Exploring Solutions for Electronic Components Logistics Supply Chain

Logistics plays a pivotal role in ensuring the seamless flow of electronic components across global supply chains. Efficient logistics management has significantly reduced lead times for critical components like DDR4/LPDDR4 memory chips, which now take 9-16 weeks instead of 20-30 weeks—a reduction of up to 55%. However, industries relying on these components face persistent challenges. Supply chain disruptions affect 41% of operations, while regulatory and trade issues account for 28%. These hurdles underscore the need for innovative solutions to enhance supply chain efficiency and meet the growing demand, projected to drive the semiconductor market to $611 billion by 2024.

Key Takeaways

Good logistics can cut waiting times for parts by 55%. This helps the supply chain work better.

Companies should use flexible plans to handle fast tech changes and short product lives.

Using many suppliers and smart tools can lower risks from global issues and supply problems.

Storing goods in special warehouses can save money by delaying taxes.

Predictive tools help businesses guess demand, manage stock, and make better choices.

Key Challenges in the Electronic Components Logistics Supply Chain

Sourcing Complexity and Supplier Management

Managing suppliers for electronic components involves navigating a web of complexities. A study of 1,004 suppliers across 23 provinces in China revealed the diversity in supplier relationships. Among these, 552 suppliers primarily served domestic customers, while 80 were foreign-owned, highlighting the varying levels of complexity in supplier management. Sourcing becomes even more challenging when dealing with hard-to-find components or obsolete parts. Sudden spikes in demand further strain the availability of critical components, disrupting production timelines and increasing costs.

Geographical and cultural distances also add layers of difficulty. These factors often lead to an overestimation of risks, especially when managing suppliers of complex components. As the complexity of electronic components increases, companies must implement stringent controls to mitigate uncertainties and ensure a steady supply chain.

Short Product Lifecycles and Rapid Technological Changes

The electronics industry thrives on innovation, but rapid technological advancements create unique challenges. Short product lifecycles mean that components quickly become obsolete, forcing manufacturers to constantly adapt. For instance, 43% of enterprises reported project delays due to obsolete parts, with each incident costing an average of $500,000. This constant evolution demands agile supply chain strategies to keep pace with market demands.

Additionally, the need for cutting-edge components often requires sourcing from specialized suppliers. This dependency increases the risk of delays and cost overruns, especially when suppliers struggle to meet the high standards of quality and innovation required in the industry.

Sudden Disruptions and Geopolitical Risks

Global supply chains for electronic components are highly susceptible to disruptions. Geopolitical tensions, such as the U.S.-China tech decoupling, have restricted access to advanced chips, complicating supply chain management. These restrictions force companies to seek alternative suppliers, often at higher costs and with longer lead times.

Natural disasters, pandemics, and trade restrictions further exacerbate these challenges. For example, lithium prices experienced a 300% swing in 2022, significantly impacting material costs. Such volatility underscores the importance of building resilient supply chains capable of withstanding sudden shocks.

Note: Companies must adopt proactive measures to address these challenges, such as diversifying supplier networks and leveraging advanced technologies for better risk management.

High Demand Volatility in the Electronics Market

The electronics market experiences frequent fluctuations in demand, driven by rapid technological advancements and shifting consumer preferences. Seasonal trends, product launches, and global events further amplify this volatility. For instance, the release of a new smartphone model can cause a sudden surge in demand for specific electronic components, such as processors or memory chips. Manufacturers often struggle to align production schedules with these unpredictable spikes, leading to inefficiencies and increased costs.

High demand volatility also creates challenges in inventory management. Companies risk overstocking components that may become obsolete or understocking critical parts, resulting in production delays. This issue becomes more pronounced in industries with short product lifecycles, where unsold inventory quickly loses value. To address these challenges, businesses must adopt agile supply chain strategies. Real-time demand forecasting and flexible production systems can help companies respond swiftly to market changes.

Limited Visibility and Data Integration Across the Supply Chain

Limited visibility and poor data integration hinder the efficiency of supply chains. Companies often lack real-time insights into inventory levels, shipment statuses, and supplier performance. This lack of transparency leads to operational inefficiencies and customer dissatisfaction. For example:

H&M faced delays in product launches due to insufficient real-time data, frustrating customers.

Walmart experienced both overstock and stockouts, resulting in high holding costs and missed sales opportunities.

IKEA struggled to predict delivery times, causing stockouts that disappointed customers.

Best Buy relied on manual inventory tracking, leading to stockouts and overselling during peak demand.

