Analysis of Challenges for Manufacturing Logistics Companies

Manufacturing logistics companies encounter numerous challenges that hinder efficiency, profitability, and customer satisfaction. For instance, manufacturers with integrated supply chains report 37% shorter lead times and 26% lower inventory costs, showcasing the potential for improvement. However, the logistics market demands faster deliveries, pushing companies to innovate continuously. Customer expectations for reliability and speed underscore the critical need to address these obstacles. Additionally, downtime costs for manufacturers can reach $50,000 per hour, emphasizing the financial impact of inefficiencies. Proactively overcoming these challenges is essential for maintaining competitiveness in an evolving global market.

Key Takeaways

Manufacturing logistics companies can work faster by using smart tools like AI and machines. This helps save money and get more work done.

Seeing the supply chain in real-time is very important. Tools like JusLink help track items and predict problems, making work smoother.

Being eco-friendly, like planning better routes and using less energy, cuts costs and helps the planet at the same time.

To fix worker shortages, companies should train workers and use machines. This keeps workers skilled and work running well.

Being quick to change is key in supply chains. Companies should handle market changes by using more suppliers and smart tools to predict issues.

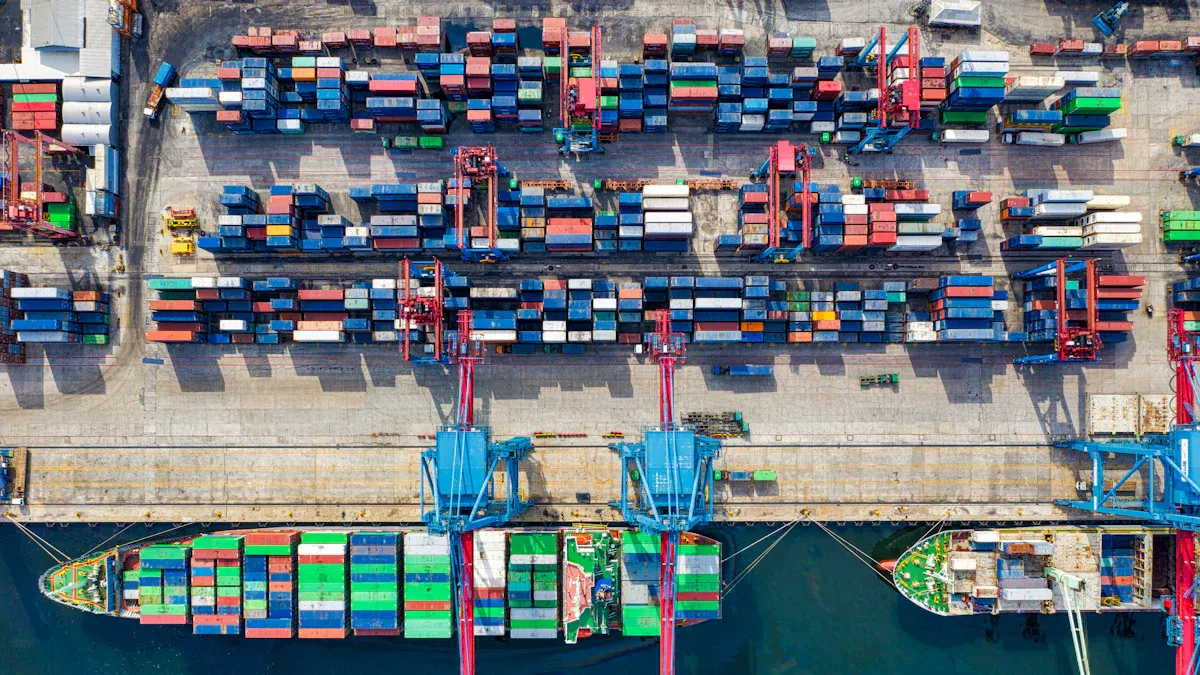

Globalization Challenges in Manufacturing Logistics

Managing Cross-Border Supply Chains with JUSDA's Solutions

Globalization has significantly increased the complexity of cross-border supply chains. Companies must navigate diverse customs regulations, manage international transportation, and ensure timely delivery across multiple regions. Rising shipping costs, which surged by over 77% between January 2021 and August 2022, further complicate operations. Additionally, total compensation costs in the manufacturing sector rose by 6.2% to $42 per hour in Q1 2022, adding financial strain. These challenges often lead to contract fulfillment issues, with 31% of executives citing supply disruptions as a top concern.

