Circular Packaging: Timing and Momentum Insights from the Automotive Industry Applied to the Electronics Industry

Automotive circular economy leaders face urgent sustainability and environmental demands, driven by strict regulations and fierce global competition. They use early integration of eco-friendly packaging, digital traceability, and AI-powered management to boost resource efficiency and reduce waste. Packaging innovation in automotive stems from embedding circular economy principles at the design stage, not just at end-of-life. Companies achieve sustainability goals by making packaging sustainable, optimizing operations, and standardizing reusable solutions. Electronics manufacturers can learn from automotive momentum, using technology and cross-functional collaboration to advance circular packaging and meet growing environmental expectations.

Key Takeaways

Automotive companies lead in circular packaging by designing reusable, recyclable, and durable packaging early in the product lifecycle, saving costs and reducing waste.

Technology like IoT, AI, and blockchain helps track packaging, improve quality, and optimize logistics, boosting circular packaging efficiency.

Electronics manufacturers face challenges adopting circular packaging but can learn from automotive best practices to improve sustainability and meet regulations.

Early integration of circular principles and cross-industry collaboration accelerate circular packaging adoption and create competitive advantages.

Tracking key metrics and using sustainable materials help companies reduce environmental impact and support a growing market for eco-friendly packaging.

Automotive Circular Economy Insights

Timing Strategies

Automotive companies lead the way in circular packaging by planning and executing strategies that maximize reuse and recycling. Renault sets an example by banning packaging disposal at its plants. They repair metal containers and foldable plastic boxes, which extends packaging life and supports sustainability. Retrofitting older packaging to fit new components helps avoid scrapping high-energy assets. This approach saves costs and supports environmental goals, even though it requires time and effort.

Automotive circular economy leaders use several timing strategies to improve packaging systems:

They focus on total cost of ownership by choosing reusable packaging that survives many shipping cycles. Leasing, renting, and repairing packaging extends its life and reduces waste.

Collapsible and foldable packaging designs help optimize space and logistics. Standardized container footprints make handling easier and more efficient.

Modular packaging systems with adjustable inserts adapt to changing automotive components. This future-proofs investments and supports circular packaging.

Regular packaging audits identify damage and opportunities for lightweighting or switching to reusable materials.

Collaboration with packaging experts brings material science and logistics knowledge, leading to innovative and flexible solutions.

Companies treat packaging as a strategic asset, aligning it with logistics, regulatory compliance, and sustainability goals.

Technology integration, such as IoT sensors and RFID, enables real-time tracking and condition monitoring. This improves decision-making and optimizes return flows.

Automotive circular economy companies map material flows within their value chains. They look for opportunities to increase reuse, remanufacturing, and recycling. Monitoring market adoption and maturity helps them decide when circular models become profitable. They plan for changes in regulations, technology, supply chain volatility, and material scarcity. Companies define their circular ambition by imagining future profit models and partnerships. The transition to circular packaging often takes a decade or longer, with signposts marking acceleration. Early partnerships support scaling circular packaging and other circular economy market solutions. Companies also watch for shifts in market structures to secure resources and gain competitive advantage.

Momentum Drivers

Momentum in the automotive circular economy comes from several powerful drivers. The shift to mono-material packaging makes recycling easier and supports circular packaging goals. ESG commitments and stricter regulations, such as Extended Producer Responsibility laws and plastic taxes, push companies to redesign packaging for circularity. The proposed EU Packaging and Packaging Waste Regulation requires reusable or recyclable packaging by 2030. Consumer and B2B market pressures favor brands that show sustainability progress. The use of bio-based, compostable, and reusable packaging materials is rising.

Automotive circular economy market growth relies on strong regulatory oversight. The EU's ELV Directive requires reuse and recovery of 95% of vehicle components. This forces automakers to design for recycling and take-back systems. OEMs and manufacturers invest in closed-loop recycling, remanufacturing, and circular battery approaches to reduce raw material use and carbon footprint. Electric vehicles drive battery lifecycle management, reuse, and second-life applications. Mercedes-Benz recovers over 96% of raw materials from end-of-life batteries through battery recycling operations. Market demand for recycled and remanufactured auto components continues to grow. Closed-loop recycling systems collect end-of-life vehicles and components, recycling materials into new vehicles and reducing waste.

