How to Apply Lean Tools in Logistics and Transportation

Lean tools simplify logistics and transportation by removing inefficiencies and focusing on customer value. These tools help you identify waste, streamline operations, and improve resource utilization. For example, Lean practices can reduce lead times by up to 70%, cut costs by 25-30%, and double your return on investment. With Lean Logistics Planning, you can optimize transportation routes, enhance quality, and boost labor productivity. By adopting these methods, you create a more efficient system that delivers better results and meets customer expectations.

Key Takeaways

Lean tools cut waste in logistics, lowering costs and boosting efficiency.

Value Stream Mapping (VSM) finds problems and improves logistics steps.

Using Just-In-Time (JIT) lowers inventory costs and makes customers happier by timing deliveries well.

The 5S method organizes work, increases productivity, and makes the workplace safer.

Watching key performance indicators (KPIs) often keeps logistics on track with Lean ideas.

Identifying Waste in Logistics and Transportation

Common Types of Waste in Logistics

Waste in logistics often stems from inefficiencies that disrupt the flow of goods and services. You can identify seven common types of waste in logistics:

Transportation Waste: Unnecessary movement of goods increases costs and delays.

Inventory Waste: Excess inventory ties up capital and storage space.

Motion Waste: Inefficient movement of workers or equipment reduces productivity.

Waiting Time: Delays in processes lead to idle resources and missed deadlines.

Overproduction: Producing more than needed creates surplus inventory.

Overprocessing: Performing unnecessary steps adds no value to the customer.

Defects: Errors in shipments or documentation result in rework and customer dissatisfaction.

By addressing these waste types, you can streamline operations and improve efficiency. For example, optimizing transportation routes reduces unnecessary movement, while better inventory management minimizes excess stock.

Tools for Waste Identification

To tackle waste effectively, you need tools that pinpoint inefficiencies. Several tools have proven successful in identifying waste in logistics:

Value Stream Mapping (VSM): This tool visualizes the entire process, helping you spot non-value-adding activities.

Flow Diagrams: These diagrams highlight bottlenecks and inefficiencies in material or information flow.

Communication Diagrams: These focus on identifying gaps in communication that lead to delays or errors.

Studies show that VSM is particularly effective for general waste identification, while flow and communication diagrams excel in identifying specific waste types like overprocessing or transportation waste. Implementing these tools not only reduces waste but also enhances sustainability and cost savings.

Value Stream Mapping in Logistics

Value Stream Mapping (VSM) is a powerful tool for improving logistics processes. It helps you visualize the flow of materials and information, making it easier to identify waste and value-adding activities. For example, VSM can reveal inefficiencies in transportation routes or highlight delays in warehouse operations.

A study found that VSM significantly improves efficiency by connecting value-adding steps and eliminating waste. However, improper use of VSM can lead to misinterpretations and errors. To avoid this, you should follow clear guidelines and ensure accurate data collection.

Key Findings | Implications |

|---|---|

VSM identifies value-adding activities and waste in logistics processes. | It enhances efficiency and reduces waste. |

Misapplications of VSM can lead to complications. | Proper training ensures accurate results. |

Challenges in VSM application vary across industries. | Tailored approaches improve its effectiveness. |

By integrating VSM into your Lean Logistics Planning, you can create a continuous flow of value, reduce waste, and improve overall efficiency.

Lean Logistics Planning for Transportation Optimization

Implementing Just-In-Time (JIT) in Transportation

Just-In-Time (JIT) in transportation focuses on delivering goods exactly when needed, reducing delays and excess inventory. This approach minimizes waste by ensuring that resources, such as vehicles and storage, are used efficiently. For example, JIT eliminates the need for large warehouses by synchronizing deliveries with production schedules.

You can implement JIT by leveraging real-time tracking systems. These systems enhance visibility, allowing you to monitor shipments and make informed decisions. Adaptive routing, which adjusts delivery paths based on traffic or weather conditions, further supports JIT by reducing delays. Predictive maintenance also plays a key role. It uses data to foresee vehicle issues, ensuring that your fleet operates without unexpected downtime.