JUSDA addresses these challenges with its advanced Supply Chain Management Collaboration Platform. This platform integrates cutting-edge technologies like AI, IoT, and blockchain to streamline global operations. By providing real-time tracking and predictive analytics, JUSDA enables companies to monitor shipments, anticipate delays, and optimize routes. For example, JusLink offers end-to-end visibility, allowing businesses to manage risks and improve decision-making.

Moreover, JUSDA's extensive global network, spanning over 155 service points and 2.5 million square meters of warehousing, ensures seamless logistics support. Its Vendor Managed Inventory (VMI) services enhance collaboration between suppliers and buyers, reducing inventory costs and improving efficiency. These solutions empower manufacturing logistics companies to overcome globalization challenges and maintain a competitive edge.

Goldman Sachs Research highlights that despite rising trade barriers, global trade remains resilient. Asia continues to gain market share in world manufacturing and exports, presenting opportunities for logistics companies to navigate the growing complexity of global shipments.

Navigating Trade Regulations and Tariffs

Trade regulations and tariffs pose significant hurdles for manufacturing logistics companies. Tariffs often force businesses to reevaluate their supply chains, considering factors like country of origin and tariff classifications. This reevaluation can lead to the creation of new logistics networks and relationships with carriers, impacting operational efficiency. Companies in sectors like healthcare and pharmaceuticals face increased costs for imported raw materials, necessitating alternative sourcing strategies.

JUSDA helps businesses navigate these complexities by offering tailored solutions. Its platform provides tools for customs coordination, enabling real-time tracking of clearance processes. This feature reduces delays and ensures compliance with regional regulations. Additionally, JUSDA's expertise in optimizing logistics models and routes helps companies mitigate the impact of tariffs.

To adapt to these challenges, businesses can take several steps:

Revise logistics models and optimize routes to maintain efficiency.

Explore alternative suppliers to reduce reliance on tariff-heavy imports.

Enhance compliance strategies to navigate cross-border complexities.

JUSDA's collaboration with industry leaders further strengthens its ability to address trade-related challenges. By leveraging its global network and advanced technologies, JUSDA ensures that manufacturing logistics companies can operate efficiently in a rapidly changing regulatory environment.

Country | LPI Score | Notes |

|---|---|---|

Singapore | 4.3 | Top-rated country with high logistics service quality. |

Finland | 4.2 | Maintains high logistics performance post-pandemic. |

India | 3.5 | Significant improvement in logistics performance. |

South Africa | 3.5 | Notable improvement in logistics capabilities. |

Technological Advancements and Digital Transformation

Integrating Automation and AI in Manufacturing Logistics

Automation and artificial intelligence (AI) have revolutionized manufacturing logistics by streamlining operations and enhancing efficiency. Companies that integrate these technologies report significant improvements in productivity and cost reduction. For instance, automation has boosted productivity by up to 48%, while AI has decreased operating costs by 42%. These advancements enable businesses to optimize workflows, reduce manual errors, and improve overall operational efficiency.

AI-powered tools, such as predictive analytics, play a crucial role in decision-making. They analyze vast amounts of data to forecast demand, identify potential disruptions, and recommend optimal solutions. Robotic Process Automation (RPA) further enhances supply chain operations by automating repetitive tasks, allowing employees to focus on strategic activities. By 2025, 60% of companies expect RPA to transform their supply chains, leading to increased efficiency and productivity.

The integration of AI also supports sustainability goals. AI-driven data analysis minimizes greenhouse gas emissions by optimizing fuel usage and reducing energy consumption. Additionally, AI enhances quality control by identifying defects before mass production, preventing costly recalls.

