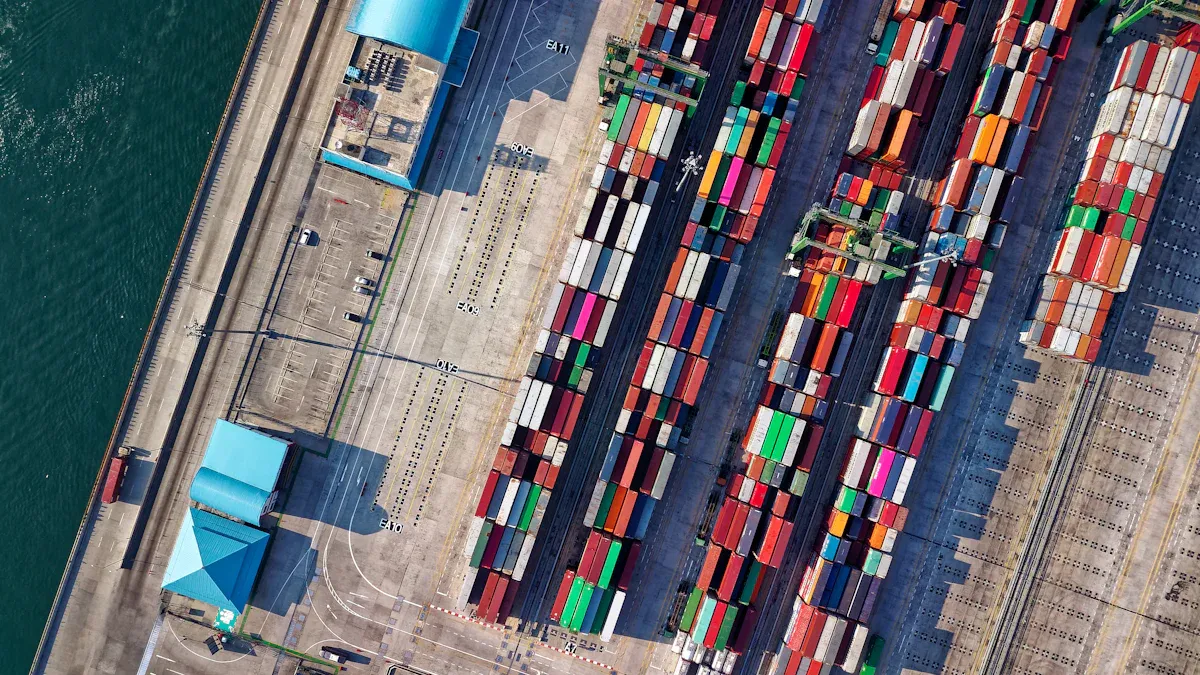

Cross-Border Logistics Landscape in Flux: Airfreight Price Volatility and the Rise of Overseas Warehousing

The global trade environment is experiencing a seismic shift. Cross-border logistics is at the heart of this transformation, driven by fluctuating airfreight prices and the increasing reliance on overseas warehousing. These changes are reshaping supply chains, compelling businesses to rethink their strategies. Companies now face a dual challenge: managing cost unpredictability while meeting growing consumer demands for faster delivery. This evolving landscape offers opportunities for those who adapt quickly and innovate effectively.

Airfreight Price Volatility in Cross-Border Logistics

Causes of Airfreight Price Volatility

Airfreight price volatility stems from several interconnected factors. Policy uncertainty plays a significant role, as seen in the sharp fluctuations caused by speculation over changes to de minimis tax exemptions. For instance, airfreight rates on North American routes dropped by 50% before rebounding when anticipated policy shifts failed to materialize. Additionally, global demand surges, such as those driven by e-commerce platforms like Temu and Shein, have pushed trans-Pacific airfreight costs to $5–$8 per kilogram. Overcapacity in the market further exacerbates volatility, with carriers reallocating excess capacity to maintain market share, intensifying price competition.

Impacts on Global Trade and Supply Chains

Volatile airfreight prices disrupt global trade and supply chains by increasing unpredictability in logistics costs. Businesses face challenges in budgeting and planning, often leading to higher operational expenses. Rising air cargo rates have prompted many companies to shift from air to ocean freight, which, while cost-effective, results in longer transit times. New tariffs and changes to de minimis rules further compound the issue, increasing customs costs and reducing the appeal of air freight.

Research, such as the study "Modeling the volatility of international air freight," highlights how price fluctuations impact supply chain management. The study uses advanced models to demonstrate how businesses adapt their logistics strategies to mitigate risks associated with unpredictable airfreight costs.

Industries Most Affected by Airfreight Price Fluctuations

Certain industries are more vulnerable to airfreight price volatility due to their reliance on timely deliveries. These include:

Automotive: Timely delivery of parts and vehicles is critical, making this sector highly sensitive to cost fluctuations.

Energy: Transportation of equipment and materials faces challenges as airfreight prices rise.

Retail: The growing demand for rapid delivery in e-commerce amplifies the impact of airfreight price changes on this sector.

