10 Emerging Trends Shaping the Logistics Industry in 2025

The logistics industry is changing fast due to new technology. Tools like AI and IoT are improving how things work. In the U.S., 72% of logistics companies use AI. They use it to plan better routes and predict needs. These changes help create smarter and greener solutions for the future.

Key Takeaways

Robots and machines are changing warehouses, making them quicker and better. Businesses save money and deliver faster by using these tools.

Smart computers and data help manage supply chains better. Companies can spend less and make customers happier by planning routes and tracking supplies.

Being eco-friendly is important in shipping. Companies can cut pollution and look good by using electric cars and clean energy systems.

Automation and Robotics in the Logistics Industry

Changing Warehouses with Automation

Automation is making warehouses faster and more effective. Robots like AMRs and AGVs are now used in many warehouses. These robots move around, carry goods, and handle materials carefully. AMRs adjust to new surroundings, while AGVs pick the best paths to avoid bumps. This cuts down on human work and speeds up deliveries.

Automating logistics helps businesses save money and avoid mistakes.

Warehouses also use GTP systems to bring items straight to workers. This saves time and helps workers do more. AS/RS systems store items better and make handling easier. For example, British Sugar uses AS/RS to manage 3,000 pallets every day. Tools like pick-to-light and voice-picking make work more accurate and reduce errors. These tools make logistics smoother and improve customer service.

Technology Type | What It Does | How It Helps |

|---|---|---|

Autonomous Mobile Robots (AMRs) | Move around and adjust to changes, carrying goods easily. | Cuts down on human work and speeds up deliveries. |

Automated Guided Vehicles (AGVs) | Work alone, choosing the best paths and avoiding obstacles. | Makes deliveries faster and more accurate. |

Goods-to-Person (GTP) | Brings items straight to workers, saving time and effort. | Reduces hard tasks and helps workers get more done. |

Self-Driving Vehicles and Drones Changing Delivery

Self-driving vehicles and drones are changing how goods are delivered. Self-driving trucks carry heavy loads over long distances. They work nonstop, save money, and are safer. Drones are great for short deliveries. They skip traffic in cities and reach faraway places quickly. This makes them perfect for fast deliveries.

Drones also help track inventory by giving live updates. Their speed gives companies an advantage. Together, self-driving vehicles and drones improve logistics. They lower costs and meet growing delivery needs. These tools are shaping the future of how things are delivered.

Artificial Intelligence Changing Supply Chain Trends

Predictive Analytics for Better Choices

AI is helping supply chains work smarter with predictive analytics. This technology guesses future needs, manages stock, and cuts waste. For example, Miroglio, a clothing company, used EvoAI to handle demand changes. This helped them manage inventory better and make more money. Another company saved $50,000 each month by updating its supply chain system.

Predictive analytics also helps logistics companies make better plans. Walmart uses AI to study sales and online shopping data. This helps them find problems and improve how they work. Many businesses see this as important. About 80% of logistics providers and 77% of shippers use predictive analytics. Plus, 91% of companies think AI is key for their future.

The predictive analytics market is growing fast. It is expected to grow by 28.3% every year until 2030. This shows how AI is becoming more important in supply chains.

AI-Powered Route Planning for Faster Deliveries

AI-powered route planning is changing how deliveries are made. Machine learning studies past and current traffic to avoid delays. This saves time, fuel, and money. For example, better routes can cut delivery miles by 35%. This lowers fuel use and reduces pollution.

Companies using AI see big improvements. Delivery times drop by 25%, and transportation costs go down by 22%. Overall costs can be cut by 50%, and fuel savings are over 15% each year. These changes make logistics better and customers happier.

Benefit Type | How It Helps |

|---|---|

Delivery Fleet Mileage | Cuts miles by up to 35% |

Delivery Time Reduction | Speeds up deliveries by 25% |

Transportation Cost Reduction | Lowers costs by 22% |

Annual Fuel Savings | Saves over 15% on fuel each year |

AI-powered logistics not only saves money but also helps the planet. By working smarter, companies can deliver more while protecting the environment.