Improvement Type | Percentage Improvement |

|---|---|

Productivity Improvement | Up to 48% |

Decrease in Operating Costs | 42% |

Increase in Productivity (IoT) | 72% |

Productivity Boost in Mines | 20% |

Human-Machine Collaboration Boost | Up to 30% |

Moreover, AI enhances customer service by personalizing interactions and improving communication through natural language processing (NLP). It also ensures safety and compliance by monitoring work environments and automating hazardous tasks. These benefits make automation and AI indispensable for modern manufacturing logistics.

Metric | Benefit Description |

|---|---|

Operational Efficiency | 60% of companies expect RPA to transform supply chains by 2025, enhancing productivity and efficiency. |

Cost Reduction | 44% of executives report AI has reduced costs in their companies. |

Eco-Friendliness | AI-driven data analysis minimizes greenhouse gas emissions and optimizes fuel usage. |

Improved Customer Service | AI enhances personalization and communication with customers through NLP and machine learning. |

Leveraging JusLink for Real-Time Supply Chain Visibility

Real-time supply chain visibility has become a critical requirement for manufacturing logistics companies. JusLink, JUSDA's intelligent supply chain platform, addresses this need by integrating IoT, cloud computing, and big data analytics. This integration enables seamless connectivity and information sharing across the supply chain ecosystem.

JusLink provides tailored solutions based on deep insights into product lifecycles and a global network of over 155 locations. It allows businesses to monitor shipments in real time, anticipate delays, and make informed decisions. This level of visibility enhances operational efficiency and reduces risks associated with supply chain disruptions.

Key features of JusLink include:

Real-time tracking of shipments and inventory.

Predictive analytics for demand forecasting and risk management.

Seamless collaboration between suppliers, manufacturers, and distributors.

These capabilities empower companies to achieve end-to-end visibility, ensuring timely deliveries and improved customer satisfaction. JusLink also supports sustainability initiatives by optimizing routes and reducing fuel consumption.

JusLink's advanced technology has transformed supply chain management, enabling businesses to adapt to dynamic market conditions and maintain a competitive edge.

Metric Type | Description |

|---|---|

Energy efficiency metrics | Measures optimization of energy and operational processes, including energy savings and reduced downtime. |

Operational efficiency metrics | Indicates reduced processing times and increased automation rates as a result of digital transformation. |

Data utilization | Assesses the effectiveness of data analytics in improving decision-making and forecasting accuracy. |

Compliance and security | Evaluates improved compliance audit results and reduced security breaches as indicators of success. |

Sustainability goals | Tracks achievements in reducing energy usage and carbon footprint through digital technologies. |

Employee productivity and satisfaction | Measures enhanced productivity and satisfaction through internal surveys and performance data. |

By leveraging JusLink, manufacturing logistics companies can enhance transparency, improve decision-making, and achieve greater efficiency in their operations.

Sustainability and Environmental Pressures

Reducing Carbon Footprints in Logistics Operations

The logistics industry plays a significant role in global greenhouse gas emissions, contributing 17% of the total, according to Boston Consulting Group. Transportation activities, including freight and delivery, are primary contributors. Sustainable practices can reduce emissions by up to 20% by 2030, as highlighted by Carbon Trust. These measures are essential for mitigating the environmental impact of logistics operations.

Several strategies effectively lower carbon footprints in logistics. Companies adopting renewable energy sources, such as solar panels and wind turbines, reduce reliance on fossil fuels. Route optimization, powered by advanced algorithms, minimizes fuel consumption by identifying the most efficient paths. Transitioning to low-emission vehicles further decreases environmental harm. These approaches not only reduce emissions but also enhance operational efficiency.

Manufacturing logistics companies can integrate these strategies into their operations to achieve sustainability goals. For instance, JUSDA leverages digital tools like JusLink to optimize transportation routes and monitor energy usage. This platform provides real-time insights, enabling businesses to make informed decisions that align with environmental objectives. By adopting green technologies and practices, companies contribute to a cleaner, more sustainable future.

Source | Evidence |

|---|---|

Carbon Trust 2022 | The logistics industry could reduce its greenhouse gas emissions by 20% by 2030 through sustainable practices. |

Boston Consulting Group | Transportation activities account for 17% of global greenhouse gas emissions. |

World Bank | CO2 emissions rose by an average of 2.08% per year from 1970 to 2013, reaching 35.84 billion tonnes in 2013. |

Implementing Green Supply Chain Practices with JUSDA

Green supply chain practices have become a cornerstone of sustainable logistics. These practices focus on reducing waste, conserving resources, and minimizing environmental impact throughout the supply chain. JUSDA offers innovative solutions to help companies implement these practices effectively.

