Automated Storage and Retrieval Systems (AS/RS)

Automated Storage and Retrieval Systems (AS/RS) use advanced technology to move goods in and out of storage with precision. These systems help companies store more products in less space and handle items quickly. Many industries, such as electronics and automotive, rely on automated storage to boost efficiency and reduce mistakes. The table below shows typical capacities and purposes for common AS/RS types:

AS/RS Type | Load Capacity | Storage Height | Throughput / Cycle Handling | Core Purpose Highlights |

|---|---|---|---|---|

Unit-Load AS/RS | Up to 1,800 kg | Up to 45 m | Up to 60 loads per hour | Maximize storage density, increase throughput, improve accuracy |

Miniload AS/RS | Up to 160 kg | Up to 20 m | Up to 6 loads per cycle | High-density storage for small items, rapid access |

AS/RS plays a key role for businesses that want to keep operations smooth and costs low. JUSDA brings automated storage solutions to companies that need reliable and smart supply chain management.

Key Takeaways

Automated Storage and Retrieval Systems (AS/RS) help companies store more products in less space while speeding up order processing and reducing errors.

Different AS/RS types, like Unit-Load and Mini-Load systems, fit various needs by handling large pallets or small items efficiently and safely.

AS/RS improves warehouse operations by using robots and smart software to track inventory in real time and bring items directly to workers.

Businesses save money with AS/RS through lower labor costs, better space use, fewer mistakes, and faster order delivery.

Signs that a company needs AS/RS include slow order fulfillment, high labor costs, limited storage space, and frequent picking errors.

Automated Storage Basics

AS/RS Core Functions

Automated Storage and Retrieval Systems (AS/RS) perform several important tasks in modern warehouses. These systems use robotics and smart software to move goods in and out of storage locations. Stacker cranes and automated guided vehicles (AGVs) handle items with speed and accuracy. Warehouse Management Software (WMS) tracks inventory and helps workers find products quickly. Many systems now use AI, machine learning, and IoT to predict maintenance needs and optimize storage space. This technology improves order processing speed and storage density.

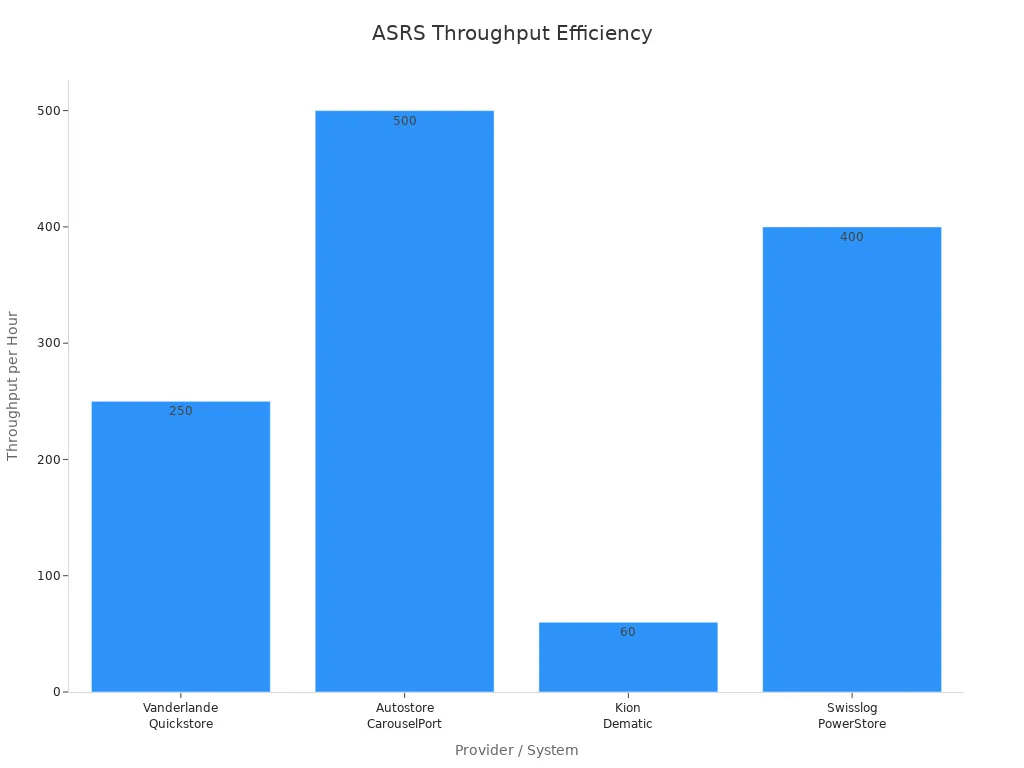

AS/RS systems have shown strong performance in real-world operations. For example, the Honeywell Intelligrated AS/RS can store over 20,000 SKUs and increase throughput by 30-40% compared to traditional methods. The Swisslog PowerStore can handle up to 400 pallets per cell per hour, even in extreme temperatures.