These challenges highlight the importance of integrated digital solutions. Advanced technologies like IoT and cloud-based platforms can provide end-to-end visibility, enabling businesses to monitor and optimize their supply chains. By leveraging these tools, companies can reduce errors, improve decision-making, and enhance customer satisfaction.

Effective Solutions for Overcoming Logistics Challenges

Optimized Network Design for Electronic Components

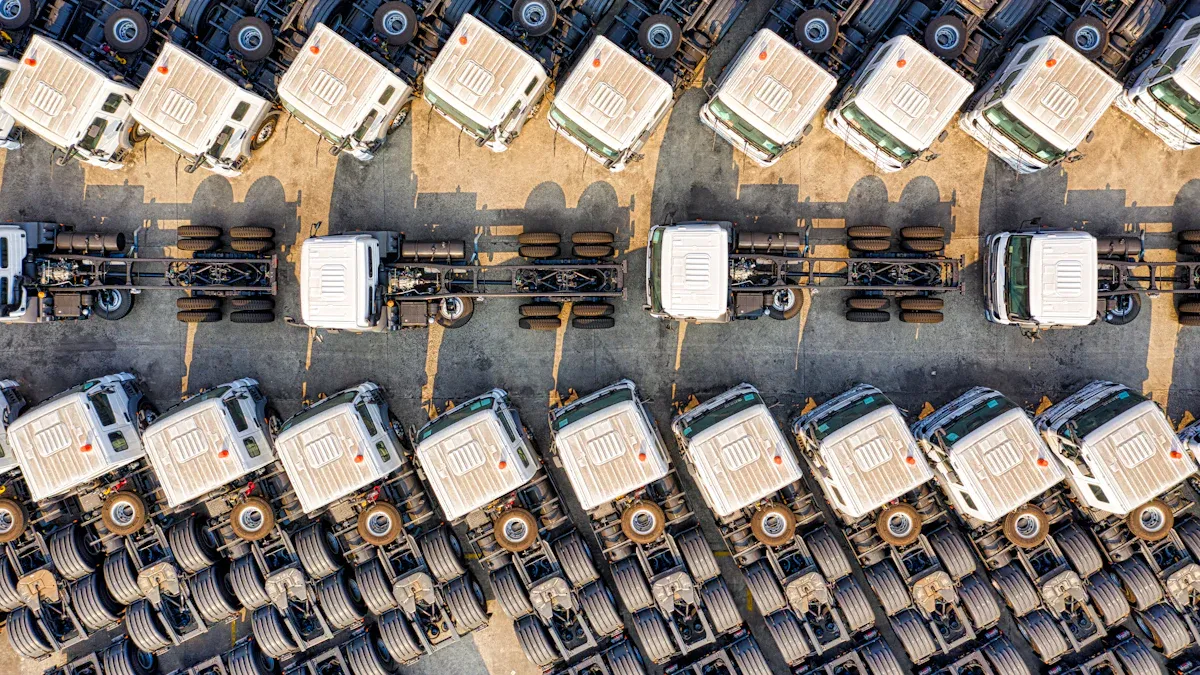

An optimized logistics network ensures the efficient movement of electronic components across global supply chains. Companies can achieve this by strategically positioning distribution centers near manufacturing hubs and consumer markets. This approach reduces transit times and minimizes transportation costs. For example, Kombiverkehr, a European logistics leader, implemented Doxis Intelligent Content Automation to streamline operations. By automating manual tasks and enhancing collaboration, they processed approximately 900,000 truck shipments annually while maintaining regulatory compliance. Such innovations demonstrate how network optimization can improve efficiency and customer satisfaction.

Additionally, leveraging advanced technologies like AI and IoT enhances route planning and resource allocation. These tools provide real-time insights into shipment statuses, enabling companies to make data-driven decisions. By integrating these technologies, businesses can reduce delays and improve overall supply chain performance.

Bonded Warehousing for Inventory Management

Bonded warehousing offers a strategic solution for managing inventory in the electronic components sector. These facilities allow companies to store goods without immediate tax payments, providing significant cost advantages. Importers can defer duties until goods leave the warehouse, improving cash flow. Furthermore, bonded warehouses offer flexibility, allowing goods to remain stored for up to five years without incurring additional taxes. This extended storage period supports gradual distribution and reduces the risk of overstocking.

Companies dealing with restricted or high-value goods benefit from bonded warehousing by avoiding higher tariffs and managing costs effectively. This approach also enhances inventory visibility, enabling businesses to track stock levels and optimize distribution strategies.