Overseas Warehousing: A Growing Trend in Cross-Border Logistics

Benefits of Overseas Warehousing for Businesses

Overseas warehousing offers businesses a range of advantages that enhance operational efficiency and customer satisfaction. Localizing inventory reduces transportation costs and delivery times, enabling companies to meet consumer expectations for faster shipping. For example, e-commerce giants like Shein achieve next-day delivery for a significant portion of their U.S. customers by utilizing strategically located warehouses.

Other benefits include improved supply chain management and scalability. Businesses can adjust inventory levels based on demand, ensuring they remain agile in fluctuating markets. Additionally, specialized warehousing solutions cater to industry-specific needs. For instance, pharmaceutical companies benefit from temperature-controlled storage that complies with regulatory standards.

Industry | Benefits |

|---|---|

Automotive | Reduced transportation costs, enhanced supply chain management, and proximity to production facilities. |

Pharmaceutical | Specialized warehousing for temperature-sensitive products, ensuring compliance with regulations. |

SMEs | Cost-effective solutions for market expansion and inventory management without heavy investment. |

Large Enterprises | Advanced technologies for efficiency, integration with ERP systems, and high inventory accuracy. |

Challenges and Risks of Implementing Overseas Warehousing

Despite its benefits, overseas warehousing presents challenges. Establishing and maintaining warehouses in foreign markets requires significant capital investment. Businesses must navigate complex regulatory environments, including customs and tax compliance, which vary by region. Additionally, managing inventory across multiple locations increases operational complexity.

Security risks also arise, particularly in regions with less robust infrastructure. Companies must invest in advanced technologies to safeguard inventory and ensure real-time tracking. Furthermore, fluctuating demand can lead to overstocking or understocking, impacting profitability.

Key Drivers Behind the Adoption of Overseas Warehousing

Several factors drive the growing adoption of overseas warehousing. The rise of e-commerce has created a need for efficient logistics solutions to handle increased order volumes. Businesses are leveraging automation and robotics to enhance warehouse efficiency and reduce costs. Technologies like AI and IoT enable real-time data analysis, improving inventory management and operational decision-making.

Key Driver | Description |

|---|---|

Enhances efficiency and reduces operational costs in warehousing. | |

Increasing Demand for Efficient Management | Businesses seek cost-effective solutions to improve warehouse operations. |

Growth of E-commerce | The rise in online shopping necessitates more efficient warehousing strategies to meet demand. |

Advancements in Technology | Technologies like AI and IoT enable real-time data analysis and autonomous inventory management. |

The cross-border e-commerce logistics market reflects this trend, with projections showing growth from $86.45 billion in 2024 to $103.52 billion in 2025, at a CAGR of 19.7%. By 2034, the market is expected to reach $1,652.06 billion, driven by advancements in warehousing and logistics management systems.

The Intersection of Airfreight Volatility and Overseas Warehousing

How Airfreight Costs Influence Warehousing Strategies

Airfreight costs significantly shape warehousing strategies, especially in cross-border logistics. Businesses often adjust their supply chain models to balance cost efficiency and delivery speed. Since March 2020, air cargo rates have doubled due to limited capacity and rising consumer demand. This surge has forced companies to rethink their reliance on air freight, particularly for time-sensitive goods. Importers and exporters increasingly opt for air freight despite its higher costs when delays in ocean freight disrupt schedules.

The textile and apparel sector exemplifies this shift. During the COVID-19 pandemic, air freight usage in this industry rose from 9% in 2019 to 22% in 2020. The surge in demand for personal protective equipment (PPE) further strained air cargo capacity, driving up costs. These changes prompted businesses to adopt overseas warehousing to mitigate the impact of fluctuating airfreight prices. By storing inventory closer to end markets, companies reduce their dependence on costly air shipments.

The Role of Overseas Warehousing in Mitigating Supply Chain Risks

Overseas warehousing plays a pivotal role in minimizing supply chain risks. By localizing inventory, businesses can shield themselves from the unpredictability of airfreight markets. Warehousing near key consumer regions ensures faster delivery times and reduces reliance on volatile shipping modes. For instance, companies using overseas warehouses can bulk ship goods via ocean freight, which is more cost-effective than air freight, and then distribute them locally.

This strategy also mitigates risks associated with customs delays and regulatory changes. Bulk customs clearance for warehouse-bound shipments faces lower inspection rates compared to individual parcels. Additionally, localized inventory allows businesses to respond swiftly to demand fluctuations, ensuring customer satisfaction even during disruptions.

Case Studies: Businesses Adapting to These Trends

Several companies have successfully adapted to the challenges of airfreight volatility by leveraging overseas warehousing. Shein, a global e-commerce giant, exemplifies this approach. By establishing warehouses in strategic locations like Los Angeles, Shein achieves next-day delivery for a significant portion of its U.S. customers. This model not only reduces shipping costs but also enhances customer satisfaction.

Similarly, during the pandemic, many textile and apparel companies shifted their logistics strategies. The rising airfreight costs for PPE imports highlighted the need for localized inventory. Businesses that adopted overseas warehousing managed to maintain supply chain stability while minimizing costs. These examples underscore the importance of integrating warehousing solutions into cross-border logistics strategies.