Sustainability and Green Logistics Industry Trends

Electric and Hydrogen-Powered Vehicles in Logistics

Logistics companies are using electric and hydrogen vehicles to cut pollution. Electric trucks produce no emissions and use energy efficiently. They turn 85-90% of energy into movement. These trucks are quiet and cost less to run. But, they can only go 250-350 miles per charge. Charging stations are also hard to find. Hydrogen trucks can travel over 600 miles on one tank. They refuel quickly in 5-15 minutes and are lighter than electric trucks. However, making hydrogen is costly, and there are few refueling stations.

Vehicle Type | Benefits | Challenges |

|---|---|---|

Electric Trucks | ✔ No Pollution | ❌ Short Range: 250-350 miles per charge |

✔ Cheaper to Operate | ❌ Few Charging Stations | |

✔ Uses Energy Well: 85-90% efficiency | ❌ Heavy and Expensive Batteries | |

✔ Quiet Driving | ||

Hydrogen Trucks | ✔ Longer Range: 600+ miles per tank | ❌ High Hydrogen Costs |

✔ Quick Refueling: 5-15 minutes | ❌ Few Refueling Stations | |

✔ Lighter Than Batteries | ❌ Expensive to Build |

These vehicles are changing logistics. They help reduce pollution and improve how things work.

Building Carbon-Neutral Supply Chains

To create carbon-neutral supply chains, many steps are needed. Companies can use climate data and customer feedback to plan better. Big projects, like hydrogen fuel networks, need funding and teamwork. Digital tools, like AI for route planning, help lower emissions. Working with governments and private groups ensures long-term success.

Steps to make supply chains carbon-neutral:

Use technology to plan routes and save fuel.

Spend money on green energy and eco-friendly systems.

Team up with others to build sustainable networks.

Benefit | Description |

|---|---|

Cuts pollution with green transport and technology. | |

Saves Money | Uses less fuel and lowers costs, helping the economy. |

Better Brand Image | Gains trust from customers who like eco-friendly businesses. |

More Efficiency | Improves work by sharing resources and planning better. |

Follows Rules | Meets environmental laws and avoids fines. |

Stronger Supply Chains | Prepares for problems and stays reliable. |

Helps Communities | Creates a cleaner environment and healthier lives. |

By following these ideas, companies can make their supply chains greener and stronger. This helps the planet and their business goals.

Blockchain Technology Making Supply Chains Clearer

Keeping Transactions Safe and Tracking Goods

Blockchain is changing how we handle transactions and track goods. It keeps a secure record of every deal, so data stays safe. This clear system helps people trust each other and spot risks early. For example, blockchain helps track environmental and social impacts, which is key for resource-heavy industries.

With blockchain, you can check transactions and follow goods live. This clear view of the supply chain helps find problems early. Fixing issues quickly stops them from getting worse. Whether it’s raw materials or finished items, blockchain makes every step easy to trace and secure.

Better Tracking in the Supply Chain

Blockchain makes tracking in logistics much faster and easier. It cuts the time to find problems from days to seconds. This is very helpful in food supply chains. For example, during an E.coli outbreak in California, farmers lost $74 million. They couldn’t find the bad spinach fast enough. Blockchain could have quickly shown where the problem started.

Better tracking also saves lives. Food illnesses hurt millions, especially young kids. Blockchain helps remove bad products quickly to stop harm. Its tracking power makes it a must-have tool for managing supply chains.

Blockchain not only makes work smoother but also keeps operations safe. Using it can make supply chains clearer, lower risks, and make them stronger.

