AI vs. Supply Chain Disruptions: Building Resilience in Healthcare Supply Chain

AI is revolutionizing how healthcare organizations respond to supply chain disruptions. Recent studies show that AI methods like machine learning and big data analytics have become the most effective tools for boosting supply chain resilience. For example, research by Belhadi et al. (2022) found that these technologies helped organizations quickly adapt to unexpected challenges. With AI, healthcare providers can predict shortages, optimize inventory, and improve collaboration—ensuring patients get the care they need, even during crises.

Key Takeaways

AI helps healthcare organizations predict supply shortages, optimize inventory, and improve supplier management to reduce disruptions and ensure patient care.

Manual processes cause many supply chain problems; automating tasks with AI cuts errors, lowers costs, and speeds up decision-making.

Real-time tracking and early warning systems powered by AI allow hospitals to spot risks quickly and act before shortages affect patients.

Successful AI adoption requires good data quality, staff training, strong collaboration, and compliance with healthcare regulations.

Healthcare leaders should embrace AI tools like JusLink, support their teams, and adapt workflows to build resilient supply chains for the future.

Supply Chain Disruptions in Healthcare

Common Challenges

Healthcare organizations face many obstacles that make supply chain management complex. Historical data shows that about 80% of hospitals reported shortages in 2021. These shortages ranked as the second highest risk for healthcare organizations in 2022. The COVID-19 pandemic made these challenges worse, causing delays, higher costs, and shortages of critical supplies.

Challenge Area | Description | Example/Result |

|---|---|---|

Manual Procure-to-Pay (P2P) | Manual steps cause errors and slowdowns. | Northwestern Medicine digitized P2P, removing manual steps to support growth. |

Manual Inventory Management | Manual tracking leads to stockouts and waste. | Forest Baptist Health automated data capture, improving accuracy and saving time. |

Contract Data Misalignment | Manual updates create pricing errors. | Piedmont Healthcare cut price exceptions by 81% with automation. |

Manual Invoice Processing | Paper invoices strain resources. | Children’s of Alabama automated invoices, reaching 90% untouched invoices. |

Late Supplier Payments | Manual payments result in late fees and missed savings. | Nebraska Methodist Health System automated payments to avoid late fees. |

Cloud Adoption | More hospitals move to cloud-based supply chain management. | Nearly 70% expect to adopt cloud SCM by 2026. |

AI Usage | AI helps forecast demand and track shipments. | 46% of healthcare companies use AI for disruption detection. |

Supply Chain Disruptions often stem from these manual processes and lack of automation. Hospitals that rely on outdated systems struggle to keep up with demand, leading to frequent shortages and inefficiencies.

Impact on Patient Care

Supply Chain Disruptions do not just affect hospital operations—they have a direct impact on patient care. Studies show a strong link between supply chain problems and lower quality of healthcare delivery. During the COVID-19 pandemic, shipment delays and travel restrictions led to missed treatments and increased patient risk. One survey found a significant negative correlation between supply chain management and healthcare quality, with disruptions reducing the standard of care.

When hospitals cannot get the supplies they need, patient outcomes suffer. Healthcare workers also feel more stress, which further affects patient care. Improving communication, planning, and supply chain management can help reduce these disruptions and improve patient outcomes.

The Resilinc Disruption Vulnerability Index uses historical data and AI to measure the frequency and severity of supply chain disruptions. This tool helps healthcare organizations identify risks and take action before problems reach patients.

AI Solutions for Resilience

JUSDA and its flagship platform, JusLink, stand at the forefront of AI-driven supply chain innovation. These solutions help healthcare organizations optimize inventory, and manage suppliers with greater accuracy and speed. JusLink uses advanced AI forecasting, real-time risk management, and intelligent agents to build resilient supply chains that can withstand disruptions.

JUSDA Solutions

To provide you with professional solutions and quotations.

