How to Create a Lean Logistics Plan for Maximum Efficiency

Lean logistics planning focuses on streamlining supply chain operations by eliminating waste and non-value-adding activities. This approach enhances efficiency while minimizing operational costs. Studies demonstrate that methods like chi-square testing identify inefficiencies, enabling managers to optimize processes and improve decision-making. These practices not only reduce risks but also transform data into actionable insights, driving measurable improvements in supply chain performance.

JUSDA, a global leader in supply chain solutions, leverages its cutting-edge technology and extensive network to support lean logistics. By integrating advanced tools like JusLink, JUSDA empowers businesses to achieve transparency, efficiency, and cost savings across diverse industries.

Key Takeaways

Lean logistics planning means cutting waste and working faster. This helps companies save money and make customers happier.

Setting clear goals is important to check if plans work. Goals like cutting delivery times by 25% help businesses stay on track.

Working with experts, like JUSDA, makes plans better. This teamwork can improve speed and lower costs.

A step-by-step plan is needed to start lean logistics. Steps include setting goals, picking good partners, and changing things one area at a time.

Always improving is key to lean logistics. Regular feedback and checking data help fix problems and stay ready for changes.

Defining a Lean Future State for Logistics

Envisioning an Optimized Logistics System with Lean Principles

An optimized logistics system built on lean principles prioritizes efficiency, waste reduction, and continuous improvement. Companies like Toyota and Amazon exemplify successful implementation of these principles. Toyota revolutionized the automotive supply chain through its Toyota Production System (TPS), which incorporates Just-in-Time (JIT) inventory and continuous improvement practices. Amazon, on the other hand, leverages data-driven optimization, robotics, and advanced technology to ensure speedy deliveries while minimizing waste.

Company | Description |

|---|---|

Toyota | Implemented the Toyota Production System (TPS) with principles like JIT inventory and continuous improvement, revolutionizing the automotive supply chain. |

Amazon | Utilizes data-driven optimization, robotics, and advanced technology to ensure speedy deliveries and minimal waste in logistics operations. |

By adopting similar strategies, organizations can streamline their logistics operations, reduce costs, and enhance customer satisfaction. Lean logistics planning serves as the foundation for achieving these outcomes, enabling businesses to align their processes with industry best practices.

Setting Measurable Objectives for Efficiency and Cost Reduction

Measurable objectives are essential for evaluating the success of lean logistics strategies. Organizations often set targets such as reducing project delivery times, minimizing budget variances, and shortening lead times. For example, a company may aim to reduce project delivery time by 25% within 12 months or decrease budget variances to less than 5%.

Objective Description | Target Example |

|---|---|

Reduce project delivery time | 25% reduction within 12 months |

Decrease project budget variances | Less than 5% variance |

Reduce time to follow up with leads in sales processes | 50% reduction within three months |

To achieve these goals, organizations should:

Clearly define objectives such as reducing waste, improving quality, or shortening lead times.

Establish baseline metrics to understand the current state and measure improvements.

Regularly track key performance indicators (KPIs) to assess progress.

Lean logistics planning provides the framework for setting and achieving these objectives, ensuring that every step contributes to overall efficiency and cost reduction.

Aligning Goals with JUSDA's Lean Logistics Planning Expertise

Aligning organizational goals with specialized expertise enhances the effectiveness of lean logistics strategies. JUSDA’s extensive experience in supply chain management positions it as a trusted partner for businesses seeking to optimize their logistics operations. Industry case studies validate the impact of aligning goals with expert planning. For instance, Toyota achieved industry-leading vehicle quality by implementing Hoshin Kanri techniques like X-Matrix and A3 reports. Similarly, Intel improved chip performance by cascading objectives across global operations using digital Hoshin boards.

Company | Key Focus Area | Hoshin Kanri Implementation | Outcome |

|---|---|---|---|

Toyota | Vehicle quality | Industry leader in vehicle quality and reliability | |

Intel | Chip performance | Cascading objectives across global operations with digital Hoshin boards | Agility in responding to market demands |

Siemens | Sustainability | Aligning diverse business units towards carbon neutrality goals | Enhanced reputation as a sustainable solutions partner |

JUSDA’s lean logistics planning expertise, supported by tools like JusLink, empowers businesses to align their objectives with actionable strategies. By leveraging JUSDA’s capabilities, organizations can achieve measurable improvements in efficiency, cost reduction, and sustainability.

Developing a Lean Logistics Action Plan

Creating a Step-by-Step Transition Plan

A well-structured transition plan ensures the seamless implementation of lean logistics planning. Organizations can follow a systematic approach to achieve this:

Define operational goals and requirements to establish clear objectives for logistics optimization.

Evaluate and select a logistics partner with proven expertise in lean methodologies.

