Digital Integration and Connectivity in Supply Chains 2025

Digital integration and connectivity in supply chain management are transforming global operations as businesses prepare for 2025. Companies are leveraging technologies like AI, IoT, and blockchain to enhance efficiency, visibility, and decision-making. AI enables predictive analytics and real-time data collection, improving forecasting and operational accuracy. IoT revolutionizes asset management by offering real-time tracking, while blockchain ensures transparency and security, critical for industries like pharmaceuticals. These innovations drive sustainability and scalability, as seen in Walmart's emission reduction goals and Unilever's sustainable packaging initiatives. Such advancements highlight the future of digital supply chain innovation.

Key Technologies Shaping Digital Supply Chains in 2025

Artificial Intelligence and Machine Learning in Supply Chain Management

Predictive analytics for demand forecasting

Artificial intelligence (AI) has revolutionized supply chain management by enhancing predictive analytics. By analyzing historical data and market trends, AI enables businesses to forecast demand with remarkable accuracy. This capability minimizes overstocking and stockouts, ensuring optimal inventory levels. Companies like Walmart and Alibaba leverage machine learning (ML) to analyze sales data, seasonality, and customer behavior, enabling them to stock products efficiently. These advancements contribute to the widespread adoption of technology in supply chains, making them future-fit and resilient.

Automation in decision-making and operations

AI-driven automation streamlines decision-making and operational processes. It processes large datasets to identify patterns, optimize workflows, and improve efficiency. For instance, Amazon uses AI to optimize warehouse layouts and delivery routes, reducing human error and operational costs. Similarly, UPS employs ML to analyze traffic patterns and weather conditions, ensuring timely deliveries. These innovations not only enhance efficiency but also support climate-smart supply chain planning by reducing emissions through optimized logistics.

Internet of Things (IoT) for Real-Time Connectivity

Real-time tracking and monitoring of goods

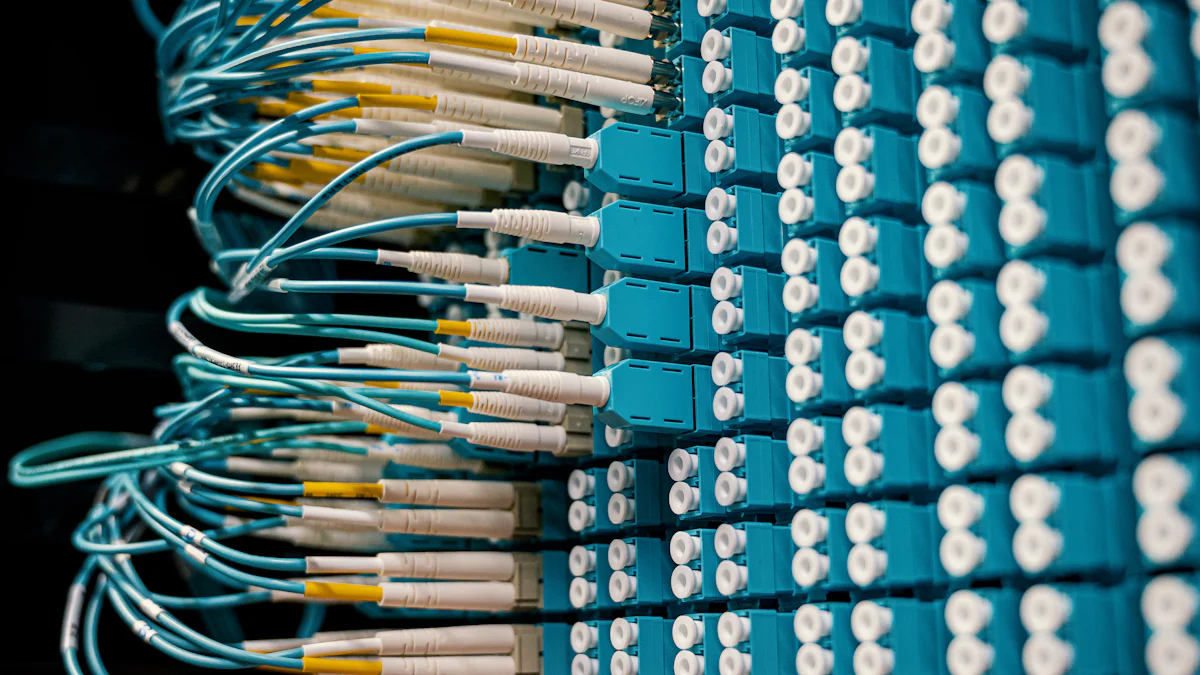

The Internet of Things (IoT) has transformed supply chain management by enabling real-time data integration. IoT sensors provide continuous insights into the location and condition of goods, ensuring supply chain transparency. Businesses can monitor shipments globally, improving risk prediction and operational efficiency. For example, RFID tags and smart shelves automate inventory tracking, reducing manual errors and enhancing traceability. These technologies play a crucial role in building a global supply chain network that is both efficient and sustainable.