JUSDA's warehousing services incorporate energy-efficient technologies, such as advanced inventory management systems, to reduce energy consumption. The company also utilizes clean room facilities that comply with stringent environmental standards. JusLink, JUSDA's intelligent supply chain platform, enhances collaboration between suppliers and manufacturers, promoting transparency and efficiency. These features enable businesses to adopt eco-friendly practices without compromising operational performance.

By integrating green supply chain practices, companies can achieve multiple benefits. Reduced energy usage lowers operational costs, while improved resource management enhances productivity. JUSDA's solutions empower manufacturing logistics companies to align their operations with sustainability goals, ensuring long-term success in an environmentally conscious market.

🌱 Tip: Companies adopting green supply chain practices not only reduce their environmental impact but also improve their brand reputation among eco-conscious consumers.

Rising Costs and Financial Pressures

Managing Fuel and Transportation Costs

Fuel and transportation costs represent a significant financial burden for manufacturing logistics companies. Rising fuel prices directly increase shipping rates, which logistics providers often pass on to businesses. This, in turn, raises consumer prices and impacts demand. The trucking industry, a primary mode of domestic freight, faces particular challenges due to fuel price volatility, which affects operational costs and profit margins.

Several trends have emerged as companies adapt to these pressures:

Rising fuel prices drive up costs for trucking, shipping, and air freight providers.

Supply chain disruptions occur as businesses adjust routes to manage fuel expenses.

Profitability pressures intensify for small and medium-sized logistics firms.

To mitigate these challenges, companies are adopting innovative strategies:

Investing in fuel-efficient vehicles to reduce consumption.

Exploring alternative energy sources, such as electric and hybrid vehicles.

Implementing route optimization software to minimize fuel usage.

Engaging in fuel hedging to stabilize costs.

Shifting to intermodal transportation to reduce reliance on fuel.

These measures not only lower costs but also enhance sustainability. Advanced tools like JusLink further support these efforts by optimizing routes and providing real-time insights into fuel consumption.

Optimizing Warehousing Costs with JUSDA's Warehouse Solutions

Warehousing costs, including storage and inventory management, significantly impact the financial health of manufacturing logistics companies. Inefficient warehousing can lead to excess inventory, stockouts, and increased operational expenses. JUSDA's warehouse solutions address these challenges by leveraging advanced technologies and tailored strategies.

Key benefits of JUSDA's warehousing services include:

Improved forecasting for better demand visibility.

Minimized overstocking and stockouts, enhancing operational efficiency.

JUSDA's facilities, spanning over 2.5 million square meters globally, integrate advanced inventory management systems like JusLink. These systems provide real-time tracking and control, ensuring transparency and efficiency. For example, JUSDA's Vendor Managed Inventory (VMI) services enable seamless collaboration between suppliers and buyers, reducing inventory costs and improving supply chain performance.

By adopting JUSDA's solutions, companies can achieve significant cost savings while maintaining high service quality. These innovations empower businesses to navigate financial pressures effectively, ensuring long-term success in a competitive market.

📊 Note: Optimized warehousing not only reduces costs but also enhances customer satisfaction by ensuring timely deliveries and accurate inventory management.

Meeting Evolving Customer Expectations

Ensuring Faster Delivery Times

Faster delivery times have become a critical expectation for customers in the logistics industry. Delays can lead to frustration and lost business, making timely deliveries essential for maintaining customer satisfaction. Companies measure delivery performance using key indicators such as lead time, delivery time, and truck turnaround rate.

Lead Time (Order Cycle): This metric tracks the time from order placement to receipt. Reducing lead time helps identify bottlenecks and improves efficiency.

Delivery Time: This measures the duration from shipment departure to customer receipt. Shorter delivery times enhance customer satisfaction by providing more accurate delivery predictions.

Truck Turnaround Rate: This indicator reflects the time trucks spend in warehouses for loading and unloading. Optimizing this rate improves driver productivity and reduces delays.