Provider / System | Throughput / Capacity | Additional Details |

|---|---|---|

Vanderlande Quickstore Miniload | 250 dual cycles per hour per crane | - |

Autostore CarouselPort | Up to 500 bins per hour | Min. exchange time: 2.5 seconds |

Kion Group Dematic Unit Load AS/RS | 60 loads per hour | Loads up to 1,800 kg, rack height over 42 meters |

Honeywell Intelligrated AS/RS | Stores 20,000+ SKUs; 30-40% throughput increase | Compared to traditional picking methods |

Swisslog PowerStore | Up to 400 pallets per cell per hour | Operates in -30°C to 50°C environments |

The global market for AS/RS reached $6.55 billion in 2023 and is expected to grow to $11.48 billion by 2030. This growth shows how important automated storage has become for many industries.

How Automated Storage Works

Automated Storage uses a mix of machines and software to manage goods. The process starts when goods arrive at the warehouse. Robots or shuttles move items to storage locations. Sensors and cameras track each item in real time. The system updates inventory records right away.

Robotic horizontal carousel systems use several levels and inserter/extractor arms to move goods.

Shuttle-based systems send shuttles directly to storage spots to pick up totes or cartons.

AI-driven robots watch inventory and help restock items before they run out.

IoT technology allows for real-time tracking and better inventory management.

Automated Storage also helps with picking and packing. Goods-to-person systems bring items to workers, making picking faster and more accurate. Automated sorters and barcode scanners help sort and distribute products. These systems reduce errors and speed up order fulfillment.

Key benefits include real-time inventory visibility, fewer picking errors, faster order delivery, and lower labor costs. Employees can focus on quality control and process improvements instead of repetitive tasks.

Types of AS/RS

Unit-Load Systems

Unit-Load Systems handle large and heavy items, such as pallets or containers. These systems use stacker cranes or shuttle vehicles to move goods between storage racks and picking stations. Companies choose Unit-Load Systems to maximize storage density and improve throughput.

Engineers measure efficiency by looking at the expected cycle time for each load movement.

Analytical models help calculate these times by considering how shuttles travel both horizontally and vertically.

Simulation models confirm these calculations, making them reliable for planning.

Throughput performance, based on these cycle times, shows how quickly the system can move goods.

Unit-Load Systems work well in warehouses that need to store many large items and want to reduce manual labor.

Mini-Load Systems

Mini-Load Systems store and retrieve smaller items, such as totes or cartons. These systems use smaller cranes or shuttles to move goods quickly and accurately.

Mini-Load ASRS increases storage capacity without expanding the warehouse.

High-density vertical storage makes the most of available space.

Automation speeds up picking and reduces mistakes.

The system operates quietly and smoothly, causing fewer disruptions.

Real-time inventory visibility gives workers instant and accurate data.

Secure storage protects items from damage or loss.

Modular design allows for easy installation and maintenance.

Mini-Load Systems help companies improve productivity and lower energy costs. Automated Storage with Mini-Load Systems supports fast order fulfillment and better inventory control.

Carousel and Shuttle Systems

Carousel and Shuttle Systems use rotating shelves or moving shuttles to bring items to workers. Vertical carousels move trays up and down, while horizontal carousels rotate shelves around a track. Shuttle systems send small vehicles to pick up and deliver goods.

These systems save space and reduce walking time for workers.

Automation increases picking speed and accuracy.

Carousels and shuttles work well for small parts and high-turnover items.

Many businesses use these systems to boost efficiency in order picking and inventory management.

Robotic Cube Storage

Robotic Cube Storage uses robots to move bins stacked in a grid or cube. Robots travel on top of the storage grid, picking up and delivering bins as needed.

This system allows for very high storage density.

Robots work together to handle many orders at once.

The design supports flexible expansion as business needs grow.

Robotic Cube Storage fits companies that need fast, scalable, and space-saving Automated Storage solutions.

Benefits of Automated Storage

Efficiency and Accuracy

Automated Storage systems help companies work faster and make fewer mistakes. Robots and smart software move goods quickly and place them in the right spots. Workers do not need to search for items or count inventory by hand. This technology helps companies process more orders in less time.

Kookaburra used automated sorting and reduced labor needs by 65%.

Bleckmann doubled its operational efficiency and made fewer sorting errors with automated sorting and RFID scanning.

Automated dispensing systems increased inventory accuracy and saved time on billing.

Automated pack-out systems can process up to 1,800 units and extract 200 orders per hour, which improves order accuracy and reduces waste.