Demand Forecasting

Accurate demand forecasting is essential for healthcare providers. AI models, such as those used in JusLink, analyze real-time data and historical trends to predict future needs. This approach reduces the risk of overstocking and stockouts. A recent industry study compared AI-based forecasting models with traditional methods and found that AI models achieved a 31% improvement in forecast accuracy. This improvement leads to better stock replenishment and less waste.

JusLink’s AI forecasting tools use deep learning to process large volumes of data from multiple sources. These tools help healthcare organizations:

Predict shortages before they occur, allowing proactive supply management.

Integrate clinical and supply chain operations for a clearer view of constraints and needs.

Continuously monitor key performance indicators to support ongoing improvements.

AI-powered demand forecasting supports lean healthcare logistics by eliminating waste and ensuring timely stock replenishment. Hospitals using these tools can reduce inventory levels by up to 30%, lower operational costs, and improve patient outcomes.

Inventory Optimization

Managing inventory in healthcare is complex. JusLink’s AI-driven inventory optimization tools automate ordering, track inventory in real time, and manage expiration dates. These features ensure that critical supplies are always available and reduce the risk of waste.

A healthcare provider that adopted an AI-powered pharmacy application saw a 30% increase in efficiency and a 15% boost in patient engagement. AI algorithms can achieve up to 95% accuracy in demand forecasting, which helps reduce stockouts and overstock. Research shows that AI can cut healthcare inventory costs by 15-30% and save the sector billions each year.

Key benefits of AI inventory optimization include:

Automated ordering based on predicted low stock.

Real-time tracking and proactive alerts for inventory levels.

Management of expiration dates to minimize waste.

Improved collaboration with suppliers and logistics partners.

Benefit | Description | Tangible Impact |

|---|---|---|

AI analyzes real-time data and trends to improve demand forecasting, reducing overstocking and stockouts. | Inventory levels can be reduced by 20-30%. | |

Reduced operational costs | Automation and improved accuracy lower costs in inventory tracking, order processing, and logistics. | Logistic costs reduced by 5-20%, procurement costs by 5-15%. |

Faster decision-making | Real-time insights and predictive analytics enable quicker, informed decisions. | Decision-making speed improved by up to 35%, reducing downtime. |

Risk mitigation | AI identifies potential supply chain risks early, allowing proactive disruption management. | Disruptions identified 25 days earlier on average. |

Greater supply chain resilience | AI provides real-time visibility and predictive insights, enabling faster response to disruptions. | Response times during disruptions improved by 60-80%. |

Enhanced sustainability | AI optimizes routes and reduces waste, supporting sustainable supply chain practices. | Supply chain waste reduced by 50% in logistics. |

Supplier Management

Supplier management is critical for healthcare organizations. JusLink’s AI-driven supplier management tools analyze supplier reliability, cost-effectiveness, and delivery timelines. These tools recommend the best suppliers and help organizations build strong, long-term partnerships.

Leading healthcare providers use AI to monitor supplier performance, automate procurement tasks, and ensure compliance with regulations. For example, Mayo Clinic and Cleveland Clinic use AI to predict demand for supplies and improve procurement accuracy. McKesson employs AI-powered solutions to streamline supplier performance monitoring.

AI supplier management systems offer several advantages:

Analyze supplier reliability and recommend optimal vendors.

Suggest bulk purchasing strategies to reduce excess inventory and waste.

Automate compliance tracking to meet regulatory standards.

Enable early warning of supply chain disruptions for proactive mitigation.

Improve supplier relationships and reduce the risk of disruptions.

JusLink’s intelligent agents, such as the Transportation Business Risk Expert and Intelligent Data Query, provide real-time insights and support decision-making. These features help healthcare organizations maintain a stable, efficient, and sustainable supply chain.

JUSDA’s customer stories highlight the real-world impact of these solutions. For example, JUSDA’s Supply Chain Management Collaboration Platform helped leading manufacturers overcome complex global supply chain challenges. The platform improved transparency, reduced manual handling, and enabled cost-effective expansion. By integrating AI, cloud computing, and blockchain, JUSDA delivered end-to-end lifecycle management and real-time risk monitoring.

