How AI Transforms Manufacturing with Accurate Demand Forecasting

AI is revolutionizing manufacturing by enhancing demand forecasting accuracy. It enables more precise predictions of customer needs, helping to avoid overproduction and reduce waste. Companies leveraging AI in manufacturing demand forecasting have achieved up to 50% improvement in accuracy. This technology also cuts inventory costs by 40% and boosts stock availability by 30%. For instance, BMW reduced excess inventory by 10% and improved inventory turnover by 25%. By utilizing AI for demand forecasting accuracy, manufacturers can optimize production processes and respond to customer demands more efficiently.

Key Takeaways

AI makes demand forecasting better, stopping overproduction and cutting waste.

With big data, AI finds trends, helping factories change plans fast.

AI lowers forecast mistakes by 20-50%, saving money and sales.

Tools like JusLink help teams work together with real-time updates.

AI adjusts to market changes, keeping forecasts accurate and businesses strong.

AI-Driven Demand Forecasting: The Role of Data-Driven Predictions

Using Big Data for Better AI Demand Forecasting

How AI handles big data to find demand patterns.

AI changes how factories use data. It looks at huge amounts of information to find patterns that older methods miss. By using big data, AI spots trends like customer likes, regional needs, and seasonal changes. This helps predict what people will want in the future. For example, AI can study past sales and current market trends to adjust production plans quickly. Switching from old methods to AI makes work smoother and uses resources better.

AI also combines data from different places. It uses sales records, supply chain info, and market reports to see the full picture of demand. This way, forecasts are accurate and can adapt to sudden changes. This helps avoid making too much or running out of stock, improving how factories work.

Why past and current data matter in predictions.

Past and current data are key for accurate AI forecasts. Past data shows long-term trends and repeating patterns. For example, looking at holiday sales helps plan for future busy times. Current data shows what’s happening now, like a sudden rise in demand for a product.

Using both types of data makes forecasts more reliable. For instance, real-time data helps adjust production schedules to match demand. This reduces downtime and keeps production in line with market needs. By using past and current data together, factories can meet customer needs while staying efficient.

Spotting Patterns and Problems with AI Forecasting

How AI finds trends and unusual changes in demand.

AI is great at finding patterns in demand data. It notices things like seasonal trends or how sales change during promotions. For example, AI might see that a product sells more in summer, so you can stock up. Spotting these patterns helps forecasts match real market behavior.

AI also finds unusual changes in demand. It flags sudden spikes or drops caused by things like economic changes or natural disasters. This helps factories deal with unexpected demand shifts. By catching these changes, AI makes forecasts more dependable, even when things are unpredictable.

How this makes forecasts better.

AI improves forecasts by spotting patterns and unusual changes. It looks at lots of data to remove guessing from predictions. For example, AI can update forecasts quickly if market conditions change, keeping predictions accurate. This helps avoid having too much or too little stock, saving time and money.

AI also learns from new data over time. This makes forecasts better and more precise as time goes on. With AI, factories can make smart decisions, work more efficiently, and stay competitive. AI doesn’t just predict demand—it adjusts to changes in the market too.

Better Forecast Accuracy with AI Automation

Cutting Down Human Mistakes in Forecasting

How AI reduces errors in predictions.

AI takes out the guessing in demand forecasting. It uses smart programs to study large amounts of data. These programs find patterns and trends people might miss. By letting AI handle this, mistakes in forecasting drop a lot.

AI forecasting lowers errors by 20-50%.

Fewer errors mean up to 65% fewer lost sales.

Storage costs go down by 5-10%, and office costs drop 25-40%.

For example, a big clothing company used AI tools. They cut unsold items by 25% and boosted sales by 15%. AI helps match production to real needs, making work more accurate and smooth.

Making repetitive tasks easier with AI.

AI handles boring tasks like gathering and studying data. This gives your team more time for important decisions. AI tools keep forecasts updated with real-time info. This keeps predictions correct even when markets change. Companies using AI see 30-50% better forecast accuracy. Automation saves time and gives steady results, cutting human mistakes.

Predicting Demand with JusLink

How AI tests different demand situations.

JusLink, a smart supply chain tool, uses AI to test demand scenarios. It checks how things like seasons or market problems affect demand. By studying these, you can plan better and make smarter choices.

For example, JusLink adjusts stock levels based on predictions. This avoids having too much or too little stock. AI’s ability to test situations helps you react quickly to changes.

How this helps factories handle surprises.

JusLink’s predictive tools help you prepare for sudden demand changes. AI studies past and current data to give useful tips. These tips help you plan production and use resources wisely.

