Essential Processes and Benefits of Supply Chain Management

Supply chain management involves the coordination of a business's entire production flow, from sourcing raw materials to delivering a finished product. It plays a crucial role in modern business by ensuring efficiency and resilience. Companies with optimized supply chains often see significant benefits. For instance, 79% of businesses with high-performing supply chains achieve revenue growth above their industry's average. This highlights the importance of effective supply chain management in enhancing business efficiency and competitiveness.

Understanding Supply Chain Management

Definition and Scope

What is Supply Chain Management?

Supply chain management (SCM) involves overseeing the entire production process, from acquiring raw materials to delivering the final product to consumers. It ensures that each step in the supply chain operates efficiently and effectively. SCM aims to streamline operations, reduce costs, and improve customer satisfaction. By managing these processes, businesses can achieve a competitive edge in the market.

Scope of Supply Chain Management

The scope of SCM extends beyond mere logistics. It encompasses various activities, including procurement, production, inventory management, and distribution. SCM also involves strategic planning and collaboration with suppliers, manufacturers, and retailers. This comprehensive approach ensures that products reach customers in a timely and cost-effective manner. Effective SCM requires a deep understanding of market dynamics and consumer demands.

Key Components

Suppliers and Manufacturers

Suppliers and manufacturers form the backbone of the supply chain. Suppliers provide the raw materials necessary for production. Manufacturers transform these materials into finished goods. Efficient coordination between suppliers and manufacturers is crucial for maintaining a steady flow of products. Companies often engage in strategic partnerships with suppliers to ensure quality and reliability.

Distributors and Retailers

Distributors and retailers play a vital role in bringing products to market. Distributors manage the transportation and storage of goods, ensuring they reach retailers on time. Retailers, in turn, sell these products to consumers. Effective distribution strategies can significantly reduce costs and improve delivery times. Retailers must also adapt to changing consumer preferences to remain competitive.

Customers

Customers are the ultimate focus of any supply chain. Their needs and preferences drive the entire process. Businesses must ensure that products meet customer expectations in terms of quality, price, and availability. Customer feedback provides valuable insights for improving supply chain operations. Companies that prioritize customer satisfaction often see increased loyalty and repeat business.

Case Studies: Successful supply chain management often involves learning from real-world examples. For instance, some high-profile companies have implemented cost-reduction strategies that resulted in significant improvements. These case studies provide valuable insights into effective supply chain practices and inspire businesses to adopt similar approaches. By analyzing these examples, companies can develop intuitive understanding and analytical skills to enhance their supply chain dynamics.

Essential Processes in Supply Chain Management

Planning

Effective supply chain management begins with meticulous planning. This stage involves two critical components: demand forecasting and inventory management.

Demand Forecasting

Demand forecasting predicts future customer demand for products. Companies use historical data, market trends, and statistical tools to make these predictions. Accurate demand forecasting helps businesses maintain optimal inventory levels, reducing the risk of overproduction or stockouts. By anticipating customer needs, companies can streamline their supply chain processes and enhance overall efficiency.

Inventory Management

Inventory management ensures that a company has the right products in the right quantities at the right time. It involves tracking inventory levels, orders, sales, and deliveries. Efficient inventory management minimizes holding costs and prevents excess stock. Companies often use technology, such as inventory management software, to automate and optimize this process. This approach not only reduces costs but also improves customer satisfaction by ensuring product availability.

Sourcing

Sourcing is a vital process in supply chain management, focusing on acquiring the necessary goods and services from suppliers.

Supplier Selection

Supplier selection involves evaluating and choosing suppliers who can provide quality materials at competitive prices. Companies assess potential suppliers based on criteria such as reliability, cost, and quality. Establishing strong relationships with suppliers ensures a steady supply of materials, which is crucial for maintaining production schedules and meeting customer demands.

Procurement Strategies

Procurement strategies define how a company acquires goods and services. These strategies may include negotiating contracts, managing supplier relationships, and optimizing purchasing processes. Effective procurement strategies help companies reduce costs and improve supply chain efficiency. By leveraging strategic sourcing, businesses can secure better terms and conditions, ultimately enhancing their competitive advantage.

Production

Production is the process of transforming raw materials into finished products. It encompasses manufacturing processes and quality control.

Manufacturing Processes

Manufacturing processes involve the actual creation of products. Companies must ensure that these processes are efficient and cost-effective. Streamlined manufacturing processes reduce waste and increase productivity. By adopting advanced technologies and methodologies, businesses can enhance their production capabilities and meet market demands more effectively.

Quality Control

Quality control ensures that products meet specific standards and customer expectations. It involves inspecting and testing products at various stages of production. Implementing robust quality control measures helps companies maintain high product quality and reduce defects. This not only enhances customer satisfaction but also strengthens the company's reputation in the market.

Logistics

Logistics plays a pivotal role in supply chain management by ensuring the efficient movement and storage of goods. It focuses on optimizing internal processes and resources to meet customer needs effectively.