Map integration points for systems and data to ensure compatibility and efficiency.

Implement changes region by region to minimize disruptions and maintain control.

Establish proactive management practices for continuous improvement and optimization.

This phased approach minimizes risks and allows businesses to adapt to challenges during the transition. JUSDA’s expertise in supply chain solutions provides the necessary support for organizations to execute these steps effectively.

Assigning Roles and Responsibilities Across Teams

Clear role assignment is critical for the success of logistics transitions. Frameworks like the RACI Matrix and digital collaboration platforms streamline this process.

Framework | Description | Benefits |

|---|---|---|

RACI Matrix | Clarifies roles and responsibilities for each team member. | Reduces ambiguity, ensures accountability, and engages stakeholders effectively. |

Digital Platforms | Tools like Slack and Microsoft Teams facilitate communication and updates. | Provides real-time updates, document sharing, and feedback mechanisms for smooth transitions. |

By leveraging these frameworks, organizations can ensure that every team member understands their responsibilities. JUSDA’s JusLink platform enhances collaboration by providing real-time visibility into logistics operations, enabling teams to work cohesively toward shared goals.

Establishing a Timeline for Implementation with JUSDA's Support

A realistic timeline ensures that logistics transitions occur without unnecessary delays. Organizations should prioritize phased implementation, focusing on one region or department at a time. This approach allows teams to address challenges incrementally while maintaining operational efficiency.

JUSDA’s support plays a pivotal role in this process. With tools like JusLink, businesses can monitor progress, identify bottlenecks, and adjust timelines as needed. JUSDA’s global network and expertise in lean logistics planning provide the resources necessary to meet deadlines and achieve measurable improvements.

Implementing and Monitoring Your Lean Logistics Plan

Communicating the Plan to Stakeholders

Effective communication ensures stakeholder alignment and support during the implementation of lean logistics strategies. Tailored communication approaches address specific concerns, fostering trust and engagement. Regular updates through multiple channels, such as email, meetings, and dashboards, keep stakeholders informed about progress and risk mitigation efforts. Involving stakeholders in decision-making processes enhances their sense of ownership and commitment to the plan.

Transparency builds confidence. Acknowledging challenges and providing context demonstrates accountability. Monitoring communication effectiveness through clear KPIs ensures continuous improvement in stakeholder engagement.

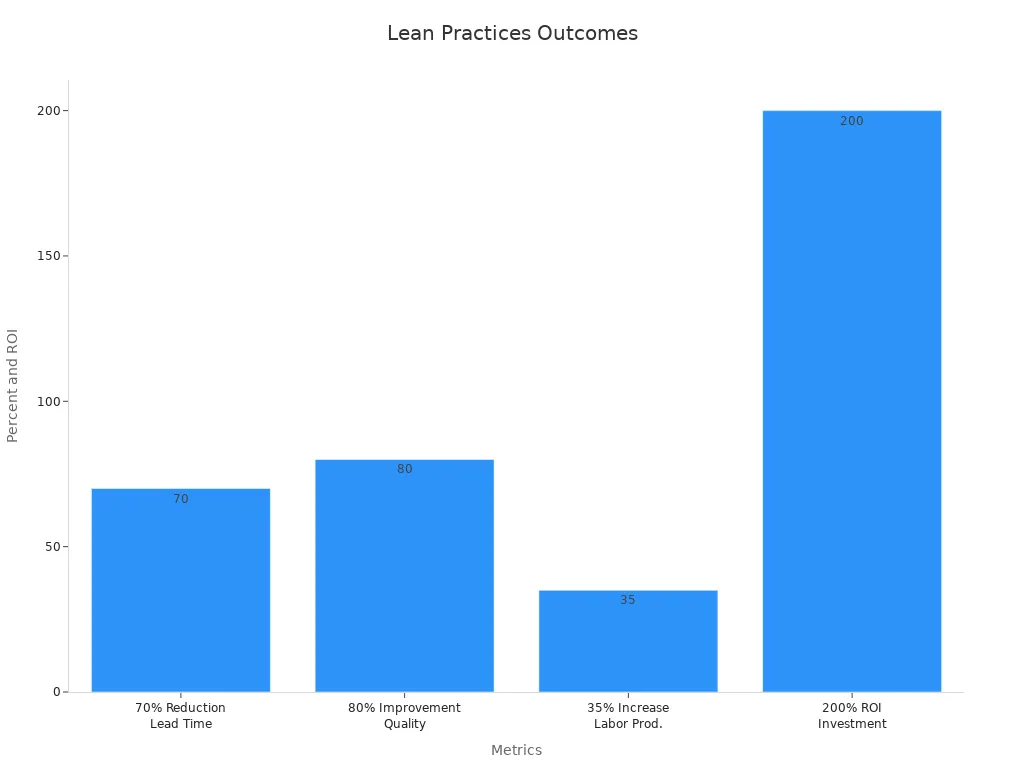

Training Teams on Lean Practices and Tools

Training equips teams with the skills needed to implement lean logistics effectively. Lean management emphasizes regular feedback and process improvement discussions, fostering a culture of accountability and creativity. Teams gain ownership over their work, leading to higher engagement and productivity.