JUSDA uses advanced warehouse management systems like eVMI and Juslink. These systems track inventory in real time and help workers find products quickly. JUSDA’s technology gives companies clear and accurate data, which helps them make better decisions. Many industries, such as electronics and automotive, rely on JUSDA’s solutions to keep their supply chains running smoothly.

Companies that use Automated Storage see fewer picking errors, faster order delivery, and better inventory control. Employees can focus on quality checks and solving problems instead of doing the same tasks over and over.

Space Optimization

Automated Storage systems help companies use their warehouse space better. These systems stack goods higher and closer together than people can. Robots and shuttles move items in tight spaces without bumping into each other. This means companies can store more products in the same area.

Automated Storage and Retrieval Systems (AS/RS) increase storage density nearly threefold.

Energy use drops by about 50% because the systems work more efficiently.

JUSDA’s warehouses use vertical storage and smart layouts to fit more goods. This helps companies avoid building new warehouses or renting extra space. JUSDA’s solutions work well for fast-moving consumer goods (FMCG), electronics, and automotive parts, where space and speed matter most.

JUSDA Solutions

To provide you with professional solutions and quotations.

Cost Savings

Automated Storage helps companies save money in many ways. They spend less on labor because machines do most of the work. They also save on energy and space costs. Fewer mistakes mean less waste and fewer returns.

Cost Category | Details / Range |

|---|---|

Unit Load AS/RS: $500,000 to $2 million+ | |

Operational & Maintenance | Energy: Hundreds to several thousand dollars/month |

Potential Cost Savings | Space Optimization: Increased storage density, reduced need for expansion |

ROI Considerations | Analyze labor savings, throughput increases, error reduction, inventory accuracy improvements |

Financing & Budgeting | Capital loans, leasing, equipment financing options |

JUSDA’s real-time inventory management and automated systems help companies lower their costs. For example, Sharp worked with JUSDA and saw a 20% drop in logistics costs and a 70% reduction in labor costs. These savings help companies invest in growth and new technology.

Many businesses in electronics, automotive, and FMCG choose JUSDA’s Automated Storage solutions to cut costs and stay competitive.

Is AS/RS Right for Your Business?

Operational Signs

Many companies wonder if they need an Automated Storage and Retrieval System. Certain signs show when a business should consider this technology.

Workers spend too much time walking or searching for items in the warehouse.

The company struggles with frequent picking errors or lost inventory.

Storage space feels tight, and products pile up in aisles or on the floor.

Order volumes keep rising, but the team cannot keep up with demand.

Labor costs keep increasing, and it is hard to find or train new staff.

The business needs faster order fulfillment to meet customer expectations.

If a company faces several of these issues, it may benefit from automation. AS/RS can help solve these problems by making storage and retrieval faster, more accurate, and less dependent on manual labor.

Tip: Companies in fast-moving industries like electronics, automotive, and consumer goods often see the biggest gains from AS/RS.

Decision Factors

Before investing in AS/RS, leaders should look at both operational needs and financial numbers. Several measurable factors help guide the decision:

Net Present Value (NPV): Shows the present value of future cash flows. A positive NPV means the project could be profitable.

Internal Rate of Return (IRR): Tells the rate at which the investment breaks even. A higher IRR than the company’s target rate signals a good choice.

Capital Expenses: Includes equipment, installation, freight, taxes, and ongoing maintenance or software fees.

Cash Flows: Considers savings from labor, space, and increased revenue after automation.

Cost of Capital: Reflects the minimum return needed to justify the investment.

Labor Savings: Compares current labor costs, including wages and benefits, to expected costs after automation.

Space Savings: Measures how much less warehouse space the company will need.

These factors help companies decide if AS/RS fits their goals and budget. A careful review ensures the system supports both growth and efficiency.

Implementing AS/RS with JUSDA

Planning and Integration

JUSDA helps companies plan and integrate AS/RS by focusing on key metrics and careful preparation. Teams start by assessing system complexity, operational volume, and warehouse size. They look at customization needs and integration costs to match the right solution to each business. JUSDA’s experts use ROI analysis and budgeting strategies to guide investment decisions. The table below shows important planning metrics:

Planning Metric | Impact on AS/RS Implementation |

|---|---|

System Complexity | Affects cost and integration feasibility |

Customization | Influences design and integration strategies |

Operational Volume | Determines system scale and throughput |

Warehouse Size | Dictates layout and installation planning |

Integration Costs | Critical for budgeting and technical planning |

Scalability | Ensures flexibility for future growth |

ROI Analysis | Guides investment justification |

Maintenance Planning | Keeps systems reliable and efficient |

Workforce Adaptation | Supports smooth transition and effective use |

JUSDA’s global warehouse network and JusLink digital platform support seamless integration. These tools provide real-time inventory tracking and help companies adapt quickly.