Enhanced visibility across the supply chain

IoT enhances visibility by collecting real-time data from connected devices. This data allows supply chain partners to identify inefficiencies and optimize logistics. Predictive maintenance, enabled by IoT, minimizes downtime and operational costs. Additionally, real-time tracking improves customer satisfaction by providing transparency about order status. These advancements align with the future of supply chain sustainability, ensuring seamless operations and enhanced traceability.

Blockchain for Transparency and Security

Ensuring transparency and traceability

Blockchain technology ensures transparency and traceability across supply chains. Each transaction is recorded on a tamper-proof ledger, allowing businesses to trace products back to their origin. For example, manufacturers use blockchain to track canned tuna from its shipping source, reducing the risk of recalls. This enhanced traceability supports supply chain sustainability by ensuring ethical sourcing and compliance with environmental standards.

Strengthening security in transactions

Blockchain enhances security by encrypting transactions with digital signatures, making them tamper-proof. Distributed data storage protects against cyberattacks, ensuring the integrity of supply chain operations. Each partner in the supply chain has a unique digital signature, securing transactions like purchase orders. This technology creates a trustworthy audit trail, fostering confidence among stakeholders and supporting the future of digital supply chain management.

JusLink: A Comprehensive Digital Supply Chain Solution

AI-driven sales forecasting and replenishment

JusLink leverages artificial intelligence to transform sales forecasting and inventory management. Its advanced algorithms analyze historical sales data, market trends, and external factors to predict demand with precision. This capability allows businesses to maintain optimal inventory levels, reducing the risks of overstocking or stockouts.

Tip: Accurate demand forecasting not only minimizes costs but also ensures customer satisfaction by meeting delivery expectations.

JusLink’s intelligent replenishment system dynamically adjusts inventory based on real-time data. It evaluates sales velocity, seasonal trends, and supply chain disruptions to recommend timely restocking. This proactive approach ensures seamless operations, even during peak demand periods. Businesses using JusLink can achieve significant cost savings while maintaining high service levels.

Intelligent risk management and real-time monitoring

JusLink’s Control Tower Intelligent Risk Management system provides unparalleled visibility into supply chain risks. By integrating external data sources, such as weather forecasts and geopolitical updates, it identifies potential disruptions before they occur. This feature enables businesses to take preventive actions, safeguarding their operations.

Note: Real-time risk monitoring is essential for industries like pharmaceuticals and electronics, where delays can have critical consequences.

The platform’s real-time monitoring capabilities extend to shipment tracking and anomaly detection. JusLink uses IoT-enabled sensors to monitor cargo conditions, ensuring compliance with quality standards. Automated alerts notify stakeholders of deviations, allowing swift corrective measures.

JusLink empowers businesses to navigate complex supply chains with confidence. Its risk management tools enhance decision-making, while real-time monitoring ensures operational efficiency. These features position JusLink as a vital asset for companies aiming to thrive in the digital supply chain era.

Challenges in Achieving Digital Integration in Supply Chains

High Initial Investment Costs

Budget constraints for small and medium businesses

Small and medium businesses (SMBs) often face financial hurdles when adopting digital supply chain strategies. Limited budgets make it challenging to invest in advanced technologies like AI, IoT, and blockchain. However, SMBs can overcome these constraints by adopting cost-effective approaches:

Embracing cloud computing for scalable and affordable solutions.

Implementing automation to streamline operations and reduce manual tasks.

Outsourcing selectively to access expertise without long-term commitments.

Regularly reviewing software strategies to align with business objectives.

These methods enable SMBs to achieve digital integration without straining their financial resources.

Balancing ROI expectations

Businesses must balance the high upfront costs of digital transformation with long-term returns. Measuring ROI involves tracking internal and customer-facing KPIs, such as on-time deliveries and reduced backorder rates. Continuous evaluation helps refine processes and prioritize future investments. This approach ensures that businesses maximize the value of their digital initiatives while maintaining financial stability.