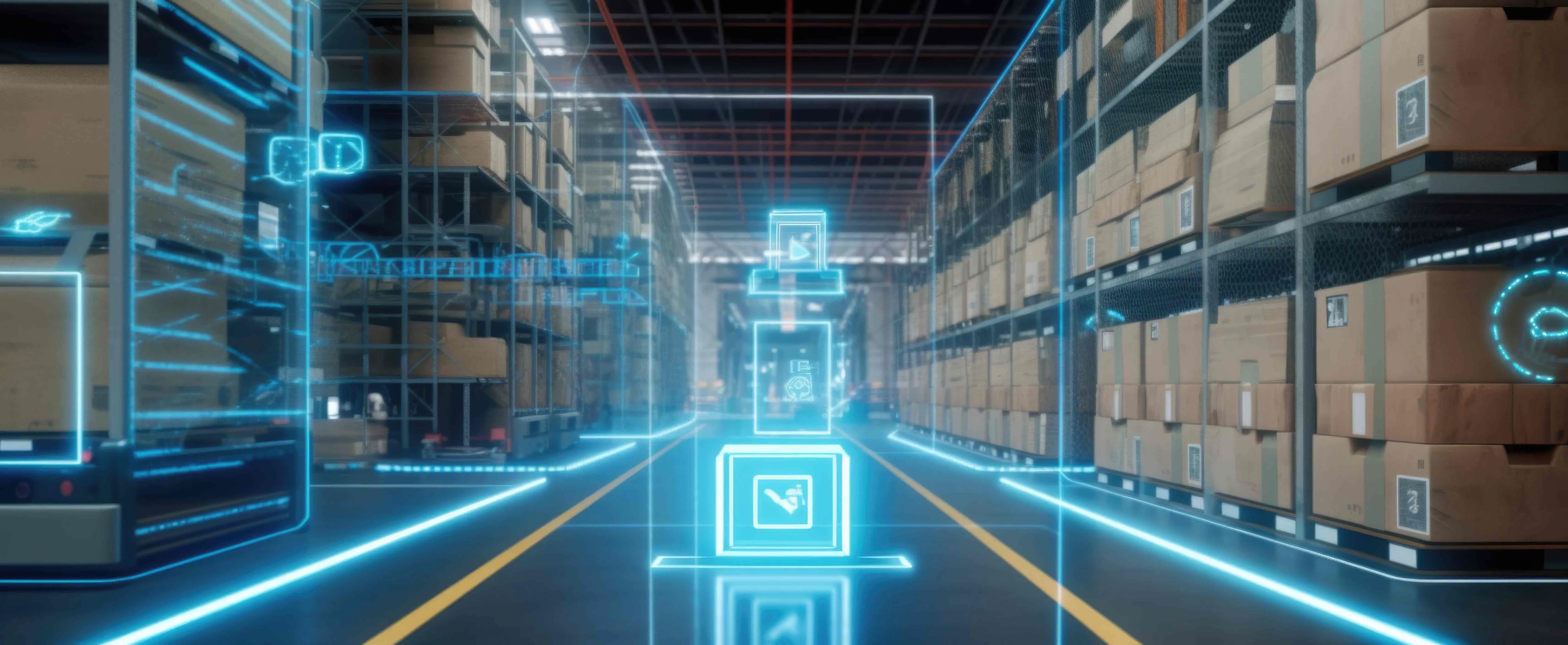

Internet of Things (IoT) in Smart Warehousing

Real-Time Tracking and Monitoring Solutions

IoT is changing how warehouses work by offering live tracking. These tools automate tasks, so less human work is needed. For example, training new workers takes 41 hours instead of 60. IoT tools also help make better choices using live data. Automated vehicles with IoT find faster delivery routes, saving time and money.

IoT makes machines work better by spotting problems early. This saves repair costs and time. Tools like RFID and smart sensors show inventory levels instantly. This prevents mistakes, stockouts, and keeps things running smoothly. IoT gateways are in demand because they connect data easily. Managers can quickly decide based on live inventory and equipment updates.

Real-time tracking has big benefits. Companies using data are 5-6% more productive and profitable. Shipment tracking cuts delays by 58%. Watching inventory all the time stops overstocking and stockouts. This improves cash flow and reduces waste.