Momentum Driver | Explanation |

|---|---|

Regulatory Oversight | EU's ELV Directive mandates reuse and recovery of 95% of vehicle components. |

OEM & Manufacturer Investments | Investments in closed-loop recycling, remanufacturing, and circular battery approaches. |

Electric Vehicle Adoption | Drives battery lifecycle management, reuse, and second-life applications. |

Market Demand | Growing demand for recycled and remanufactured auto components. |

Closed-Loop Recycling Systems | Collecting end-of-life vehicles and components for recycling into new vehicles. |

Mercedes-Benz opened battery recycling operations in Europe to recover raw materials from batteries. Stellantis invested USD 43.2 million in a circular economy hub in Italy, focusing on remanufacturing, sorting, and dismantling. OEMs invest in remanufacturing to extend product life, reduce costs, and offer sustainable alternatives. Closed-loop practices support environmental compliance and cost reduction.

Technology plays a key role in building momentum for circular packaging in the automotive circular economy. Blockchain enables tracing of assets and products, ensuring security and recordkeeping. This supports sharing, reuse, and remanufacturing in packaging supply chains. AI, combined with IoT and big data, processes real-time data, monitors manufacturing, and optimizes performance. These tools improve resource efficiency and waste reduction in packaging production and supply chains. The combination of blockchain, AI, and IoT supports distributed economies, local recycling, and peer-to-peer circularity. These technologies help redefine waste and value, supporting new business models and localized circular packaging solutions.

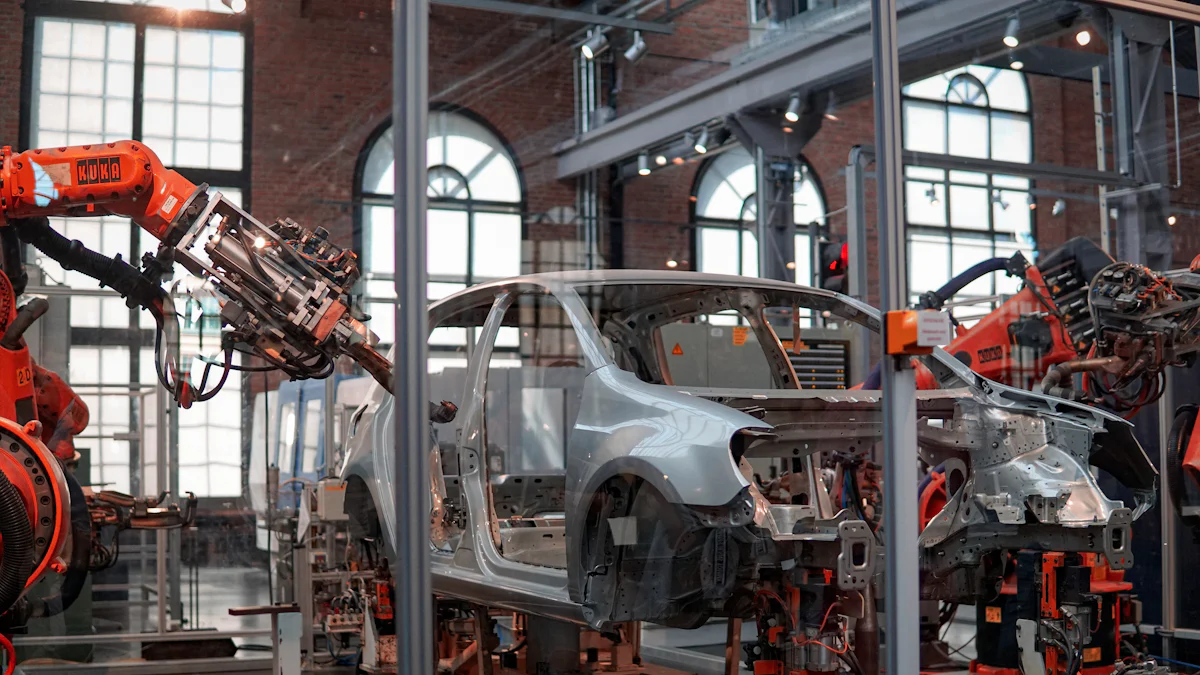

Automotive circular economy initiatives use technology and early integration to drive sustainability. Companies embed circular packaging principles at the design stage, not just at end-of-life. This approach supports environmentally friendly vehicles and advances the circular economy market. The focus on reuse, recycling, remanufacturing, and battery recycling creates a strong foundation for sustainable growth.

Circular Packaging in Electronics

Industry Relevance

Electronics manufacturers face growing pressure to adopt circular packaging. The EU Circular Economy Action Plan targets electronics and ICT as high-priority sectors for resource efficiency and circularity. Several regulations, such as the Ecodesign for Sustainable Products Regulation and the Packaging and Packaging Waste Regulation, encourage companies to use recyclable, compostable, and reusable packaging. These rules aim to reduce waste, improve recycling, and support the reuse of materials. The Packaging and Packaging Waste Regulation also helps create a stronger market for secondary raw materials and recyclable materials.