Air Freight Consolidation for Speed and Cost Efficiency

Air freight consolidation combines multiple shipments into a single load, reducing costs and improving delivery speed. This method is particularly beneficial for small and medium-sized enterprises (SMEs) that need to optimize budgets. Consolidated shipments lower the cost per unit of cargo compared to individual shipments. Additionally, processing consolidated loads at airports minimizes transit times, ensuring timely delivery.

For instance, air freight consolidation reduces delays by expediting shipment processing. It also optimizes budgets, making it a cost-effective solution for businesses managing high-demand products. By adopting this approach, companies can enhance their logistics efficiency while meeting customer expectations.

Automation and Digitalization in Logistics Operations

Automation and digitalization have transformed logistics operations, offering significant improvements in efficiency and accuracy. Automated systems streamline repetitive tasks, reducing human error and increasing productivity. For instance, automated sorting systems in warehouses accelerate order fulfillment, ensuring timely deliveries. Digitalization enhances data integration, enabling real-time tracking and better decision-making. Companies adopting these technologies gain a competitive edge by optimizing their supply chains.

A closer look at the logistics industry reveals untapped potential for automation. More than 80% of warehouses currently lack automation, presenting a substantial opportunity for investment. Cloud computing, viewed as the most impactful technology, enhances data access and collaboration. Approximately 50% of supply chain organizations plan to invest in AI applications and analytics by 2024, driven by the need for faster decision-making. These advancements highlight the growing importance of technology in logistics operations.

The integration of digital tools like IoT and AI enables predictive analytics, helping companies anticipate demand fluctuations. Real-time data sharing improves communication across supply chain stakeholders, reducing delays and inefficiencies. By embracing automation and digitalization, businesses can enhance their logistics operations, ensuring the seamless flow of electronic components.

Statistic | Description |

|---|---|

80% | More than 80% of warehouses have no automation, indicating a significant opportunity for investment in automation. |

40% | Cloud computing is viewed as the most impactful technology for digital transformation in logistics, enhancing data access and collaboration. |

50% | 50% of supply chain organizations plan to invest in AI applications and analytics by 2024, driven by the need for faster decision-making. |

Collaboration with Reliable Partners like JUSDA

Collaborating with reliable partners like JUSDA offers numerous advantages for logistics solutions. JUSDA’s expertise in supply chain management ensures efficient operations, reducing costs and improving service quality. Their tailored solutions address industry-specific challenges, making them a trusted partner for businesses.

JUSDA’s advanced forecasting capabilities enhance customer service by anticipating consumer demand. This reduces stock-outs and improves order fulfillment. Accurate demand predictions lower excess inventory, increasing profitability. Effective CPFR (Collaborative Planning, Forecasting, and Replenishment) solutions eliminate inefficiencies, maximizing the return on technology investments. Collaboration also fosters stronger relationships between trading partners, promoting mutual growth.

JUSDA’s innovative technologies, such as the JusLink Intelligent Supply Chain platform, integrate IoT and cloud computing for real-time visibility. This enables businesses to monitor shipments, optimize routes, and improve decision-making. By partnering with JUSDA, companies can align production schedules with forecasts, reducing setup times and optimizing capacity utilization. These benefits make JUSDA an invaluable partner in the logistics industry.

Success Metric | Description |

|---|---|

Improved customer service | Enhanced forecasting leads to better anticipation of consumer demand, reducing stock-outs and improving fulfillment. |

Lower inventories for higher profits | Accurate demand predictions reduce excess inventory, lowering carrying costs and improving cash flow. |

Improved ROI on technology investment | Effective CPFR solutions reduce overhead by eliminating inefficiencies in processes and systems. |

Improved relationships between trading partners | Collaboration fosters better understanding and communication, creating mutually beneficial partnerships. |

Cost reduction | Aligning production schedules with forecasts decreases setup times and optimizes production capacity utilization. |

Real-World Case Studies

JUSDA's Role in Optimizing Supply Chains for Electronics Manufacturers

JUSDA has played a pivotal role in transforming supply chains for electronics manufacturers. By leveraging its JusLink Intelligent Supply Chain platform, the company has enhanced visibility and efficiency across global operations. This platform integrates IoT and cloud computing to provide real-time tracking and inventory management. Electronics manufacturers benefit from reduced lead times and improved order accuracy. For instance, JUSDA’s collaboration with Sharp streamlined global e-commerce logistics, cutting logistics costs by 20% and accelerating order processing cycles. These advancements demonstrate JUSDA’s ability to address the unique challenges of the electronics industry.

