Effective Trade Strategies for High-Tech Manufacturing Growth

High-tech industries play a pivotal role in driving global economic activity, with high-tech manufactures constituting nearly 13% of total U.S. production. The strength of global economic activity within these industries is particularly notable, accounting for about 10% of total Japanese manufacturing. In 2024, significant transformations are anticipated in the high-tech manufacturing sector, presenting both challenges and opportunities for businesses. High-tech manufacturing encompasses diverse sectors such as pharmaceuticals, medical devices, aeronautics, space, defense manufacturing, automotive manufacturing, and electronics. Trade solutions are expected to play a crucial role in facilitating global trade within these industries.

Understanding High-Tech Manufacturing

Definition and Scope

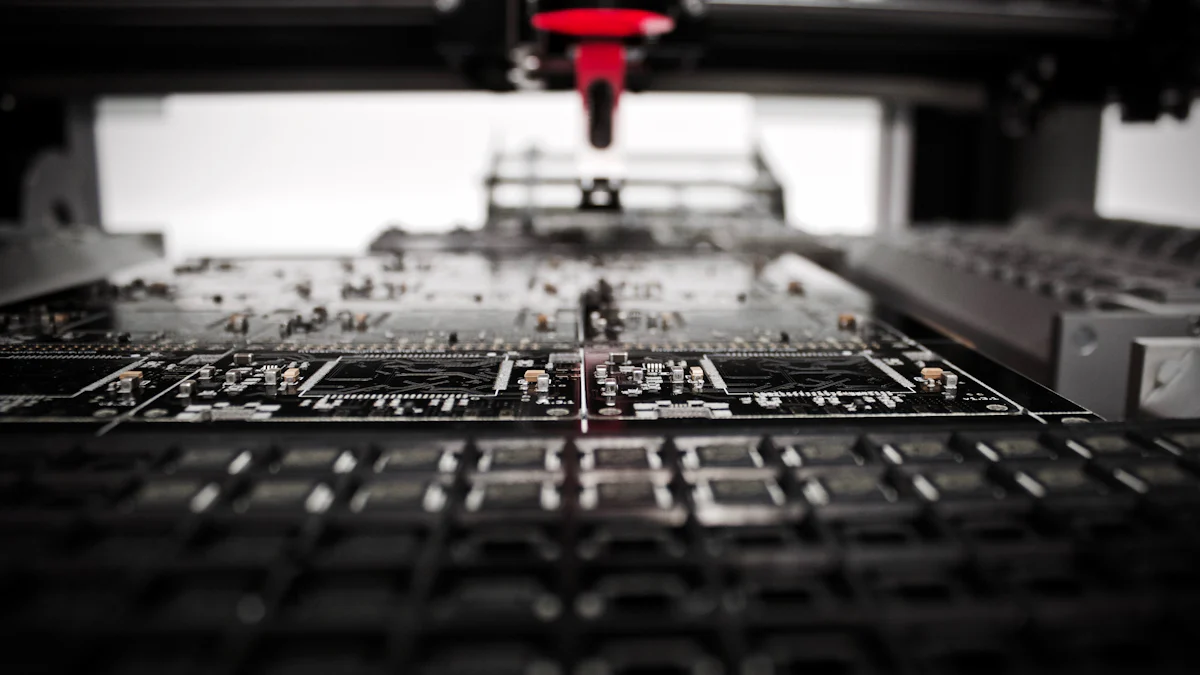

High-tech manufacturing, a subset of the manufacturing industry, focuses on products with advanced technologies like circuit boards, semiconductors, fiber optic cables, and capacitors.

Some definitions expand high-tech manufacturing to include chemical processing and the production of drugs and medicines.

Key Characteristics

Precision Engineering: Products are meticulously crafted to meet exact specifications.

Innovation-Driven: Constant research and development lead to cutting-edge solutions.

Complex Assembly: Components are intricately assembled using state-of-the-art machinery.

Major Players in the Industry

Leading companies in high-tech manufacturing include global giants specializing in electronics, aerospace, pharmaceuticals, and defense.

These players drive innovation and set benchmarks for quality and technological advancement.

Current Trends and Innovations

Technological Advancements

Continuous advancements in automation, robotics, and artificial intelligence revolutionize production processes.

Integration of Internet of Things (IoT) enhances connectivity across manufacturing operations.

Market Dynamics

Rapid globalization opens new avenues for market expansion and international collaborations.

Increasing focus on sustainability drives eco-friendly practices throughout the supply chain.