Risk Management and Early Warning

Disruption Prediction

Healthcare organizations face constant threats from unexpected events that can disrupt the flow of medical supplies. Proactive risk management and early warning systems play a vital role in preventing these issues. A 2020 healthcare survey showed that 51% of workers struggled to access N95 masks, and 25% reported shortages of personal protective equipment when needed. These numbers highlight the importance of anticipating risks before they impact patient care.

Professionally designed risk management processes help organizations minimize the frequency and impact of supply chain risks. The following table shows how risk management, resilience, and robustness are measured in healthcare supply chains:

Category | Example Statements | Explanation |

|---|---|---|

Risk Management Perception | "Employees are highly sensitized to supply risks"; "Risk management processes are professionally designed" | These statements measure how well risk management is perceived and implemented. |

Supply Chain Resilience | "Able to cope with changes caused by disruptions"; "Provide quick response" | These statements assess the ability to respond and adapt to disruptions. |

Supply Chain Robustness | "Supply chain remains stable over time"; "Performs well without adaptations" | These statements show the stability and strength of the supply chain during disruptions. |

AI and machine learning models, such as regression analysis and neural networks, process large datasets to improve prediction accuracy. Anomaly detection systems identify irregularities in real time, allowing early intervention. Predictive analytics enhances demand forecasting and reduces stockouts. Leading companies report success rates of 85-95% with strong data infrastructure and AI talent, while industry averages range from 60-80%. These tools help healthcare providers anticipate Supply Chain Disruptions and maintain steady operations.

Real-Time Alerts

Real-time alert systems give healthcare organizations the ability to respond quickly to changing conditions. Digital twin technology uses real-time IoT data and AI-driven analytics to simulate supply chain scenarios and forecast disruptions. Hospitals use these systems to improve vaccine logistics, manage inventory, and reduce costs.

The Stock Visibility System (SVS) detects high- and low-consumption clinics, helping redistribute diagnostic tests and prevent overstocking.

Drone technology delivers medical supplies to rural hospitals, reducing human error and saving time.

Digital twin pilot projects have shown measurable improvements in operational efficiency and risk mitigation.

These real-time alert systems help healthcare organizations act before problems grow. By using continuous monitoring and instant notifications, hospitals can prevent Supply Chain Disruptions and ensure patients receive the care they need.

Visibility and Automation

End-to-End Tracking

AI-powered end-to-end tracking systems give healthcare organizations a clear view of their entire supply chain. These systems collect and analyze real-time data from many sources, including point-of-sale scanners, customs declarations, and freight bookings. By using advanced dashboards, such as those created by Google’s Video AI, organizations can spot abnormal demand changes and quickly identify the causes. This early detection helps prevent disruptions before they affect patient care.

AI tools monitor traffic conditions and supply chain tiers, such as ports and warehouses, to detect issues like worker shortages or shipping delays.

Algorithms extract and combine data from both structured and unstructured documents, creating dynamic maps of the supply chain.

Startups use generative AI and large language models to help employees ask questions in plain language, improving communication and logistics accuracy.

Studies show that AI adoption leads to better supply chain performance by enhancing information processing and decision-making. AI reduces out-of-stock events by over 56%, making sure critical supplies are available when needed. These systems also help healthcare supply chains become more agile and responsive, which is vital during uncertain times.

End-to-end tracking powered by AI gives healthcare leaders the visibility they need to make fast, informed decisions and keep supply chains running smoothly.

Automated Processes

Automation transforms healthcare supply chain management by reducing manual work and increasing efficiency. Robotic Process Automation (RPA) handles order processing and stock tracking, which cuts down on human errors and speeds up inventory management. AI-driven predictive analytics improve demand forecasting, helping organizations keep optimal inventory levels and use resources wisely.