JUSDA addresses these challenges by leveraging advanced technologies like JusLink. This platform optimizes routes and streamlines operations, ensuring faster deliveries. Its predictive analytics capabilities help anticipate potential delays, allowing companies to take proactive measures. By focusing on these performance indicators, manufacturing logistics companies can meet customer expectations for speed and reliability.

Indicator | Role and Impact | Significance |

|---|---|---|

Lead Time (Order Cycle) | Measures the time from order placement to receipt, identifying bottlenecks. | Reducing lead time enhances customer satisfaction and efficiency. |

Delivery Time | Tracks the duration from shipment to receipt by the customer. | Reducing delivery time leads to more accurate predictions. |

Truck Turnaround Rate | Measures the time a truck spends in a warehouse for loading/unloading. | Reflects loading efficiency and optimizes driver hours. |

Providing Real-Time Tracking and Transparency with JusLink

Transparency has become a cornerstone of customer satisfaction in logistics. Customers expect real-time updates about their shipments to reduce uncertainty and enhance trust. JusLink, JUSDA's intelligent supply chain platform, fulfills this need by offering seamless tracking across various freight types.

JusLink provides real-time visibility into shipments, enabling users to monitor their orders from initiation to delivery. This advanced platform integrates IoT, cloud computing, and big data analytics to deliver accurate updates. Customers benefit from timely notifications about shipment status, delays, or changes, ensuring they remain informed throughout the process.

For example, JusLink allows businesses to track shipments across international borders with precision. This capability not only improves operational efficiency but also strengthens customer relationships by fostering transparency. By leveraging JusLink, manufacturing logistics companies can meet evolving customer expectations while maintaining a competitive edge in the market.

Tip: Real-time tracking not only enhances customer satisfaction but also reduces operational risks by identifying potential disruptions early.

Metric | Description |

|---|---|

Gather direct feedback from customers about their delivery experience, including time and condition. | |

Net Promoter Score (NPS) | Measures likelihood of customers recommending the service, indicating overall satisfaction. |

Delivery Performance Metrics | Quantitative assessment of delivery times, order accuracy, and customer complaints. |

Social Media Reviews | Unfiltered customer feedback on platforms, reflecting satisfaction or dissatisfaction. |

Timely Deliveries | Essential for customer satisfaction; delays can lead to frustration and lost business. |

Accuracy of Orders | Correct products in the right quantity are crucial for maintaining customer trust. |

Transparency and Communication | Keeping customers informed about their orders reduces uncertainty and enhances satisfaction. |

Condition of Goods | The state of delivered products significantly impacts customer satisfaction. |

Cost-Efficiency | Affordable shipping options are important for retaining customers, even with high-quality products. |

Security Risks in Manufacturing Logistics

Addressing Cybersecurity Threats in Supply Chains

The increasing reliance on digital tools in manufacturing logistics has amplified cybersecurity risks. Supply chains often involve multiple third-party vendors, creating vulnerabilities that can disrupt operations. Bitsight's research highlights that even security-conscious companies remain exposed to risks from smaller software providers.

Bitsight's research emphasizes that even security-conscious companies are vulnerable to weaknesses in their supply chain, particularly due to third-party vendors. The report highlights that smaller specialized software providers can pose significant risks, and a security failure at one of these companies could trigger cascading effects across industries.

Complex cloud environments further exacerbate these risks. According to PwC, 81% of industry leaders agree that such environments increase cyber and privacy vulnerabilities. Additionally, 63% of sector leaders expect a rise in third-party threats, with 58% anticipating more incidents at the supply chain software level. These findings underscore the urgent need for robust cybersecurity measures.

Companies can mitigate these risks by adopting advanced cybersecurity practices. Real-time monitoring, encryption, and regular audits enhance data protection. Platforms like JusLink provide end-to-end visibility, enabling businesses to identify and address potential threats proactively. Organizations with strong cybersecurity frameworks not only safeguard their operations but also achieve higher shareholder returns—up to 372% more than those without such measures.