Research shows that most electronics companies focus on product use, not packaging or end-of-life management. This gap highlights the need for holistic design approaches that include packaging as part of the product life cycle. Companies must consider packaging when setting sustainability goals and meeting environmental standards.

The electronics industry must address:

High resource use and waste from packaging.

Market demand for sustainable and eco-friendly packaging.

Regulatory requirements for recyclable, compostable, and biodegradable packaging.

Circular packaging supports sustainability by promoting reuse, recycling, and remanufacturing. These practices help companies meet environmental goals and respond to consumer expectations for sustainable products.

Adoption Challenges

Electronics manufacturers encounter several challenges when adopting circular packaging:

Complex global supply chains make transparency and circular adoption difficult.

Many companies lack awareness and training on eco-friendly packaging solutions.

Limited understanding of circularity science and labeling among supply chain actors.

Some view reverse supply chains for reuse and recycling as commercially nonviable.

Regulatory conflicts can arise, such as safety rules taking priority over environmental safety.

Economic and infrastructure barriers, like non-energy-efficient logistics vehicles, slow progress.

Few government incentives exist to promote green logistics and circular packaging.

Remanufacturing and recycling processes for packaging and batteries require multi-stakeholder involvement.

Early-stage adoption means companies need more policy support and advocacy.

Companies must raise awareness about circular packaging and provide training to support green growth. They should involve top management and multiple players to improve remanufacturing, recycling, and reuse. Overcoming these challenges will help the electronics sector achieve sustainability and environmental goals.

Circular Packaging Market Size and Growth

Automotive Sector Trends

The automotive circular economy continues to expand as companies focus on sustainability and resource efficiency. The automotive parts packaging market is valued at USD 6.8 billion in 2024 and is expected to reach USD 9.4 billion by 2033. This growth, at a CAGR of 3.48%, reflects increased automobile production and the rise of e-commerce. Companies in the automotive sector adopt renewable, recycled, and biodegradable packaging materials to meet strict regulations and consumer demand for eco-friendly solutions. The automotive circular economy market as a whole is much larger, valued at USD 148.2 billion, and is projected to grow at a 10.7% CAGR from 2025 to 2034.

Market Segment | Market Size (2024) | CAGR / Growth Rate | Notes |

|---|---|---|---|

Automotive Circular Economy Market | USD 148.2 billion | 10.7% CAGR (2025-2034) | Includes reuse, remanufacturing, recycling, sustainable design |

Automotive Parts Packaging Market | USD 6.8 billion | 3.48% CAGR (2025-2033) | Packaging for automotive parts, not isolated to circular packaging |

Automotive companies lead the adoption of circular packaging, especially in Asia Pacific, where strong production and smart packaging drive growth. Corrugated products, which are recyclable, show the fastest growth at 5.2% CAGR. OEMs invest in durable, eco-friendly packaging, and industry collaborations support new solutions. The automotive circular economy market creates momentum for circular packaging by aligning with regulatory demands and technological innovation.

Electronics Sector Opportunities

The global circular packaging market size is estimated at around USD 252 billion in 2025 and could reach nearly USD 390 billion by 2032, growing at a CAGR of 6.4%. The electronics industry plays a key role in this expansion. Companies face challenges with packaging durability, but they continue to invest in recyclable and biodegradable materials. Consumer demand for sustainable packaging is strong, with 74% of buyers willing to pay more for eco-friendly options.

Electronics manufacturing growth and global trade increase the need for advanced, protective, and sustainable packaging.

Companies invest in smart packaging technologies, such as RFID and IoT, to improve supply chain efficiency and support the circular economy market.

Regulations and incentives encourage the adoption of circular packaging, while innovations in biodegradable plastics and molded fiber packaging help reduce waste.

The shift toward portable and wearable devices drives new packaging solutions that balance protection and environmental responsibility.

The electronics sector benefits from the expanding circular economy market. As companies adopt circular packaging, they gain competitive advantages and meet global sustainability goals. The market expansion in both automotive and electronics creates new opportunities for circular packaging adoption, supporting a more sustainable future.

Adapting Automotive Strategies

Early Integration

Automotive companies have shown that early integration of circular economy principles leads to better packaging outcomes. They start by designing packaging for reuse, recyclability, and durability from the beginning of product development. This approach helps them reduce waste and improve resource efficiency. Electronics manufacturers can follow this model to achieve similar results.

