Top AI Solutions Compared for Logistics Efficiency Improvement

AI+Logistics achieves efficiency improvement by transforming every aspect of the logistics process. Leading companies such as Maersk, DHL, Amazon, and UPS leverage artificial intelligence to enhance logistics operations, customer order fulfillment, and supply chain management.

AI Solution | Company | Effectiveness Description |

|---|---|---|

AI-driven documentation system | Maersk | Fewer mistakes and easier work steps |

Generative AI chatbots | DHL | Faster and better customer service |

Automated route optimization | Amazon | Better guessing of demand and faster deliveries |

Predictive logistics planning | UPS | More correct deliveries |

AI+Logistics achieves efficiency improvement through demand forecasting, real-time tracking, warehouse robotics, and fraud prevention.

AI+Logistics achieves efficiency improvement by providing actionable insights, reducing out-of-stock issues by 96%, improving demand prediction, and lowering future hiring needs by 89%. "AI+Logistics" achieves efficiency improvement by streamlining workflows, optimizing order fulfillment, and delivering valuable intelligence for large-scale operations.

Key Takeaways

AI in logistics helps work get done faster. It does this by automating jobs, making better guesses about demand, and finding the best routes. This means deliveries are quicker and cost less.

Companies that use AI can lower logistics costs by up to 15%. They can also keep better track of inventory. This makes sure products are there when customers want them.

Using AI tools helps businesses run smoother. It also helps them give better customer service. They can use data to make smart choices for supply chain management.

AI in Logistics Overview

Key Benefits

Using ai in logistics has changed how things work. In the last five years, people use ai in logistics 250% more. Now, 72% of workers in logistics use ai tools. This is 14% more than in other jobs. This fast growth shows that ai is very helpful for logistics and supply chains.

Benefit | Description |

|---|---|

ai looks at lots of data to help companies get ready for problems. | |

Inventory Optimization | ai checks sales numbers to change stock and save money. |

Enhanced Customer Service | ai chatbots give quick updates and answer questions. |

Fraud Detection | ai finds strange things to stop cargo from being stolen. |

Dynamic Pricing | ai changes prices when the market or customers change. |

Document Processing | ai makes data entry faster and helps stop mistakes. |

Supply Chain Simulations | ai tests different plans for moving goods safely. |

Safety Monitoring | ai finds dangers and makes sure rules are followed. |

Route Optimization | ai picks the best shipments and gives good ETAs. |

Sustainability | ai helps things run better and cuts down on harm to the environment. |

Demand Forecasting | ai guesses what people will want using lots of data. |

Real-time Tracking | ai lets people see where shipments are with IoT devices. |

Risk Identification | ai uses smart guesses to spot problems before they happen. |

Customer Satisfaction | ai makes sure products are there and answers fast. |

Main Use Cases

ai helps with many important jobs in logistics. Companies use ai for warehouse automation, smart guessing, and computer vision. These tools help make supply chains better and improve how logistics works.

Warehouse automation makes warehouses work faster and with less people.

Smart guessing helps companies know what to order and when.

Computer vision watches shipments and finds damage.

Ready-to-use APIs help companies add image tools quickly.

Custom ai solutions fix special problems and help supply chains for a long time.

ai now helps make supply chains better, so logistics is faster, stronger, and can change quickly.

Predictive Analytics

Features

Predictive analytics tools have changed how companies handle logistics. These tools use ai to help teams make smarter choices.

The main things about predictive analytics tools in logistics are that they are easy to use, can do tasks automatically, and are simple to get. These tools now work for both experts and people who are not tech-savvy. This means you can use them for predictions without needing to know a lot about computers. There is a big difference between old regression-based tools and machine learning-based tools. Machine learning models use new data to make guesses, but regression models use math to guess how things connect.

Teams use ai to look at supply chain data and guess what will happen next. Machine learning models change their guesses when new data comes in. This helps companies act fast when things change in the supply chain.