Importance of Trade Strategies

Enhancing Competitiveness

To enhance competitiveness in the high-tech manufacturing industry, companies must focus on implementing cost reduction techniques and quality improvement methods effectively. By optimizing these areas, businesses can strengthen their position in the market and drive sustainable growth.

Cost Reduction Techniques

Implementing Lean Manufacturing Principles:

Streamlining production processes to eliminate waste and improve efficiency.

Reducing unnecessary inventory levels to minimize storage costs.

Outsourcing Non-Core Activities:

Partnering with specialized service providers to reduce operational expenses.

Leveraging economies of scale by collaborating with external vendors for cost-effective solutions.

Investing in Sustainable Practices:

Adopting energy-efficient technologies to lower utility expenses.

Recycling materials and reducing waste to cut down on disposal costs.

Quality Improvement Methods

Implementing Total Quality Management (TQM):

Fostering a culture of continuous improvement to enhance product quality.

Empowering employees to participate in quality control initiatives for better outcomes.

Conducting Regular Quality Audits:

Performing systematic evaluations of manufacturing processes to identify areas for improvement.

Addressing quality issues promptly to maintain high standards across all operations.

Embracing Advanced Technologies:

Integrating cutting-edge tools for quality assurance and testing procedures.

Investing in training programs to upskill employees on new technologies for improved quality control.

Market Expansion

Expanding into new markets is essential for high-tech manufacturing companies looking to diversify their customer base and increase revenue streams. By identifying untapped opportunities and developing effective strategies for market penetration, businesses can achieve sustainable growth and global recognition.

Identifying New Markets

Conducting Market Research:

"Optimizing market expansion strategy by learning from mistakes, adapting products/services, and adjusting strategies based on analysis and insights."

Analyzing consumer trends and preferences in potential target markets.

Evaluating competitors' market presence and identifying gaps for entry.

Assessing Business Capacity:

"Different approaches to market expansion including competitive pricing, competitor analysis, evaluating business capacity, and resources."

Evaluating internal capabilities and resources available for market expansion.

Aligning product offerings with the demands of new markets for strategic positioning.

Strategies for Market Penetration

Competitive Pricing Strategies:

Offering competitive prices without compromising on product quality.

Implementing promotional campaigns tailored to attract customers in new markets.

Product Localization Initiatives:

Adapting products or services to meet the cultural preferences of target markets.

Collaborating with local partners or distributors for better market penetration opportunities.

Key Trade Strategies for Growth

Supply Chain Optimization

Efficient Inventory Management

Implementing advanced technologies like Artificial Intelligence (AI) and Machine Learning (ML) can streamline inventory management processes.

Utilizing predictive maintenance tools to anticipate inventory needs and prevent shortages.

Enhancing data security measures to protect sensitive inventory information.

Supplier Relationship Management

Establishing clear communication channels with suppliers to ensure timely deliveries and quality control.

Implementing blockchain technology for transparent and secure supplier transactions.

Leveraging autonomous vehicles and drones for efficient supplier interactions.

Leveraging Technology

Automation and Robotics

Integrating Autonomous mobile robots (AMR) into manufacturing processes to optimize efficiency.

Implementing automation solutions to reduce manual labor and enhance production speed.

Utilizing cloud computing for real-time data analysis and decision-making.

Data Analytics and AI

Harnessing the power of Internet of Things (IoT) devices for data collection and analysis.

Applying advanced analytics and big data techniques to extract valuable insights from manufacturing operations.

Using AI algorithms for predictive maintenance, quality control, and demand forecasting.

Strategic Partnerships

Collaborations and Alliances

Forming strategic alliances with industry partners to share resources, knowledge, and expertise.

Collaborating on research and development projects to drive innovation in high-tech manufacturing.

Establishing long-term partnerships based on mutual trust, respect, and shared goals.

Joint Ventures and Mergers

Exploring joint venture opportunities to expand market reach and diversify product offerings.

Considering mergers with complementary companies to strengthen competitive advantages.

Evaluating potential synergies in technology, distribution channels, or market presence.

Case Studies and Examples

Successful Implementations

Company A's Strategy

Case Study: Successful Forex Trading Case Studies

Path to Success:

Implemented a diverse trading approach to capitalize on market fluctuations.

Utilized a combination of technical analysis and fundamental research for informed decisions.

Demonstrated consistent profitability through risk management strategies.

Valuable Lessons Learned:

Adapting to changing market conditions is essential for sustained success.

Balancing risk and reward is crucial in optimizing trading performance.

Continuous learning and skill development are key drivers of long-term profitability.

