What Are Automated Storage and Retrieval Systems and How Do They Benefit Indian Warehouses

Automated Storage and Retrieval Systems (ASRS) use advanced machines and software to store and pick goods inside warehouses. These systems help Indian warehouses by:

Saving space through high-density storage and modular designs

Lowering labor needs by allowing fast, automated access and real-time data checks

Improving safety by limiting manual handling

Automated Storage and Retrieval Systems in India address common challenges like labor shortages and the need for efficient, accurate operations.

Key Takeaways

Automated Storage and Retrieval Systems (ASRS) help Indian warehouses save space by using vertical storage and compact designs, reducing floor space needs by up to 85%.

ASRS cut labor costs by up to 70% by automating item picking and delivery, allowing fewer workers to handle more orders faster and more accurately.

These systems improve accuracy with error rates as low as 0.1% and speed up order processing, which is vital for fast-growing sectors like e-commerce.

Real-time inventory tracking and secure storage reduce stock errors, protect goods, and help warehouses plan better.

Though initial costs and integration challenges exist, ASRS offer strong long-term savings, safer work conditions, and flexible growth options for Indian warehouses.

What Is ASRS

Core Components

Automated Storage and Retrieval Systems use several important parts to move and store goods efficiently. These systems rely on both machines and software to keep everything organized. The main components include:

Storage structure: Strong racks and shelves hold goods in fixed locations. These racks can handle heavy loads and help save space.

Automation equipment: Machines like stacker cranes, shuttles, and robots move items in and out of storage. They travel along rails or aisles between racks.

Conveyance interface: Conveyors and other devices connect the storage system to loading and unloading areas. This setup helps move products quickly from one place to another.

Control system: Computers and warehouse management software control all movements. They track inventory, assign storage spots, and make sure everything runs smoothly.

Note: Each part works together to reduce errors and speed up warehouse operations.

How It Works

The process starts when goods arrive at the warehouse. Workers or machines scan items and enter them into the system. The software then decides the best storage location based on how often the item is used and its size. Stacker cranes or shuttles pick up the goods and place them in the right spot on the racks.

When someone needs an item, the system receives a request. The control software sends instructions to the machines. The machines travel along their paths, retrieve the item, and bring it to a pick-up station. Conveyors or robots may then move the item to shipping or production areas.

Step | Description |

|---|---|

1 | Goods are scanned and entered into the system |

2 | Software assigns storage locations |

3 | Machines store goods in racks |

4 | Retrieval requests are made |

5 | Machines pick and deliver items to pick-up points |

Automated Storage and Retrieval Systems in India often use these steps to handle large numbers of orders quickly. The system tracks inventory in real time and generates reports on performance, such as travel time and order speed. This approach helps warehouses reduce waiting times and improve accuracy.

Automated Storage and Retrieval Systems in India

Local Warehouse Challenges

Warehouses in India face several unique challenges. Many facilities operate in crowded urban areas where space is limited. High land costs make it difficult to expand storage capacity. Manual processes often lead to errors and slow order fulfillment. Labor shortages and rising wages add to operational difficulties. Seasonal demand spikes, especially during festivals or sales, put extra pressure on warehouse staff. These issues can cause delays, lost inventory, and higher costs.

Automated Storage and Retrieval Systems in India help address these problems. They use vertical storage to maximize available space. Automation reduces the need for manual labor and lowers the risk of mistakes. Real-time tracking improves inventory accuracy. Many warehouses now rely on these systems to handle complex logistics and diverse product ranges, especially in sectors like automotive and e-commerce.

Note: Automation also supports safer working conditions by reducing heavy lifting and repetitive tasks.

Adoption Trends

The adoption of Automated Storage and Retrieval Systems in India is growing rapidly. The warehousing and distribution sector accounts for over 35% of global ASRS market revenue, showing strong market penetration. In India, industries such as auto and ancillary, retail, and e-commerce lead the way in using these systems to improve efficiency and accuracy.

