How AI-driven Demand Forecasting Transforms Supply Chains

You see ai-driven demand forecasting changing supply chains in many industries. The demand forecasting part now has 35.3% of the market in global supply chains. This shows many companies use it. JUSDA uses ai to make fewer forecasting mistakes by up to 50%. It helps lower inventory costs and makes deliveries faster.

JUSDA’s smart logistics solutions also help you use less fuel. They help you avoid waste with better demand planning.

Key Takeaways

AI-driven demand forecasting makes supply chains more accurate and efficient. It helps companies spend less on inventory. It also helps them avoid running out of stock. Companies can deliver products faster.

Using AI tools like JUSDA’s JusLink platform helps connect data in real time. It also helps with smarter planning. This leads to less waste and lower fuel use. Customers are happier.

To use AI well, companies need clean data and clear goals. They also need teamwork and to start slowly. This helps them solve problems and save money. It also helps them work better.

AI-driven Demand Forecasting Impact

Supply Chain Transformation

AI-driven demand forecasting helps you manage your supply chain better. When you use AI, you can see demand signals more clearly. This helps you spot trends quickly. You can react before problems get worse. AI lets you make flexible models for each product or market. These models change when new data comes in. Your forecasts stay correct.

Here are some ways AI-driven demand forecasting helps your supply chain:

You fill more orders because you know what customers want and when.

Your service gets better since you plan for changes early.

Planners guess less and make smarter choices.

You stop problems before they happen. AI predicts delays and helps you plan for risks.

You spend less on inventory by keeping only what you need. AI models real-world changes and keeps your stock at the right level.

AI-driven demand forecasting helps with production planning too. You can set schedules that match what customers want. This works even when suppliers or markets change. You deliver on time and waste less. Companies using predictive planning get faster order times and lower costs.

Industry benchmarks help you check your forecasting. You can use metrics like Mean Absolute Error (MAE) and Mean Absolute Percentage Error (MAPE) to see how accurate you are. Forecast bias shows if you guess too high or too low. R-squared values show how well your model fits the data. Customer satisfaction and inventory turnover ratios show how your planning works in real life. Lower Cost of Goods Sold (COGS) means your forecasting saves money.

JUSDA’s JusLink AI Solution

JUSDA’s JusLink AI Solution gives you strong tools for AI-based demand planning. You can use analytics to see trends, predict demand, and plan for changes. JusLink uses real-time data from many places. Your predictions stay current.

Here is how real companies use AI with JusLink:

Customer | AI Application | Impact on Supply Chain Performance | Key Results |

|---|---|---|---|

BMW | Predictive demand analytics and real-time data capture | Better production planning and inventory management by improving demand forecasting | Less waste, better inventory levels, fewer stockouts, happier customers |

Poloplast | AI-driven risk assessment and centralized data collaboration | Stronger risk control with early warnings and longer prediction window | Longer prediction time from 1 month to 18 months, faster responses, less downtime, saved time in planning |

JUSDA’s JusLink Platform | AI-powered predictive maintenance and logistics planning | Stronger supply chain with equipment failure prediction and better transportation | Less unplanned downtime, lower transportation costs, more efficiency and savings |

JUSDA’s JusLink platform links all your supply chain systems. You can track shipments, manage inventory, and plan deliveries with AI forecasting. The platform’s smart agents help you decide faster. You get early warnings about risks. You can act before problems hurt your business.

JUSDA’s customer story shows how AI-driven demand forecasting helps global manufacturers. When Chinese companies moved production overseas, JUSDA used AI to build a platform that connects buying, shipping, and warehousing. This platform gives you real-time data. It helps you plan for demand changes in different places. You spend less on inventory, get better accuracy, and make your supply chain work better.

With JusLink, you use AI-based demand planning to improve every part of your supply chain. You get better predictions, more accurate planning, and faster reactions to market changes. This leads to happier customers and better business results.