Technology and Scalability

JUSDA uses advanced technology, including AI, robotics, and IoT, to make AS/RS scalable and efficient. Their solutions allow companies to start small and expand as business grows. JUSDA’s systems handle high operational volumes and adapt to new product lines. The JusLink platform connects all warehouse locations, giving managers full visibility and control.

Tip: Planning for scalability ensures that the AS/RS can grow with the business, avoiding costly upgrades later.

Overcoming Challenges

Companies often face challenges like labor shortages, integration complexity, and operational disruptions during AS/RS implementation. JUSDA addresses these with phased rollouts and continuous optimization. For example, automation can reduce manual labor by up to 45%. Phased implementation limits disruptions and spreads costs over time. JUSDA trains staff to adapt to new systems, ensuring a smooth transition.

Challenge | Result with JUSDA’s Approach |

|---|---|

Labor shortages | |

Integration complexity | Phased rollout reduces risk and cost |

Operational disruptions | Controlled piloting minimizes disruptions |

Accuracy and throughput | Up to 50% operational increase, 99.9% accuracy |

Case Study: SHARP and JUSDA

Sharp partnered with JUSDA to transform its supply chain. After implementing AS/RS and JusLink, Sharp reduced logistics costs by 20% and labor costs by 70%. Order delivery times improved by 30%. JUSDA’s integrated approach helped Sharp achieve real-time inventory visibility and faster order processing. This case shows how JUSDA’s solutions deliver strong ROI and operational improvements.

Future Trends

AI and Automation

AI and automation continue to change how warehouses operate. Many companies now use smart sensors and AI-driven software to monitor equipment and predict when repairs are needed. For example, platforms like IBM’s Watson IoT and Microsoft’s Azure IoT suite use sensors in robotic arms to watch for problems. These sensors send alerts if something goes wrong, which helps fix issues before they cause delays. This makes warehouse systems more reliable and efficient.

More warehouses plan to invest in AI. About 42% of them want to add more AI technology soon. Companies like Mahindra and Mahindra have already seen results. They improved their forecast accuracy by 10%, raised service levels by 10%, and cut inventory costs by 20% using AI and predictive analytics. The market for AI-powered warehouse systems is growing fast. Experts expect the market to reach about $12 billion by 2032, with North America leading in adoption. Robotics now make up over 60% of new warehouse installations worldwide.

Trend Area | Details and Impact |

|---|---|

AI-driven ASRS Installations | 15% in 2020, rising to 45% by 2030 in North America |

Robotics in Warehouses | Over 60% of new installations by 2025 |

Efficiency Gains | Up to 35% more throughput, 30% lower labor costs |

Industry Sectors | E-commerce, manufacturing, logistics, healthcare |

AI and automation help warehouses move goods faster, reduce mistakes, and save money.

Digital Supply Chains

Digital supply chains use technology to connect every part of the warehouse and shipping process. Companies like Amazon and DHL use thousands of robots and automated vehicles to move products. These digital tools help track inventory in real time and make sure orders go out quickly.

Automation also cuts labor costs by up to 50% in busy warehouses. Sorting systems now reach 99.9% accuracy, which means fewer errors and happier customers. Many companies invest between $500,000 and $5 million in automation hardware and software, but they often see a quick return because of the gains in speed and accuracy.

Digital supply chains give managers better control and help companies respond quickly to changes in demand.

Automated Storage and Retrieval Systems help companies lower costs, improve order accuracy, and speed up delivery. The table below shows how automation boosts supply chain performance:

Metric Category | Key Performance Indicators (KPIs) |

|---|---|

Cost Metrics | Total supply chain costs, cost per unit, inventory turnover rates |

Quality Indicators | Order accuracy rates, supplier performance, perfect order fulfillment |

Time and Speed | Order cycle time, lead time, on-time delivery, warehouse utilization rates |

JUSDA’s solutions give businesses the tools to grow and adapt. Companies can review their operations and see how digital supply chains will shape the future.

FAQ

What is an Automated Storage and Retrieval System (AS/RS)?

An AS/RS uses machines and software to move and store goods in a warehouse. These systems help companies save space, reduce mistakes, and work faster.

How does AS/RS improve warehouse safety?

AS/RS reduces the need for people to lift heavy items or climb ladders. Machines handle most tasks, which lowers the risk of accidents and injuries.

Can small businesses use AS/RS?

Yes, small businesses can use AS/RS. Many systems come in different sizes. Companies can start with a small setup and expand as they grow.

What industries benefit most from AS/RS?

Industries like electronics, automotive, and fast-moving consumer goods (FMCG) see big gains from AS/RS. These systems help manage large inventories and speed up order delivery.