Improvement Area | Statistic/Impact |

|---|---|

Productivity | Companies using data-driven decision-making are 5 to 6 percent more productive and profitable. |

Delay Reduction | Real-time shipment tracking can reduce delays by up to 58%. |

Inventory Management | Continuous monitoring prevents stockouts and overstocking, improving cash flow and reducing waste. |

JUSDA’s Warehouse Innovations with IoT Integration

JUSDA is leading smart warehouses by using IoT in its work. With over 2.5 million square meters of space worldwide, JUSDA uses IoT to boost efficiency. Its JusLink platform mixes IoT, cloud computing, and big data for live inventory tracking. This gives full supply chain visibility for better decisions.

JUSDA’s warehouses use RFID and smart sensors to track inventory live. These tools lower mistakes and improve accuracy. For instance, JUSDA Vietnam uses eVMI systems to connect suppliers and buyers. This keeps inventory levels just right, cutting costs and improving work.

JUSDA also focuses on fixing problems before they happen. IoT sensors check equipment health and find issues early. This keeps operations smooth and avoids downtime. By using IoT, JUSDA improves logistics and sets a high standard for innovation.

E-Commerce and Last-Mile Delivery Trends

Micro-Fulfillment Centers for Faster Deliveries

Micro-fulfillment centers (MFCs) are changing how deliveries happen. These small centers are closer to cities, making deliveries faster. They help meet the need for same-day or next-day shipping. By being near customers, MFCs lower delivery costs and save time. For example, they can handle up to 15,000 orders each week, keeping inventory organized.

Automation is very important in MFCs. It lowers the cost of filling orders by almost 75%. This helps companies save money while keeping customers happy. Since 61% of people want fast shipping, MFCs are a great solution for today’s needs.

Efficiency Metric | Benefit |

|---|---|

Faster Delivery Times | Same-day or next-day delivery due to being close to customers. |

Reduced Last-Mile Costs | Fewer miles driven, cutting transportation costs. |

Improved Inventory Management | Manages up to 15,000 orders weekly, keeping storage efficient. |

Cost Savings | Automation lowers order costs by nearly 75%. |

On-Demand Delivery Models Shaping Consumer Expectations

On-demand delivery models are changing how people get goods. These systems focus on speed and convenience. You can get items when and where you want them. Companies like Amazon have grown their centers by 30% to deliver faster. By 2025, 99% of stores plan to offer same-day delivery.

