How AI Forecasting Models Revolutionize Supply Chain Operations in 2025

AI forecasting models are revolutionizing supply chain operations in 2025, enabling businesses to predict and adapt to market demands with unprecedented accuracy. Companies leveraging these technologies report significant benefits: logistics costs have dropped by up to 15%, and service levels have improved by 65%. By 2025, half of large global companies are expected to integrate AI, advanced analytics, and IoT into their supply chains. These advancements not only enhance efficiency but also mitigate disruptions, ensuring smoother operations and better resource utilization.

Key Takeaways

AI tools help supply chains work better by guessing demand, cutting costs, and making services better.

Businesses using AI save up to 15% on shipping costs and improve service by 65%.

Using live data and smart devices helps companies act fast to changes, avoiding too much or too little stock.

Adding AI to supply chains is key for success, with over 75% of companies likely to use it by 2026.

AI-driven plans cut planning mistakes by 20% and use resources more wisely.

The Evolution of Supply Chain Forecasting

Limitations of Traditional Forecasting Methods

Traditional forecasting methods rely heavily on historical data and static models. While these approaches worked in stable environments, they struggle to adapt to modern supply chain complexities. Key limitations include:

Inability to process real-time data, leading to delayed responses.

Over-reliance on past trends, which may not reflect current market dynamics.

Lack of collaboration among stakeholders, resulting in fragmented forecasts.

These shortcomings often lead to inefficiencies, such as overstocking or stockouts, which disrupt operations and increase costs.

Why AI Forecasting Models Are the Future

AI forecasting models address the limitations of traditional methods by leveraging advanced technologies like machine learning and real-time data processing. They enable businesses to predict demand with greater accuracy and adapt to changes swiftly.

Several trends highlight the growing reliance on AI in supply chain forecasting:

Real-time data analysis allows immediate adjustments to forecasts.

Demand sensing uses short-term data for precise near-future predictions.

Collaborative forecasting integrates inputs from multiple stakeholders for unified planning.

By 2026, over 75% of enterprises are expected to adopt AI in their supply chains. Companies using AI forecasting models report a 10-20% improvement in forecast accuracy, according to McKinsey. This shift underscores the competitive necessity of AI, with 67% of supply chain leaders viewing it as essential for future success.

AI forecasting models not only enhance accuracy but also transform supply chains into proactive systems. They empower businesses to anticipate disruptions, optimize resources, and maintain a competitive edge in an increasingly dynamic market.

