Building a Fair and Quantifiable Warehouse Performance Management System

You want fair and accurate results when you measure warehouse performance. Many warehouses now use technology like electronic monitoring and algorithmic management. These tools help track worker productivity and movements in detail, making measurement more precise. However, fairness can become a challenge. Some systems may reduce worker autonomy or create rigid rules. You also face issues like unclear goals, biased evaluations, and inconsistent feedback. JUSDA focuses on using advanced systems to improve efficiency, transparency, and fairness in warehouse solutions.

Key Takeaways

Set clear, specific goals using the SMART framework to stay focused and motivated in your warehouse work.

Track important performance metrics like inventory accuracy and order accuracy to measure and improve warehouse efficiency.

Use real-time data and automation tools to spot problems quickly and keep warehouse operations running smoothly.

Give and receive regular feedback based on data to find areas for improvement and support continuous learning.

Ensure fairness by using transparent reward systems and involving employees in designing incentive programs.

SMART Goals

Role-Based Objectives

You need clear goals to guide your work in the warehouse. The SMART framework helps you set goals that are Specific, Measurable, Achievable, Relevant, and Time-Bound. When you use SMART goals, you know exactly what you must do and how to measure your progress. This approach makes your objectives realistic and easy to understand.

You play an important role in meeting company targets. Open dialogue helps you see how your daily tasks connect to larger business goals. When you join goal-setting discussions, you feel more engaged and motivated. Managers support you with training and resources, so you can reach your goals. Regular feedback lets you track your progress and adjust your actions if needed.

Tip: Setting SMART goals helps you stay focused and confident. You know what is expected and how your work matters.

Here is how SMART goals align your role with company objectives:

You discuss company goals and learn how your job supports them.

You understand why each objective is important.

You help set goals and make decisions.

You get support and recognition for your efforts.

You review your progress and update goals as needed.

Alignment with Business Needs

Your warehouse goals must support the company’s overall strategy. You work with people from sales, procurement, and finance to make sure everyone moves in the same direction. Clear inventory management goals help reduce costs and improve turnover. You use key performance indicators like order accuracy and inventory turnover to measure success.

You use technology such as Warehouse Management Systems (WMS), data analytics, and IoT to track performance and respond to changes in demand.

Data visibility lets you tailor goals to your department and meet company expectations.

Insights from warehouse operations show where you can improve or where you excel.

Meeting customer expectations through efficient inventory and returns processing helps the business succeed.

You form teams with members from different departments to set goals and solve problems. You define what you want to achieve and how to measure it. You keep communication clear and make sure everyone understands the plan. When you use best practices like regular audits and automation, you help the warehouse run smoothly and support business growth.

Performance Metrics

Key Indicators

You need clear and reliable metrics to measure warehouse performance. These metrics help you see how well your warehouse runs and where you can improve. When you track the right indicators, you make better decisions and keep your warehouse efficient.

Here are some of the most important key performance indicators (KPIs) you should know:

Inventory Accuracy: This shows if your records match the actual stock. High accuracy means you avoid overstocking and shortages.

Efficiency of Receiving: This measures how quickly and correctly you receive goods. Fast and accurate receiving keeps your supply chain moving.

Picking and Packing Costs: You track the money spent on picking and packing orders. Lower costs mean higher profits.

Inventory Turnover: This tells you how often you sell and replace your inventory. High turnover means you manage stock well and meet customer demand.

Customer Cycle Order Time: This is the time from when a customer places an order to when they receive it. Shorter times lead to happier customers.

Order Accuracy: This measures if you send the right items to customers. High order accuracy builds trust and reduces returns.

Dock-to-Stock Cycle Time: This tracks how long it takes to move goods from receiving to storage. Faster times mean better efficiency.

Perfect Order Rate: This combines accuracy, timeliness, and completeness. A high rate means you deliver what customers want, when they want it.

Tip: World-class warehouses often reach 97% or higher in inventory accuracy and 98-99% in order accuracy.