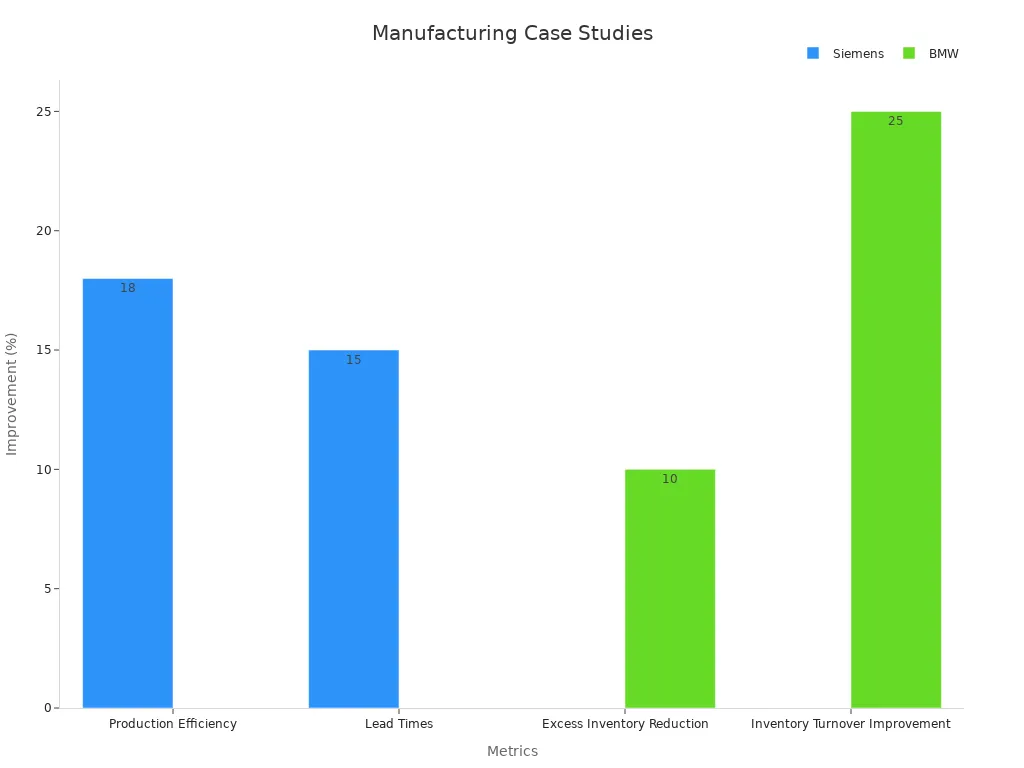

Here’s how companies improved with AI:

Company | Metric | Improvement |

|---|---|---|

Siemens | Production Efficiency | 18% |

Siemens | Lead Times | 15% |

BMW | Excess Inventory Reduction | 10% |

BMW | Inventory Turnover Improvement | 25% |

Adding JusLink to your work improves forecasts and keeps you ready for market needs. This makes your factory run better and stay strong.

AI-Powered Decision-Making in Manufacturing

How AI Works with Manufacturing Systems

How AI links ERP and MES systems for smooth operations.

AI connects systems like ERP (Enterprise Resource Planning) and MES (Manufacturing Execution Systems). It gathers data in one place for better insights. This helps track production, supply chains, and quality in real-time. For example, AI-powered ERP tools improve supply chain tracking by 40%. This lets you make quicker and smarter choices.

Here’s why linking AI with these systems helps:

Centralized data improves quick decision-making.

Better workflows boost production efficiency.

Tracking processes ensures higher product quality.

Studies show AI systems lower costs, improve quality, and meet rules better. They also make factories more flexible to handle market changes and customer needs.

Automating stock management and buying decisions.

AI handles tasks like managing stock and ordering supplies. It studies demand and adjusts stock levels automatically. This avoids having too much or too little material. For example, AI automation has cut production costs by 60% for many companies. By automating these tasks, teams can focus on bigger decisions and improve supply chains.

Using AI to Manage Resources Better

How AI helps use materials and labor wisely.

AI helps factories use materials and workers more efficiently. It predicts demand so only needed resources are used. This cuts waste and boosts productivity. For instance, AI robots assemble parts with 98% accuracy, saving time and reducing mistakes.

AI also checks where resources are wasted. It suggests moving them to areas where they’re needed more. This makes operations smoother and improves supply chain performance.

Saving money with smarter choices.

AI makes better decisions by studying large amounts of data. It helps save energy, materials, and time by improving schedules. Research shows AI boosts productivity by 20-30% and cuts defects by 90%. These changes save businesses a lot of money.

Here’s a quick look at AI benefits:

Benefit | Improvement |

|---|---|

Lower production costs | 60% of companies report |

Lower maintenance costs | Up to 40% |

Higher productivity | Boost of 20-30% |

Fewer production defects | Up to 90% |

Using AI improves supply chains, saves money, and keeps businesses competitive.

