How Automation Improves Efficiency and Reduces Logistics Spend

Automation changes logistics by helping companies work better and spend less money. Many businesses save a lot of money by using technology like AI and automation.

U.S. business logistics cost $2.3 trillion, so smart spending is important.

Automation in the supply chain helps things run smoother and makes fewer mistakes.

Key Takeaways

Automation in warehousing, transportation, and document handling helps companies save money. It does this by lowering labor costs, making fewer mistakes, and making things faster.

Using real-time data and smart technology helps businesses plan better routes. They can track shipments and manage inventory. This lowers freight costs and makes things work better.

Having clear goals, pilot projects, and employee training helps automation go smoothly. It also helps companies save money for a long time and have better control over logistics.

Reduce Logistics Costs with Automation

Automation helps companies save money in logistics. It makes warehousing, transportation, and document work faster and easier. Businesses use technology to keep logistics costs low and run things better. JUSDA’s global network and smart solutions show how automation cuts freight costs and helps manage spending.

Warehouse Automation

Warehouse automation changes how companies handle inventory and fill orders. Automated warehouses use robotic arms, AMRs, and AI systems. These tools make picking, packing, and sorting faster. They help lower labor needs and reduce mistakes, which saves money.

59% of warehouses have trouble hiring hourly workers. This makes labor more expensive and pushes companies to use automation.

Warehouses with lots of automation have 25% fewer injuries. This means they spend less on accident costs.

Hybrid automation uses both robots and people. It makes work safer and more productive. Companies often get their money back in about 18 months.

Automation tools like AS/RS and pick-to-light systems help use space better and move inventory faster.

JUSDA’s warehouse solutions use systems like eVMI and JusLink. These tools track inventory in real time. They help companies save money by giving better control and clear information. JUSDA runs over 2.5 million square meters of warehouse space. They help industries like electronics, cars, and FMCG. Their automated warehouses help clients cut costs, make fewer mistakes, and lower freight costs.

Almost 90% of warehouse operators say new technology is needed to compete. Automation helps them spend less and work better.

Transportation Optimization

Transportation optimization uses technology to cut transport costs and deliver faster. Companies use IoT GPS tracking to watch trucks in real time. This helps them pick better routes and avoid problems, which saves money.

Real-time tracking and data help companies plan routes and use less fuel. For example, Emerson used a transport system to get real-time data and pick better carriers. This made deliveries faster and cheaper, even during disasters. Best Home Furnishings used AI to plan routes and check shipping costs. They saved up to 12% on transport by making better deals.

JUSDA’s transport system works with JusLink for real-time tracking and route planning. This helps clients save money, control spending, and run logistics better. JUSDA’s network supports air, land, sea, and rail. This makes sure logistics costs stay low and freight costs go down.

Transportation optimization not only saves money but also helps the environment by cutting emissions and using fewer resources.

Document and Data Automation

Document and data automation makes logistics work smoother by cutting manual tasks and mistakes. Tools like OCR and machine learning pull out, sort, and check data automatically. This can cut document handling time by up to 75% and helps lower freight costs.

Companies finish invoices and transactions faster, sometimes just 10 minutes after delivery.

Automation cuts down on typing mistakes and lowers costs.

Automated workflows help follow rules and give real-time updates on logistics.

Sharp, a top tech company, improved logistics by using document automation. They linked order filling and label printing to many carriers. This cut mistakes, sped up work, and lowered costs. JUSDA’s solutions helped Sharp cut logistics costs by 20%, labor costs by 70%, and made deliveries 30% faster.

JUSDA’s supply chain platform automates document work, billing, and customs. This helps clients spend less, make fewer mistakes, and grow their business easily.

Document and data automation saves money by cutting admin work and making data more accurate.

Automation in warehousing, transportation, and document work helps companies save money and control spending. JUSDA’s smart solutions and global network give the tools and know-how for good logistics cost management and lower freight costs across the supply chain.

Improve Efficiency and Reduce Spend

JUSDA Solutions

JUSDA’s smart supply chain solutions use new technology to help companies work better and spend less on logistics. JusLink is a cloud platform that links partners in the supply chain. It lets everyone see what is happening from start to finish. Real-time updates make talking to others cheaper and help companies act fast when things change. Big data helps spot problems before they get worse. This lets companies make good choices early. JUSDA’s one-stop solutions mix main and extra services. They give each client special help. These tools let businesses control their supply chain all over the world. This makes work smoother and saves money.

JUSDA’s AI and automation tools help companies run warehouses, move goods, and manage inventory better. Automated forklifts use sensors and AI to stop accidents and keep workers safe. These forklifts also pick the best routes, waste less time, and use less energy. This helps the planet. AI analytics help fix machines before they break and plan better storage. This can cut labor costs by up to 70% and make inventory almost perfect. JUSDA’s tech lets companies work all day and night. They can meet demand without spending more. These solutions help companies spend less on logistics and save money.

JUSDA’s digital supply chain platform gives clients real-time updates, smart predictions, and easy teamwork. This leads to better efficiency and lower freight costs.