The Asia-Pacific region, including India, is expected to see the fastest growth in ASRS adoption from 2025 to 2030. The following table highlights key trends:

Aspect | Details |

|---|---|

Projected CAGR for ASRS in India (2025-2030) | Highest in Asia Pacific |

Market Penetration in Warehouses | 15-20% (large untapped potential) |

Key Growth Drivers | E-commerce boom, labor cost reduction, automation demand |

Challenges |

Many companies invest in Automated Storage and Retrieval Systems in India to keep up with rapid retail and e-commerce expansion. The COVID-19 pandemic also accelerated adoption, as businesses needed to minimize human contact and maintain supply chain resilience. Integration of AI and IoT technologies further boosts system flexibility and efficiency.

Key Benefits

Space Optimization

Warehouses in India often face space shortages, especially in cities where land costs are high. Automated Storage and Retrieval Systems in India help solve this problem by using vertical storage and compact shelving. These systems can reduce floor space usage by up to 85%. High-density racks and dynamic storage locations allow more products to fit in the same area. Research shows that ASRS technology lowers total warehouse costs and improves space utilization. By condensing inventory into smaller modules, companies avoid expensive building expansions and make better use of their existing facilities.

Tip: Vertical storage not only saves space but also makes it easier to organize and access goods.

Labor and Cost Savings

Manual warehouse work often involves long hours of walking and searching for items. Workers in traditional warehouses spend up to 65% of their time just moving around. Automated Storage and Retrieval Systems in India deliver goods directly to operators, reducing walking and search time. This leads to significant labor savings. One operator can do the work of several manual pickers, allowing companies to reassign up to two-thirds of their staff to other tasks. Labor cost reductions can reach up to 70%. Automation also helps companies manage rising wages and labor shortages, which are common challenges in India.

