From Predictive Forecasting to Digital Twins: The AI Revolution Shaping Electronics Logistics

The ai-powered revolution is rapidly transforming procurement and supply chain management in the electronics industry. Companies now see a clear need to adapt as new technologies drive efficiency and accuracy.

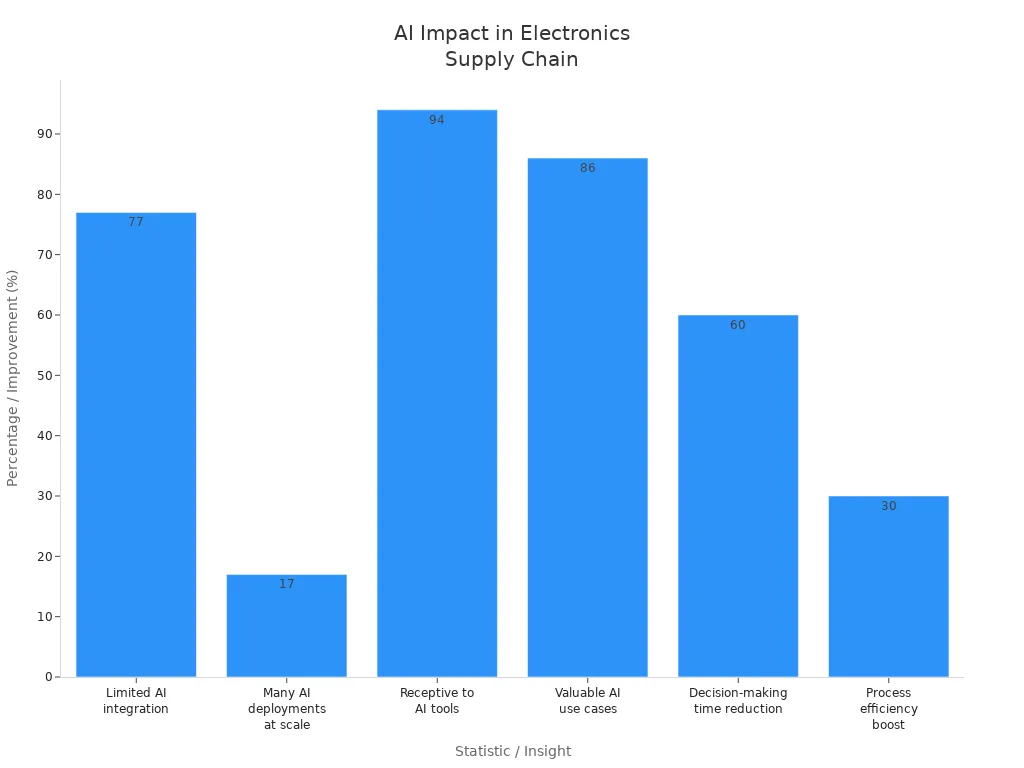

Statistic / Insight | Value / Description |

|---|---|

Supply chain leaders reporting limited AI integration | |

Leaders completing many AI deployments at scale | 17% completed many AI deployments at scale in the past year |

Leaders receptive to AI tools | 94% are entirely receptive to using AI tools |

Leaders identifying valuable AI use cases | 86% identify valuable use cases for AI integration |

Reduction in decision-making time | Up to 60% reduction |

Boost in process efficiency | 30% increase |

JUSDA and its JusLink platform lead the ai-powered revolution with real-world solutions. JusLink uses AI for dynamic inventory management and automated procurement, which supports electronics manufacturers facing complex cross-border demands. JUSDA’s global presence and localization strategies ensure that supply chain management adapts to changing markets. These innovations highlight the urgency for leaders to embrace the ai revolution and drive progress in this fast-paced industry.

Key Takeaways

AI boosts efficiency in electronics supply chains by automating tasks and improving demand forecasting, helping companies reduce costs and avoid stock problems.

Platforms like JusLink provide real-time visibility and smart tools that help manufacturers track shipments, manage inventory, and respond quickly to risks.

AI helps companies handle complex global supply chains by improving supplier selection, risk management, and logistics through data integration and automation.