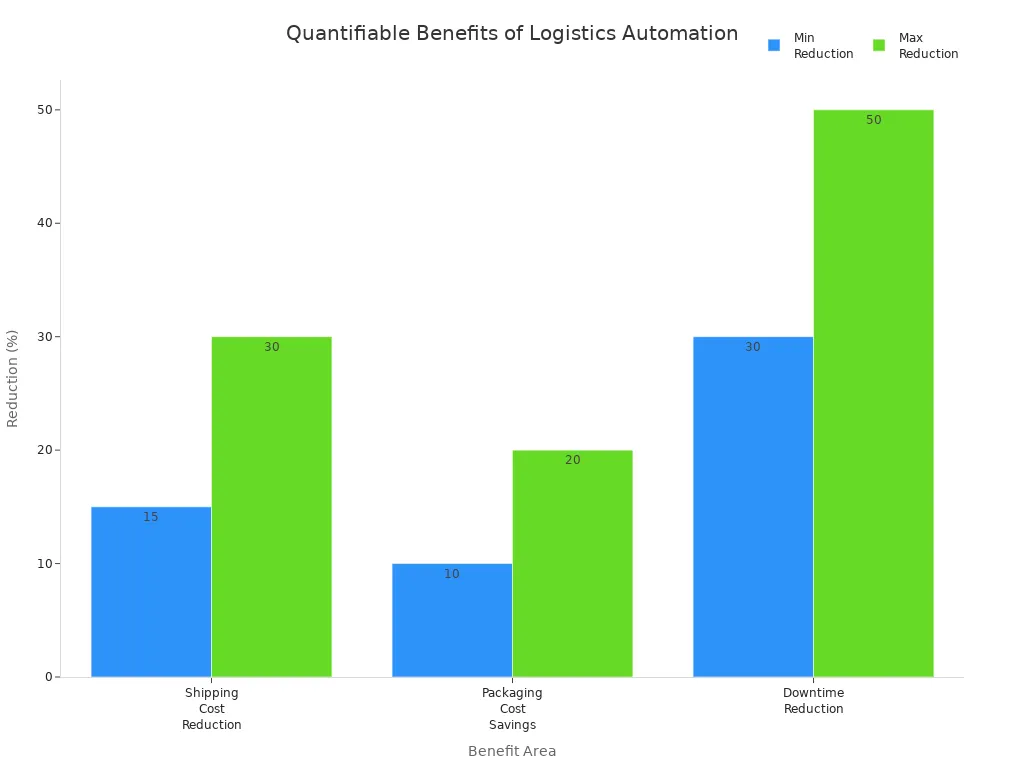

Quantifiable Benefits

Companies using automation in logistics see clear results they can measure. The table below shows some of the biggest benefits:

Benefit Area | Quantifiable Impact | Description |

|---|---|---|

Shipping Cost Reduction | 15-30% reduction | AI-driven container loading optimizes space and reduces trips. |

Packaging Cost Savings | 10-20% reduction | AI-powered dimensioning cuts material waste. |

Downtime Reduction | 30-50% reduction | Predictive maintenance prevents unplanned downtime. |

Labor Cost Reduction | 20-30% | Automation in planning and monitoring lowers labor expenses. |

Improved Resource Utilization | Not precisely quantified | AI monitoring enhances asset use and yard management. |

Enhanced Customer Satisfaction | Qualitative improvement | Faster, more reliable logistics operations. |

Operational Efficiency Increase | Not precisely quantified | Automation boosts throughput and reduces idle times. |

Groups using advanced AI and automation tools have seen up to 30% lower costs and 50% faster work. Efficiency often gets over 40% better. Many companies get back three times what they spend in six months. They expect to grow by 73% in three years. Route planning cuts travel time and fuel use. AI quality checks lower waste and delays. These ways to cut costs help companies work better and manage logistics spending.

Industry numbers show automated inventory can be 99.99% correct. This means fewer manual checks and less trouble. Transportation systems can cut freight costs by up to 8%. Route planning software can save about 15% on fuel. Amazon and Walmart both saved a lot on freight by using machine learning and working with suppliers.

Automation also makes customers happier. AI in logistics cuts supply chain mistakes by 20-50%. It speeds up deliveries and gives real-time tracking. These changes mean more accurate delivery times and better service. This helps customers trust the company.

Implementation Steps

Businesses can use a simple checklist to start automation and save money on logistics:

Define Clear Objectives

Find out what is hard in logistics and set clear goals for automation.Build a Centralized Data Foundation

Bring together sales, inventory, and transport data for AI and automation.Select the Right Technology

Pick AI tools and automation systems that fit the business and supply chain.Start with Pilot Projects

Try small projects first to test automation and get support.Focus on Multiple Use Cases

Use automation in many areas like warehouses, route planning, and document work to get the most benefits.Establish Feedback Loops

Always collect feedback and improve automation for better results.Maintain Human Oversight

Keep people involved in important jobs to make sure things are safe and work well.Train Employees and Manage Change

Teach workers and explain the benefits to help them trust new technology.Monitor and Optimize

Watch key numbers like cost per shipment, mistakes, and process times. Use data to find new ways to save and work better.

Tip: Watch out for problems like not knowing the real costs, not having enough tech skills, or not matching automation to business goals. Start with small projects, get leaders to help, and keep training to do well.

By following these steps, companies can spend less on logistics, work better, and find new ways to save money. Automation helps manage logistics costs, lowers supply chain spending, and keeps freight costs down.

JUSDA Solutions

To provide you with professional solutions and quotations.

Automation helps companies work faster and spend less. JUSDA’s solutions show real savings and better results. Managers can take these steps to find new ways to improve:

Use real-time dashboards to spot problems early.

Train teams on new tools and ask for feedback.

Start with modular automation that fits current needs.

Add smart inventory software for better data.

Work with trusted partners for smooth changes.

Companies that review their operations and use new technology can see big gains in efficiency and cost savings.

See Also

How Robotics Technology Transforms Warehouse Productivity Levels

Understanding Robotic Automation To Improve Warehouse Efficiency

Artificial Intelligence Driving The Future Of Supply Chains

Top Insider Tips To Maximize Savings In Logistics Operations

Innovative AI Solutions Unlock Greater Supply Chain Efficiency