You can also use other KPIs like space utilization, fill rate, and cases shipped per labor hour. These indicators give you a full picture of your warehouse performance. Automated warehouses use extra metrics, such as Mean Missions Before Obstruction (MMBO) and Mean Missions Before Intervention (MMBI), to track how well robots work and how often they need help. Manual warehouses focus more on labor efficiency and order picking accuracy.

Recent research shows that time, cost, and efficiency are the most important groups of KPIs. You should also consider environmental and social KPIs, such as energy use and workplace safety, for a balanced approach.

Balancing Quality and Quantity

You want your warehouse to move goods quickly, but you also need to keep quality high. Balancing these two goals is key to strong warehouse performance. If you only focus on speed, you may see more mistakes or damaged goods. If you only focus on quality, you might slow down and miss customer deadlines.

You can use different KPIs to track both quality and quantity. Here is a table that shows some common examples:

KPI Category | KPI Name | Description | Example Calculation |

|---|---|---|---|

Quality | Measures how many products meet standards | (Good Units / Total Units) × 100 | |

Quality | Damage Rate | Tracks the percentage of damaged products | (Damaged Units / Total Units Handled) × 100 |

Quality | Rate of Return Due to Quality | Shows returns caused by quality issues | (Returns Due to Quality / Total Returns) × 100 |

Quality | Audit Score Compliance | Checks if you follow industry rules and policies | (Audit Points Achieved / Total Possible) × 100 |

Quantity | Warehouse Throughput | Measures how many goods move through the warehouse | Total Output / Time Period |

Quantity | Fill Rate | Shows the percentage of orders filled from stock | (Orders Filled from Stock / Total Orders) × 100 |

Quantity | Inventory to Sales Ratio | Balances inventory levels with sales | Ending Inventory Value / Total Sales |

Quantity | Labor Productivity | Measures how much work your team completes | N/A |

You can also use Overall Equipment Effectiveness (OEE) to see how well your equipment works. OEE combines availability, performance, and quality into one score.

Many warehouses use technology to help balance quality and quantity. Real-time tracking and automation tools let you spot problems early and fix them fast. For example, you can use order tracking to catch errors before they reach the customer. You can also use faster shipping methods to boost throughput without lowering quality.

Note: When you track both quality and quantity, you find the right balance. This helps you keep customers happy and run a successful warehouse.

You should set benchmarks for your KPIs. For example, top warehouses aim for 98-99% order accuracy and high throughput, such as 50 orders per hour. High inventory turnover shows you move stock quickly and avoid waste.

By watching these metrics, you make sure your warehouse performance stays strong. You can spot trends, fix issues, and keep improving every day.

Technology in Warehouse Performance

Real-Time Data

You need real-time data to keep your warehouse running smoothly. When you use live updates, you always know your inventory levels, order status, and shipping details. This helps you avoid mistakes and make quick decisions. Real-time data lets you spot problems early and fix them before they grow.

You see live updates on inventory, so you avoid stockouts and overstocking.

Managers can act fast to restock items or prioritize urgent orders.

You track every order as it moves through the warehouse, which reduces errors and delays.

Real-time dashboards show you key metrics like inventory turnover and order accuracy.

You can quickly adjust staffing and equipment to match busy times.

Continuous tracking means you spend less time on manual counts and more time on important tasks.

JUSDA’s warehouse management systems, such as eVMI and Juslink, give you this real-time visibility. These systems use barcode scanning, RFID, and smart drones to track every item. You get instant updates on stock and order status. This level of transparency helps you make better decisions and keeps your warehouse performance high.

Tip: Real-time data helps you respond to changes fast. You can spot trends, fix issues, and keep your warehouse efficient.

Automation Tools

Automation tools change the way you work in the warehouse. They help you measure performance fairly and accurately. When you use automation, you turn raw data into clear metrics everyone understands. This makes it easy to see what success looks like and how to reach it.

Automated systems track scan rates, errors, and worker speed.

Voice-directed picking and robot carts guide you step by step, making your job easier and reducing mistakes.

Augmented reality smart glasses help you pick orders faster and with fewer errors.

Automated storage and retrieval systems (AS/RS) move items quickly, cutting down on manual work.

Real-time alerts warn you about low stock or delays, so you can act right away.

