Empowering Chinese Manufacturers’ Global Expansion Through Intelligent Supply Chain Solutions

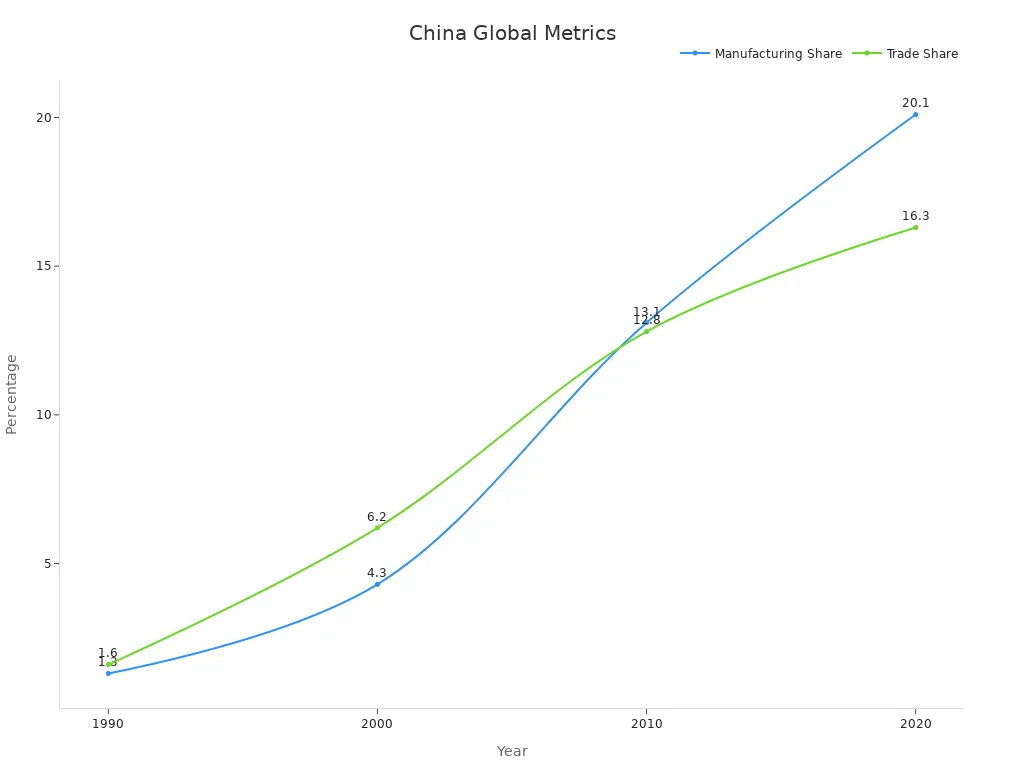

Global growth is key for empowering Chinese manufacturers to stay competitive. In 1990, China made up 1.3% of global manufacturing. By 2020, this grew to 20.1%. Its share in global trade also rose from 1.6% to 16.3%. This shows how important it is to enter new markets to keep growing and adjust to global changes.

But handling international trade is not easy with old methods. Smart supply chain tools help solve problems like tracking goods and being flexible. For example, 55% of manufacturers focus on better tracking to work smoothly and avoid delays. Using these tools can help empower your business to succeed in a connected world.

Key Takeaways

Use smart tools to track goods and stay flexible. This avoids delays and keeps your business strong.

Learn global trade rules to avoid fines and work smoothly. Use programs to handle tricky regulations better.

Use data to spot risks and make better choices. This saves money and strengthens your supply chain.

Go green to please customers and improve your brand. Start small, like using eco-friendly packaging.

Try AI and blockchain to make work easier and clearer. These tools can make your business more efficient.

The Global Manufacturing Landscape

China’s Leadership in Global Manufacturing

China leads the world in manufacturing, helping the global economy grow. In 2023, its manufacturing value was $4.66 trillion, making up 29% of the total worldwide. This is more than the combined output of the U.S., Japan, Germany, and India. Over time, China’s role in global manufacturing has grown a lot:

Year | China's Share in Global Manufacturing | China's Share in Global Trade |

|---|---|---|

1990 | 1.3% | 1.6% |

2000 | 4.3% | 6.2% |

2010 | 13.1% | 12.8% |

2020 | 20.1% | 16.3% |

This growth shows China’s key role in global trade and its ability to meet changing market needs. Using smart tools and better supply chain systems can help your business succeed in this tough market.