Successful AI adoption requires good data quality, workforce training, and a clear strategy to overcome challenges and maximize benefits.

The future of electronics supply chains will rely on advanced AI technologies, such as generative AI and digital twins, to increase resilience, sustainability, and innovation.

AI-Powered Revolution in Supply Chain

Key Drivers of the AI Revolution

The ai-powered revolution in the electronics industry relies on several technological advancements. Companies now use artificial intelligence and automation to transform supply chain operations.

Machine learning algorithms and AI-driven analytics process large amounts of data from many sources.

Blockchain technology secures transactions and improves transparency.

Robotics and intelligent automation handle repetitive tasks, reducing errors and increasing efficiency.

Predictive analytics identify risks early, allowing companies to act before disruptions occur.

AI-powered telematics and real-time tracking improve logistics and transportation management.

Robotics and autonomous vehicles change how warehouses, production lines, and distribution centers operate.

These technologies help companies use energy more efficiently and reduce waste, supporting sustainability goals.

AI-driven solutions also strengthen strategic sourcing and supplier management, making supply chain management more resilient during global challenges.

Major companies like Amazon and Panasonic have already shown how these tools improve consumer electronics supply chains.

Impact on Electronics Procurement

Artificial intelligence now plays a central role in procurement for the electronics sector. AI analyzes supplier data, market trends, and historical performance to help companies choose the best partners. This approach leads to smarter sourcing decisions and better contract negotiations. AI-powered forecasting tools predict demand more accurately, which helps companies avoid overstock and stockouts.

Consumer electronics supply chains benefit from real-time insights, allowing procurement teams to respond quickly to market changes. Automation speeds up order processing and reduces manual errors. Artificial intelligence also supports risk management by monitoring global events and supplier performance.

With these advancements, supply chain management becomes more agile and efficient. Companies in the electronics industry can now meet customer demands faster and manage costs more effectively. The ai-powered revolution continues to shape procurement and consumer electronics supply chains, setting new standards for performance and reliability.

Traditional Supply Chain Challenges

Complexity and Fragmentation

The electronics industry faces significant challenges due to the complexity and fragmentation of traditional supply chains. Globalization has expanded supplier networks, making coordination more difficult. Companies in the semiconductor industry often work with many suppliers and customers across different regions. This complexity increases the risk of disruptions, as seen during the COVID-19 pandemic and the Suez Canal blockage. Over-optimized but fragmented supply chains lack resilience, which became clear during recent semiconductor shortages.

Fragmentation also comes from shifting trade policies and regional regulations. These changes make it harder for companies to manage procurement and compliance. Each partner in the supply chain may use different systems and processes, which leads to uncoordinated operations and delays.

The number and variety of suppliers and customers.

Constant changes in customer demands and industry standards.

Internal communication breakdowns and shifting business strategies.

External factors like economic and geopolitical volatility.

Global transportation routes, customs, and weather disruptions.

Consumer electronics supply chains must adapt quickly to these changes. Diversified supplier networks can help reduce some risks, but they also add new layers of complexity in managing transparency and quality.

Visibility and Data Silos

Visibility remains a major challenge in traditional supply chain management. Data silos fragment information across sourcing, planning, and operations. Many companies in the semiconductor industry cannot see beyond their first-tier suppliers. This lack of supply chain visibility makes it hard to track shipments and manage delivery schedules.

Key issues caused by data silos:

69% of companies lack a comprehensive view of their supply chain.

62% of manufacturers struggle with limited visibility.

Supplier data often sits in separate systems, making risk management and spend control difficult.

The semiconductor industry, with its global distribution, is especially vulnerable. Data silos prevent real-time monitoring and slow down procurement decisions. Consumer electronics supply chains need unified data to optimize inventory and respond to disruptions. Integrating data from manufacturing, transportation, and warehousing systems is essential for accurate forecasting and labor planning. Companies that overcome these challenges gain a competitive edge in the fast-moving electronics market.