How AI Forecasting Models Drive Supply Chain Innovation

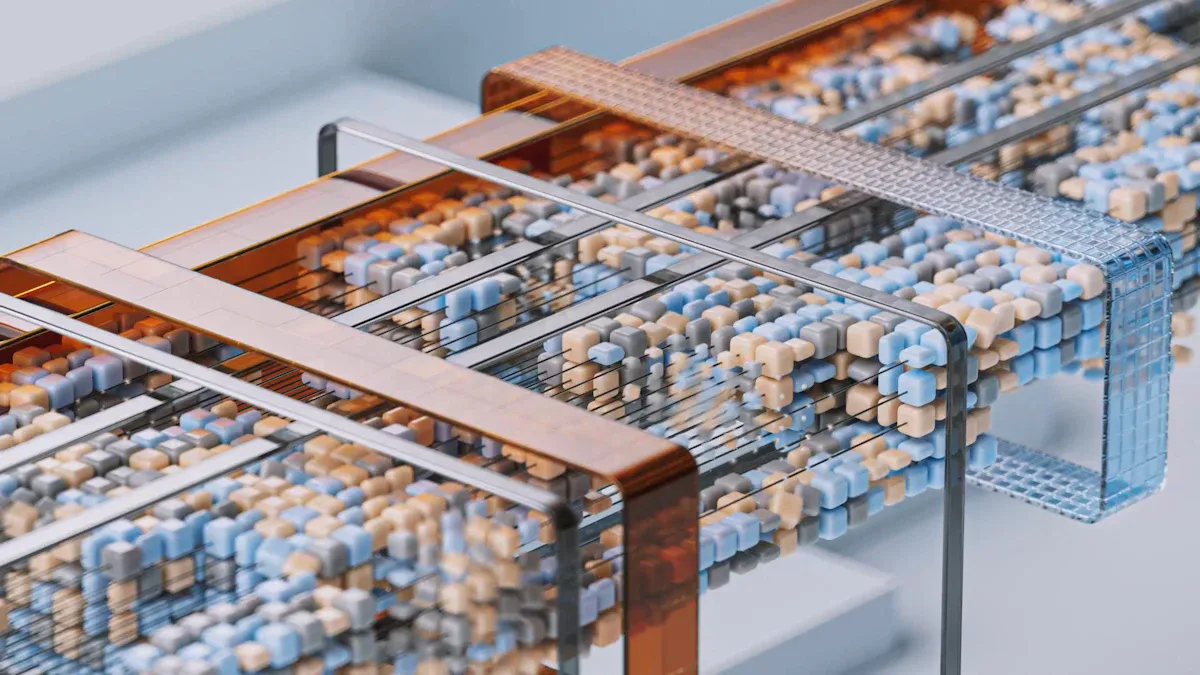

Key Technologies Behind AI Forecasting Models

Machine Learning and Predictive Analytics

Machine learning and predictive analytics form the backbone of AI forecasting models. These technologies analyze vast datasets to identify patterns and trends, enabling businesses to make data-driven decisions. For instance, machine learning algorithms can process historical sales data and market trends to predict future demand. Predictive analytics evaluates seasonal trends and consumer behavior, helping businesses anticipate stock shortages and optimize inventory levels.

Real-world applications highlight their impact. A large hospital network used predictive analytics to reduce emergency orders by 40%, ensuring a steady supply of medical essentials. Similarly, an automotive manufacturer implemented AI-driven shortage prediction systems, cutting lead times by 20% and improving inventory turnover rates. These examples demonstrate how these technologies enhance supply chain efficiency and responsiveness.

Real-Time Data Processing and IoT Integration

Real-time data processing and IoT integration revolutionize supply chain operations by providing instant insights. IoT devices collect data from various points in the supply chain, such as warehouses and transportation networks. This data, when processed in real-time, allows businesses to monitor operations and address issues proactively.

For example, IoT sensors in warehouses track inventory levels, enabling automated replenishment when stock runs low. This reduces the risk of stockouts and overstocking. Additionally, real-time data processing helps businesses adjust forecasts quickly in response to market changes, enhancing agility and responsiveness.

Measurable Outcome | |

|---|---|

Improved Accuracy in Demand Forecasting | Higher accuracy in anticipating demand fluctuations, reducing stockouts and excess inventory. |

Reduction in Inventory Costs and Stockouts | Optimized inventory levels leading to reduced holding costs and minimized risk of stockouts. |

Enhanced Agility and Responsiveness | Rapid adjustments to forecasts enabling flexible responses to market changes and disruptions. |

Increased Collaboration Across the Supply Chain | Streamlined data integration fostering collaboration among suppliers, manufacturers, and retailers. |