Preventing Theft and Cargo Loss

Theft and cargo loss remain significant challenges in global logistics. Companies face direct financial losses from stolen goods, increased insurance premiums, and operational disruptions. The FBI estimates that annual losses from cargo theft in the U.S. range between $15 billion and $30 billion. In the first quarter of 2024 alone, 925 cargo theft incidents resulted in $76 million in losses, with an average of $281,757 per robbery.

Direct financial losses from stolen goods can be substantial.

Increased insurance premiums due to theft incidents add to operational costs.

Cargo theft incidents in 2024 averaged $281,757 per robbery.

To combat these issues, businesses are implementing advanced security measures. GPS tracking, geofencing, and secure storage facilities reduce the risk of theft. JUSDA's warehousing solutions, equipped with real-time monitoring systems, enhance cargo security. By adopting these strategies, companies can minimize losses and maintain operational efficiency.

Capacity Bottlenecks and Infrastructure Challenges

Managing Limited Warehouse Space with JUSDA's Warehousing Solutions

Limited warehouse space presents a significant challenge for manufacturing logistics companies. Inefficient use of storage areas often leads to increased costs and reduced operational efficiency. On average, warehouses utilize only 68% of their capacity, leaving room for improvement in space management. Labor costs, which can account for up to 65% of a warehouse's budget, further emphasize the need for optimized operations.

JUSDA's warehousing solutions address these issues by integrating advanced inventory management systems like JusLink. These systems provide real-time tracking and control, enabling businesses to maximize space utilization and reduce carrying costs. JUSDA's facilities, spanning over 2.5 million square meters globally, offer tailored solutions such as Vendor Managed Inventory (VMI) services. These services enhance collaboration between suppliers and buyers, ensuring efficient inventory management.

Metric | Description |

|---|---|

Space Utilization | Measures how efficiently a warehouse is maximizing its available space. |

Storage Productivity | Indicates the efficiency of storage operations in relation to the space used. |

Carrying Cost of Inventory | Reflects the costs associated with holding inventory, which can be impacted by limited space. |

By leveraging JUSDA's expertise, companies can overcome capacity bottlenecks, improve productivity, and achieve cost savings. These solutions empower businesses to maintain operational efficiency while meeting the demands of a dynamic market.

Addressing Transportation Network Congestion

Transportation network congestion poses another critical challenge for manufacturing logistics. Idling trucks waste fuel, increase operational expenses, and contribute to carbon emissions. Congestion also reduces loading and unloading throughput, causing delays and creating unsafe conditions for yard personnel.

To mitigate these issues, logistics companies must adopt proactive strategies:

Identify bottlenecks in transportation networks to address delays effectively.

Invest in technology, such as traffic management systems and route optimization software, to enhance efficiency.

Improve procedures by streamlining loading and unloading processes to reduce congestion.

JUSDA's JusLink platform plays a pivotal role in addressing these challenges. By providing real-time visibility and predictive analytics, JusLink enables businesses to optimize routes and manage transportation networks efficiently. This approach not only reduces delays but also minimizes environmental impact, aligning operations with sustainability goals.

Manufacturing logistics companies that implement these strategies can enhance their transportation efficiency, reduce costs, and improve overall service quality. Addressing congestion effectively ensures smoother operations and strengthens customer satisfaction.

Workforce Shortages and Labor Challenges

Attracting and Retaining Skilled Workers

Workforce shortages have become a pressing issue in the logistics sector, with 76% of supply chain leaders reporting significant challenges in maintaining a stable workforce. A declining number of skilled workers, coupled with high turnover rates, has created operational inefficiencies. For example, 67% of transportation operations and 56% of warehouse operations are directly impacted by labor shortages. These gaps lead to increased costs, shipping delays, and higher prices for consumers.

To address these challenges, companies are focusing on workforce partnerships and employee development programs. Emphasizing career advancement opportunities and implementing mentorship initiatives can reduce turnover. Training programs tailored to bridge skill gaps also play a critical role in improving workforce stability. For instance, optimizing hiring strategies and offering clear paths for progression attract skilled workers and enhance retention.

Manufacturing logistics companies must prioritize these strategies to remain competitive. By investing in their workforce, they can mitigate the impact of labor shortages and improve operational efficiency.