Company B's Approach

Case Study: Market Situations Case Studies

Creating Big Gains:

Leveraged market volatility to identify lucrative trading opportunities.

Employed a disciplined trading strategy based on thorough market analysis.

Achieved substantial gains by diversifying investment portfolios effectively.

Resourceful Insights:

Timing and precision play vital roles in maximizing trading outcomes.

Strategic decision-making based on data-driven insights leads to profitable trades.

Managing emotions and adhering to predefined trading rules are critical for success.

Lessons Learned

Best Practices

Case Study: Options Trading Case Studies

Exploring Strategies:

Examined successful and not-so-successful options trading approaches for comprehensive insights.

Integrated risk management techniques to mitigate potential losses effectively.

Revealing Potential and Pitfalls:

Highlighted the importance of thorough market research before executing trades.

Emphasized the significance of adapting strategies based on evolving market conditions.

Common Pitfalls

Case Study: Trader Improvement Case Study

Demonstrating Improvement:

Showcased real-life examples of traders enhancing their strategies over time.

Illustrated the impact of continuous learning and adaptation in achieving trading goals.

Enhancing Strategy Effectiveness:

Emphasized the value of analyzing past trades to identify areas for improvement.

Encouraged traders to seek mentorship and peer support for ongoing development.

FAQs and Best Practices

Common Questions

Addressing Trade Barriers

Identifying Trade Barriers: Understanding the various obstacles that hinder international trade is crucial for high-tech manufacturing companies. By recognizing trade barriers such as tariffs, quotas, and regulatory restrictions, businesses can strategize effectively to navigate these challenges.

Resolving Trade Disputes: When faced with trade disputes, companies must engage in diplomatic negotiations and seek resolution through established channels. Maintaining open communication with trading partners and government authorities can help mitigate conflicts and ensure smooth trade operations.

Adapting to Regulatory Changes: Staying informed about evolving trade regulations and compliance requirements is essential for high-tech manufacturers. Adapting swiftly to regulatory changes ensures seamless cross-border transactions and minimizes disruptions in supply chains.

Managing Risks

Risk Assessment Strategies: High-tech manufacturing firms should conduct comprehensive risk assessments to identify potential threats to their global trade operations. By evaluating risks related to currency fluctuations, geopolitical instability, and supply chain disruptions, companies can proactively implement risk mitigation measures.

Implementing Risk Management Plans: Developing robust risk management plans is vital for mitigating uncertainties in international trade. Establishing contingency measures, diversifying suppliers, and investing in insurance coverage are effective strategies to manage risks effectively.

Leveraging Technology for Risk Monitoring: Utilizing advanced technologies like blockchain and predictive analytics enables high-tech manufacturers to monitor risks in real-time. Automated risk detection systems provide early warnings of potential disruptions, allowing companies to take proactive measures promptly.

Best Practices

Continuous Improvement

Embrace a Culture of Innovation: Encouraging a culture of continuous improvement fosters creativity and drives innovation within high-tech manufacturing organizations.

Implement Feedback Mechanisms: Establish feedback loops with employees, customers, and suppliers to gather insights for process enhancement and product development.

Invest in Employee Training: Providing ongoing training programs equips staff with the latest skills and knowledge required for adapting to industry advancements.

"Continuous improvement is not about perfection but rather about constant progress towards excellence."

Staying Updated with Trends

Monitor Industry Developments: Stay abreast of emerging trends in high-tech manufacturing by actively engaging with industry publications, attending conferences, and networking with experts.

Collaborate with Research Institutions: Partnering with research institutions allows access to cutting-edge technologies and facilitates collaboration on innovative projects.

Engage in Continuous Learning: Encourage employees at all levels to participate in professional development activities like workshops, webinars, and online courses.

"Staying updated with industry trends ensures that high-tech manufacturers remain competitive in a rapidly evolving market landscape."

To manage trade risk effectively, businesses can utilize strategies such as hedging, diversification of suppliers and customers, monitoring global economic and political trends, contingency planning, and negotiating contracts.

Market expansion strategies play a vital role in the growth and success of businesses by enabling revenue growth, accessing new customers, and mitigating risks through globalization and technological advancements.

Each trading strategy has its usefulness based on the trader's style and market conditions. Adapting these strategies to individual preferences is crucial for maximizing success in financial markets.

See Also

Collaborative Innovation: Improving Vendor Partnerships in Technology Manufacturing

Unlocking Achievement: Explanation of Technology Manufacturing Consulting

Guiding Efficient Logistics for Success in Technology Manufacturing

Efficient Solutions for Technology Manufacturing's Supply Chain Challenges