Benefits

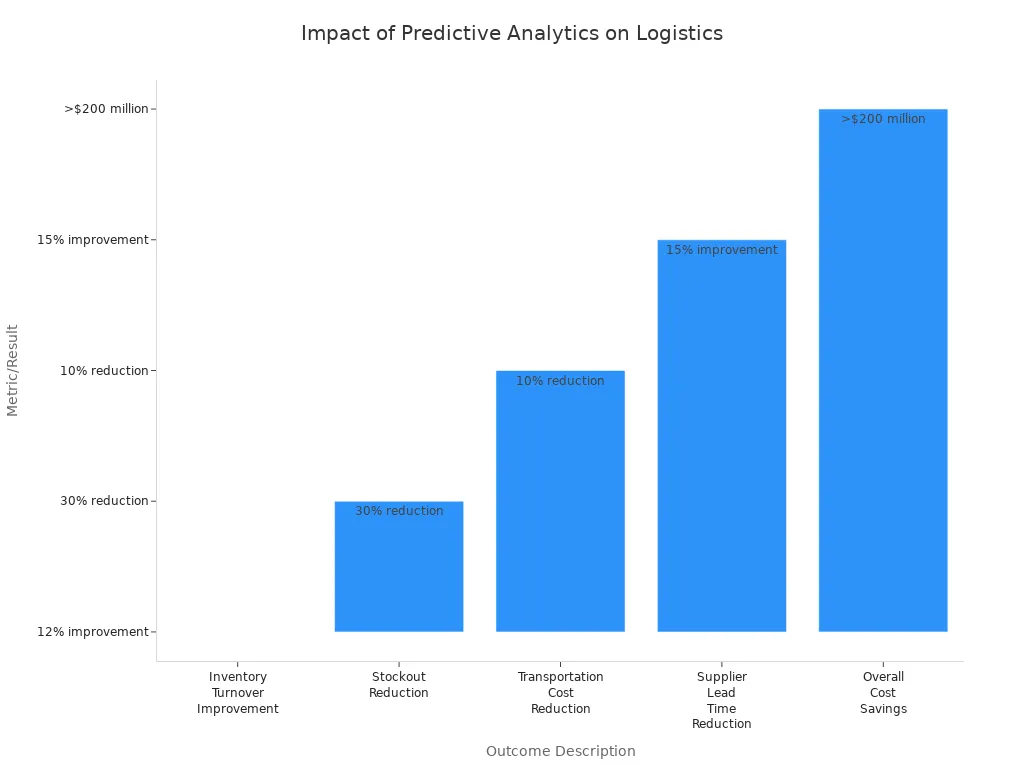

Predictive analytics helps companies plan better in logistics. Ai models guess what people will want, help with inventory, and save money. Companies have fewer times when items run out and their supply chains work better.

A big retailer used ai-driven predictive analytics to change its logistics. The company made inventory turnover 12% better, had 30% fewer stockouts, and spent 10% less on transportation. Suppliers got faster by 15%, and the company saved over $200 million.

Challenges

Logistics companies have some problems when using ai for predictive analytics in the supply chain.

Challenge | Description | Solution |

|---|---|---|

Data Quality | Bad data can make logistics predictions wrong. | Cleaning data helps fix mistakes and makes supply chain data better. |

Data Integration | It is hard to put different supply chain data together. | Data governance and DataOps teams help mix logistics data well. |

Inexperience | Teams might not know enough about ai for supply chain analytics. | Training and hiring experts make strong logistics analytics teams. |

User Adoption | Workers may not like new ai tools in logistics. | Sharing results and good marketing help more people use supply chain tools. |

User Trust | Security and being open are important in logistics analytics. | Showing that ai works helps people trust supply chain data. |

Project Maintenance | Ai models need updates to keep working well in logistics. | Feedback and KPIs help keep supply chain analytics working right. |

Actionability | Results must be easy for logistics teams to understand. | Clear reports help users use supply chain insights. |

Route Optimization

Leading Tools

Route optimization is now very important in logistics. Companies use ai-powered tools to make deliveries faster and save money. The table below shows top tools and what makes them special:

Tool Name | Unique Features |

|---|---|

Relog | AI Optimization, Marketplace of Drivers, Comprehensive Analytics, Seamless Integration |

Locate2u | Route Optimization, Real-time Traffic Integration |

Dispatch Science | Automated Route Optimization, Improved Driver Performance |

Mojro | Dynamic Planning, 6D Optimization |

Route4Me | Automated route planning, Real-time traffic integration, GPS tracking |