Tip: Companies that invest in employee development not only reduce turnover but also foster a more engaged and productive workforce.

Enhancing Efficiency Through Automation

Automation offers a powerful solution to labor shortages in logistics. Advanced technologies like robotics and AI streamline operations, reducing reliance on manual labor. For instance, UPS's ORION system saves $300-$400 million annually by optimizing delivery routes. Similarly, automation reduces warehouse operational costs by up to 50% and labor costs by 40%.

The benefits of automation extend beyond cost savings. Predictive maintenance reduces equipment failures by 35%, while error rates in demand forecasting drop by 20-50%. Warehouse throughput increases by 40%, and safety improves by 90%. These advancements not only enhance efficiency but also ensure higher service levels, with a 65% improvement reported in some cases.

Manufacturing logistics companies can leverage automation to address workforce shortages effectively. By integrating technologies like JusLink, businesses gain real-time insights and predictive analytics, enabling smarter decision-making. Automation not only fills labor gaps but also drives long-term growth and sustainability.

Efficiency Gain | Numerical Evidence |

|---|---|

Warehouse operational cost reduction | Up to 50% |

Labor cost reduction in warehouses | 40% |

Increase in service levels | 65% |

Warehouse throughput increase | 40% |

Error reduction in demand forecasting | 20-50% |

Improvement in safety | 90% |

Note: Automation is not just a solution to workforce shortages; it is a pathway to transforming logistics operations for the future.

Supply Chain Transparency and Visibility

Leveraging JusLink for End-to-End Tracking

End-to-end tracking has become a cornerstone of efficient supply chain management. JusLink, JUSDA's intelligent supply chain platform, offers a comprehensive solution for achieving this transparency. By integrating advanced technologies, JusLink ensures seamless connectivity and real-time monitoring across the supply chain.

JusLink employs several cutting-edge features to enhance visibility:

Employs cloud computing to improve data accessibility and sharing.

Incorporates big data analytics to derive actionable insights and optimize decision-making.

These capabilities revolutionize operations in industries like electronics manufacturing and automotive. JusLink also provides tailored solutions for 3C appliances, meeting evolving consumer demands. Additionally, it optimizes bulk materials management through lean methodologies, ensuring efficiency and cost-effectiveness.

The platform's ability to provide real-time updates empowers businesses to anticipate disruptions and respond proactively. This level of visibility not only reduces operational risks but also enhances customer satisfaction by ensuring timely deliveries. JusLink's role in transforming supply chain transparency makes it an indispensable tool for modern manufacturing logistics.

Tip: Real-time tracking not only improves operational efficiency but also builds stronger relationships with customers by fostering trust.

Building Trust Through Transparent Practices

Transparency in supply chain operations fosters trust among stakeholders. Customers, suppliers, and partners value clear communication and reliable information. JusLink supports this by offering real-time updates and predictive analytics, ensuring all parties stay informed.

Transparent practices include:

Sharing accurate shipment statuses with customers.

Providing suppliers with demand forecasts to improve collaboration.

Offering distributors insights into inventory levels for better planning.

These practices reduce uncertainties and enhance decision-making across the supply chain. For example, JusLink's predictive analytics help businesses identify potential delays and take corrective actions. This proactive approach minimizes disruptions and strengthens trust among stakeholders.

By adopting transparent practices, companies not only improve operational efficiency but also enhance their reputation. In a competitive market, trust becomes a key differentiator, enabling businesses to build long-term relationships with their clients and partners.

🌟 Note: Transparency is not just a strategy; it is a commitment to accountability and excellence in supply chain management.

The Need for Agility and Adaptability

Responding to Market Fluctuations

Market fluctuations demand swift and strategic responses from manufacturing logistics companies. Volatile demand, shifting consumer preferences, and global economic changes often disrupt supply chains. Companies that embrace agility can adapt to these challenges effectively. For instance, Reckitt Benckiser localized production in the U.S., investing $200 million to reduce lead times and meet fluctuating demand for essential products. This strategic move highlights the importance of adaptability in manufacturing logistics.