Strategies for Businesses to Adapt to the Changing Cross-Border Logistics Landscape

Leveraging Technology for Supply Chain Optimization

Advanced technology is revolutionizing supply chain management, enabling businesses to optimize operations and improve efficiency. Tools like AI and machine learning enhance demand forecasting, increasing accuracy by up to 30%. Real-time tracking solutions provide end-to-end visibility, allowing companies to monitor shipments across multiple transportation modes. These innovations reduce inventory costs by 15-30% and improve order fulfillment cycles by 20-50%, as highlighted by McKinsey & Company.

Automation also plays a critical role in streamlining logistics. Automated guided vehicles and robotics improve warehouse efficiency, while driver routing applications optimize delivery routes. Despite these advancements, only 16% of companies currently use automated fleet tour planning, indicating significant room for growth. By adopting these technologies, businesses can reduce operating costs, enhance collaboration, and achieve better inventory turnover.

Diversifying Supply Chains to Mitigate Risks

Diversifying supply chains is a proven strategy for mitigating risks associated with disruptions like airfreight price fluctuations. Multisourcing and multishoring expand supplier pools geographically, enhancing resilience against local and regional challenges. For example, during labor strikes, companies with diverse supplier networks adapted more effectively than those relying on single sources.

However, geographic diversification alone may not always suffice. During the Chinese lockdown in early 2020, firms with higher inventory levels managed disruptions better than those relying solely on alternative suppliers. This underscores the importance of combining diversification with robust inventory management. Businesses must also invest in complex logistics planning to ensure the effectiveness of multishoring strategies.

Adopting Sustainable Practices in Logistics

Sustainability is becoming a cornerstone of modern logistics. Companies adopting green practices benefit from reduced emissions, cost savings, and enhanced brand reputation. For instance, the automotive sector has achieved a 30% reduction in emissions by implementing green logistics strategies. These efforts align with regulatory standards, improving operational flexibility and reducing legal risks.

Metric | Description |

|---|---|

Regulatory Alignment | Compliance with emissions standards, enhancing operational flexibility and reducing legal risks. |

Operational Efficiency | Improved resource utilization and reduced fuel costs, leading to higher profit margins. |

Enhanced Resilience | Increased adaptability to challenges, ensuring business continuity and stakeholder confidence. |

Market Differentiation | Strengthened brand reputation and market position by meeting consumer demand for sustainability. |

Sustainable logistics also contribute to global environmental goals. Cleaner operations reduce carbon emissions and pollution, preserving ecosystems and biodiversity. Companies can further enhance sustainability by optimizing routes, improving load efficiency, and recycling materials, generating both environmental and financial benefits.

Building Resilience Through Strategic Partnerships

Strategic partnerships play a crucial role in fortifying supply chains against disruptions. Businesses that collaborate with reliable partners gain access to diversified resources, shared expertise, and enhanced operational agility. These partnerships enable companies to adapt swiftly to unforeseen challenges, ensuring continuity in global trade.

Tip: Resilient supply chains rely on proactive collaboration with partners who prioritize flexibility and innovation.

Several practices validate the effectiveness of strategic partnerships in building resilience:

Agility: Incorporating agile practices allows supply chain managers to respond quickly to disruptions.

Stress Testing: Simulating disaster scenarios helps identify vulnerabilities in supply chain design.

Diversification: Multisourcing and diversifying supply channels reduce dependency on single sources.

Strategic Inventory Management: Maintaining buffer capacity prevents inventory shortages during crises.

Local Sourcing: Nearshoring minimizes reliance on fragile global networks, ensuring faster recovery.

Recent events highlight the importance of these strategies. The Covid-19 pandemic exposed significant weaknesses in global supply chains. A British parliamentary committee reported food shortages caused by logistical disruptions, underscoring the need for resilient systems. Similarly, the White House’s Executive Order on Supply Chain Security advocates for secure and diverse supply chains to mitigate risks.

Partnerships also foster innovation. Collaborative efforts often lead to the adoption of advanced technologies, such as AI-driven inventory management and IoT-enabled tracking systems. These tools enhance visibility and efficiency, enabling businesses to anticipate and address challenges effectively.

By leveraging strategic partnerships, companies can transform vulnerabilities into opportunities. Resilient supply chains not only withstand disruptions but also thrive in dynamic markets, ensuring long-term success in cross-border logistics.

Airfreight price volatility and the rise of overseas warehousing are transforming global logistics. These trends demand businesses to rethink their strategies to remain competitive in an evolving trade environment.

Adaptation is key: Companies must embrace technology to optimize supply chains and improve efficiency.

Diversification matters: Expanding supplier networks and warehousing locations enhances resilience.

Sustainability drives success: Green logistics practices reduce costs and align with consumer expectations.

Pro Tip: Businesses that stay proactive and flexible can turn these challenges into opportunities, ensuring long-term growth in the dynamic global market.

See Also

Understanding Trends in Logistics Risk Management Today

Transforming Logistics Through Innovative Supply Chain Solutions

Addressing Global Supply Chain Growth Challenges Effectively