Routific | Traffic-aware routing, Intelligent route planning, Scalable machine learning |

SimpliRoute | AI-powered route planning, Real-time traffic integration |

Wise Systems | Real-time route optimization, Predictive analytics |

Core Advantages

AI-driven route optimization helps logistics in many ways. Companies can change delivery routes quickly if there is traffic or bad weather. Teams can deliver important things first, like medical supplies. If there is a problem, the system can find a new route fast. Companies can save up to 20% on costs and keep 30% less inventory. McKinsey says ai helps lower costs and makes supply chains work better. Mojro and SimpliRoute help use less fuel and lower pollution, which is good for the planet.

Drawbacks

Some teams have problems when they start using ai for route optimization. Adding new tools to old systems means workers need training and must change how they work. But companies that use ai get good results. For example, one online store made deliveries 30% faster and spent 25% less money after using ai-powered route optimization. These results show that ai is very helpful for logistics and supply chains.

Warehouse Automation

Top Platforms

Warehouse automation is now very important in logistics. Big companies like Amazon Robotics, GreyOrange, and Locus Robotics use ai to change how supply chains work. These platforms use smart robots and special vehicles to help with inventory. They also use advanced software to make order picking easier. Companies pick these platforms if they work well with their current systems. They also want platforms that can share data quickly across the supply chain.

Benefits

ai-powered warehouse automation brings many clear improvements. Companies see faster work, better efficiency, and more orders filled. The table below shows the main benefits:

Benefit | Description |

|---|---|

Improved Efficiency | ai makes storage better and cuts down on walking, so warehouses work faster. |

Accurate Demand Forecasting | ai helps guess what will be needed, so there is less extra or missing stock. |

Predictive Maintenance | ai finds equipment problems early, so things do not break down as much. |

Real-Time Inventory Visibility | ai lets people see inventory live, so mistakes are fixed right away. |

Enhanced Productivity | ai gives jobs to workers based on how well they do, so more gets done. |

Improved Employee Safety | ai watches for danger and does risky jobs, so workers stay safe. |

Sustainability | ai helps use less energy and waste, so the supply chain is greener. |

Precision Cost Reduction | Shrinkage goes down by up to 20%, so companies save money. |

Higher Throughput | Warehouses move 25–30% more items without needing more people or machines. |

Enhanced Traceability | ai helps find products fast and follow rules in the supply chain. |

A big store used ai warehouse automation and got great results. Inventory accuracy went up by 25%. Picking speed got 30% faster. Workers did their jobs 20% better. Costs went down by 15%. These numbers show that ai really changes logistics and supply chains.

Implementation Issues

Companies have some problems when they add ai to warehouses.

Data privacy and security are important because there is a lot of data.

Workers may worry about new jobs or learning new things, so change is slow.

It can be hard to connect ai to old systems.

Sometimes it is tough to see how much ai helps and if it is worth it.

Tip: Good logistics teams set clear goals, pick the best ai tools, test them first, and check results with good numbers. A long-term plan helps keep making the supply chain better.

Demand Forecasting

Best Solutions

Logistics companies use ai to guess what products people will want. Zara uses ai agents to look at sales numbers and spot trends. This helps them restock fast and not run out of items. They also avoid having too much extra stock. Machine learning models like ARIMA and SARIMA make fewer mistakes than old ways. These models can cut errors by 20-50%. These tools help teams make smart choices and keep things moving well.

Zara uses ai agents to check sales and guess demand.

ARIMA and SARIMA models make fewer mistakes in predictions.

Many logistics companies use ai tools to plan better.