AI Solutions in Logistics and Procurement

JUSDA and its JusLink platform stand at the forefront of ai-powered logistics and supply chain automation. These platforms deliver advanced ai-driven solutions that address the unique challenges of electronics manufacturing. JusLink integrates artificial intelligence, automation, and real-time analytics to transform procurement and logistics operations. The platform supports electronics manufacturers by providing enhanced demand forecasting, dynamic inventory management, and intelligent risk controls.

Real-Time Visibility with JusLink

JusLink acts as an intelligent control tower for electronics manufacturers. The platform integrates data from suppliers, logistics providers, and customers, creating real-time visibility across the entire supply chain. This real-time insight enables companies to monitor shipments, track inventory, and respond quickly to disruptions. JusLink leverages ai-powered logistics tools, IoT, RFID, and warehouse management systems to deliver end-to-end transparency. Electronics manufacturers benefit from seamless collaboration and digital transformation, which are essential for managing complex global supply chains.

JusLink’s real-time tracking and analytics allow proactive issue resolution. The platform collects and analyzes data from raw materials to finished products, supporting smarter decision-making. By integrating advanced technologies, JusLink ensures operational accuracy and efficiency. Companies can optimize logistics and supply chain processes, reduce delays, and improve customer satisfaction.

Description | |

|---|---|

Dynamic Inventory Management | Enables real-time adjustment and optimization of stock levels to meet demand efficiently. |

Auto Procurement | Automates purchasing processes to reduce manual intervention and speed up procurement cycles. |

Risk Management | Uses AI to identify and mitigate potential supply chain risks proactively. |

Real-time Tracking and Analytics | Provides end-to-end visibility and control over logistics operations, allowing proactive issue resolution. |

Advanced Technologies Integration | Incorporates RFID and Warehouse Management Systems (WMS) to enhance operational accuracy and automation in warehousing. |

Automation in Warehousing | Reduces manual errors and increases productivity through AI-driven automation. |

Tailored Logistics Solutions | Customizes logistics services specifically for high-value-added industries like electronics, ensuring specialized support. |

JusLink’s real-time capabilities support smarter collaboration and help companies adapt to rapid changes in the electronics market.

AI-Driven Demand Forecasting

Artificial intelligence has revolutionized demand forecasting in electronics procurement. JusLink uses ai-powered forecasting models to analyze sales data, web traffic, and market trends. The platform enables companies to adjust forecasts daily, not just monthly. This real-time approach captures demand spikes faster and reduces both stockouts and excess inventory.