The Impact of Trade Tensions and Post-Pandemic Recovery

Trade issues and the pandemic have changed global supply chains. The Global Supply Chain Pressure Index (GSCPI) shows big disruptions that hurt economies. For example, sectors like utilities and telecom in China faced problems during high pressure times.

To handle these challenges, businesses need to be flexible and strong. By spreading out supply chains and using smart solutions, you can reduce risks and find new chances in the global market.

Helping Chinese Manufacturers with Smart Supply Chain Tools

AI for Predicting Demand and Managing Inventory

AI is changing how businesses handle demand and inventory. It studies past data and market trends to predict needs. This helps reduce mistakes in forecasting and keeps stock levels just right. Fewer mistakes mean lower costs and less waste. AI also lets you quickly adjust to market changes. Being flexible is important to compete globally.

AI gives useful advice to make better decisions. You can use it to plan production or manage resources wisely. For example, FreightAmigo’s AI system cuts shipping costs by 20%. It also speeds up customs work, saving time and avoiding errors. These tools help Chinese manufacturers work smarter and stay competitive.

IoT for Tracking and Better Visibility

IoT makes it easier to see your supply chain clearly. Sensors and trackers give live updates on goods’ location and condition. This helps you follow shipments across borders without problems. Some tracking tools send more updates during shipping for better details. Bluetooth adds precise tracking indoors and outdoors.

IoT alerts warn you about issues right away. For example, sensors can spot temperature changes to protect products. Smart systems also reorder items automatically, stopping stockouts. These tools help Chinese manufacturers build strong and smooth supply chains.

Blockchain for Safe and Clear Operations

Blockchain makes supply chains safer and more transparent. It keeps records that everyone can trust and can’t change. This builds trust and stops data tampering. Extra security features make it great for industries like medicine.

Blockchain also saves time by cutting down on paperwork. A global retailer improved shipping by using blockchain. It also helps track eco-friendly goals, meeting sustainability needs. By using blockchain, you can find risks early and follow rules. This helps Chinese manufacturers work confidently and securely.

Data analytics for reducing risks and making better decisions

Data analytics helps lower risks and make smarter choices in supply chains. It studies large amounts of data to find patterns and trends. This helps you predict problems and take action early. For example, predictive tools can show future challenges and possible outcomes.

Data analytics has a big impact on supply chains. Look at these numbers:

Statistic | Description |

|---|---|

81% | Experts say analytics can cut supply chain costs a lot. |

79% | Strong supply chains help companies grow faster than others. |

15% lower | Great supply chains cost 15% less to run. |

These stats show how data helps save money and improve operations. Using analytics makes planning and forecasting better. This keeps your supply chain strong during tough times.

Analytics also helps spot risks early. For instance:

It shows possible problems so you can plan ahead.

Predictive tools help you prepare for supply chain issues.

Advanced tools improve visibility, making operations smoother.

For Chinese manufacturers growing globally, analytics is a big advantage. It helps you make better choices, save money, and stay efficient. Adding analytics to your supply chain plan helps you handle challenges and find new chances in the global market.

Tip: Begin with small analytics projects in one part of your supply chain. Expand as you see good results.

Case Studies: Success Stories of Helping Chinese Manufacturers

JUSDA’s Growth in India, Vietnam, and North America

JUSDA has helped Chinese manufacturers grow in global markets. They entered India, Vietnam, and North America with smart strategies. In India, they helped move factories and offered storage and transport. Vietnam’s growing logistics industry let them create better transport systems. They also expanded into electronics and energy industries there. In North America, they solved labor and rule challenges with smart tools. They also built strong customer connections.

These efforts match China’s success in global trade. For example:

China’s exports grew from $14.3 billion in 1978 to $2.2 trillion in 2018.

Foreign investments rose from $0.57 billion in 1978 to $137.3 billion in 2018.

