Empowering Chinese Manufacturing to Go Global in the Era of Smart Logistics

Smart logistics has changed how Chinese factories compete worldwide, empowering Chinese manufacturing to thrive in the global arena. Using tools like robots and IoT, factories work faster and better. These tools help them meet global rules and handle changing markets. Watching work in real-time and using resources wisely improves product quality. Smart supply chains have helped Chinese factories succeed in tough global markets.

Key Takeaways

Smart logistics helps Chinese factories by using tools like AI and IoT. This makes work faster and products better.

Working with local delivery companies helps factories grow worldwide. It speeds up shipping and lowers expenses.

Teaching workers to use digital tools makes them work better. It also helps factories use new technology easily.

Being eco-friendly is important. Green practices save money and meet world rules.

Tracking in real-time and smart supply chains help factories adjust fast. This keeps them strong in the market.

The Evolution of Chinese Manufacturing

From "Made in China" to "Innovated in China"

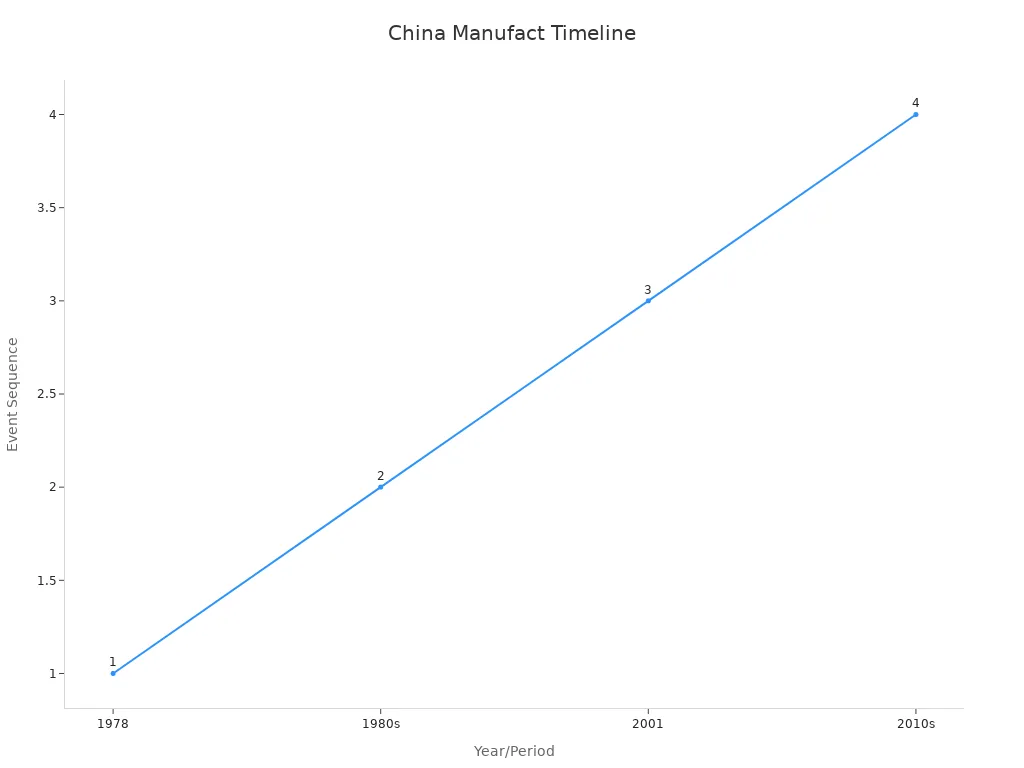

Over the years, Chinese manufacturing has changed a lot. It started with making cheap goods but now focuses on new ideas and advanced tools. This change began in 1978 when China opened its economy to the world. Special Economic Zones (SEZs) were created to attract foreign money and grow industries. By the 2010s, plans like "Made in China 2025" pushed factories to use modern technology and depend less on foreign ideas.

Important steps in this journey include:

1978: Deng Xiaoping started economic reforms.

2001: China joined the World Trade Organization (WTO), linking to global trade.

2010s: Shifted to high-tech fields like robots, biotech, and green energy.

These changes made China a leader in smart supply chains, using real-time tracking and saving resources.

The Rise of China as a Global Manufacturing Powerhouse

China's growth in manufacturing is unmatched. By the 1990s, it became "the world’s factory" due to cheap labor and helpful government rules. Many foreign companies built factories in China to save costs. By 2022, China stayed the top manufacturing country for 13 years, making about 30% of the world’s goods.

The industry gives jobs to nearly 100 million people and helps the economy grow. Major exports include electronics, clothes, machines, and steel, proving China’s global strength.

Adapting to Shifting Global Trade Dynamics

Chinese factories have adjusted well to global trade changes. Economic challenges have made people spend carefully, with 58% of city families saving more. This careful spending increased the need for good-quality but affordable items. Also, the growing middle class has influenced markets, pushing factories to create better and smarter products.