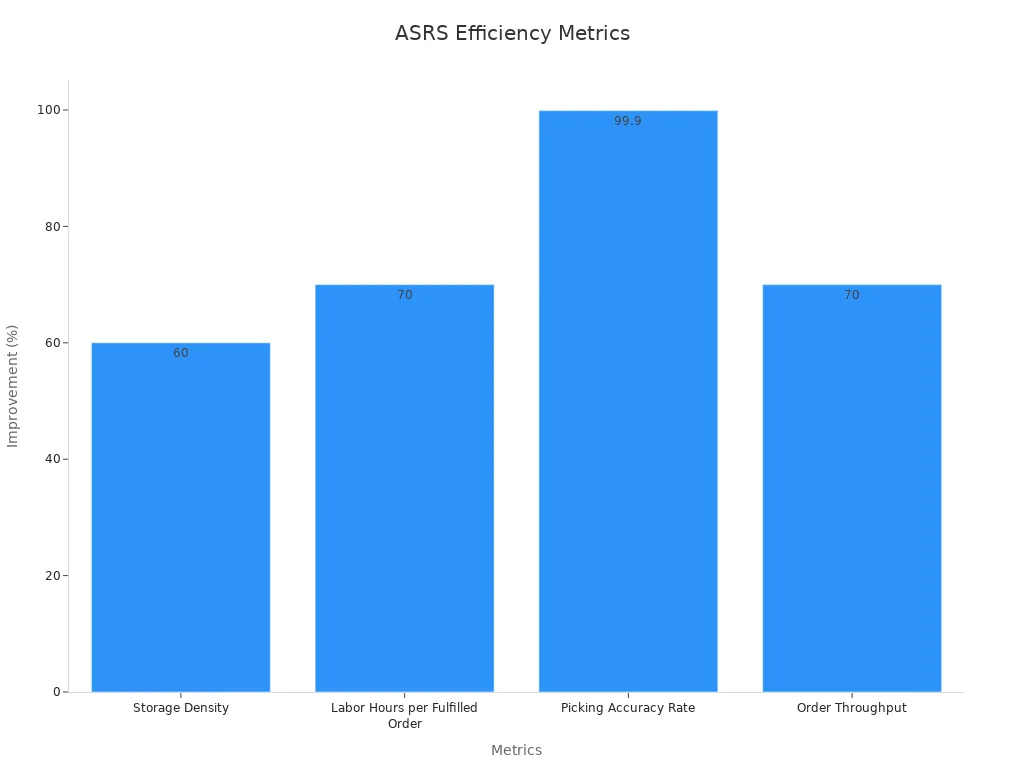

Metric | Reported Improvement/Benefit |

|---|---|

Storage Density | Up to 60% increase in storage capacity |

Labor Hours per Order | |

Picking Accuracy Rate | Exceeds 99.9% |

Order Throughput | Up to 70% faster picking speed |

Accuracy and Speed

ASRS technology brings a new level of accuracy to warehouse operations. Studies show that error rates drop to as low as 0.1%, with picking accuracy exceeding 99.9%. Advanced systems use light-directed picking and goods-to-operator processes, which reduce mistakes and speed up order fulfillment. Throughput can double or even quadruple compared to manual systems. Some shuttle ASRS solutions improve picking speed by up to 10 times. This high accuracy and speed are especially important for e-commerce and retail companies in India, where fast and error-free delivery is critical.

Inventory Control

Automated Storage and Retrieval Systems in India provide real-time visibility into stock levels and locations. The system tracks every item as it moves in and out of storage. This reduces the risk of overstocking or running out of products. Integration with warehouse management software helps guide staff through optimized picking routes, lowering the chance of mistakes. Error rates can drop to as low as 0.1%, which means fewer stock discrepancies and costly returns. Secure, enclosed storage also protects goods from damage and theft, further improving inventory accuracy.

Real-time inventory data helps with better planning.

Secure storage lowers shrinkage and protects items.

Safety and Ergonomics

Warehouse work can be physically demanding and sometimes dangerous. ASRS systems improve safety by reducing the need for workers to bend, reach, climb, or lift heavy items. Automation handles the most strenuous tasks, lowering the risk of injuries. Improved ergonomics mean workers face less physical strain, which leads to better health and fewer days lost to injury. Companies also see lower costs related to workers’ compensation and lost productivity.

Note: Automation creates a safer and more comfortable workplace for everyone.

Scalability and Flexibility

Automated Storage and Retrieval Systems in India offer strong scalability and flexibility. Modular racking can be installed quickly, sometimes in just six weeks. Companies can add more robots or storage units during busy seasons, such as festivals or sales. High storage density supports growth without major changes to the warehouse. These systems adapt to different product types and order sizes, making them ideal for fast-growing sectors like e-commerce. Built-in redundancy ensures 24/7 operation, and predictive maintenance keeps downtime low.

Modular design allows for quick expansion.

Flexible robot deployment supports peak demand.

Systems adapt to changing product mixes and order volumes.

Implementation in India

Investment and ROI

Companies in India often see high upfront costs when installing Automated Storage and Retrieval Systems in India. The initial investment for a goods-to-person picking system can reach $3,000,000. However, annual savings from labor reduction and better space use can total $1,300,000. Most businesses recover their investment within three years, which is shorter than the equipment’s lifespan. The internal rate of return stands at 14.36%, much higher than the typical hurdle rate of 8%. These numbers show that, despite the large initial cost, the long-term financial benefits are strong. Companies also save money by delaying or avoiding expensive warehouse expansions and by reducing costs for hiring, training, and insurance.

Metric | Value | Explanation |

|---|---|---|

Capital Investment | $3,000,000 | Initial cost for goods-to-person picking system |

Annual Savings | $1,300,000 | Savings from labor reduction and space utilization |

Payback Period | Within 3 years | Time to recover investment, shorter than equipment life |

Net Present Value | +$350,000 | Positive NPV over 3 years at 8% hurdle rate, indicating returns above cost of capital |

Internal Rate of Return (IRR) | 14.36% | IRR exceeds 8% hurdle rate, confirming financial viability |

Integration and Training

Successful adoption of ASRS depends on careful integration and staff training. Companies often use a phased approach to roll out new systems. This method helps reduce disruptions and allows teams to adjust. Staff receive detailed training on how to operate and troubleshoot the system. Safety protocols and emergency procedures protect both workers and equipment. Performance monitoring tracks system uptime, error rates, and throughput. Ongoing support and maintenance keep the system reliable.