Case Study on Bonded Warehousing Reducing Lead Times

Bonded warehousing has proven effective in reducing lead times for electronic components. JUSDA’s bonded warehousing solutions allow companies to store goods without immediate tax payments, improving cash flow and operational flexibility. A leading electronics manufacturer utilized JUSDA’s bonded facilities to manage high-value components. This approach deferred duties and optimized inventory distribution, enabling the company to meet fluctuating demand efficiently. The extended storage period of up to five years also minimized the risk of overstocking. These benefits highlight the strategic value of bonded warehousing in managing complex supply chains.

Success Story of Air Freight Consolidation in Managing Demand Spikes

Air freight consolidation has emerged as a cost-effective solution for managing demand spikes in the electronics market. JUSDA’s air freight services combine multiple shipments into a single load, reducing costs and ensuring timely delivery. During a surge in demand for memory chips, JUSDA implemented air freight consolidation to expedite shipments. This strategy minimized transit times and optimized budgets, allowing the manufacturer to meet market demands without delays. The integration of advanced route planning further enhanced efficiency, showcasing the potential of air freight consolidation in addressing high-demand scenarios.

Logistics Solution | Description | Impact |

|---|---|---|

Real-time Tracking | ClearChain apps enable tracking and tracing of orders in real time. | Enhanced customer service and reduced errors. |

Cost Reduction | Weekly tracking and gainshare programs reduce fuel consumption. | Lower operational costs and improved mpg targets. |

Dependability | Penske manages labor and asset fluctuations effectively. | Minimized cost impacts for manufacturers. |

ClearChain technology supports inventory management and route optimization. | Improved customer service and reduced disruptions. |

These case studies illustrate how innovative logistics solutions can address the challenges of managing electronic components in a dynamic market.

Future Trends in Electronic Components Logistics

Adoption of Artificial Intelligence and Machine Learning

Artificial intelligence (AI) and machine learning (ML) are revolutionizing logistics operations by enhancing efficiency and accuracy. These technologies optimize routing and load planning, reducing fuel consumption and improving delivery times. AI-powered systems also enable real-time tracking and instant customer support, ensuring a seamless logistics experience. For example, predictive analytics powered by AI helps companies detect supply chain disruptions early, minimizing risks and delays.

In warehousing, AI-driven automation improves order fulfillment through automated sorting and picking systems. Predictive maintenance for warehouse equipment reduces downtime, while optimized storage strategies ensure efficient use of space. By 2025, robotics in logistics is expected to significantly enhance operational efficiency. These advancements demonstrate the transformative potential of AI and ML in managing the complexities of electronic components logistics.

Blockchain for Enhanced Transparency and Security

Blockchain technology is emerging as a critical tool for enhancing transparency and security in supply chains. Its decentralized structure ensures data integrity by preventing unauthorized alterations. This creates an immutable ledger that stakeholders can trust. Blockchain also provides complete traceability, allowing companies to verify the origin and quality of electronic components.

The technology reduces discrepancies and errors in transactions, improving overall supply chain efficiency. For instance, blockchain enhances consumer confidence by ensuring safety and quality control. It also protects against fraud through encryption and transparent record-keeping. These features make blockchain an indispensable asset for modern logistics operations, particularly in industries requiring high levels of trust and accountability.

Green Logistics and Sustainability Initiatives

Sustainability is becoming a top priority in the logistics sector due to environmental concerns and regulatory pressures. Over 90% of a company’s environmental impact stems from supply chain operations, highlighting the need for green logistics. The market for sustainable logistics is projected to grow at a compound annual growth rate (CAGR) of 10.7% from 2023 to 2030, reaching $1.4 trillion.

Companies are adopting eco-friendly practices such as using biodegradable materials and optimizing transportation routes to reduce emissions. Consumers are also driving this shift, with 71% willing to pay a premium for sustainable practices. Investments in green logistics not only benefit the environment but also enhance brand reputation and customer loyalty. These initiatives align with the growing demand for environmentally responsible solutions in the electronic components industry.

Predictive Analytics for Demand Forecasting

Predictive analytics has become a cornerstone for demand forecasting in logistics. By analyzing historical data and real-time insights, businesses can anticipate market trends and align their supply chain strategies accordingly. This approach minimizes inefficiencies and enhances decision-making processes.

One of the key advantages of predictive analytics lies in its ability to improve forecasting accuracy. Advanced algorithms analyze multiple variables and detect intricate patterns that traditional methods often overlook. Machine learning tools further enhance this process by uncovering hidden trends in supply chain data. These insights enable businesses to predict demand fluctuations with greater precision, reducing the risk of stockouts or overstocking.

