additionally, the energy consumption of advanced technologies adds to operational costs.

Barrier Type | Percentage of Respondents |

|---|---|

Cost Barriers | |

Cost Barriers | 23% (U.K. and U.S.) |

Potential Disruption to Services | 12% |

Lack of Internal Expertise | 11% |

Many companies also worry about the return on investment (ROI). The need for comprehensive digitization and overcoming legacy systems further complicates the process. These challenges highlight the importance of strategic planning to balance costs and benefits.

Workforce adaptation and reskilling requirements

AI and automation demand new skills, which means you must invest in workforce reskilling. Identifying skill gaps and aligning training with business goals is essential.

Strategy | Description |

|---|---|

Skills Gap Analysis | Assess current skills and identify training needs to align with objectives. |

Personalized Learning | Use AI to create tailored learning paths for employees. |

Continuous Learning Culture | Provide ongoing growth opportunities through courses and mentorship. |

Leadership support and measurable outcomes ensure the success of reskilling programs. By fostering a culture of continuous learning, you can prepare your workforce for technological advancements.

Ethical considerations and data privacy challenges

AI in logistics raises ethical concerns, especially regarding data privacy. Extensive data collection can lead to increased surveillance and potential privacy infringement. You must comply with regulations like GDPR and adopt transparent data handling practices.

Balancing AI benefits with privacy protection is a complex challenge. Inclusive policies and evolving guidelines are necessary to address data bias and automated decisions.

Integrating AI with existing logistics technology

Integrating AI with your current systems can be challenging. Compatibility issues, data security concerns, and reliability problems often arise. Ensuring seamless integration requires robust planning and testing. Addressing these challenges will help you unlock the full potential of AI in logistics.

Future Logistics Trends and Innovations by 2025

AI-driven demand forecasting and inventory management

AI-driven automation is revolutionizing demand forecasting and inventory management. By 2025, you can expect predictive analytics to anticipate demand fluctuations with greater precision. Real-time forecasting will become standard, allowing you to adjust inventory based on consumer behavior. Personalized demand forecasting will tailor offerings to individual preferences, enhancing customer satisfaction. Collaborative forecasting will also improve, enabling departments to work together for accurate predictions. These advancements will optimize inventory levels, reduce waste, and prioritize sustainability metrics in your operations.

Enhanced visualization tools, such as interactive dashboards, will make data easier to understand. Ethical AI practices will ensure fairness and transparency in forecasting models. By integrating these innovations into supply chain management, you can align inventory with customer needs while minimizing costs.

Fully automated supply chains and smart warehouses

Fully automated supply chains and smart warehouses will redefine logistics trends. Artificial intelligence and machine learning will enhance productivity by optimizing robotic routes and automating packing processes. Drones will handle inventory tasks in hard-to-reach areas, while cobots will assist with repetitive tasks alongside human workers. The Internet of Things (IoT) will enable seamless communication between devices, automating inventory management and reducing errors. Mobile devices will further enhance efficiency by allowing employees to manage tasks on the go.

These technologies will create a streamlined logistics process, reducing manual labor and improving accuracy. By adopting these systems, you can achieve faster operations and better resource utilization.

Blockchain for secure and transparent logistics

Blockchain technology will play a critical role in improving security and transparency in logistics operations. Its immutable nature will prevent unauthorized tampering, ensuring data integrity. Real-time tracking will provide up-to-date information about product locations, enhancing visibility across the supply chain. Trust will increase as all parties access the same data, enabling independent verification of transactions.

By integrating blockchain, you can reduce fraud, improve operational transparency, and build stronger relationships with partners and customers.

Generative AI and real-time analytics in logistics technology

Generative AI will transform logistics technology by enhancing real-time analytics. It will identify patterns in historical data to improve demand forecasting. Routing will become more efficient as AI discovers optimal shipping paths. Generative AI will also strengthen risk management by identifying potential disruptions, such as adverse weather or political instability.

These advancements will allow you to make data-driven decisions quickly, ensuring smoother logistics operations and better customer experiences.

Sustainability-focused innovations in logistics companies

Sustainability will remain a key focus in logistics trends. Electric vehicles and alternative fuel fleets will reduce carbon emissions. Optimized routing will lower fuel consumption, while green packaging solutions will minimize waste. Warehouses and distribution centers will invest in renewable energy sources to power operations. IoT sensors will optimize container collections, further improving efficiency.

By adopting these innovations, you can align your logistics operations with environmental goals while maintaining cost efficiency.

The future of logistics lies in embracing these trends. By leveraging AI, blockchain, and sustainability-focused solutions, you can stay ahead in a rapidly evolving industry.

JUSDA’s Role in Shaping the Future of Logistics

Leveraging AI and automation in JUSDA’s supply chain solutions

JUSDA employs advanced AI and automation strategies to optimize supply chain operations. Dynamic inventory management ensures efficient stock control, while auto procurement simplifies purchasing processes. Real-time tracking and analytics provide you with greater visibility and control over logistics. These strategies reduce delays and improve decision-making.

JUSDA’s JusLink platform integrates AI-powered tools for end-to-end supply chain management. It offers intelligent risk management features, helping you anticipate and mitigate potential disruptions. By leveraging these technologies, JUSDA enhances operational efficiency and ensures seamless logistics processes.

JUSDA’s advanced warehouse technologies for logistics transformation

JUSDA’s warehouses utilize cutting-edge technologies to transform logistics. Automated systems like robotics and eVMI streamline inventory management, ensuring accuracy and speed. Real-time tracking tools allow you to monitor stock levels and optimize storage space. Value-added services, such as picking, packing, and labeling, further enhance efficiency.

These innovations create smarter warehouses that reduce manual labor and improve order fulfillment. By adopting these technologies, you can achieve faster operations and better resource utilization.

How JUSDA integrates AI to enhance global supply chain visibility

JUSDA integrates AI to provide unparalleled visibility across global supply chains. Dynamic inventory management and auto procurement ensure smooth operations. Real-time tracking tools allow you to monitor shipments and address issues proactively. JusLink, JUSDA’s AI-powered platform, enables you to manage supply chains end-to-end. It also includes intelligent risk management features, helping you navigate uncertainties effectively.

This integration empowers you to make data-driven decisions, ensuring transparency and control in your logistics operations.

JUSDA’s commitment to sustainability and innovation in logistics

JUSDA prioritizes sustainability by implementing green logistics initiatives. These efforts reduce carbon emissions and align with global environmental standards. By optimizing delivery routes and adopting energy-efficient technologies, JUSDA minimizes its environmental impact. This commitment not only supports eco-friendly practices but also enhances operational efficiency.

Through continuous innovation, JUSDA addresses the growing demand for sustainable logistics solutions, ensuring a greener future for the industry.

JUSDA Solutions

To provide you with professional solutions and quotations.

AI and automation are revolutionizing logistics by streamlining operations and enhancing efficiency. Technologies like robotics, drones, and real-time tracking optimize last-mile delivery and inventory management. Adopting these innovations allows you to reduce costs, improve customer satisfaction, and stay competitive in a rapidly evolving industry. JUSDA exemplifies leadership in this transformation through its JusLink platform, real-time tracking tools, and sustainable logistics practices. Their commitment to innovation ensures operational excellence and positions them as a pioneer in the logistics sector.

See Also

Exploring AI's Hidden Capabilities in Logistics Management

Transforming Future Logistics Through AI Supply Chain Solutions

Discovering AI's Role in Shaping Future Supply Chains

Navigating Tomorrow's Logistics with Advanced Digital Technologies

Innovative Supply Chain Solutions Transforming the Logistics Landscape