Statistic | Outcome |

|---|---|

Reduces production lead times by 70-90%. | |

25-30% Decrease in Manufacturing Costs | Achieves 25-30% reductions in costs. |

80% Improvement in Quality | Defect reductions averaging 80%. |

35% Increase in Labor Productivity | Yields an average 35% increase in productivity. |

200% Return on Investment | Delivers an average 200% ROI within 12-18 months. |

Lean practices also encourage direct communication between employees and managers, enhancing team morale and operational efficiency. By investing in comprehensive training, organizations can ensure their teams are well-prepared to execute lean logistics planning.

Using JUSDA's JusLink Platform for Real-Time Monitoring

Real-time monitoring is critical for tracking the performance of lean logistics initiatives. JUSDA’s JusLink platform provides advanced analytics and data-driven insights, enabling businesses to make informed decisions. The platform integrates sophisticated tools for performance forecasting, operational metrics tracking, and supply chain agility.

Key Insight | Description |

|---|---|

Emphasizes measurable, data-backed decisions in logistics management. | |

Advanced Analytics | Uses statistical tools for predictable, impactful outcomes. |

Performance Forecasting | Improves forecasting accuracy for supply chain operations. |

Operational Metrics | Tracks system health to enhance operational excellence. |

Agility in Supply Chain | Creates a roadmap for adapting to changes effectively. |

JusLink’s real-time capabilities empower organizations to identify bottlenecks, optimize processes, and maintain transparency across the supply chain. This ensures that lean logistics planning achieves its intended outcomes efficiently.

JUSDA Solutions

To provide you with professional solutions and quotations.

Evaluating and Continuously Improving Your Lean Logistics Plan

Measuring Results Against Lean Objectives

Measuring results is essential for assessing the effectiveness of lean logistics strategies. Key performance indicators (KPIs) provide quantitative insights into logistics operations, enabling organizations to track progress and identify areas for improvement. These metrics evaluate various functions, including purchasing, warehousing, transportation, and delivery.

Receiving efficiency

Capacity utilization

Inventory accuracy

Order fulfillment metrics

By analyzing these KPIs, businesses can determine whether their logistics processes align with lean objectives. For example, tracking inventory accuracy ensures that stock levels meet demand without overstocking, reducing waste and improving efficiency. Similarly, monitoring order fulfillment metrics helps organizations maintain high customer satisfaction by ensuring timely deliveries.

Gathering Feedback from Stakeholders and Teams

Feedback from stakeholders and teams plays a pivotal role in refining logistics processes. Regular feedback sessions foster collaboration and uncover operational challenges that may not be evident through data alone. Engaging employees in discussions about lean practices encourages ownership and accountability, driving continuous improvement.

Open communication channels build trust and ensure that all voices are heard. This approach not only identifies inefficiencies but also fosters a culture of innovation and adaptability.

Stakeholders, including suppliers and customers, provide valuable insights into the broader supply chain. Their feedback helps organizations address external challenges, such as delays or compliance issues, ensuring a more resilient logistics network.

Iterating and Refining Processes with JUSDA's Expertise

Continuous improvement lies at the heart of lean logistics. The Deming Cycle—Plan, Do, Check, Act—offers a structured approach to refining processes. Organizations can follow these steps:

Identify inefficiencies in current logistics operations.

Analyze existing processes to pinpoint root causes.

Develop strategies for improvement and implement changes.

Lean Principle | Key Action | Outcome |

|---|---|---|

Continuous Improvement | Use lean tools like 3P and kaizen. | Enhanced efficiency and reduced waste. |

Leadership Support | Foster lean thinking among employees. | Improved team engagement and innovation. |

JUSDA’s expertise in lean logistics planning ensures that businesses can iterate effectively. Tools like JusLink provide real-time visibility, enabling organizations to monitor changes and adapt quickly. This iterative process not only enhances efficiency but also strengthens the overall supply chain.

Assessing Your Current Logistics State with JUSDA

Evaluating Existing Processes for Waste and Inefficiencies

A thorough evaluation of existing logistics processes is essential for identifying waste and inefficiencies. This step ensures that organizations can optimize their operations and align them with lean principles. JUSDA employs a systematic approach to uncover inefficiencies and streamline logistics workflows. Key methods include:

Regular Equipment/Service Inspections: Routine evaluations of equipment and services help detect operational issues early, ensuring smooth logistics operations.