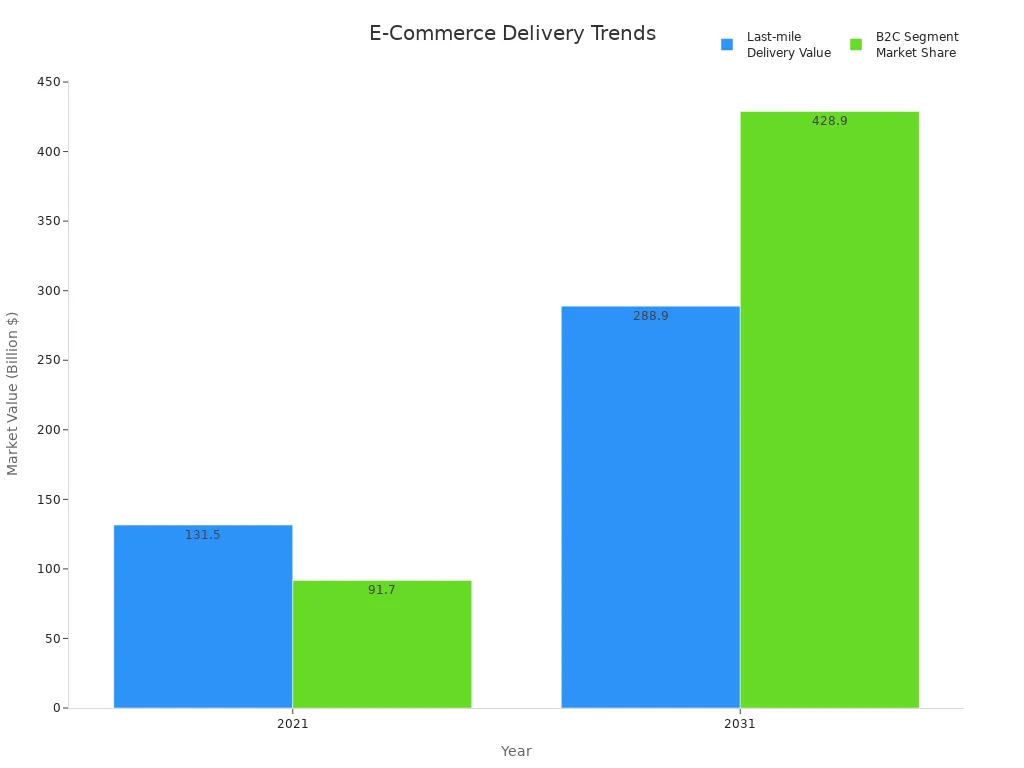

E-commerce has made this change happen. The last-mile delivery market was worth $131.5 billion in 2021. It is expected to grow to $288.9 billion by 2031. The B2C market will also grow from $91.7 billion to $428.9 billion in the same time.

On-demand delivery improves the customer experience. It makes deliveries faster, lowers costs, and uses roads better. By following these trends, businesses can stay ahead in the fast-changing delivery world.

Indicator Type | Description |

|---|---|

Delivery Cost | Cuts the money spent on delivering items. |

Delivery Efficiency | Makes sure deliveries are on time. |

User Experience | Makes customers happier with better service. |

Total Road Utilization | Uses roads wisely for smoother transportation. |

Resilient Supply Chains for Risk Management

Using Many Suppliers to Lower Risks

A strong supply chain needs many suppliers. Relying on one supplier or area is risky. Events like COVID-19 showed how fragile supply chains can be. Working with more suppliers spreads risk and keeps things running. Many companies now use a "country plus-one" plan. This means they get supplies from extra regions to avoid problems. For example, clothing companies are moving from China to Vietnam and Thailand. Chipmakers are also looking beyond Asia due to shortages.

This idea is growing fast. In China, 57% of factories want a "supplier +1" plan. Around the world, 77% of businesses will add more suppliers in two years. Using more suppliers not only avoids risks but also adds flexibility. Bringing suppliers closer, like reshoring or nearshoring, cuts delays and costs. These methods make supply chains faster and more efficient.

Smart Plans for Stronger Supply Chains

To make supply chains stronger, you need a good plan. Use tools like the Supply Chain Resilience Framework. This helps keep things running and manage risks. Metrics like Time to Recover (TTR) show how fast you bounce back after problems. Shorter recovery times mean better resilience.

Technology helps improve supply chains too. AI and predictive tools make managing inventory and demand easier. They reduce mistakes and prepare you for surprises. Watching how suppliers perform and using more of them also lowers risks. Companies using these ideas stay ahead and build trust with customers.

Metric/Framework | What It Does |

|---|---|

Time to Recover (TTR) | Shows how fast things return to normal after problems. |

Inventory Management Efficiency | Tracks how well stock is handled during demand changes. |

Supplier Diversification | Checks if you rely on many suppliers to avoid risks. |

Customer Satisfaction and Retention | Measures how problems affect customer happiness and loyalty. |

By following these steps, you can build a supply chain that handles problems and stays successful.

Big Data Analytics in the Logistics Industry

Smarter Decisions with Big Data

Big data helps logistics companies make better choices. It uses information to find trends, predict needs, and improve work. For example, studying order times during shifts can fix delays. One company cut order times by 15% by solving these issues. Checking fuel use for different trucks saved another company 10% on fuel each year.

Big data also makes deliveries faster and inventory more accurate. Comparing delivery routes helped one business cut delivery times by 12%. Another company improved how fast they restocked items, saving money and reducing mistakes. These examples show how using data leads to better results.

Example | Results | Key Improvements |

|---|---|---|

Order Time Study | Cut order times by 15%. | Reduced delays in processing. |

Fuel Use Check | Saved 10% on fuel costs yearly. | Found better fuel efficiency. |

Delivery Route Comparison | Shortened delivery times by 12%. | Improved route planning. |

Inventory Restocking Improvement | Made inventory more accurate. | Faster restocking and fewer errors. |

Big data tools help save time, lower costs, and make customers happier.