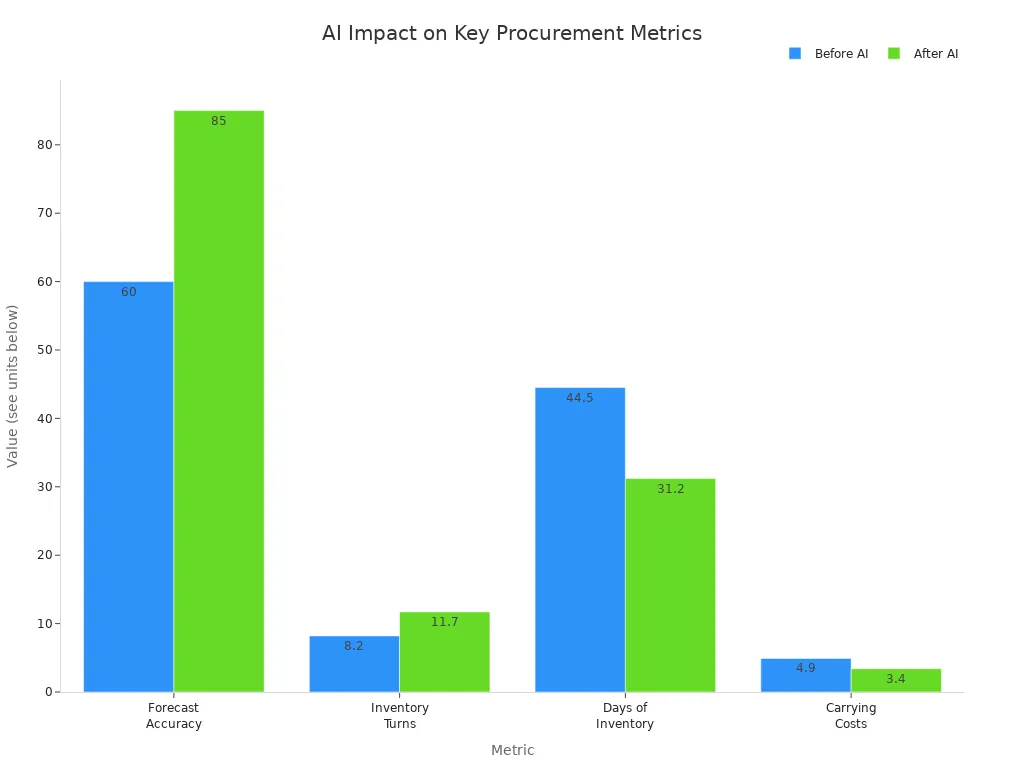

Electronics retailers have seen measurable improvements with ai-driven solutions. Forecast accuracy increased from 60% to 85%. Inventory turns rose by 42.7%, and days of inventory dropped by 30%. Companies reduced carrying costs by over 30% and improved product availability by 15%. These gains lead to higher customer satisfaction and more repeat purchases.

An electronics shop improved forecast accuracy from 60% to 85% by analyzing web traffic, social media buzz, and supplier data.

A consumer electronics retailer reduced stockouts caused by promotions by 40% using ai-powered demand sensing.

A leading electronics retailer cut inventory holding costs by 22% and improved in-store product availability by 15%.

A home upgrade retailer reduced stockouts by 37% within six months, with customer satisfaction rising by 18% and repeat purchases by 7%.

JusLink’s ai-powered logistics platform supports enhanced demand forecasting, helping companies align supply with market needs and optimize inventory levels.

Intelligent Risk Management

Risk management in electronics supply chains has become more proactive with artificial intelligence. JusLink uses ai-driven solutions to identify and mitigate risks before they disrupt operations. The platform monitors supplier performance, predicts delivery delays, and assesses external threats such as natural disasters or economic changes.

Lenovo uses ai-powered vendor risk assessments to predict delivery dates and delays across over 2,000 suppliers, optimizing manufacturing capacity and meeting customer demand.

Microsoft integrates ai in its supply chain management platform to predict manufacturing bottlenecks and forecast shortages years in advance.

Maersk employs ai-driven natural language processing and generative ai to automate supplier negotiations, speeding up deal closures at scale.

Frito-Lay applies ai-based predictive maintenance using IoT sensors to anticipate equipment failures, resulting in zero unexpected breakdowns in the first year.

JusLink’s risk management tools provide real-time monitoring and early warnings. The platform maps multiple tiers of suppliers and synthesizes complex data, enabling early risk identification. Predictive analytics monitor equipment conditions and forecast failures, allowing proactive maintenance. JusLink’s ai-powered logistics capabilities help companies develop contingency plans and maintain supply chain resilience.

JUSDA Solutions

To provide you with professional solutions and quotations.

Automated Application Management

Automation plays a critical role in modern logistics and procurement. JusLink’s automated application management streamlines workflows, reduces manual errors, and speeds up processes. The platform uses ai to optimize route planning, factoring in traffic, weather, and delivery constraints. This reduces fuel costs and emissions, supporting sustainability goals.

AI-driven risk assessment predicts delays and suggests alternative suppliers or routes, enhancing resilience.

Fraud detection systems analyze transaction patterns to prevent financial losses.

AI-enabled employee training through AR/VR improves safety and productivity.

Cost optimization is achieved via ai-managed energy systems and predictive maintenance, reducing downtime and expenses.

Scalability is supported by cloud-based ai platforms coordinating multiple sites and automating inventory and fleet management.

JusLink automates document processing, such as extracting data from invoices and bills of lading. AI-powered chatbots enhance customer service by quickly answering logistics queries. The platform supports dynamic pricing and fraud detection, improving cost control and security. Companies benefit from scalable ai-powered logistics systems that handle growing volumes without proportional cost increases.

JusLink’s ai-driven solutions outperform traditional methods in speed and accuracy. AI-powered procurement processes large datasets rapidly, automates document management, and provides real-time visibility into spending. Companies using ai-powered logistics and supply chain automation achieve higher cost savings, faster decision-making, and improved operational efficiency.