Value

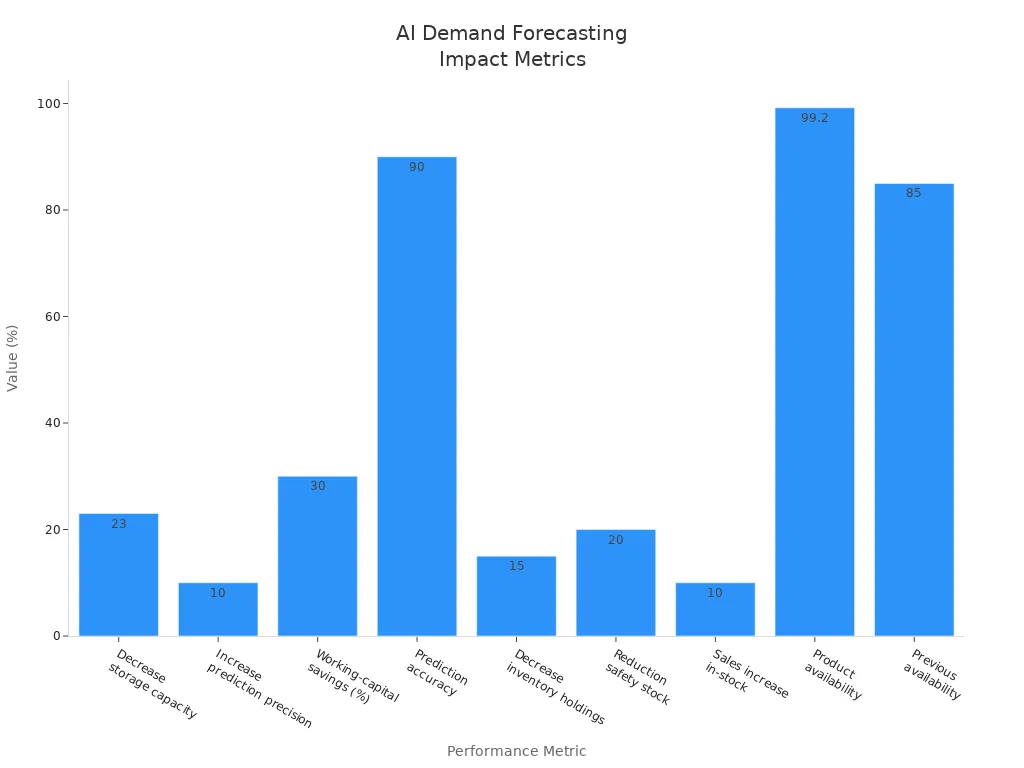

Ai-powered demand forecasting helps logistics a lot. Companies guess better, have less extra stock, and more products ready to sell. The table below shows how ai makes logistics work better:

Metric | Value |

|---|---|

Decrease in storage capacity | 23% |

Increase in precision of predictions | 10% |

Working-capital savings | >€4 million (30%) |

Prediction accuracy | >90% |

Decrease in overall inventory holdings | 15% |

Reduction in excess safety stock | 20% |

Sales increase attributable to in-stock quantities | 10% |

Product availability | 99.2% |

Previous product availability | ~85% |

Considerations

Logistics teams need ai tools that fit their needs. They should pick tools that work with what they already use. Good ai tools give clear answers and help spot trends. Ai helps companies see what customers want and what is happening in the market. This makes it easier to keep the right amount of stock. It also helps stop problems like having too much or too little. One big store used ai and got product availability up from 85% to 99.2%. They saved a lot of money and had less extra stock. Ai demand forecasting changes how logistics companies plan and work.

ai+logistics Achieves Efficiency Improvement

Cost Reduction

ai+logistics helps companies save money in the supply chain. Businesses that use ai spend less on many things. Smart process changes help cut out waste and extra steps.

ai can lower supply chain and logistics costs by up to 15%.

By early 2025, 72% of retailers using ai say their costs went down.

These facts show ai+logistics makes work simpler and cheaper. Companies pay less for fuel, workers, and storage. They also avoid mistakes and delays that cost money. When costs go down, profits go up and prices can be better for customers. ai in logistics helps companies keep up in a fast-moving world.

Workflow Automation

ai+logistics makes work easier by doing simple jobs automatically. ai in logistics uses smart tools to make each step better. This helps warehouses run smoother and customers get their orders faster. Companies make fewer mistakes and deliver things on time.

Process | Improvement Description |

|---|---|

Inventory Management | ai guesses what stock is needed using past sales and real-time data, so there are fewer mistakes. |

Route Optimization | ai finds the best ways to deliver, so companies use less fuel and save time. |

Scheduling | ai updates delivery times and dock spots using live data, so there are fewer delays. |

ai-driven automation cuts costs by handling boring jobs. Companies get better at guessing what they need and can grow faster. ai in logistics lets teams do more important work instead of typing or making schedules by hand. This helps everyone get more done and grow quickly.