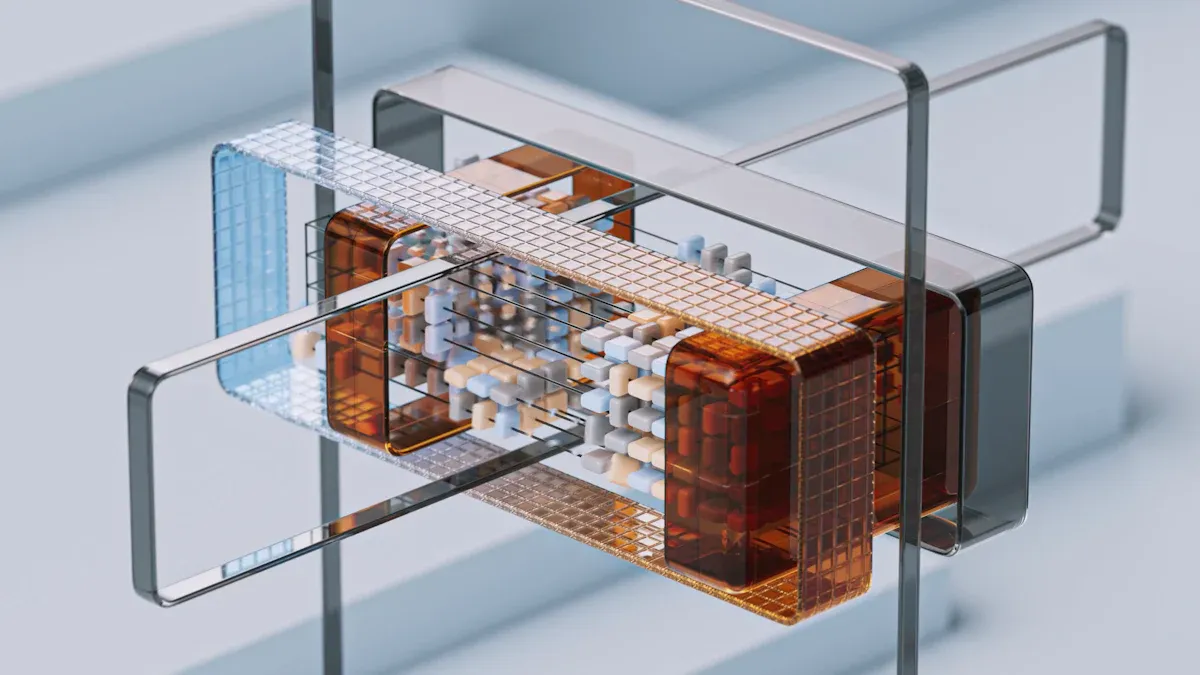

JusLink’s Role in AI-Driven Supply Chain Management

JusLink, JUSDA's intelligent supply chain platform, exemplifies the transformative power of AI forecasting models. It integrates advanced technologies like machine learning and IoT to provide real-time updates on demand forecasts and supply risks. Retailers using JusLink benefit from predictive analytics, which helps them anticipate market trends and adjust inventory dynamically. This ensures proactive management of supply chain disruptions.

JUSDA Solutions

To provide you with professional solutions and quotations.

JusLink also enhances logistics efficiency. Automated warehouses and intelligent logistics solutions streamline order fulfillment, reducing delivery times by 50% for certain clusters. Additionally, its simulation studio enables businesses to analyze optimal strategies, resulting in an average monthly cost savings of 5.76%. These capabilities position JusLink as a leader in AI-driven supply chain management.

Transitioning from Reactive to Proactive Supply Chains

AI forecasting models enable businesses to shift from reactive to proactive supply chain strategies. Traditional supply chains often respond to disruptions after they occur, leading to inefficiencies. AI transforms this approach by predicting potential issues and enabling preemptive actions.

Proactive strategies yield measurable benefits. Companies report a 20% reduction in planning errors and a 20-50% decrease in inventory levels while maintaining service quality. AI systems optimize stock allocation and improve resilience through real-time risk management. This transition not only enhances operational efficiency but also strengthens the supply chain's ability to adapt to market changes.

Note: Proactive supply chains represent the future of logistics, where AI forecasting models play a pivotal role in driving innovation and ensuring resilience.

Real-World Applications of AI Forecasting Models

JUSDA’s Warehouse Solutions for Optimized Inventory

JUSDA’s advanced warehouse solutions demonstrate the practical benefits of AI forecasting models in inventory management. By leveraging tools like JusLink and eVMI, JUSDA ensures real-time inventory tracking and dynamic replenishment. These systems enable businesses to maintain optimal stock levels, reducing both overstocking and stockouts. For example, JUSDA’s Vietnam warehouses utilize AI-driven demand forecasting to align inventory with market needs, improving efficiency and lowering costs.

The integration of AI with IoT devices further enhances warehouse operations. Sensors monitor inventory levels and trigger automated replenishment processes. This approach minimizes human error and ensures a seamless supply chain. JUSDA’s cleanroom facilities, compliant with stringent standards, also highlight the adaptability of AI in specialized environments like electronics and medical industries.

Case Study: AI in Retail and Manufacturing Supply Chains

Real-world examples validate the transformative impact of AI in supply chains. Companies like Domino’s Pizza UK & Ireland have adopted AI-driven demand forecasting, improving inventory management and customer satisfaction. Similarly, UPS’s ORION system uses advanced algorithms for route optimization, saving fuel and reducing delivery miles.

Outcome Description | Measurable Impact |

|---|---|

Optimized inventory levels | Reduction in costs associated with overstocking or understocking |

Reduction in stockouts | 30% reduction in stockouts within the first year for a major retail chain |

Decrease in production delays | 30% decrease in production delays for a global manufacturer |

These examples illustrate how AI forecasting models enhance operational efficiency and reduce risks across industries.

Challenges in Implementing AI Forecasting Models

Data Quality and Sharing Barriers

Data quality and sharing remain significant obstacles in adopting AI forecasting models. Reliable forecasts depend on accurate, comprehensive, and up-to-date data. However, many organizations struggle with fragmented or incomplete datasets. For instance, a logistics company experienced operational disruptions when inconsistent data led to wildly inaccurate AI-driven demand forecasts. This caused supply chain chaos and financial losses.

Several factors contribute to these barriers:

Data Quality and Quantity: Poor-quality data undermines the reliability of AI predictions.

Lack of Collaboration: Limited information sharing among stakeholders results in fragmented data.

Siloed Systems: Legacy systems often store data in isolated formats, making integration difficult.