Transportation Management

Transportation management involves planning, executing, and optimizing the movement of goods. Companies must select the most efficient transportation modes, such as air, land, sea, or rail, to minimize costs and delivery times. Effective transportation management ensures that products reach their destinations safely and on schedule. By leveraging technology and data analytics, businesses can enhance route planning and monitor shipments in real-time, leading to improved operational efficiency.

Warehousing and Distribution

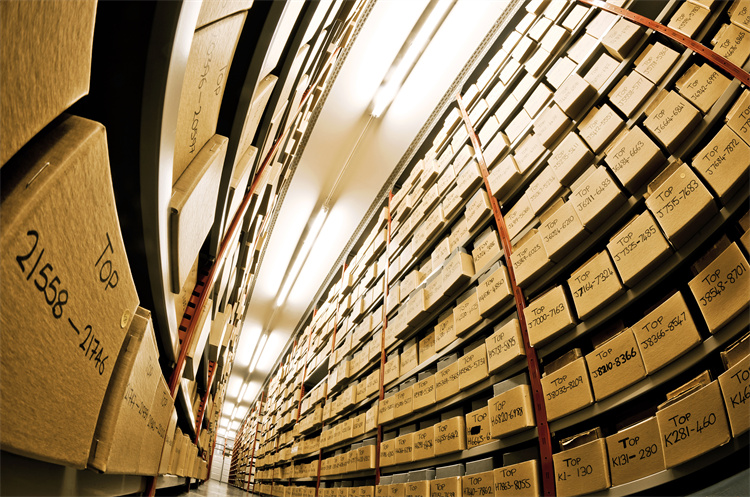

Warehousing and distribution are critical components of logistics. Warehousing involves storing goods until they are needed for distribution. Efficient warehousing practices help reduce inventory holding costs and ensure product availability. Distribution, on the other hand, focuses on delivering products to retailers or end customers. Companies must develop strategic distribution networks to optimize delivery routes and minimize transit times. By integrating warehousing and distribution processes, businesses can achieve seamless supply chain operations and enhance customer satisfaction.

Return Management

Return management is an essential aspect of supply chain management that deals with handling product returns and exchanges. It ensures that returned products are processed efficiently and cost-effectively.

Reverse Logistics

Reverse logistics involves managing the flow of returned goods from customers back to the company. It includes activities such as product inspection, refurbishment, recycling, or disposal. Efficient reverse logistics processes help companies recover value from returned products and minimize waste. By implementing robust reverse logistics strategies, businesses can reduce costs and improve sustainability.

Handling Returns and Exchanges

Handling returns and exchanges requires a systematic approach to ensure customer satisfaction. Companies must establish clear return policies and procedures to facilitate smooth returns. This involves providing customers with easy-to-follow instructions and prompt refunds or replacements. By prioritizing customer service in return management, businesses can build trust and loyalty, ultimately enhancing their competitive advantage in the market.

Benefits of Effective Supply Chain Management

Effective supply chain management offers numerous advantages that significantly impact a business's success. By optimizing various processes, companies can achieve cost reduction, improved customer satisfaction, and increased flexibility.

Cost Reduction

Minimizing Operational Costs

Supply chain management plays a crucial role in minimizing operational costs. Companies streamline their operations by optimizing logistics and inventory management. This reduces unnecessary expenses. For example, during the Industrial Revolution, the invention of machinery and railways transformed transport systems. This led to faster and more efficient goods flow. Businesses today continue to benefit from these advancements by implementing efficient supply chain strategies.

Efficient Resource Utilization

Efficient resource utilization is another key benefit of effective supply chain management. Companies maximize their resources by coordinating production schedules and managing supplier relationships. This ensures that materials and labor are used optimally. The introduction of cargo container standardization after World War II facilitated efficient transshipment of goods. This innovation allowed businesses to utilize resources more effectively, reducing waste and improving overall efficiency.

Improved Customer Satisfaction

Timely Delivery

Timely delivery is essential for maintaining customer satisfaction. Supply chain management ensures that products reach customers on time by optimizing transportation and distribution processes. The emergence of automobiles in the early 20th century, with the invention of the internal combustion engine, led to faster and more flexible transportation of goods. Today, companies leverage advanced technologies to monitor shipments in real-time, ensuring timely delivery and enhancing customer satisfaction.

Enhanced Product Quality

Enhanced product quality is a direct result of effective supply chain management. Companies implement robust quality control measures to ensure that products meet customer expectations. By maintaining high standards throughout the production process, businesses can deliver superior products. This not only satisfies customers but also strengthens the company's reputation in the market.

Increased Flexibility and Responsiveness

Adapting to Market Changes

Supply chain management enables companies to adapt to market changes swiftly. Businesses can respond to fluctuations in demand by maintaining flexible supply chain processes. After World War II, logistics transitioned from warfare to business, focusing on important aspects like distribution and customer service. This shift allowed companies to become more agile and responsive to market dynamics.