Scenario planning also benefits from predictive analytics. Companies can use data-driven insights to anticipate potential disruptions and implement contingency plans. For instance, predictive models can identify risks such as supplier delays or geopolitical tensions, allowing businesses to mitigate their impact proactively. This capability ensures a more resilient supply chain.

The integration of real-time data with historical records further strengthens inventory management. Businesses can monitor inventory levels dynamically, optimizing stock to meet demand without incurring excess costs. Accurate forecasts improve cash flow by reducing unnecessary inventory holding expenses.

Evidence Type | Description |

|---|---|

Advanced Forecasting | Predictive analytics improves forecasting accuracy by analyzing more variables and detecting intricate patterns. |

Scenario Planning | Businesses can use data-driven insights to anticipate potential disruptions and implement contingency plans. |

Real-time Data Utilization | Incorporating real-time insights with historical data enhances decision-making for inventory management. |

Machine Learning Integration | ML tools help uncover patterns in supply chain data that traditional methods might overlook, improving demand predictions. |

Improved Inventory Management | Accurate forecasts reduce stockouts and overstocking, optimizing inventory levels and cash flow. |

Predictive analytics empowers businesses to stay ahead in a competitive market. By leveraging these tools, companies can enhance operational efficiency and meet customer demands effectively.

The electronic components logistics supply chain faces numerous challenges, including vulnerabilities, limited visibility, and geopolitical uncertainties. Solutions such as nearshoring, digital platforms, and agile strategies address these issues effectively.

Challenges | Solutions |

|---|---|

Vulnerabilities in the supply chain | Nearshoring and localized manufacturing to enhance visibility. |

Lack of visibility and traceability | Investment in digital solutions for end-to-end visibility and centralized supply chain management. |

Geopolitical uncertainties and tariff impacts | Exploration of new suppliers and markets to mitigate risks. |

Rapid product obsolescence | Adoption of agile supply chain strategies and advanced manufacturing technologies. |

Sustainability pressures | Establishing robust guidelines for ethical sourcing and responsible practices. |

Integration challenges among stakeholders | Implementation of digital supply chain platforms for real-time collaboration and data sharing. |

JUSDA’s innovative products, such as the JusLink Intelligent Supply Chain platform, empower businesses with real-time visibility and efficiency. Companies must adopt proactive, technology-driven strategies to navigate future complexities and achieve sustainable growth.

FAQ

What makes JUSDA's logistics solutions unique?

JUSDA combines advanced technologies like IoT, AI, and blockchain with a global network of over 155 service points. This integration ensures real-time visibility, optimized routes, and cost-effective operations. Tailored solutions address industry-specific challenges, making JUSDA a trusted partner for efficient supply chain management.

How does bonded warehousing benefit electronics manufacturers?

Bonded warehousing allows manufacturers to store goods without immediate tax payments, improving cash flow. It also provides flexibility for gradual distribution and reduces overstocking risks. JUSDA’s bonded facilities enhance inventory visibility and streamline operations, ensuring efficient management of high-value electronic components.

Can JUSDA handle demand spikes in the electronics market?

Yes, JUSDA’s air freight consolidation services effectively manage demand spikes. By combining multiple shipments into a single load, JUSDA reduces costs and ensures timely delivery. Advanced route planning further enhances efficiency, enabling manufacturers to meet sudden market demands without delays.

How does JUSDA ensure supply chain transparency?

JUSDA’s JusLink Intelligent Supply Chain platform integrates IoT and cloud computing for real-time tracking. This technology provides end-to-end visibility, enabling businesses to monitor shipments, optimize routes, and make data-driven decisions. Enhanced transparency improves operational efficiency and customer satisfaction.

Why is predictive analytics important in logistics?

Predictive analytics helps businesses anticipate demand fluctuations and potential disruptions. By analyzing historical and real-time data, companies can optimize inventory levels, reduce risks, and improve decision-making. JUSDA leverages AI-powered tools to provide accurate forecasts, ensuring a resilient and efficient supply chain.

See Also

Enhancing High-Tech Manufacturing Supply Chains Through Smart Solutions

Transforming Logistics with AI Innovations for the Future

Addressing Global Supply Chain Growth Challenges Effectively

Mastering Lean Logistics to Achieve High-Tech Manufacturing Goals

Unleashing Robotics Innovations to Transform Supply Chain Dynamics