Early adoption of circular economy principles in electronics increases the reuse of packaging materials, especially shipping containers.

Companies like Benchmark have reused durable shipping containers more than ten times without repair, preventing large amounts of landfill waste.

Electronics firms can make sustainable sourcing decisions by partnering with suppliers who offer reusable packaging, which lowers the carbon footprint.

These actions reduce packaging waste, cut costs, and support sustainability goals.

Automotive circular economy leaders also provide practical guidance on packaging materials collection and handling. They recommend specific methods for sorting, space planning, and signage to maximize recyclable material recovery. Electronics companies can adapt these tested approaches to improve their own circular packaging systems. By doing so, they enhance recovery rates and reduce waste.

Early integration of circular packaging strategies helps companies avoid costly redesigns later. It also ensures that packaging supports both environmental and business objectives from the start.

Technology Transfer

The automotive circular economy relies on advanced technology to optimize packaging systems. Companies use digital tools such as IoT, blockchain, and AI to track packaging in real time. These technologies improve monitoring, quality control, and logistics efficiency. Electronics manufacturers can transfer these solutions to their own operations to boost circular packaging performance.

Automotive companies have adopted several strategies that work well in electronics:

They adapt product designs to increase recyclability and durability.

They design products to be repairable and reusable.

They optimize recycling processes and invest in digital solutions.

They review waste management processes and introduce innovative recycling solutions.

They establish strategic partnerships to leverage global material flows and recycling opportunities.

Valeo’s remanufacturing and waste management programs show how automotive companies reuse sub-components and create closed-loop recycling systems. For example, Valeo disassembles headlamps to recover and reuse electronic sub-components, which avoids landfill waste. They also use recycled plastics in new components, even pulverizing non-recyclable parts as filler replacements. These practices highlight the value of reuse, recycling optimization, and innovation sharing across sites.

A table below summarizes best practices for technology transfer from automotive to electronics:

Automotive Practice | Electronics Application |

|---|---|

Closed-loop recycling systems | Improved packaging material recovery |

Packaging redesign for reuse | Longer-lasting, reusable packaging for electronics |

Digital quality assurance tools | Consistent packaging standards and reduced waste |

Life cycle analysis tools | Tracking environmental impact of packaging choices |

Strategic partnerships | Access to global recycling and remanufacturing networks |

Automotive circular economy initiatives have proven that designing for recyclability and integrating circularity principles drive both environmental and financial benefits. Electronics companies that adopt these strategies can improve their circular packaging systems, reduce environmental impact, and gain a competitive edge in the circular economy market.

Companies that transfer technology and best practices from the automotive sector position themselves as leaders in the growing circular economy market. They also meet rising regulatory and consumer demands for sustainable packaging.

Automotive leaders demonstrate that early integration and technology adoption drive circular packaging success. Electronics companies can accelerate progress by embedding circular principles at the design stage and using proven frameworks from automotive. To foster innovation and collaboration, industry stakeholders should:

Set measurable targets and actionable roadmaps.

Invest in track-and-trace platforms for transparent supply chains.

Share reusable packaging solutions across sectors.

These steps help the electronics sector advance circular packaging and achieve greater sustainability.

FAQ

What is circular packaging?

Circular packaging refers to packaging designed for reuse, recycling, or composting. Companies use it to reduce waste and conserve resources. This approach supports environmental goals and helps meet regulatory requirements.

Why should electronics companies adopt circular packaging?

Electronics companies benefit from circular packaging by lowering costs, meeting sustainability targets, and improving brand reputation. Customers prefer products with eco-friendly packaging. Regulations also encourage companies to use recyclable and reusable materials.

How does technology improve circular packaging?

Technology such as RFID, IoT, and AI helps companies track packaging, monitor quality, and optimize logistics. These tools increase transparency, support recycling, and make packaging systems more efficient.

What challenges do companies face with circular packaging?

Companies face challenges like complex supply chains, lack of awareness, and limited infrastructure. They must train staff, invest in new materials, and work with partners to overcome these barriers.

Can circular packaging reduce environmental impact?

Circular packaging reduces environmental impact by minimizing waste and promoting reuse. Companies that use recyclable and compostable materials help protect natural resources and support a cleaner environment.

See Also

Expert Strategies For Overcoming Automotive Supply Chain Challenges

Enhancing Automotive Demand Forecasting Through Data-Driven Insights

Maximizing Efficiency Within Your Automotive Supply Chain Network

Mastering Lean Logistics To Drive High-Tech Manufacturing Growth

Building Strong Supplier Partnerships For High-Tech Manufacturing Innovation