AI-based Demand Planning Benefits

Forecasting Accuracy

You want to know how much inventory you need. Ai-based demand planning helps you guess better. It uses smart forecasting models that learn from your data. These models change their predictions as new data comes in. You can spot demand patterns that old methods miss. Ai-powered forecasting uses machine learning. It mixes data like sales history, weather, and market trends. This makes your guesses more trustworthy.

Ai-based demand planning makes forecasts up to 15% more accurate. You can earn 3% more before tax with better forecasting. Companies say ai-powered forecasting is over 95% correct. You do less manual work because ai prepares the data for you. You get more time to plan and think about strategy.

Here is a table that shows how ai-based demand planning helps your forecasting:

Improvement Aspect | Reported Result/Metric |

|---|---|

Forecast Accuracy | Over 95% accuracy achieved with ai-powered demand planning |

Inventory Volume Reduction | 160% reduction in inventory volume compared to traditional sales budgets |

Cost Savings | Up to $300 million annually in storage and operating cost savings |

Operational Efficiency | Inventory management hours reduced from 80 to 2 per month |

Forecasting Capability | Real-time adjusted forecasts using 100+ ai models and 200+ external variables |

Order Fulfillment Rate | Increased due to better forecast accuracy and inventory optimization |

Stock Breaks | Reduced, improving customer experience |

Cash Flow and Profitability | Improved by avoiding overstock and aligning purchases to real demand |

You get better forecasts and smarter planning. Ai-based demand planning helps you react fast when demand changes. You avoid running out of stock and keep customers happy.

Cost and Efficiency Gains

Ai-based demand planning helps you save money and work faster. You waste less and spend less on inventory. Ai-powered forecasting models look at lots of data and find patterns people miss. You make less extra stuff and pay less to store it. You also lower the chance of having old stock you can't sell.

Ai does hard forecasting and data analysis for you. You spend less time doing things by hand.

Retailers see 15% lower inventory holding costs. Factories report 25% less waste.

Ai-based demand planning makes production planning 20-30% more efficient.

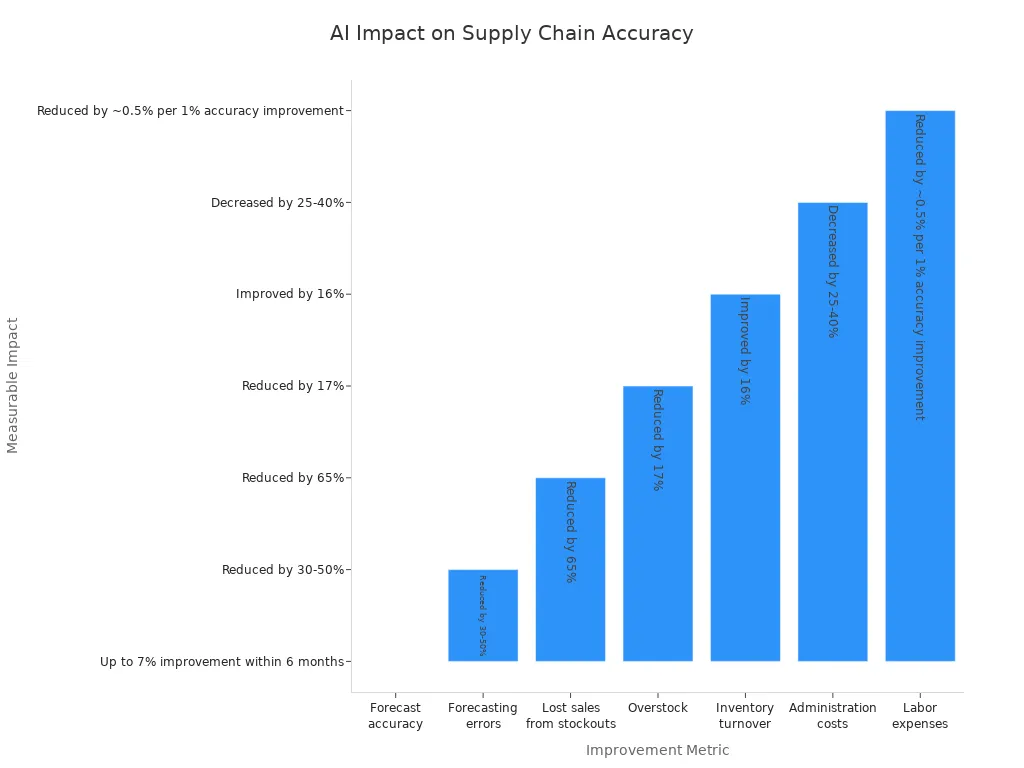

You pay 5-10% less for warehousing and 25-40% less for administration.