IoT and RFID systems track assets in real time, saving hours by quickly locating equipment and supplies.

Blockchain technology boosts transparency and security, reducing fraud and improving quality control.

Intelligent automation eliminates repetitive tasks, raising productivity and lowering operational costs.

RPA streamlines medicine inventory management by updating stock levels automatically and ensuring essential medicines remain available. Automation also enables faster data sharing across departments, reducing delays. AI-driven ordering systems increase productivity by minimizing manual requests. These improvements support better patient care by providing timely access to supplies and information.

Automation in healthcare supply chains leads to fewer errors, lower costs, and more reliable delivery of critical supplies, directly benefiting both providers and patients.

Implementing AI in Healthcare Supply Chains

Integration Challenges

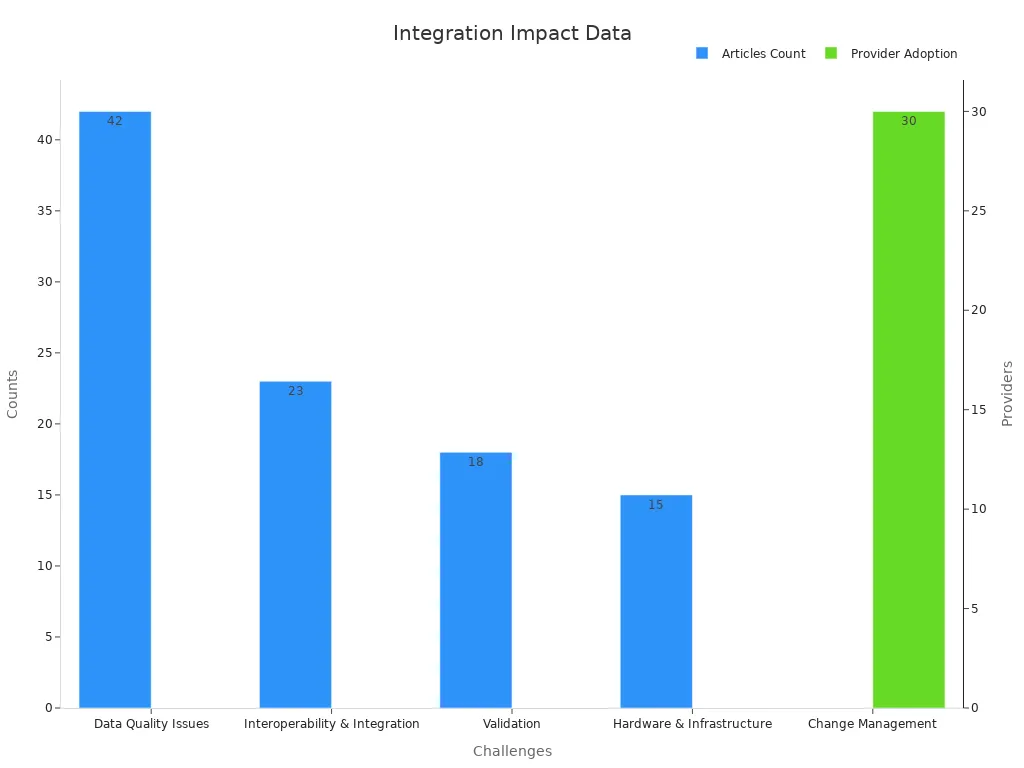

Healthcare organizations face several hurdles when integrating AI into their supply chains. Data quality stands out as a major concern. Many hospitals use outdated machines or collect low-quality data, which limits AI performance. Interoperability also creates barriers. Different systems often cannot share information easily, making it hard to build accurate predictive models or connect clinical workflows.

A recent review found that 42 articles discussed data barriers, while 23 focused on interoperability and integration issues. Validation remains a challenge, with most studies relying on retrospective data instead of real-time trials. Hardware and infrastructure needs add another layer of complexity. Hospitals must invest in new IT systems and data-sharing platforms, which can be costly and time-consuming.