Agile supply chains deliver measurable benefits. A McKinsey & Company report reveals that 94% of companies using agile practices achieve on-time delivery and maintain inventory cycles under 85 days. In contrast, companies without agile solutions hold inventory for over 108 days and deliver on time only 87% of the time. These statistics underscore the critical role of agility in ensuring operational efficiency and customer satisfaction.

To respond effectively to market fluctuations, companies can adopt several strategies:

Diversify suppliers to reduce dependency on single sources.

Invest in predictive analytics to forecast demand and adjust production schedules.

Enhance collaboration with partners to improve communication and decision-making.

In today’s business environment, characterized by volatility and uncertainty, an agile supply chain is not just a nice-to-have; it’s a necessity. By embracing agility, companies can ensure that they are not only prepared for the unexpected but are also equipped to turn challenges into opportunities.

Preparing for Disruptions and Uncertainties

Disruptions and uncertainties, such as natural disasters, geopolitical tensions, and pandemics, pose significant risks to manufacturing logistics. Companies must prepare for these challenges by building resilience into their supply chains. Gartner reports that nearly 90% of supply chain leaders plan to invest in agility, emphasizing its importance in navigating unpredictable scenarios.

Proactive measures can mitigate the impact of disruptions. Risk assessments help identify vulnerabilities, while contingency plans ensure swift responses to unexpected events. JusLink, JUSDA's intelligent supply chain platform, enhances preparedness by providing real-time visibility and predictive analytics. These tools enable companies to anticipate disruptions and adjust operations accordingly.

Localized production also strengthens resilience. By reducing reliance on global networks, companies can minimize delays and maintain consistent service levels. This approach aligns with the growing need for adaptability in a volatile market.

Manufacturing logistics companies that prioritize agility and preparedness can transform challenges into opportunities. By investing in advanced technologies and strategic planning, they ensure long-term success in an unpredictable business environment.

Manufacturing logistics companies encounter diverse challenges that demand innovative solutions. Globalization, technological advancements, and workforce shortages create hurdles that require proactive strategies. JUSDA's warehouse services and JusLink platform provide tools to enhance efficiency and reduce costs. These solutions also improve customer satisfaction by streamlining operations. Companies that address these challenges effectively can transform their logistics operations into a competitive advantage. This approach ensures long-term success in a complex and evolving industry.

FAQ

What industries benefit most from JUSDA's logistics solutions?

JUSDA serves industries like electronics manufacturing, automotive, FMCG, and medical health. Its tailored solutions address specific challenges in these sectors, such as supply chain visibility, inventory management, and cross-border logistics. Companies in these industries gain efficiency and cost savings through JUSDA's advanced technologies and global network.

How does JusLink improve supply chain transparency?

JusLink integrates IoT, cloud computing, and big data to provide real-time tracking and predictive analytics. Businesses monitor shipments, anticipate delays, and optimize routes. This transparency enhances decision-making, reduces risks, and ensures timely deliveries, meeting customer expectations for visibility and reliability.

What sustainability practices does JUSDA implement?

JUSDA adopts green supply chain practices, including energy-efficient warehousing and route optimization. Its JusLink platform minimizes fuel consumption and emissions. These initiatives align with environmental goals, helping companies reduce their carbon footprint while maintaining operational efficiency.

How does JUSDA address workforce shortages?

JUSDA leverages automation and AI to reduce reliance on manual labor. Technologies like robotic process automation streamline operations, improve accuracy, and enhance productivity. These innovations fill labor gaps and ensure consistent service quality, even during workforce shortages.

What makes JUSDA's warehousing solutions unique?

JUSDA's warehousing services feature advanced inventory management systems like JusLink. These systems provide real-time tracking, optimize space utilization, and reduce carrying costs. Value-added services, such as labeling and kitting, further enhance operational efficiency, making JUSDA's solutions highly adaptable to diverse business needs.

Tip: Explore JUSDA's official website for more details on its innovative logistics solutions.

See Also

Mastering Lean Logistics For Success In Tech Manufacturing

Enhancing Supply Chain Solutions For High-Tech Manufacturing

Overcoming Automotive Supply Chain Challenges: Pro Tips

Boosting Warehouse Efficiency With Logistics Robotics Technology

Transforming Logistics Through Innovative Supply Chain Strategies