In 2019, China made up 28% of global manufacturing value-added.

These numbers show how Chinese manufacturers can succeed with the right help.

Solving Logistics Problems with Storage and Transport

JUSDA fixed shipping problems using storage and transport solutions. These services keep things running smoothly, even with tough customs rules. Bonded storage holds goods temporarily, cutting delays at customs. Inland transport speeds up deliveries and ensures materials arrive on time.

Important performance measures show these strategies work:

Measure Name | What It Shows |

|---|---|

Trailer Space Use | Uses trailer space well, lowering transport costs. |

Truck Loading Time | Speeds up loading and unloading, saving time. |

Cuts delays at facilities, making drivers happier. | |

Delivery Time | Finds slow spots, ensuring goods arrive on time. |

Ship Schedule Reliability | Tracks on-time arrivals, important for urgent shipments. |

These measures prove JUSDA’s solutions help Chinese manufacturers stay efficient.

Using Digital Tools for Trade Rules and Customs

Digital tools make following trade rules and customs easier. JUSDA’s platforms simplify tasks, cut delays, and improve data accuracy. For example, AI checks data to find risks, prioritize checks, and follow trade laws.

Benefits of using digital tools include:

Benefit Type | What It Does |

|---|---|

Automation speeds up customs clearance. | |

Better Accuracy | Real-time updates reduce mistakes and keep data correct. |

Improved Risk and Rule Management | AI finds risks early, helping follow rules and avoid fines. |

Lower Costs | Automation cuts admin costs and boosts efficiency. |

Eco-Friendly and Reliable | Digital tools save paper and keep things running during crises. |

By using these tools, you can make your supply chain stronger and ready for global growth.

Lessons from successful global supply chain transformations

Learning from global supply chain changes can help manufacturers grow. These lessons show why being flexible, using technology, and relying on data are important to solve problems and find new chances.

One big lesson is using predictive analytics to handle problems early. Events like COVID-19 and global tensions showed how weak supply chains can be. Predictive tools let you spot risks before they happen. For example, studying past data can reveal patterns of delays or shortages. This helps you act quickly to avoid bigger issues.

Another important point is using data-driven decision-making frameworks. Many companies now use these to improve operations and see things clearly. Tools like AI help make processes better, cut waste, and guide smart choices. This not only saves time but also helps manage tricky supply chain systems.

Better supply chain visibility is a top goal for over half of manufacturers. Seeing every step of the supply chain helps fix problems faster. For instance, real-time tracking shows where shipments are and solves issues early. This keeps everything running smoothly and avoids delays.

Lastly, being flexible is key to success. Changing with market needs, like new rules or demand shifts, keeps your supply chain strong. Using modular tools and scalable tech makes it easier to adjust and face new challenges.

Takeaway: Use predictive tools, data strategies, and better visibility to improve your supply chain. These steps will help you grow and compete globally.

Future Outlook for Intelligent Supply Chain Solutions

New Technologies Changing Supply Chain Management

New technologies are changing how supply chains work. They bring tools to make things faster and smarter. These changes will reshape global business operations:

Artificial Intelligence (AI): AI helps improve planning and efficiency. By 2024, half of supply chain companies will use AI.

Cloud Solutions: Cloud systems allow quick data sharing and better decisions.

Blockchain Technology: Blockchain makes tracking easier and stops fraud. It also automates tasks like checking invoices.

Data-Driven Decision Making: Data tools help improve services and keep customers happy.

AI is now key for managing shipping, storage, and transport.

Cloud systems share data instantly, speeding up decisions.

Blockchain saves time by automating work and boosting productivity.

These tools will help businesses stay ahead in a fast-changing world.

Why Sustainability and Green Logistics Matter

Being eco-friendly is now a must for supply chains. Customers and governments want greener practices. Here’s how you can help:

Use warehouses powered by renewable energy.

Choose packaging that can be recycled or breaks down naturally.

Work with others to share resources and create green solutions.

Big companies are leading the way. For example, Unilever aims for zero emissions by 2039. DHL plans to cut all logistics emissions by 2050. These actions protect the planet and build trust with customers.

Tip: Start small by using green packaging or energy-saving lights in warehouses.