By accepting these changes, China keeps growing in the global market, staying strong and competitive.

Empowering Chinese Manufacturing Through Smart Logistics

Key technologies driving smart logistics (AI, IoT, robotics, blockchain)

Smart logistics uses advanced tools to improve supply chains. Artificial intelligence (AI) helps predict demand and manage inventory better. The Internet of Things (IoT) connects devices to track cargo in real-time. Robotics handles warehouse tasks, making work faster and needing fewer workers. Blockchain keeps transactions safe and clear, building trust in trade.

These tools bring new ideas to logistics. AI finds quicker delivery routes, saving time and money. IoT sensors spot problems early, avoiding delays. Drones and self-driving vehicles make transportation easier. Together, these tools help Chinese factories compete worldwide.

Applications in global supply chains

Smart logistics tools are used in many supply chain areas. IoT helps keep machines working well with predictive maintenance. JD.com uses IoT to cut delivery times by 47%. Robots in warehouses, like at Amazon, speed up order packing. Blockchain secures deals, following global trade rules.

Chinese factories use these tools to grow globally. Alibaba's Cainiao Network uses drones for fast deliveries, showing smart transport systems. These ideas make supply chains stronger, helping factories meet global needs quickly.

Benefits for efficiency, cost reduction, and supply chain visibility

Smart logistics brings clear benefits. AI and IoT make work smoother and reduce delays. JD.com saved 40% on logistics costs by using IoT. Real-time tracking improves visibility, helping better decisions.

Important performance measures show these gains:

KPI | What It Measures |

|---|---|

On-Time Delivery (OTD) | Orders delivered on or before the promised date. |

Total Order Cycle Time | Time from placing an order to delivery. |

Routing Compliance | Shipments following planned routes for reliability. |

Freight Cost Per Unit Shipped | Cost of transporting each unit effectively. |

Perfect Order Rate (POR) | Orders completed without mistakes, keeping customers happy. |

By using smart logistics, Chinese factories save money, work better, and stay competitive globally. These changes help Chinese manufacturing succeed in the world market.

Case Studies: Success Stories in Smart Logistics

JUSDA’s global strategies in India, Vietnam, and North America

JUSDA helps Chinese factories grow worldwide with smart logistics. In India, it offers bonded warehouses, transport, and customs help. These services solve problems like tough pricing and tricky customs rules. In Vietnam, JUSDA uses the "China +1" plan to expand. It provides transport options and supports electronics and energy industries. In North America, JUSDA focuses on growing markets and new products. It also manages risks for dangerous goods. These plans show how JUSDA adjusts to each region’s needs, helping factories succeed globally.

Lessons from JUSDA’s digital supply chain tools

JUSDA shows how technology improves today’s logistics. Using IoT, companies track supply chains in real-time. This makes work faster and smoother. For example, Haier uses IoT to track inventory and customer needs. This helps plan production better. JUSDA also uses data to make smart choices and save resources. Strong security keeps data safe as more devices connect. These lessons show how digital tools improve supply chains.

JUSDA Solutions

To provide you with professional solutions and quotations.

Chinese factories using smart logistics for global success

Many Chinese factories use smart logistics to compete globally. Tesla’s Shanghai factory uses sensors to plan production, improving quality. Fast Retailing tracks inventory with RFID to lower returns. Sephora uses IoT to keep products stored correctly. Cainiao Logistics built a smart network with automation to work faster. These examples prove smart logistics helps Chinese factories succeed worldwide.

Challenges in Global Expansion with Smart Logistics

Rules and compliance issues

Expanding globally brings tough rules for Chinese factories. Different areas have their own trade laws and safety rules. For example, the EU's REACH law and U.S. CPSC rules need factories to change how they work. These changes often mean cleaner methods, which cost more and are harder to manage.

Customs rules make things even harder. Countries like India have tricky customs steps that slow shipments. Political problems in some places add risks, making long-term plans uncertain. Factories also need to handle cultural differences, like language and business habits, to work smoothly with others.

Technology and infrastructure problems

Using smart logistics worldwide needs good tools and systems. But some areas lack these, slowing progress. Not enough money for research in central areas stops new ideas. Poor teamwork between government groups and weak policies make things worse.

Infrastructure problems also cause trouble. In places like Vietnam, higher land and worker costs hurt logistics. Uneven foreign investments slow building better systems. These issues make it hard to use tools like IoT and AI. Fixing these problems is key for Chinese factories to compete globally.

Tough competition in world markets

Chinese factories face strong rivals from big global brands. Fast changes in technology and digital tools make markets tricky. Low prices and similar products push factories to stand out and improve.

Smart supply chain tools are now a must to stay ahead. But higher worker costs and world tensions make some companies move factories. This increases competition in new markets. Careful planning and changes are needed to grow and succeed in these crowded markets.