Organizations must prioritize data governance to overcome these challenges. Establishing unified data standards and fostering collaboration across departments can significantly improve data accuracy and accessibility.

Tip: Companies can mitigate data-sharing issues by creating secure platforms that promote transparency while protecting sensitive information.

Integration with Legacy Systems

Integrating AI with legacy systems presents technical challenges. Many older systems lack the compatibility required to work seamlessly with modern AI technologies. This often leads to disruptions in functionality and delays in implementation. Middleware software can act as a bridge, enabling smoother integration between AI applications and existing systems.

A phased approach to AI adoption has proven effective. Starting with pilot projects allows businesses to identify and address compatibility issues early. For example, a manufacturing firm successfully implemented AI by first testing it in a single production line before scaling it across the organization.

Key Insight: Gradual integration minimizes risks and ensures that AI solutions align with existing workflows.

Ethical and Transparency Concerns in AI

Ethical considerations in AI forecasting models are gaining attention. Issues like bias, discrimination, and lack of transparency can erode trust among stakeholders. For example, the Monetary Authority of Singapore collaborated with Accenture to develop a framework addressing fairness and accountability in AI systems. This initiative highlights the importance of ethical AI practices.

Transparency in AI predictions is equally critical. Businesses must ensure that their AI models comply with data privacy regulations and provide clear explanations for their forecasts. Promoting responsible AI use builds trust and fosters long-term collaboration with stakeholders.

Note: Ethical AI practices not only enhance trust but also reduce risks associated with regulatory non-compliance.

Overcoming Resistance to Change in Organizations

Resistance to change often emerges as a significant hurdle when organizations adopt AI forecasting models. Employees may fear job displacement or struggle to adapt to new technologies. Addressing these concerns requires a strategic approach that fosters trust and collaboration.

Transparent communication plays a vital role in reducing resistance. Organizations should clearly explain the purpose of AI and its benefits. Employees need to understand how AI supports their roles rather than replacing them. For example, BMW faced initial resistance when introducing AI tools for electric vehicle production. By clarifying that AI would augment employee tasks, the company reduced resistance by 20%.

Involving employees early in the planning and implementation phases also helps. When employees participate in decision-making, they feel valued and more willing to embrace change. This approach encourages a sense of ownership and reduces uncertainty. Companies can organize workshops or feedback sessions to gather employee input and address concerns.

Pilot programs offer another effective strategy. Small-scale implementations allow organizations to demonstrate the tangible benefits of AI before a full rollout. These programs provide employees with hands-on experience, helping them build confidence in the technology. For instance, a logistics firm used a pilot program to showcase how AI could streamline inventory management. The success of the pilot eased employee apprehensions and paved the way for broader adoption.

Tip: Building a culture of continuous learning can further ease transitions. Providing training programs ensures employees develop the skills needed to work alongside AI systems.

By prioritizing communication, collaboration, and education, organizations can overcome resistance and create a workforce ready to embrace AI-driven innovations.

AI forecasting models have redefined supply chain operations by enhancing efficiency, reducing costs, and improving service levels. Early adopters have reported a 15% reduction in logistics costs, a 35% improvement in inventory levels, and a 65% enhancement in service quality. These advancements highlight the critical role of AI in building resilient supply chains capable of adapting to disruptions.

JUSDA and JusLink continue to lead this transformation by integrating predictive analytics, real-time monitoring, and scenario modeling into their solutions. Their commitment to innovation ensures businesses can anticipate challenges, optimize resources, and achieve sustainable growth. As AI evolves, these platforms will remain at the forefront, driving smarter and more agile supply chain ecosystems.

Note: Generative AI not only improves logistics but also identifies potential suppliers and assesses environmental impacts, paving the way for a sustainable future.

FAQ

What are AI forecasting models, and how do they work?

AI forecasting models use machine learning and predictive analytics to analyze historical and real-time data. These models identify patterns and trends, enabling businesses to predict demand, optimize inventory, and improve decision-making. They rely on algorithms to process large datasets and provide actionable insights.

How do AI forecasting models improve supply chain efficiency?

AI forecasting models enhance efficiency by predicting demand accurately, reducing stockouts, and minimizing overstocking. They enable real-time adjustments to inventory and logistics, ensuring optimal resource allocation. Businesses using these models report lower costs and faster response times to market changes.

See Also

Transforming Logistics For The Future With AI Supply Chains

Exploring AI Integration For The Future Of Supply Chains

Enhancing Supply Chain Efficiency Through AI Innovations

Revolutionizing Supply Chain Management Using Big Data And ML