Data Security and Privacy Concerns

Protecting sensitive supply chain data

Digital supply chains handle vast amounts of sensitive data, making them vulnerable to breaches. Common risks include attackers targeting vendors, unpatched software vulnerabilities, and compromised hardware. Poor security practices by lower-tier suppliers further exacerbate these risks. Businesses must adopt robust measures to safeguard data and maintain supply chain transparency.

Resistance to Change in Supply Chain Management

Overcoming organizational inertia

Resistance to change often stems from fear of the unknown, lack of trust in leadership, or exclusion from decision-making. Effective communication of the vision and benefits of change is crucial. Involving stakeholders in the design and implementation process fosters a sense of ownership and reduces resistance. Aligning incentives with desired outcomes further motivates employees to embrace change.

Training employees for new technologies

Adopting new technologies requires equipping employees with the necessary skills. Effective training methods include:

On-demand training for flexible learning schedules.

Tailored training specific to roles for targeted skill development.

Cross-functional teams to enhance visibility across the supply chain.

Continuous learning systems ensure employees remain adaptable, enabling businesses to thrive in a rapidly evolving landscape.

Integration Complexity in Digital Supply Chains

Ensuring compatibility between legacy systems and new technologies

Integrating legacy systems with modern digital technologies presents a significant challenge for businesses. Older systems often lack the flexibility required to adapt to advanced solutions, creating barriers to seamless digital transformation. Compatibility issues frequently arise when outdated infrastructure cannot communicate effectively with new platforms. These mismatches can lead to errors, delays, and inefficiencies across the supply chain.

Organizations must invest heavily in custom coding to bridge the gap between incompatible systems. This process demands substantial financial and technical resources, which can strain budgets, particularly for small and medium-sized enterprises. Additionally, the time required to implement these changes can disrupt ongoing operations.

Tip: Businesses can mitigate these challenges by adopting modular systems that allow incremental upgrades, reducing the need for complete overhauls.

Resistance to change further complicates integration efforts. Employees accustomed to legacy systems may hesitate to adopt new technologies, slowing the transition process. Clear communication about the benefits of digital transformation and comprehensive training programs can help overcome this resistance.

Managing multi-stakeholder coordination

Digital supply chains involve multiple stakeholders, including suppliers, manufacturers, logistics providers, and customers. Coordinating these diverse entities requires robust communication and collaboration tools. However, differences in technology adoption levels and operational priorities can create friction.

Note: Effective stakeholder management is crucial for ensuring smooth operations and achieving shared goals.

Disparate systems used by various stakeholders often lack interoperability, complicating data sharing and decision-making. This fragmentation can result in misaligned objectives, delayed responses, and reduced efficiency. Establishing standardized protocols and leveraging platforms like JusLink can streamline coordination by providing a unified interface for all participants.

Building trust among stakeholders is equally important. Transparent communication and shared performance metrics foster collaboration and accountability. By addressing these complexities, businesses can create a cohesive and resilient digital supply chain ecosystem.

Strategies for Implementing Digital Integration in Supply Chains

Developing a Clear Digital Roadmap for 2025

Setting realistic goals and timelines

A clear digital roadmap is essential for achieving supply chain integration by 2025. Businesses must define a vision that aligns with their objectives and ensures strong leadership to guide the transformation. Setting realistic goals and timelines allows organizations to manage resources effectively and measure progress. Digital transformation requires more than digitizing existing processes. It involves reimagining supply chain operations to leverage technology for maximum efficiency.

Prioritizing key areas for digital transformation

Organizations should focus on areas that deliver the most value. Enhancing visibility enables real-time tracking of products and customer demand. Automating manual processes improves efficiency and reduces errors. Increasing production throughput minimizes lead times, while fostering collaboration among stakeholders ensures seamless operations. These priorities help businesses achieve sustainability and remain competitive in the evolving landscape of supply chain management.

Leveraging Solutions like JusLink for Digital Supply Chain Success

Accessing scalable and customizable tools

JusLink offers businesses a scalable and customizable platform to address the complexities of modern supply chains. Its microservices architecture allows companies to tailor features to their specific needs. This flexibility ensures that businesses of all sizes can adopt JusLink without overhauling their existing systems. By integrating advanced technology, JusLink empowers organizations to optimize operations and improve risk prediction.

Enhancing visibility and collaboration with JusLink

JusLink enhances visibility by providing real-time data on inventory, shipments, and supply chain risks. Its intelligent risk management tools enable businesses to predict and mitigate disruptions effectively. The platform fosters collaboration among stakeholders by offering a unified interface for communication and decision-making. This level of integration ensures that all participants work toward shared goals, improving overall efficiency and resilience.