Seasonal and Trend Analysis in AI-Driven Demand Forecasting

Finding Seasonal Demand Patterns with JusLink

How AI spots repeating demand trends.

AI is great at finding repeating demand patterns. It studies big data like past sales, weather, and market trends. For example, AI might notice air conditioners sell more in summer or certain foods are popular during holidays. This helps you plan ahead for what customers will need.

JusLink, a smart supply chain tool, goes further. It combines data from many sources to give real-time updates. This helps you quickly change plans based on customer behavior. With AI, you can predict demand spikes and avoid having too much or too little stock.

AI studies big data to find demand patterns.

It uses weather and sales info to improve forecasts.

Real-time updates help businesses adjust to market changes fast.

Matching production to seasonal trends.

After AI finds seasonal patterns, it helps you plan production. JusLink’s tools adjust inventory so you have the right stock ready. For example, if AI predicts more winter clothing sales, you can start making them early.

This planning cuts waste and improves efficiency. By matching production to seasonal needs, you meet customer demands and work better. AI-driven forecasting keeps your factory flexible and ready.

AI uses past sales to predict future needs.

It gives real-time updates about market trends.

Better inventory planning reduces waste and keeps stock ready.

Keeping Up with Long-Term Market Trends

How AI predicts and adjusts to customer changes.

AI helps you follow long-term market trends. It uses smart programs to study customer habits and predict what they’ll want. For example, AI might see more people want eco-friendly products, so you can offer those.

JusLink uses this to make forecasts even better. It helps you stay ahead by giving useful tips. With AI, you can improve planning, manage stock better, and even create ads that match customer needs.

AI makes demand forecasts more accurate and useful.

It helps understand customer habits and market changes.

Businesses use AI for smarter pricing and better marketing.

Staying strong in a changing market.

Markets change fast, so staying competitive is important. AI gives tools to handle surprises and grab chances. JusLink’s real-time tools help you make smart choices. Whether it’s changing prices or moving resources, AI keeps you ready.

Using AI lets you react faster than others. Better data tools improve forecasts and decisions. This keeps your business strong and ahead of the competition.

AI changes how businesses predict demand.

Real-time tools improve decisions and work efficiency.

Smart forecasting helps businesses stay competitive in tough markets.

How AI, IoT, and Blockchain Work Together for Better Transparency

Making Demand Forecasting Clearer with IoT

How IoT devices help with real-time updates.

IoT devices make demand forecasting easier by giving live updates. They collect data from places like warehouses, trucks, and factories. This data shows stock levels, delivery progress, and production status. For example, IoT sensors can check if temperature-sensitive items stay safe during shipping.

When IoT works with AI, it predicts demand changes better. This helps plan resources and improve deliveries. It ensures products arrive on time, lowers costs, and keeps stock balanced. IoT is now a key part of modern supply chains.

How blockchain keeps data correct and traceable.

Blockchain makes sure supply chain data is accurate and easy to track. It creates a secure record of every step in the process. This lets you follow a product from raw materials to the customer. For example, blockchain can confirm where goods come from and if they meet quality rules.

With AI, blockchain boosts transparency even more. It helps find and fix problems like delays or mistakes quickly. This builds trust and keeps the supply chain running smoothly.

How JusLink Improves Teamwork in Supply Chains

Sharing demand updates across the supply chain with AI.

JusLink uses AI to share demand updates with everyone in the supply chain. It collects data from many sources and gives live updates to all partners. For example, if demand for a product rises suddenly, JusLink tells suppliers to adjust production.

This quick sharing of information improves teamwork and avoids delays. It also prevents having too much or too little stock, keeping things efficient.

Building trust with clear and secure data.

Sharing clear data builds trust among supply chain partners. JusLink combines AI and blockchain to make this happen. Blockchain checks that data is real, while AI studies it to give useful tips.

This clear sharing of data helps partners work better together. It also reduces mistakes and keeps everyone on the same page. With JusLink, supply chains become more connected and reliable.

AI demand forecasting changes how factories handle production and stock. Using AI helps cut waste, make production better, and keep customers happy. Companies like Siemens and BMW have gained big results. They cut lead times by 15% and improved inventory turnover by 25%. Tools like JusLink make teamwork easier with IoT and blockchain. These tools help factories stay strong in changing markets. AI demand forecasting brings many benefits to businesses.

See Also

Transforming Data Into Insights: Enhancing Automotive Demand Predictions

Enhancing Supply Chain Performance Through AI Innovations

The Future of Logistics: AI's Impact on Supply Chains

Exploring AI Integration: Shaping the Future of Supply Chains

Leveraging Big Data: Transforming Supply Chain Management via Machine Learning