Challenge Area | Description | Supporting Reference(s) |

|---|---|---|

AI integration raises concerns about data privacy and security, requiring robust regulatory frameworks. | Kumar and Mallipeddi (2022) | |

Sustainability | Need for sustainable AI practices in supply chains to ensure long-term viability and environmental care. | Samuels et al. (2024b) |

Regulatory and Standardisation Deficiencies | Lack of cross-industry AI standards and regulatory adaptation, especially in healthcare, hinders adoption. | Frontiers (2024), Layode (2024) |

Human-Centric Integration | Challenges in blending AI with human resources to leverage both technology and creativity effectively. | Samuels et al. (2024a) |

Collaboration Complexity | Effective AI integration requires enhanced collaboration among supply chain partners to manage risks. | Belhadi et al. (2021), Layode (2024) |

Sector-Specific Challenges | Healthcare faces unique regulatory and adoption challenges compared to other sectors like agriculture. | Frontiers (2024) |

Change management also plays a key role. Over 30 healthcare providers have adopted AI transcription tools, showing that adoption is possible with the right support. Training, upskilling, and workflow integration help staff accept new technology and reduce fears of job loss.

Best Practices

Successful AI implementation in healthcare supply chains depends on several best practices:

Invest in Staff Training: Hospitals should offer AI literacy programs and certifications. These programs help staff understand new tools and reduce resistance.

Prioritize Data Quality: Clean, accurate data improves AI performance. Regular audits and updates ensure reliable results.

Promote Collaboration: Teams must work together across departments and with external partners. Open communication supports smooth integration.

Ensure Compliance: Following industry regulations and standards protects patient data and builds trust.

Foster a Culture of Learning: Continuous education and support help staff adapt to changes and encourage innovation.

Tip: Platforms like JusLink simplify AI adoption. JusLink offers customizable features, real-time monitoring, and intelligent agents that support seamless integration. Hospitals can use JusLink to manage data, automate processes, and improve supply chain resilience with less disruption.

By following these best practices, healthcare organizations can overcome integration challenges and unlock the full potential of AI-driven supply chains.

AI has changed healthcare supply chain management. Longitudinal data from Premier Inc. shows that predictive analytics help hospitals predict shortages weeks ahead, allowing them to find substitutes and keep care on track. Hospitals using AI-powered forecasting and inventory tools report fewer shortages and lower costs over time. Leaders should start by training teams, improving data quality, and choosing platforms like JusLink for seamless adoption. Proactive investment in AI will help healthcare organizations stay ready for future Supply Chain Disruptions and deliver better patient care.

FAQ

What is JusLink and how does it help healthcare supply chains?

JusLink is an AI-powered platform from JUSDA. It predicts demand, manages inventory, and monitors risks in real time. Healthcare organizations use JusLink to reduce shortages, cut costs, and improve supply chain visibility.

Can AI prevent all supply chain disruptions in healthcare?

AI cannot stop every disruption. It helps organizations predict problems, respond faster, and reduce risks. AI tools like JusLink give early warnings and support better planning, making supply chains more resilient.

How does JusLink ensure data security and compliance?

JusLink uses advanced encryption and follows strict industry standards. The platform protects sensitive data and supports compliance with healthcare regulations. Regular audits and updates keep security strong.

What steps should healthcare leaders take to start using AI in supply chains?

Leaders should train staff, improve data quality, and choose a trusted platform like JusLink. They need to set clear goals, monitor progress, and encourage teamwork. Early adoption builds a stronger, more reliable supply chain.

See Also

Identifying Risks To Protect Your Supply Chain Effectively

JUSDA Strategies To Ensure Strong And Ready Supply Chains

Don’t Overlook Supply Chain Threats Safeguard Your Business

Understanding Inflation’s Impact On Supply Chain Challenges

Complete Guide To Managing And Overcoming Supply Chain Issues