Data Analysis and Performance Tracking: Advanced analytics tools provide insights into waste patterns, enabling organizations to address inefficiencies effectively.

Training & Education for Employees: Comprehensive training programs empower employees to identify and mitigate waste in their daily tasks.

Engaging Waste Experts: Collaborating with specialists in waste management fosters innovative solutions for optimizing logistics processes.

By leveraging these strategies, businesses can eliminate non-value-adding activities and enhance overall efficiency. JUSDA’s expertise in lean logistics planning ensures that organizations can implement these evaluations seamlessly, driving measurable improvements in their supply chain operations.

Identifying Bottlenecks in Supply Chain Operations

Bottlenecks in supply chain operations can disrupt workflows, increase costs, and delay deliveries. Identifying these bottlenecks requires a data-driven approach. JUSDA utilizes key metrics to pinpoint areas of concern and develop targeted solutions.

Metric | Description |

|---|---|

Current Stock | The amount of inventory currently available in the supply chain. |

The total quantity of products demanded over the previous month. | |

Expected Lead Time | The anticipated time required to fulfill an order. |

Financial Cost of Stock Out | The potential financial loss incurred if an order is not placed in time. |

Financial Cost of Overstock | The risk associated with having excess inventory that may not be sold. |

These metrics provide a comprehensive view of supply chain performance, enabling organizations to identify inefficiencies and implement corrective measures. For example, monitoring expected lead times helps businesses address delays proactively, while analyzing stock levels ensures optimal inventory management. JUSDA’s JusLink platform enhances this process by offering real-time visibility into supply chain operations, allowing businesses to adapt quickly to changing demands.

Analyzing Costs and Resource Utilization in Warehousing

Effective cost analysis and resource utilization are critical for optimizing warehousing operations. JUSDA’s advanced warehousing solutions integrate cutting-edge technology to enhance efficiency and reduce costs. Key areas of focus include:

Key Area | Description |

|---|---|

Optimized through better negotiation and technological integration. | |

Warehousing and inventory management | Enhancements can be achieved through automation and efficient storage practices. |

Administrative and processing charges | Reduced via process automation and integration of smart technologies. |

By analyzing these areas, businesses can identify opportunities for cost savings and resource optimization. For instance, automating inventory management reduces manual errors and improves accuracy, while efficient storage practices maximize warehouse capacity. JUSDA’s JusLink platform provides real-time data on warehousing operations, enabling organizations to make informed decisions and achieve sustainable improvements.

Creating a lean logistics plan involves defining objectives, developing actionable strategies, and continuously refining processes. This approach minimizes waste, enhances operational efficiency, and reduces costs. Businesses adopting lean logistics planning gain a competitive edge by streamlining workflows and improving customer satisfaction.

JUSDA’s expertise in supply chain solutions provides the tools and support necessary for implementing lean logistics effectively. Its innovative platforms, such as JusLink, empower organizations to achieve transparency and measurable improvements. Exploring JUSDA’s solutions ensures businesses can optimize their logistics operations and drive sustainable growth.

FAQ

What is lean logistics planning, and why is it important?

Lean logistics planning focuses on eliminating waste and optimizing supply chain processes. It enhances efficiency, reduces costs, and improves customer satisfaction. Businesses adopting lean logistics gain a competitive edge by streamlining operations and achieving measurable improvements in performance.

How does JUSDA support lean logistics implementation?

JUSDA provides advanced tools like JusLink, real-time monitoring, and tailored supply chain solutions. Its expertise in logistics planning ensures seamless implementation, helping businesses achieve transparency, efficiency, and cost savings across diverse industries.

What industries benefit most from JUSDA’s solutions?

JUSDA serves industries such as automotive, electronics, FMCG, medical health, and heavy equipment. Its tailored solutions address unique challenges, ensuring optimized supply chain operations and improved efficiency for each sector.

How does JusLink enhance supply chain visibility?

JusLink integrates IoT, cloud computing, and big data to provide real-time insights. It tracks inventory, monitors performance, and identifies bottlenecks, enabling businesses to make informed decisions and adapt to changing demands.

Can JUSDA’s solutions help reduce warehousing costs?

Yes, JUSDA’s advanced warehousing solutions optimize storage practices, automate inventory management, and reduce manual errors. These improvements lower operational costs while enhancing efficiency and accuracy in logistics operations.

See Also

Mastering Lean Logistics For Success In Tech Manufacturing

Unlocking Logistics Savings: Expert Tips For Supply Chain Success

Essential Strategies For Optimizing Your Supply Chain Effectively

Reducing Logistics Costs: A Comprehensive Guide For Businesses

JUSDA's Approach To Logistics: Redefining Operational Efficiency