Strategies to Overcome Challenges

Working with local logistics companies

Teaming up with local logistics companies helps manufacturers expand globally. These partnerships make deliveries faster and cover more areas. They also improve efficiency by sharing tools and using better technology. For example, YTO Express Group Co. Ltd connects global supply chains. It focuses on fast delivery under the Belt and Road Initiative. This helps cross-border online shopping and grows markets overseas.

Partnerships also lower costs by sharing resources and using bigger networks. Local experts help manufacturers understand new markets better. Sharing risks with local companies reduces problems and keeps things running smoothly. To succeed, trust, clear goals, and good communication are very important.

Using digital tools and training workers

Using digital tools and training workers solves global challenges. Smart tools like IoT and AI make logistics faster and stronger. The smart logistics market may grow to $750 billion by 2033. But high costs and setup problems can slow progress. Spending on digital tools and training fixes these issues.

For example, companies using online training saw 29% more worker interest. They also saved 70% on training costs. A factory spent $50,000 on digital training and kept 50% of workers, compared to 10% with old methods. These efforts save money and create skilled workers, helping Chinese factories succeed worldwide.

Handling rules with expert help

Dealing with tough rules needs expert help. Knowing local laws, like GDPR for data, avoids fines. Hiring local advisors helps companies follow business rules in new places. Working with customs experts makes shipping easier and faster.

Experts also give advice on local rules and cultures. This helps companies make better choices and avoid risks. With this smart planning, factories can grow successfully in global markets.

The Future of Chinese Manufacturing in the Era of Smart Logistics

New trends in global supply chains

Global supply chains are changing fast with new technology. Drones and self-driving vehicles help deliver items quickly. Digital twins copy supply chains to find and fix problems early. Blockchain makes trade safer and more trustworthy. AI and machine learning predict problems and improve delivery routes.

China leads these changes. The government supports smart supply chains with plans like the Belt and Road Initiative. These efforts make Chinese factories stronger and better at using resources. The smart logistics market is growing fast, from $43.26 billion in 2023 to $181 billion by 2031. This shows how important digital tools are for supply chains.

Chances for new ideas and teamwork

Smart logistics creates chances for new ideas and teamwork. Tools like AI, automation, and IoT are changing supply chains. IoT connects devices to collect data and improve work. AI helps plan better, predict demand, and manage inventory. Blockchain keeps trades safe and quick.

Working together is also important. Companies like Foxconn and Huawei show how technology improves supply chains. Foxconn uses robots and AI to work faster. Huawei uses AI to make logistics smarter. These examples show how teamwork and technology help Chinese factories succeed worldwide.

Sustainability in smart logistics

Sustainability is now a big part of smart logistics. Green practices save money and protect the planet. Cutting carbon emissions by 30% in five years lowers costs and helps the environment. Recycling and saving water are also key goals.

Chinese factories are going green to meet global standards. Smart logistics systems plan better routes to use less fuel and cut emissions. Electric delivery vehicles and automated warehouses also help. These steps keep Chinese factories competitive while caring for the environment.

Smart logistics helps Chinese factories succeed globally. It makes supply chains stronger and helps factories handle market changes. Using smart tools lowers costs and makes work faster. In eastern China, smart logistics helps factories more than in other areas. Over time, it builds better industries, helping factories grow and stay strong worldwide. The future of Chinese factories depends on new ideas, teamwork, and using these tools for success.

Key Findings | Description |

|---|---|

Positive Impact | Smart logistics makes supply chains stronger and more reliable. |

Cost Reduction | Using smart tools cuts costs and improves efficiency. |

Regional Variance | Eastern China benefits more from smart logistics than other regions. |

Long-term Dynamics | Smart logistics supports better industries and long-term growth. |

FAQ

1. What is smart logistics?

Smart logistics uses tools like AI, IoT, and robots. These tools make supply chains faster and more efficient. They cut costs and track shipments in real-time. This helps factories meet global needs and handle market changes.

2. How does smart logistics help Chinese factories?

Smart logistics makes supply chains clear and reduces delays. It saves money and improves product quality. Factories can use resources better and meet world standards. These benefits help Chinese factories compete globally.

3. What does AI do in smart logistics?

AI helps plan delivery routes and manage inventory. It predicts demand and spots problems early. AI also suggests fixes to keep things running smoothly. This saves time, money, and improves efficiency.

4. Why is being eco-friendly important in smart logistics?

Eco-friendly practices protect the planet and meet global rules. Using electric vehicles and better routes cuts pollution. These steps save money and help factories stay competitive in green markets.

5. How can factories solve global logistics problems?

Factories can work with local logistics companies and use smart tools. Training workers and hiring experts for rules also helps. These steps make it easier to grow and succeed worldwide.

See Also

Transforming Future Logistics Through AI Supply Chain Solutions

Achieving Success in High-Tech Manufacturing With Lean Logistics

Enhancing Supply Chain Strategies for High-Tech Manufacturing Challenges

Addressing Global Supply Chain Growth Challenges Effectively

Transforming Logistics Through Innovative Supply Chain Practices