Training & Integration Steps | Description |

|---|---|

Staff Training | Comprehensive education on ASRS operation and troubleshooting to ensure user competence |

Safety Protocols | Implementation of strict safety measures and emergency procedures to protect staff and equipment |

Phased Implementation | Gradual rollout of ASRS to minimize operational disruption and allow adjustment |

Performance Monitoring | Continuous tracking of system metrics such as uptime, error rates, and throughput to evaluate effectiveness |

Ongoing Support | Provision of maintenance and technical assistance to sustain system reliability |

Tip: E-commerce and food warehouses in India have seen retrieval times cut in half and labor costs drop by 40% after proper training and integration.

Common Challenges

Companies face several challenges when bringing ASRS into their warehouses. Integration can be complex, involving software, hardware, and mechanical parts. High initial costs for machines and infrastructure changes can be a barrier. Staff used to manual systems may need extra training. Some systems may not adapt easily to sudden changes in demand. Ongoing maintenance requires skilled technicians. Coordination with vendors is important for smooth setup. Testing and trial runs help find problems before full launch. Companies must also monitor and adjust the system after installation to keep it running well.

Integration complexity with software, hardware, and mechanical parts

High upfront investment and infrastructure changes

Need for extensive staff training and adoption

Limited flexibility for sudden demand changes

Ongoing maintenance and need for skilled technicians

Importance of vendor coordination and robust deployment schedules

Continuous monitoring and adjustment post-implementation

Note: Despite these challenges, many Indian warehouses report strong improvements in accuracy, safety, and cost savings after adopting Automated Storage and Retrieval Systems in India.

Automated Storage and Retrieval Systems in India deliver strong results for warehouse efficiency, accuracy, and cost savings. Many warehouses now benefit from up to 65% space savings, lower labor costs, and improved real-time inventory control. Companies see faster order processing and 24/7 operations, which help them handle more goods without expanding their facilities.

Narrower aisles and vertical storage increase capacity.

Automation reduces manual labor and overtime expenses.

Modular systems allow gradual upgrades and easier investment.

Warehouse managers can consult ASRS providers or review case studies to plan their next steps. Investing in automation supports long-term growth and helps Indian warehouses stay competitive.

FAQ

What types of products can ASRS handle in Indian warehouses?

ASRS can store many product types, including boxes, pallets, small parts, and even fragile items. The system adjusts to different sizes and weights. Many industries, such as retail, automotive, and food, use ASRS for safe and efficient storage.

How long does it take to install an ASRS in India?

Most ASRS installations finish within 6 to 12 weeks. The timeline depends on warehouse size and system complexity. Companies often use a phased approach to reduce disruptions and keep operations running during setup.

Is ASRS suitable for small and medium warehouses?

Yes, ASRS works well for small and medium warehouses. Modular designs allow companies to start small and expand later. Many Indian businesses use compact ASRS solutions to save space and improve efficiency without large investments.

Does ASRS require special training for warehouse staff?

Staff need training to operate and maintain ASRS. Training covers system use, safety, and troubleshooting. Most companies provide hands-on sessions and support materials. Well-trained staff help keep the system running smoothly and safely.

Can ASRS help during peak seasons or festivals?

ASRS supports fast order processing during busy times. The system handles high volumes and adapts to sudden demand spikes. Many Indian warehouses use ASRS to manage festival sales and seasonal surges with fewer errors and delays.

See Also

Discovering Hidden Opportunities Of Artificial Intelligence In Logistics

Exploring JUSDA’s Advanced Logistics Solutions For Manufacturing

Revealing How AI Transforms Efficiency In Supply Chains

Improving Supply Chain Performance Through Cloud-Based Technologies