Enhanced Decision-Making

ai+logistics gives leaders better info to make good choices. ai in logistics looks at old data and market trends to guess what will happen next. This helps companies plan for what people will want. ai also picks the best routes by checking traffic and weather, so deliveries are faster and cheaper. Watching goods in real time helps teams fix problems right away.

ai makes demand forecasting better, so supply chain plans are more accurate.

ai picks better routes, so deliveries are faster and cost less.

Real-time tracking helps teams act fast if something goes wrong.

With these tools, companies make smarter choices about stock, shipping, and helping customers. ai+logistics turns data into useful ideas. This helps companies keep less extra stock, stay safe, and do a better job for customers.

Companies using ai in logistics have fewer empty shelves, safer places to work, and faster help for customers. ai+logistics makes every part of the supply chain smarter and quicker to react.

Comparing Solutions by Need

Small vs. Large Operations

Picking the best ai in logistics depends on how big your company is. Small businesses want easy tools that help them work better without spending a lot. They look for ai that helps with inventory, makes warehouse jobs easier, and helps deliver packages to customers. These companies like ai that can guess when problems might happen and do simple jobs automatically. Big companies need more advanced ai in logistics because their supply chains are complicated. They want ai that helps control assets, does customs paperwork, and gives live updates for every part of the process. Big companies also care about using ai for fixing equipment before it breaks and keeping everything safe.

Tip: Choose ai that fits what you need right now. You can add more as your company grows and your goals change.

Industry Recommendations

Different industries have their own logistics problems. Stores use ai in logistics to keep track of stock and fill orders fast. Factories use ai to spot slowdowns and make warehouses work better. Online shops use ai to make deliveries faster and keep customers happy. Healthcare uses ai to keep the supply chain safe and follow rules.

The table below shows important things to think about when picking ai for logistics:

Factor | Description |

|---|---|

Operational optimization | AI helps things run smoother and makes sure everything works together in the supply chain. |

Smart inventory control | Gives a clear picture of inventory, so companies can react quickly and trust their numbers. |

Bottleneck and disruption prediction | AI looks at lots of things to guess where slowdowns or problems might happen. |

Load optimization | AI figures out the best way to move goods, saving money and following rules. |

Warehouse system optimization | Makes warehouse jobs faster and easier by using live data. |

Predictive maintenance | AI can tell when machines might break, so they get fixed before stopping work. |

Last-mile delivery routing | Changes delivery routes right away if there is traffic or other issues. |

Automated customs processing | Makes shipping across borders faster by doing paperwork automatically. |

Security, compliance, and resilience | AI helps keep things safe and makes sure companies follow the rules. |

Picking the right ai in logistics helps companies work better, see what is happening in the supply chain, and do a better job in any industry.

AI solutions help different logistics teams based on their size. Small teams get help from warehouse automation and route optimization. Big companies use predictive analytics to see the whole supply chain.

Here are some useful steps:

Connect data to see the whole supply chain

Automate work to save money

Train workers so more people use AI

Keep checking to make sure things run well

Trend | Description |

|---|---|

Responsible AI | Helps supply chains work better and be fair |

Predictive Analytics | Helps guess what will be needed and when |

Route Optimization | Cuts costs and makes deliveries faster |

Warehouse Automation | Makes work more correct and saves on labor |

AI keeps changing how logistics and supply chains work. Companies need to use AI if they want to keep up with others.

FAQ

What are the main benefits of using ai in logistics?

Companies get faster deliveries and spend less money. They also keep better track of their inventory. McKinsey says ai can make logistics work up to 20% better.

How does ai help with real-time tracking in logistics?

ai uses IoT sensors to watch shipments as they move. It also uses smart analytics to check where things are. Gartner says ai helps people see shipments better and cuts down on delays.

Can small businesses use ai for logistics improvement?

Small businesses can use ai for warehouse automation and route planning. Deloitte found that ai helps teams save time and make fewer mistakes.

See Also

Exploring AI's Hidden Power in Logistics and Supply Chains

Enhancing Supply Chain Performance Through AI Innovations

Transforming Future Logistics With AI Supply Chain Solutions