Agile Supply Chain Strategies

Agile supply chain strategies are essential for maintaining competitiveness. Companies develop strategies that allow them to quickly adjust to changing market conditions. By leveraging technology and data analytics, businesses can anticipate trends and make informed decisions. This agility ensures that companies remain competitive and can capitalize on new opportunities.

Competitive Advantage

Innovation and Differentiation

Innovation and differentiation stand as pillars of competitive advantage in supply chain innovation. Companies that embrace innovative practices often lead their industries. They introduce new technologies and processes that streamline operations and enhance product offerings. For instance, the Industrial Revolution marked a significant shift with the invention of machinery and railways. These advancements transformed transport systems, enabling faster and more efficient goods flow. Today, businesses continue to innovate by integrating cutting-edge technologies like IoT and big data analytics into their supply chains. This not only improves efficiency but also sets them apart from competitors.

Differentiation involves creating unique products or services that meet specific customer needs. Companies achieve this by understanding market trends and consumer preferences. They tailor their offerings to stand out in a crowded marketplace. By focusing on innovation and differentiation, businesses can build a strong brand identity and attract loyal customers. This approach not only enhances their market position but also drives long-term success.

Market Leadership

Market leadership results from a company's ability to consistently outperform its competitors. Effective supply chain management plays a crucial role in achieving this status. Companies that optimize their supply chains gain a significant edge over rivals. They reduce costs, improve product quality, and ensure timely delivery. These factors contribute to increased customer satisfaction and loyalty.

Historical advancements in logistics have paved the way for modern market leaders. After World War II, logistics transitioned from warfare to business. This shift emphasized important aspects like distribution and customer service. Companies that adapted to these changes became more agile and responsive to market dynamics. Today, businesses leverage advanced logistics strategies to maintain their leadership positions. They focus on efficient resource utilization and agile supply chain processes. By doing so, they can quickly adapt to market changes and capitalize on new opportunities.

JUSDA's Role in Supply Chain Management

JUSDA stands as a leader in supply chain management, offering innovative solutions and industry-specific services. Their approach enhances efficiency and competitiveness for businesses across various sectors.

Innovative Solutions

JUSDA provides cutting-edge solutions that transform supply chain operations. These innovations streamline processes and improve overall performance.

JusLink Intelligent Supply Chain

JusLink integrates IoT, cloud computing, and big data to create an intelligent supply chain. This platform facilitates real-time collaboration and information sharing. Companies benefit from enhanced visibility and control over their supply chains. By leveraging these technologies, businesses can optimize operations and reduce costs. Survey Results: 79% of companies believe that supply chain optimization directly improves revenue. JusLink plays a crucial role in achieving this optimization.

Cloud Warehousing and Consolidation

JUSDA's cloud warehousing solutions offer advanced inventory management. Businesses can track inventory levels in real-time, ensuring product availability. This approach minimizes holding costs and enhances customer satisfaction. Consolidation services further streamline logistics by combining shipments. This reduces transportation costs and improves delivery times. Companies that adopt these solutions gain a competitive edge in the market.

Industry-Specific Services

JUSDA tailors its services to meet the unique needs of different industries. This customization ensures that businesses receive the most effective supply chain solutions.

Electronic Manufacturing and 3C Home Appliances

In the electronic manufacturing sector, JUSDA provides specialized logistics services. These services support the production and distribution of electronic components and 3C home appliances. Efficient supply chain management is crucial in this fast-paced industry. JUSDA's solutions help companies maintain high-quality standards and meet tight deadlines. By optimizing supply chain processes, businesses can enhance product quality and customer satisfaction.

Automotive and New Energy Sectors

JUSDA also serves the automotive and new energy sectors. These industries require precise logistics and supply chain management. JUSDA's services ensure timely delivery of parts and materials. This reliability supports production schedules and reduces downtime. Companies in these sectors benefit from improved operational efficiency and cost savings. By partnering with JUSDA, businesses can focus on innovation and growth.

Conclusion: JUSDA's role in supply chain management highlights the importance of innovative solutions and industry-specific services. Their offerings enable businesses to optimize operations and achieve a competitive advantage. As a result, companies experience increased revenue and improved customer satisfaction.

JUSDA Solutions

To provide you with professional solutions and quotations.

Supply chain management encompasses essential processes that drive business success. Companies benefit from cost reduction, improved customer satisfaction, and increased flexibility. Effective strategies in supply chain management provide a competitive edge. Businesses should invest in these strategies to enhance their operations.

Michigan State University: “Excellent supply chain strategies provide ways to move ahead of the competition in an increasingly complex marketplace.”

JUSDA plays a pivotal role in enhancing supply chain efficiency. Their innovative solutions and industry-specific services support businesses in achieving operational excellence. By leveraging JUSDA's expertise, companies can optimize their supply chains and achieve greater success.

See Also

Innovative Approaches: Transforming Supply Chain Operations

Logistics Transformation: Effects of Supply Chain Innovation

The Importance of Security in Supply Chain Logistics

Ensuring Success: Applying Leading Supply Chain Efficiency Techniques

Improving Supply Chains through Cloud-Based Technological Solutions