Warehouse Management Best Practices: JUSDA's Insights

Warehouse management is a critical aspect of supply chain operations, ensuring the seamless flow of goods from receipt to delivery. Implementing best practices in warehouse management is essential for efficient and cost-effective operations. JUSDA, a key player in the industry, revolutionizes warehouse management with cutting-edge solutions and global expertise.

Introduction to Warehouse Management Theories and Operational Techniques

Key Theories

Warehouse management relies on Inventory Management Systems (IMS) and Warehouse Management Systems (WMS) to ensure smooth operations. An IMS helps in tracking inventory levels, managing stock movements, and optimizing storage space. On the other hand, a WMS focuses on controlling warehouse operations, enhancing order fulfillment processes, and improving overall efficiency.

Operational Techniques for Warehouse Management

Picking and Packing

Efficient Batch Picking is crucial for optimizing warehouse operations. By grouping multiple orders together and picking them simultaneously, warehouses can save time and reduce labor costs. Implementing Batch Picking strategies streamlines the picking process, leading to faster order fulfillment.

Inventory Handling Process

The Inventory Handling Process involves receiving, storing, and moving goods within the warehouse. It is essential to have clear procedures for handling different types of inventory, ensuring accuracy and minimizing errors. Implementing ergonomic pick locations can improve staff productivity and reduce workplace injuries.

Storage and Space Utilization

Effective Inventory Handling Process contributes to maximizing storage space utilization. By organizing inventory based on demand frequency or product characteristics, warehouses can optimize space usage. Implementing automated systems like RFID tags or sensors can further enhance space utilization efficiency.

Pain Points of Warehouse Management in the Manufacturing Industry

Common Challenges

Inventory Accuracy

Maintaining Accuracy in inventory records is crucial for smooth warehouse operations. When inventory levels are inaccurate, it can lead to order fulfillment errors, stockouts, and delayed shipments. To ensure Accuracy, warehouses must conduct regular cycle counts, reconcile discrepancies promptly, and invest in advanced tracking technologies like RFID.

Cost Management

Cost Management is a significant concern for warehouse operations. Balancing operational costs while maintaining efficiency is essential for sustainable business growth. Implementing cost-effective strategies such as optimizing storage space, reducing waste, and streamlining processes can help warehouses manage expenses effectively.

Productivity Issues

Productivity plays a vital role in warehouse management. Increased Productivity leads to faster order processing, reduced lead times, and improved customer satisfaction. However, warehouses often face challenges related to staff productivity due to inefficient workflows, inadequate training, or suboptimal resource allocation.

Specific Issues in Manufacturing

Inventory and Warehouse Management

Effective Inventory and Warehouse Management is critical for manufacturing facilities. Ensuring the right inventory levels, proper storage methods, and accurate tracking systems are essential to support production processes. By implementing robust inventory management plans and leveraging technology solutions like WMS, manufacturers can optimize their warehouse operations.

Warehouse Management Process Flow

The Management Process Flow within warehouses can impact overall operational efficiency. Streamlining processes from receiving goods to order fulfillment is key to reducing lead times and improving customer service. Properly designed workflows that prioritize accuracy, speed, and safety contribute to a well-functioning warehouse environment.

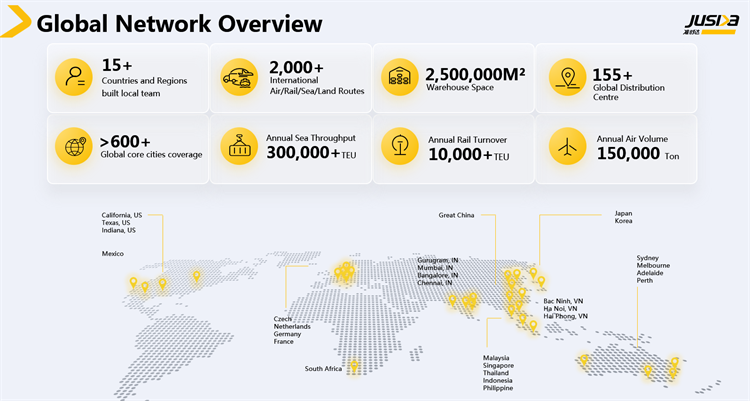

JUSDA's Global Network and Distribution Centre

JUSDA have built the strong networks with cross-border transfer centers and international logistic partnerships, which provide the accountable logistics solutions from our joint ventures in North America, Europe, South Korea, Japan, Vietnam, India, Australia, Southeast Asia, and the Middle East. JUSDA, with years of experience in 3C manufacturing supply chain, has launched many core products which include road freight, air freight,ocean freight, rail freight, warehousing and JusTrade import and export sevice platform. The strong location networks, 155 locations worldwide space, 45 logistics and logistics service centers, 110 overseas cross-border operations centers, and more than 1,500 international air, ocean and truck routes, give great competence to enhance business efficiency.