JUSDA’s eVMI and Juslink systems use these automation tools to boost warehouse performance. You get real-time tracking, automated alerts, and clear dashboards. These features help you avoid errors, speed up order processing, and keep customers happy. Automation also makes performance measurement fair. Everyone gets judged by the same standards, not by guesswork or favoritism.

Note: Automation tools make your work more transparent. You always know how you are doing and what you need to improve.

When you use technology like JUSDA’s systems, you see big improvements in warehouse performance. You reduce errors, speed up deliveries, and make sure everyone gets treated fairly. Real-time data and automation work together to give you the best results.

Feedback and Improvement

Data-Driven Reviews

You need regular feedback to keep improving your work in the warehouse. When you use data-driven reviews, you see exactly how your actions affect results. Managers collect information from daily operations, such as order fulfillment times and error rates. You can look at these numbers to find areas where you do well and places where you need to improve.

Managers set up feedback channels so you can share your ideas and concerns.

You help spot problems by giving on-ground insights.

Teams use these insights to change warehouse processes and make them better.

Real-time monitoring systems track your work and show where bottlenecks happen.

Predictive analytics help you prepare for future trends and disruptions.

Tip: When you review data often, you find small issues before they become big problems. You help your team stay ahead and keep the warehouse running smoothly.

You play a key role in feedback loops. Your input helps managers refine operations and create a culture of continuous improvement. When you see your feedback lead to changes, you feel valued and motivated to keep sharing ideas.

Continuous Training

You need training to keep your skills sharp and stay safe at work. Continuous training gives you new knowledge and helps you adapt to changes in technology and warehouse processes. When you learn new skills, you feel more confident and ready for new challenges.

Ongoing training programs offer career growth opportunities. You see clear paths for advancement, which makes you more likely to stay with your company. Surveys show that most employees would stay longer if they had chances to learn and grow. Training also improves safety by teaching you the latest protocols and compliance rules. This reduces accidents and keeps everyone protected.

Note: Companies that invest in training see higher job satisfaction and lower turnover rates. You become more engaged and loyal when you know your employer cares about your development.

You join workshops, leadership programs, and continuing education courses. These activities prepare you for future roles and help you contribute to innovation in the warehouse. When you learn together with your team, you build a strong culture of adaptability and success.

Incentives and Fairness

Transparent Rewards

You want to know how your hard work gets recognized. Transparent reward systems help you see the link between your effort and your rewards. When you understand the rules, you feel more motivated and trust your workplace. JUSDA uses clear and open reward programs in warehouse operations. These programs combine both monetary and non-monetary incentives, such as bonuses, public recognition, and professional development opportunities.

Organizations with strong recognition and rewards programs see up to 20% higher employee engagement.

Companies that focus on recognition have 31% lower voluntary turnover.

Employees who receive regular appreciation are 2.7 times more likely to stay engaged.

Well-designed reward systems can boost average performance by 11%.

You benefit from a fair pay structure, clear criteria for bonuses, and regular feedback. JUSDA’s value-added services, like training and skill development, also support your motivation and growth. These services help you feel valued and encourage you to keep improving your warehouse performance.

Tip: Transparent rewards make it easier for you to understand how your work leads to recognition and success.

Employee Involvement

You play a key role in shaping incentive programs. When you share your ideas and feedback, you help create fair and effective rewards. JUSDA involves employees in designing incentive systems. This approach ensures that rewards match your needs and preferences.

Setting clear and measurable goals helps define what you need to achieve.

Understanding what motivates you makes incentives more meaningful.

Fairness and transparency in program design build trust.

Regular feedback and evaluation keep the program relevant.

Well-communicated rules and eligibility support clarity.

You can join surveys, focus groups, or team meetings to share your thoughts. JUSDA listens to your feedback and adjusts programs to fit changing needs. This involvement helps you feel respected and increases your satisfaction. When you help design the system, you know it is fair and supports your success.