Emerging Technologies in AI Logistics

Generative AI Applications

Generative AI is changing how electronics companies manage their supply chains. This technology analyzes large sets of data, such as supplier records, shipping routes, and sales cycles. It helps companies predict demand and optimize inventory, which prevents both shortages and excess stock. Generative AI also improves transportation by creating efficient delivery routes. It considers traffic, weather, and schedules to reduce costs and speed up deliveries.

Companies use generative AI to simulate risk scenarios, such as supplier disruptions or natural disasters. This allows them to prepare for problems before they happen. Microsoft Dynamics 365 Copilot, for example, uses artificial intelligence to spot external risks and automate communication, helping teams respond quickly. Generative AI also automates document processing, making it easier to access important information and speeding up order fulfillment. These advances in ai-powered logistics lead to better customer satisfaction and lower costs.

Generative AI supports data-driven decision-making and increases supply chain resilience. It helps companies adapt to changes in the market without needing to change their entire infrastructure.

Digital Twins and IoT Integration

Digital twins and IoT integration are transforming ai in logistics for the electronics industry. Digital twins create virtual models of real-world logistics systems. IoT sensors collect real-time data, such as temperature and equipment status, and feed it into these models. Artificial intelligence then analyzes this data to detect patterns, predict failures, and suggest improvements.

With digital twins, companies can simulate warehouse layouts and test new processes before making changes in real life. This helps optimize space and resource use. AI-powered logistics platforms use these simulations to improve production scheduling and resource allocation. Predictive maintenance becomes possible because AI can spot equipment issues early, reducing downtime and extending asset life.

IoT and digital twins also improve quality control. They monitor product parameters and adjust processes in real time to maintain high standards. This integration leads to smarter, more efficient, and resilient logistics operations. Electronics companies benefit from faster decision-making and greater transparency across their supply chains.