JusLink Solutions

To provide you with professional solutions and quotations.

Fostering a Culture of Innovation and Adaptability

Encouraging employee buy-in and adaptability

Employee buy-in is critical for successful digital transformation. Businesses should involve employees in the planning process to address their concerns and insights. Sharing the vision and benefits of digital initiatives fosters trust and motivation. Leaders must prioritize user-friendly technology to encourage adoption and maintain open communication channels for feedback. A structured rollout plan ensures a smooth transition, aligning employees with organizational goals.

Providing training and upskilling opportunities

Training equips employees with the skills needed to adapt to new technologies. Project-based learning encourages problem-solving, while on-demand training offers flexibility. Tailored programs address specific roles, ensuring targeted skill development. Cross-functional teams enhance visibility across the supply chain, promoting collaboration. Continuous learning systems prepare employees for future challenges, enabling businesses to thrive in a dynamic environment.

Ensuring Robust Data Management and Security

Implementing strong cybersecurity measures

Digital supply chains face increasing threats from cyberattacks, making robust cybersecurity measures essential. Businesses must adopt a comprehensive risk management framework that incorporates Cyber Supply Chain Risk Management (C-SCRM) principles. This approach ensures that vulnerabilities across the supply chain are identified and mitigated effectively.

Insight: Regina Lewie, a senior vice president and chief risk officer, emphasized the importance of third-party risk management. She stated, "You can’t talk about risk management without addressing third-party risk and business resiliency."

Organizations should conduct thorough due diligence when selecting vendors to assess their cybersecurity posture. Regular security assessments and audits of existing vendors help evaluate their controls and ensure compliance with cybersecurity standards. Contracts with supply chain providers must include stringent cybersecurity requirements to safeguard sensitive data.

Continuous monitoring and detection mechanisms play a critical role in identifying cyber threats in real time. These systems enable businesses to respond swiftly to potential breaches, minimizing disruptions. Additionally, regular cybersecurity awareness training for employees and stakeholders strengthens the overall security framework.

Tip: Implementing these measures not only protects data but also enhances trust among supply chain partners, fostering long-term collaboration.

Establishing data governance policies

Effective data governance policies ensure the integrity and reliability of supply chain data. Businesses must begin by mapping out and assessing the value chains of their major products to identify potential risks. Thorough documentation and analysis of these risks provide valuable insights for developing mitigation strategies.

Regular audits guarantee data consistency across the supply chain. Validation procedures at data entry points help verify accuracy, while data cleansing removes outdated or incorrect information. These practices ensure that supply chain operations rely on high-quality data.

Note: Adhering to regulatory requirements like GDPR and CCPA is crucial for maintaining customer trust and avoiding legal complications.

Clear and consistent data enhances collaboration among supply chain partners. Standardized information eliminates confusion, ensuring that all stakeholders operate with the same understanding. This approach improves communication, streamlines processes, and reduces redundancies.

Benefits of Data Governance:

Increased Efficiency: Faster decision-making and quicker response times.

Cost Savings: Reduced operational costs through minimized errors.

Customer Satisfaction: Accurate deliveries improve the overall customer experience.

By implementing robust data governance policies, businesses can optimize their supply chain operations and build a resilient digital ecosystem.

Digital integration and connectivity in supply chain management are poised to redefine global operations by 2025. Businesses adopting these advancements will unlock unparalleled opportunities for efficiency improvements, visibility, and innovation. Enhanced collaboration, actionable insights, and cost savings will empower organizations to build future-fit supply chains. Technologies like AI, IoT, and blockchain will drive sustainability by reducing waste and improving resource utilization.

JUSDA, with its JusLink platform, exemplifies leadership in digital supply chain transformation. By offering scalable tools and real-time monitoring, it enables businesses to navigate complexities with confidence. Companies embracing digital supply chain strategies will achieve sustainability, resilience, and a competitive edge in the global market.

Insight: 50% of organizations using digital tools are more likely to meet sustainability targets, showcasing the direct link between digital integration and supply chain sustainability.

The future of supply chain management lies in leveraging technology to create climate-smart supply chain planning. Businesses must act now to secure their place in this evolving landscape.

See Also

Exploring Digital Twins: Transforming Supply Chain Management

Discovering AI Integration: Shaping Tomorrow's Supply Chain

Revolutionizing Logistics: The Role of AI in Supply Chains

Get Prepared: Innovations in Transport Tech for Supply Chains