Ai does up to half of workforce tasks in some jobs, saving 10-15% in costs.

Ai-powered forecasting helps you change plans quickly when the market shifts. You keep service good and avoid big problems.

Ai-based demand planning helps you use less fuel and waste, which is better for the planet.

PwC’s 2024 report says companies using ai get 20-30% more productivity and revenue. EY found 97% of leaders who use ai see good returns. Gartner says half of supply chain leaders will use generative ai soon and spend 6% of their budgets on ai tools.

Here is a table that shows how ai-based demand planning saves money:

Industry Sector | Cost Savings Metric | Measurement Methodology |

|---|---|---|

Retail | 15% reduction in inventory holding costs | Comparing inventory costs before and after ai implementation |

Manufacturing | 25% decrease in wastage | Measuring waste quantities pre- and post-ai adoption |

General Operational Efficiency | 20-30% improvement in production planning efficiency | Reported by MIT Sloan Management Review based on operational KPIs |

You save money and plan faster. Ai-based demand planning helps you make smarter choices and improve your supply chain.

Real-world Examples with JUSDA

JUSDA’s ai-based demand planning gets great results in many industries. You see better forecasting, planning, and efficiency. JusLink’s ai-powered forecasting models help you guess inventory needs and react to demand changes.

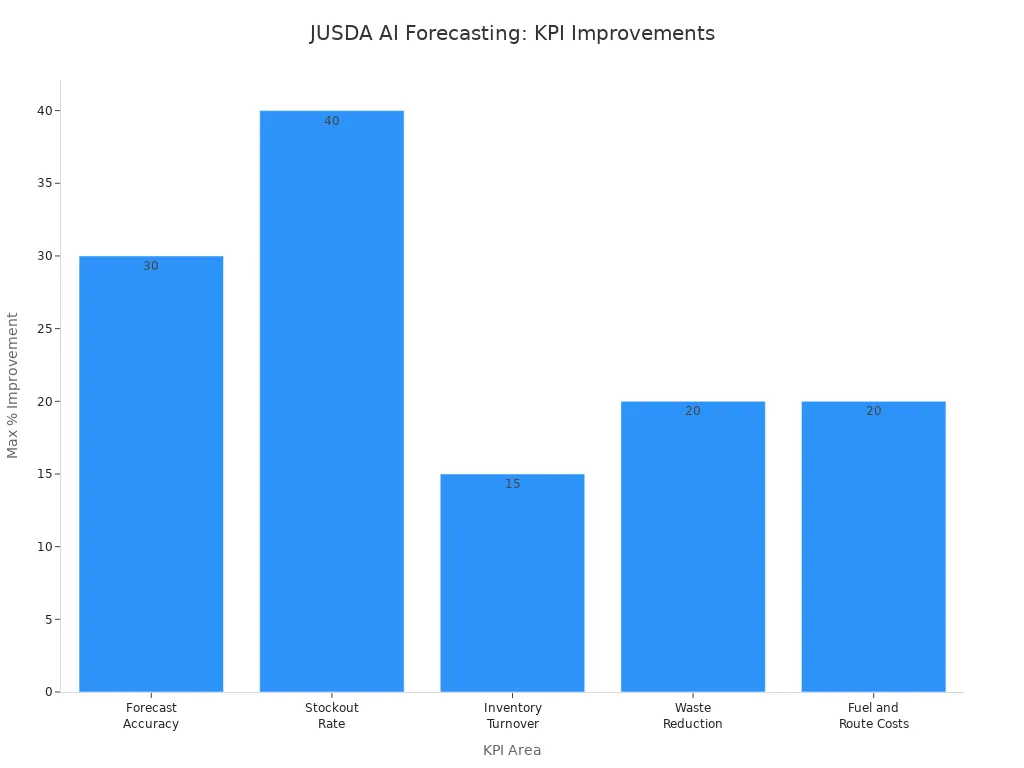

Here is a table that shows how JUSDA’s ai-based demand planning improves performance:

KPI Area | Measurable Improvement | Description / Impact Summary |

|---|---|---|

Forecast Accuracy | Up to +30%, reaching 90–95% accuracy | JUSDA’s ai forecasting makes demand prediction more accurate, so retail stock planning is less uncertain. |

Stockout Rate | Reduced by 30–40% | Fewer stockouts mean products are available and customers are happier. |

Inventory Turnover | Increased by 15% | Faster inventory turnover means lower costs and better cash flow. |

Waste Reduction | Decreased by 20% | Less waste from unsold goods saves money and helps the environment. |

Fuel and Route Costs | Reduced by 10–20% | Ai-driven route planning uses less fuel and cuts delivery costs, making logistics better. |

You see these results in real life. JUSDA helped a company cut extra inventory by 25%, saving $200,000 each year. Ai-based demand planning also made inventory turnover 15% faster and lowered stockouts by 40%. You get smarter planning, better forecasts, and quicker reactions to market changes.

Ai-based demand planning works in electronics, FMCG, cars, and medical health. You see better forecast accuracy, cost savings, and efficiency. JusLink’s ai-powered forecasting models help you make smart choices and keep your supply chain working well.

Implementing AI-powered Forecasting

Data Preparation

You need good data for ai-powered forecasting to work well. First, make sure your data is right and complete. Bring all your data together from supply chain systems like ERP, WMS, and TMS. Use cloud storage so you can keep lots of data and use it fast. Clean your data and change it so ai tools can use it. Update your data often to keep your forecasts correct.

If your data is good, your forecasts are better. Bad or old data makes your forecasts wrong. Make rules to manage your data and check it often.

Here are the main steps to get your data ready:

Make sure your data is right and complete.

Put data from all your systems together.

Use cloud storage for fast data use.

Clean and match your data for ai.

Make changes slowly to stop problems.

Keep your data fresh to help forecasting.

Integration with JUSDA

JUSDA’s JusLink platform helps you connect ai-powered forecasting to your systems. You can link real-time inventory, sales, and even prices from other companies. JusLink uses smart ai to do jobs like talking to suppliers and making orders. The platform works with ERP, WMS, and TMS, so you get real-time data and better forecasts. JusLink’s ai agents help you find risks, plan routes, and manage deliveries. You save time and money by letting ai do simple jobs.

JusLink lets you see your supply chain as it happens. You can make quick choices with real-time data.

Overcoming Challenges

You might have problems when you start using ai-powered forecasting. Data stuck in one place, not enough skills, and high costs can slow you down. Some people may worry about losing jobs. To fix these, talk about how ai helps. Get leaders to help and teach your team. Start small with test projects and grow bigger later. Make sure your data is clean and your systems can use real-time data. Celebrate wins and keep making your ai better.

Tip: Show your team how ai helps them. Keep everyone working together and learning.

A smooth move to ai-powered forecasting needs clear goals, good data, and teamwork. With JUSDA’s JusLink, you can use ai to make your supply chain smarter and faster.

JUSDA Solutions

To provide you with professional solutions and quotations.

AI-driven demand forecasting helps your supply chain work better. You get more accurate results, spend less money, and react faster. JUSDA is a leader in this change. They use smart tools, cloud systems, and automation to help.

You see what is happening right now. You waste less and make customers happier.

Begin with clear goals and good data. Try small projects first to make your business ready for the future.

See Also

Enhancing Supply Chain Efficiency Through Advanced AI Solutions

Exploring How AI Is Shaping The Future Supply Chain

Transforming Logistics With AI For The Supply Chain Future

Improving Automotive Demand Forecasting Using Data-Driven Decisions

Using Machine Learning And Big Data To Redefine Supply Chains