Benefits of JIT in transportation include:

Reduced lead times.

Lower inventory costs.

Improved customer satisfaction.

By adopting JIT, you create a streamlined transportation process that aligns with Lean Logistics Planning principles. This ensures that your operations remain efficient and responsive to customer needs.

Using 5S for Fleet and Warehouse Management

The 5S methodology—Sort, Set in Order, Shine, Standardize, and Sustain—improves organization and efficiency in fleet and warehouse management. It begins with identifying waste in operations, such as unnecessary inventory or inefficient workflows. Sorting eliminates non-essential items, while setting in order ensures that tools and materials are easily accessible.

For example, a study of 138 manufacturing firms in Kenya showed that applying 5S significantly improved performance. Companies achieved smoother material flows, better visibility, and enhanced work organization. This framework also emphasizes regular maintenance and cleanliness, which reduces equipment failures and enhances safety.

Steps to implement 5S in your operations:

Conduct a 5Ws analysis to identify waste.

Apply the 5S principles to organize your fleet and warehouse.

Monitor progress and make adjustments to sustain improvements.

By integrating 5S into your Lean Logistics Planning, you create a more efficient and organized system that supports long-term success.

Standard Work for Streamlined Operations

Standard work establishes consistent processes for logistics and transportation tasks. It ensures that every team member follows the same procedures, reducing variability and errors. For example, creating a standard checklist for loading and unloading goods minimizes delays and prevents damage.

You can develop standard work by analyzing current processes and identifying best practices. Regular reviews and updates ensure that these standards remain relevant and effective. Continuous improvement, a core principle of Lean Logistics Planning, plays a vital role in refining standard work.

Findings | Description |

|---|---|

Lean tools enhance service efficiency by optimizing existing resources. | |

Capacity Increase | Implementation of Lean principles leads to increased operational capacity. |

Continuous Improvement | Lean methodologies foster ongoing enhancements in logistics processes. |

Standard work not only improves efficiency but also boosts employee morale by providing clear guidelines. It creates a foundation for consistent and reliable operations, ensuring that your logistics processes meet customer expectations.

JUSDA Solutions

To provide you with professional solutions and quotations.

Real-World Examples of Lean in Logistics

Case Study: Lean Implementation in Freight Services

Lean tools have transformed freight services by improving efficiency and reducing waste. For example, Lean Six Sigma principles focus on continuous improvement and strategic analysis. These methods streamline processes like payment handling and request-to-ship workflows. By applying Lean tools, freight companies achieve faster deliveries and lower operational costs.

You can see measurable outcomes in freight services through process management. Lean tools help identify inefficiencies and optimize workflows. For instance:

Payment processes become faster and more accurate.

Request-to-ship workflows reduce delays and improve customer satisfaction.

These improvements demonstrate how Lean tools create value for both businesses and customers.