Benefits of AI in Supply Chain

Efficiency and Cost Savings

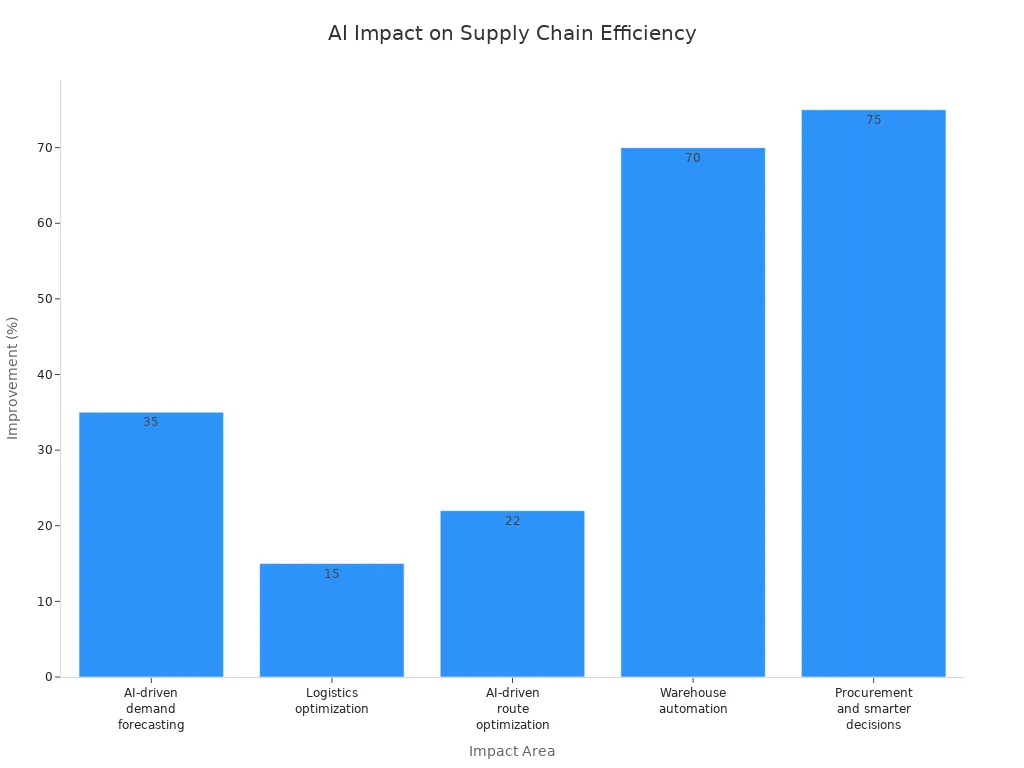

AI transforms the supply chain by driving operational efficiency and reducing costs. Companies in the electronics industry use automation to streamline processes and improve accuracy. AI-driven demand forecasting helps businesses lower inventory levels by 35%. Logistics optimization powered by AI leads to a 15% improvement in logistics costs. Route optimization reduces transportation costs by 22%. Warehouse automation adoption has reached 70%, showing how automation changes daily operations. Supply chain professionals rely on AI-driven analytics for smarter procurement decisions, with 75% using these tools.

Metric Description | Statistic / Percentage | Impact Area |

|---|---|---|

Decrease in inventory levels | 35% | |

Improvement in logistics costs | 15% | Logistics optimization |

Decrease in transportation costs | 22% | AI-driven route optimization |

Adoption of AI-driven automation in warehouses | 70% | Warehouse automation |

Use of AI-driven analytics by supply chain professionals | 75% | Procurement and smarter decisions |

Automation increases supply chain agility by speeding up order processing and reducing manual errors. AI-powered automation also improves operational efficiency by allowing companies to monitor and adjust processes in real time. These advances help businesses save money and respond quickly to market changes.

Resilience and Sustainability

AI strengthens supply chain resilience and supports sustainable practices in the electronics sector. Companies use automation for real-time monitoring and predictive analytics, which improves decision-making and inventory optimization. Automation also enables proactive risk management, helping businesses avoid disruptions.

AI supports supply chain agility by analyzing trade-offs between cost and risk, making it easier to diversify suppliers and locations.

Automation in energy management systems reduces carbon footprints and supports sustainable manufacturing processes.

AI-powered logistics platforms optimize routes, use electric fleets, and encourage sustainable packaging, lowering emissions.

Automation accelerates sustainable practices by reducing energy use and waste, which helps companies grow while protecting the environment.

Supply chain leaders see automation as a key driver for operational efficiency and sustainable practices. AI-powered automation helps companies meet environmental goals and build a more resilient supply chain for the future.

JUSDA Case Study: AI Revolution in Action

Global Process Optimization

JUSDA has helped global manufacturers in the semiconductor industry overcome complex challenges. Many companies in this sector face issues with overseas supply chains and global procurement. JUSDA introduced its JusLink platform to address these problems. The platform uses ai to connect suppliers, logistics partners, and customers. It provides real-time data across every stage of the supply chain.

JusLink supports process optimization by integrating systems like ERP, TMS, and WMS. This integration allows companies to track shipments, manage inventory, and coordinate production in real-time. The semiconductor industry benefits from these features because it relies on precise timing and coordination. JUSDA’s solution reduces manual work and standardizes operations. Companies see lower costs and faster decision-making. They also gain the ability to expand globally with less risk.

JUSDA’s ai-driven platform helps manufacturers respond to market changes quickly. Real-time insights support better planning and reduce delays.

Enhanced Transparency and Efficiency

JUSDA’s JusLink platform delivers enhanced supply chain transparency for the semiconductor industry. The platform collects real-time information from multiple sources. It monitors shipments, inventory, and supplier performance without delays. This real-time visibility helps companies identify risks and solve problems before they grow.

JusLink uses ai to analyze data and provide alerts. Companies receive real-time warnings about disruptions, such as late shipments or equipment failures. The platform also supports real-time collaboration between teams. This approach improves efficiency and builds trust among partners.

Key results achieved by JUSDA’s customers:

30% reduction in manual handling

25% faster order processing

20% lower inventory costs

Improved global expansion with real-time control

JUSDA’s focus on real-time data and ai has set new standards for efficiency in the semiconductor industry. Companies now operate with greater speed, accuracy, and confidence.