Faster Changes with Advanced Analytics

Advanced analytics makes logistics quicker and more flexible. It finds problems, improves routes, and predicts future needs. For example, it helps manage stock better, avoiding too much or too little. It also shows what’s happening in the supply chain, so companies can fix issues faster.

Important measures show how advanced analytics helps. It leads to smarter choices and smoother operations. Companies can also serve customers better by knowing what they need and delivering faster.

Benefit Type | How It Helps |

|---|---|

Smarter Choices | Gives clear insights for better decisions. |

Smoother Operations | Finds and fixes problems in processes. |

Happier Customers | Meets needs quickly and improves service. |

Better Stock Management | Keeps the right amount of inventory. |

Clearer Supply Chain View | Shows what’s happening for better teamwork. |

Risk Prevention | Spots risks early and makes backup plans. |

Staying Competitive | Improves service and operations to lead the market. |

Using advanced analytics helps companies stay ahead. It reduces risks, adapts to changes, and delivers great results.

Workforce Changes in the Logistics Industry

Teaching Workers New Skills for Modern Tools

The logistics industry is using more advanced tools now. Workers need new skills to use these tools well. Training programs teach workers how to use AI, IoT, and automation. This helps them do their jobs better and make fewer mistakes.

Many companies are spending more on training workers. Almost half of businesses are increasing training budgets. They want workers to use new tools in their daily tasks. When workers learn new skills, they feel valued and stay longer. This lowers the number of people leaving their jobs.

Hands-on training and certifications help workers improve. For example, teaching them to use smart devices or AI software makes work faster. Workers who know these tools can solve problems quickly and make better choices.

Solving Worker Shortages with Smart Ideas

Finding enough workers is a big problem in logistics. To fix this, companies are using smart ideas like robots and flexible jobs. Robots and self-driving vehicles do simple tasks, so workers can focus on harder jobs.

Flexible work options, like part-time or remote jobs, attract more people. Working with schools can also help find skilled workers. Programs like internships bring young people into logistics jobs.

Using technology and creative hiring plans can solve worker shortages. This makes sure there are enough workers and keeps supply chains strong.

Globalization and Regionalization in Supply Chain Trends

Mixing Global and Local Supply Chain Plans

Using both global and local supply chains is smart. Global supply chains let you get goods and resources from anywhere. They save money and keep products flowing. But depending only on global networks can be risky. Problems like natural disasters or trade issues can cause delays.

Local supply chains are faster and more flexible. They cut delivery times and lower shipping costs by staying close to customers. Many companies now build local hubs to meet nearby needs quickly. This also helps follow local rules and makes customers happier.

Combining global and local plans makes supply chains stronger. You get the reach of global networks and the safety of local ones. This mix keeps your supply chain running smoothly and ready for changes.

Handling Political and Economic Changes

Political and economic changes can hurt supply chains. Studies show these problems cause 32% of price changes. This means adjusting supply chains is key to avoiding risks. Companies with many suppliers do better during tough times. Spreading out suppliers lowers risks and keeps things running.

Different industries feel these changes in different ways. For example, utilities and telecoms lose more when global supply chains fail. Adding local suppliers can help reduce these losses. Tools like predictive analytics can warn you about risks early. Planning ahead keeps your business steady and safe.

JUSDA Solutions

To provide you with professional solutions and quotations.

The future of logistics is about new ideas and being green. Companies need to follow these trends to stay ahead. JUSDA’s smart solutions make it a great partner for success. Learning and acting quickly will help businesses grow in this changing industry.

See Also

Five Key Trends Shaping Future Supply Chain Efficiency

Understanding Current Trends in Logistics Risk Management

Get Prepared: Discovering New Transport Technologies for Supply Chains

Transforming Logistics: The Role of AI in Supply Chains

Navigating Future Logistics Through Advanced Digital Technologies