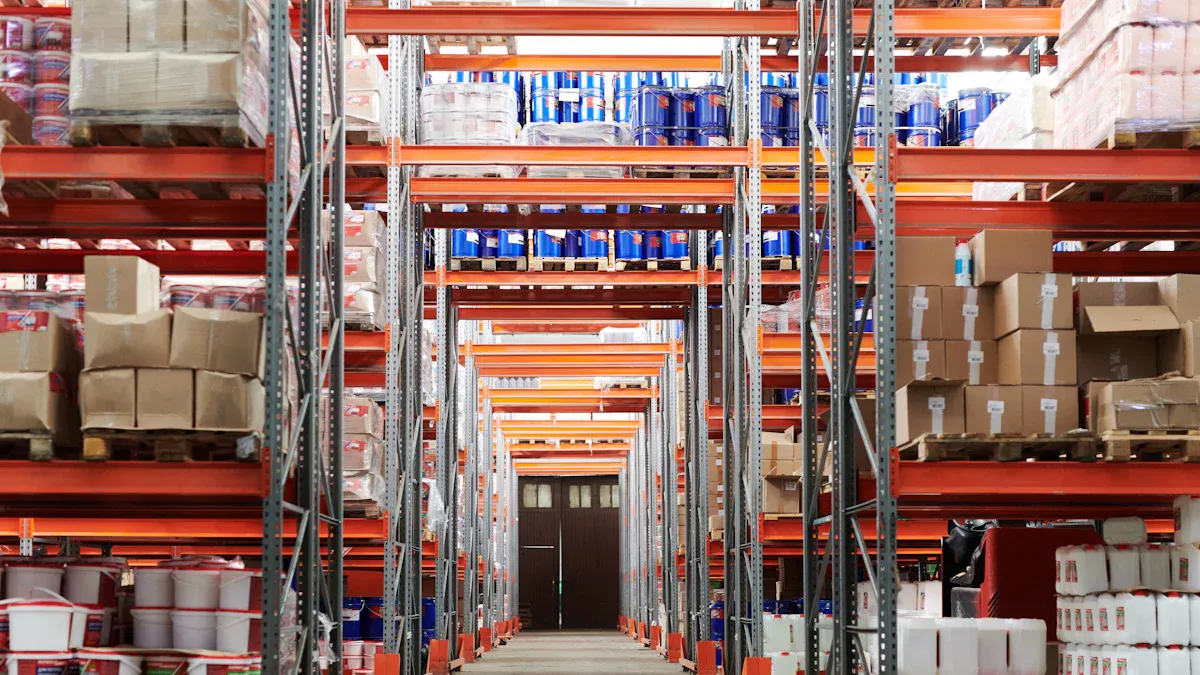

Case Study: Warehouse Optimization with Lean Tools

Lean-driven warehouse optimization focuses on accomplishing more tasks with fewer resources. Strategies like cross-docking and Lean inventory practices reduce storage durations and holding costs. For example, implementing a Warehouse Management System (WMS) minimizes human error and provides quick access to inventory locations.

Strategy | Benefits |

|---|---|

Cross-Docking | Reduced storage durations and quicker deliveries. |

Lean Inventory Practices | Maximizes value while minimizing waste, leading to lower holding costs. |

Just-In-Time (JIT) | Reduces holding costs by replenishing stock only when needed. |

By adopting these strategies, you can enhance warehouse efficiency and streamline operations. Lean tools ensure that your warehouse operates with precision and agility, meeting customer demands effectively.

Case Study: Transportation Route Optimization

Transportation route optimization is a key area where Lean tools deliver measurable benefits. By focusing on waste reduction and performance metrics, you can achieve faster shipments and higher customer satisfaction.

Benefit | Measurable Outcome |

|---|---|

Waste Reduction | |

Improved Customer Satisfaction | Faster shipments and deliveries leading to higher satisfaction |

Enhanced Performance Metrics | Focus on productivity costs leading to minimized wastage |

For example, Lean Logistics Planning integrates adaptive routing and predictive maintenance to optimize delivery paths. These methods reduce delays and ensure efficient fleet operations. By applying Lean tools, you create a transportation system that prioritizes speed, reliability, and customer value.

Sustaining Lean Practices in Logistics

Building a Lean Culture

Creating a Lean culture in logistics starts with leadership. You need to set clear expectations and lead by example. When leaders embrace Lean principles, employees are more likely to follow. Encourage open communication and empower your team to identify and solve problems. This approach fosters a sense of ownership and accountability.

A Lean culture thrives on continuous improvement. Daily Kaizen activities, for instance, allow your team to make small, incremental changes that add up over time. Replace static reports with dynamic tools like box score reporting. These tools provide real-time operational statistics, enabling faster decision-making and process improvements. Visualization tools, such as performance boards, also help link metrics to strategic goals. They engage employees in problem-solving and align their efforts with organizational objectives.

Tip: Recognize and reward employees who contribute to Lean initiatives. This motivates others to participate and strengthens the Lean mindset across your organization.

Training Teams on Lean Principles

Training equips your team with the skills needed to apply Lean tools effectively. Focus on practical, hands-on learning that connects theory to real-world logistics challenges. For example, teach employees how to use Value Stream Mapping to identify waste or implement 5S in their workspaces.