In addition to its global presence, JUSDA offers a wide range of Service Offerings that cater to diverse business needs:

Warehouse Management Software

JUSDA's cutting-edge Warehouse Management Software (WMS) is designed to streamline warehouse operations efficiently. The software provides real-time visibility into inventory levels, enabling businesses to track stock movements accurately. By implementing robust inventory monitoring mechanisms, companies can minimize excess inventory and prevent stockouts. This meticulous control over inventory levels enhances operational efficiency and streamlines order fulfillment processes.

WMS Implementation

JUSDA excels in the seamless implementation of Warehouse Management Systems (WMS). Leveraging AI and digital supply chain advancements, JUSDA integrates with clients to provide end-to-end solutions from component procurement to factory manufacturing and consumer segments. With a vast network of 155+ service locations worldwide and over 2.5 million square meters of warehousing space, JUSDA offers scalable storage options that align with evolving business requirements.

The integration of advanced technology such as IoT, cloud computing, and big data analytics through the JusLink Smart Supply Chain platform revolutionizes traditional supply chain silos. From electronics manufacturing to automotive industries, JUSDA tailors agile solutions that adapt to rapidly changing consumer demands.

Embracing Industry 4.0 principles, JUSDA continues to push boundaries with multimodal transport networks, advanced warehouse management systems, and a commitment to making supply chains smarter and more sustainable. Businesses partnering with JUSDA benefit from lower operational costs due to increased efficiency and optimized processes without compromising on quality or service standards.

Looking ahead, JUSDA is poised for remarkable future developments in the supply chain industry. Businesses are encouraged to explore JUSDA's services for optimized operations and sustainable growth. Embrace the future of supply chain management with JUSDA's innovative solutions!

Elaboration on the JUSDA Warehouse Technical Committee

The JUSDA Warehouse Technical Committee plays a pivotal role in driving innovation and excellence in warehousing practices. By focusing on talent development and technological advancements, the committee aims to elevate warehouse management standards globally.

Purpose and Goals

What's the JUSDA Warehouse Technical Committee?

The JUSDA Warehouse Technical Committee serves as a committee for fostering collaboration, knowledge sharing, and skill development among warehousing professionals. It brings together experts from diverse backgrounds to exchange insights, address industry challenges, and drive continuous improvement in warehouse operations.

How to cultivate warehousing talents?

Cultivating warehousing talents is a core objective of the committee. Through training programs, mentorship initiatives, and hands-on experience opportunities, the committee nurtures a new generation of skilled professionals equipped to tackle evolving warehouse management demands. By investing in talent development, JUSDA ensures a sustainable pipeline of competent individuals ready to navigate complex supply chain landscapes.

The significance of the JUSDA Warehousing Technical Committee

Drive digital transformation

The JUSDA Warehouse Technical Committee spearheads digital transformation initiatives within the warehousing sector. By leveraging data analytics, automation technologies, and smart inventory systems, the committee empowers warehouses to operate more efficiently and intelligently. Embracing digital tools not only enhances operational speed but also enables real-time decision-making based on accurate insights.

Project Support

The JUSDA Warehouse Technical Committee provides invaluable support to manufacturing industry warehouse projects . From optimizing workflows to implementing best practices, the committee offers guidance and expertise that drive project success. By collaborating with industry partners and leveraging global insights, JUSDA ensures that warehouses are equipped with the latest strategies and tools for sustainable growth.

Recap of Best Practices:

Prioritizing inventory accuracy ensures seamless operations.

Cost management strategies optimize efficiency and sustainability.

Enhancing productivity leads to improved customer satisfaction.

JUSDA's Contributions to Warehouse Management:

Customer satisfaction is at the core of JUSDA's service philosophy. Through a relentless focus on quality and reliability, JUSDA ensures reliable service that exceeds customer expectations. The seamless coordination between warehousing operations and transportation services guarantees timely deliveries and accurate order fulfillment. By prioritizing customer needs and maintaining high service standards, JUSDA fosters long-term partnerships built on trust and excellence.

Future Outlook for Warehouse Management:

Embracing digital transformation for enhanced efficiency.

Leveraging advanced technologies for smarter supply chains.

Continued commitment to innovation in warehouse practices.

See Also

Revealing JUSDA's Expertise in Inventory Optimization

Redefined Efficiency: JUSDA's Logistics Optimization

Enhancing Efficiency: JUSDA's Complete Supply Chain Visibility