What’s Next for Global Supply Chains?

The next 10 years will bring big changes to supply chains. Robots, AI, and new shopping habits will lead the way. Drones and self-driving vehicles will change how goods are delivered. Online shopping will need faster and smarter logistics.

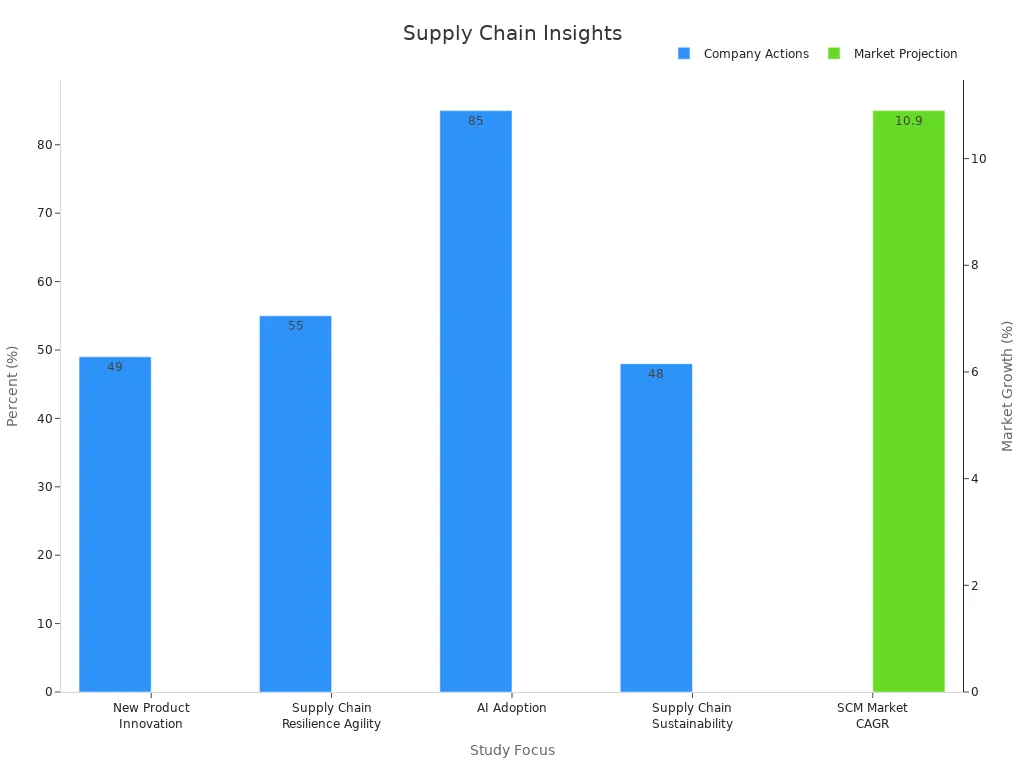

Statistic | Description |

|---|---|

49% | Companies focusing on faster product launches in 2023, up from 11% in 2022. |

55% | Medium businesses improving supply chain flexibility in 2023. |

85% | Leaders planning to use AI for better supply chains. |

48% | Companies feeling pressure to go green in supply chains. |

10.9% | Expected yearly growth of the supply chain market from 2022 to 2032. |

The supply chain market will grow a lot thanks to new technology. By using these tools, businesses can stay strong and succeed in a tough market.

Smart supply chain tools have changed how Chinese manufacturers grow globally. By upgrading factories and using new technology, products get better. This also helps create more types of products to sell. These changes make companies stronger in local and global markets. Learning from big global companies has improved local supply chains too. This shift moves industries from using lots of workers to using smart machines. Now, Chinese manufacturers lead in areas like cars and phones.

Using these tools early keeps your business ahead of others. Spending on smart plans lowers risks and helps your business grow over time. Build a better and stronger supply chain now to succeed worldwide.

See Also

Addressing Global Supply Chain Growth Challenges Effectively

Improving Supply Chain Efficiency Through Cloud-Based Solutions

Streamlining Supply Chain Problems in Advanced Manufacturing

Transforming Industries with Innovative Cloud Supply Chain Solutions