Training outcomes often include improved decision-making and higher productivity. The table below highlights some key benefits:

Evidence Description | Outcome/Benefit |

|---|---|

Real-time reporting tools replace static reports. | Enables rapid process improvements. |

Lean accounting exposes waste and quantifies it. | Drives higher quality and reliability. |

Visualization tools link metrics to goals. | Enhances decision-making and employee engagement. |

Aligning inventory with demand. | Optimizes costs and material flow. |

By investing in training, you build a knowledgeable workforce capable of sustaining Lean practices.

Monitoring KPIs for Continuous Improvement

Key performance indicators (KPIs) help you track progress and identify areas for improvement. Use metrics that align with your goals, such as safety, cost, quality, and customer satisfaction. For example, monitor the first-pass yield rate to measure product quality or track inventory turnover time to assess efficiency.

The table below outlines common KPIs in logistics:

Category | Examples of Indicators |

|---|---|

Safety | Frequency rate, Severity rate, Frequency index |

Cost | Logistics cost per unit, Labor cost per product |

Product Quality | First-pass yield rate, Rejection rate, Scrap rate |

Time Savings | Cycle time, Inventory turnover time, Machine downtime |

Customer Satisfaction | Net Promoter Score (NPS), Customer satisfaction rate |

Regularly reviewing these KPIs ensures that your Lean initiatives remain effective. Share the results with your team to maintain transparency and encourage collaboration. Continuous monitoring keeps your logistics operations aligned with Lean principles and customer expectations.

Lean tools offer significant benefits for logistics and transportation. They help you reduce waste, improve efficiency, and enhance customer satisfaction. For example, tools like Value Stream Mapping and Gemba Walks identify inefficiencies, while strategies such as Just-In-Time production and Kaizen drive continuous improvement. These methods create streamlined operations that deliver value to your customers.

Metric | Description |

|---|---|

Cost Reduction | Decrease in operational costs through optimized processes. |

Improved Delivery Performance | Enhanced speed and reliability of deliveries. |

Enhanced Customer Satisfaction | Increased customer approval and loyalty. |

Increased Flexibility | Ability to adapt quickly to changes in demand or supply. |

By adopting Lean tools, you can achieve faster deliveries, lower costs, and higher customer satisfaction. Start small by focusing on one area of improvement, such as inventory management or transportation routes. Over time, these incremental changes will transform your operations into a more efficient and customer-focused system.

FAQ

What are the key benefits of using Lean tools in logistics?

Lean tools help you reduce waste, improve efficiency, and enhance customer satisfaction. They streamline operations, lower costs, and increase delivery speed. By focusing on value-adding activities, you create a system that meets customer needs while optimizing resources.

How can I start implementing Lean tools in my logistics operations?

Begin with small steps. Use tools like Value Stream Mapping to identify waste. Apply 5S to organize your warehouse or fleet. Focus on one area, such as inventory management, and gradually expand Lean practices across your operations.

Is Lean suitable for small logistics businesses?

Yes, Lean works for businesses of all sizes. Small businesses benefit from reduced costs and improved efficiency. Start with simple tools like 5S or Just-In-Time. These methods require minimal investment and deliver measurable results.

How do I measure the success of Lean practices?

Track key performance indicators (KPIs) like delivery time, inventory turnover, and customer satisfaction. Use these metrics to evaluate improvements. Regularly review your data to ensure your Lean initiatives align with your goals.

Can Lean tools help with sustainability in logistics?

Absolutely! Lean reduces waste and optimizes resource use, which supports sustainability. For example, route optimization lowers fuel consumption, and better inventory management minimizes excess stock. These practices reduce your environmental impact while saving costs.

See Also

Mastering Lean Logistics For Success In Tech Manufacturing

Unlocking Logistics Savings: Expert Tips For Supply Chain Success

Harnessing Robotics In Logistics To Boost Warehouse Efficiency

Reducing Logistics Costs: Your Comprehensive Guide To Savings

Five Groundbreaking Techniques For Optimizing Your Supply Chain