Action Steps for Electronics Businesses

Assessing AI Readiness

Electronics businesses must take a structured approach before starting automation and ai integration in their supply chain. A comprehensive readiness assessment helps companies avoid costly mistakes and ensures successful adoption. Leaders should begin by reviewing six key pillars: strategy, infrastructure, data, governance, talent, and culture. Each pillar supports a different part of the automation journey.

Define a clear ai strategy that aligns with business goals and has executive support.

Check if current IT infrastructure can handle automation workloads, including cloud and on-premise systems.

Review data quality, availability, and integration to ensure reliable sources for ai models.

Establish governance frameworks that address ethics, privacy, and risk management.

Identify talent gaps and invest in training for automation and ai leadership.

Foster a culture that encourages innovation and safe experimentation with automation.

Companies should also focus on data security and privacy. Encryption, access controls, and compliance with regulations protect sensitive information. Integrating ai systems with cybersecurity protocols helps detect threats early. Regular risk assessments and secure model development practices reduce vulnerabilities. Evaluating third-party vendors and setting compliance agreements further strengthen the supply chain.

Formal assessment tools, such as the Cisco AI Readiness Assessment, help benchmark maturity and identify gaps. Addressing these gaps before scaling automation prevents wasted resources and project failures.

Building a Data-Driven Culture

A strong data-driven culture supports successful automation and ai integration in sourcing and procurement. Modernizing procurement infrastructure is the first step. Companies should replace outdated systems with agile, cloud-based platforms. This enables real-time data access and seamless automation.

Build responsible ai frameworks that focus on ethics, transparency, and human oversight.

Measure automation’s value using key performance indicators for risk, supplier performance, and sustainability.

Encourage collaboration among procurement, IT, legal, and compliance teams to create innovative strategies.

Invest in continuous learning and upskilling for procurement professionals. Training in analytics, ai ethics, and automation tools bridges knowledge gaps.

Provide adaptive education tailored to daily roles and strategic goals.

Promoting cross-functional teamwork and ongoing education helps employees adapt to new technologies. This approach ensures that automation becomes part of daily operations and supports long-term supply chain success.

The AI-powered revolution has changed procurement and supply chain management in the electronics industry. Companies now use AI to automate routine tasks, improve supplier selection, and predict demand more accurately. JusLink by JUSDA gives businesses a competitive edge with real-time insights and smarter decision-making.

AI helps teams:

Increase efficiency by automating repetitive work

Analyze supplier data for better quality and cost control

Forecast demand and optimize inventory

Identify risks early and manage them proactively

Electronics businesses should break down silos, focus on data quality, and start with clear AI use cases. Taking these steps will help them stay ahead and drive continuous innovation.

FAQ

What is JusLink and how does it help electronics companies?

JusLink is an AI-powered supply chain platform from JUSDA. It helps electronics companies manage inventory, forecast demand, and track shipments in real time. JusLink improves efficiency and reduces risks by using advanced analytics and automation.

How does AI improve demand forecasting in the electronics industry?

AI analyzes sales data, market trends, and supplier information. It predicts future demand more accurately than manual methods. Companies can adjust inventory quickly, avoid stockouts, and reduce excess stock.

Can AI help manage supply chain risks?

Yes. AI monitors supplier performance, predicts disruptions, and sends early warnings. Companies use this information to create backup plans and respond faster to problems.

Is JusLink suitable for global supply chains?

JusLink supports global operations. It connects suppliers, logistics partners, and customers across different countries. The platform provides real-time data and helps companies manage complex international supply chains.

What are the main benefits of using AI in procurement?

Benefit | Description |

|---|---|

Cost Savings | AI reduces manual work and errors. |

Faster Decisions | AI processes data quickly. |

Better Planning | AI improves forecasting accuracy. |

Risk Reduction | AI identifies problems early. |

See Also

How Artificial Intelligence Is Transforming Future Supply Chains

Discovering Robotics Innovations Driving Supply Chain Change

Maximizing Efficiency Within Automotive Supply Chain Networks

Collaborating To Improve Supplier Bonds In Advanced Manufacturing