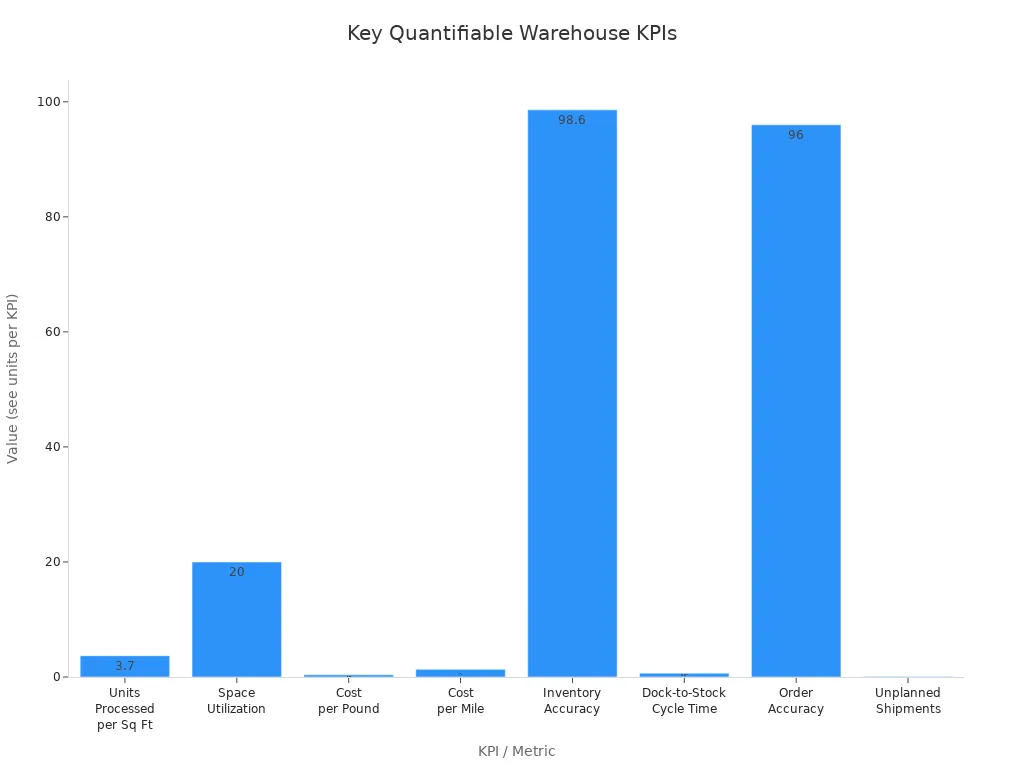

You can build a fair and quantifiable warehouse performance system by setting clear goals, tracking key metrics, and using real-time data. Regular evaluation and adaptation help you sustain improvements. The table below shows measurable outcomes you can achieve:

KPI / Metric | Description | Example / Explanation |

|---|---|---|

Inventory Accuracy | Accuracy of inventory records | |

Order Accuracy | Percentage of correct orders | 96% order accuracy |

Dock-to-Stock Cycle Time | Time from receipt to storage | 0.67 hours per shipment |

Space Utilization | Percentage of warehouse space used | 20% space utilization |

Keep improving by reviewing KPIs, involving employees, and updating processes.

Use JUSDA’s advanced solutions for continuous Warehouse Performance gains.

Explore guides from WERC or Michigan State University for best practices.

FAQ

What is a fair way to measure warehouse performance?

You use clear KPIs like order accuracy and inventory turnover. You track results with real-time data. You compare everyone’s work using the same standards.

Tip: Fair measurement helps you trust the results and improve your work.

How does JUSDA’s technology help you in the warehouse?

You get instant updates on inventory and orders. You use systems like eVMI and Juslink for tracking. Automation tools help you work faster and make fewer mistakes.

Real-time dashboards

Automated alerts

Can you give feedback on warehouse processes?

You share ideas during team meetings or surveys. Managers listen to your feedback and use it to improve operations. Your input helps create a better workplace for everyone.

What rewards can you earn for good performance?

You earn bonuses, public recognition, and training opportunities. JUSDA uses transparent reward programs. You see how your hard work leads to success.

Reward Type | Example |

|---|---|

Monetary | Bonus |

Non-monetary | Public recognition |

Development | Training programs |

See Also

How Robotic Automation Significantly Improves Warehouse Efficiency

Unlocking Warehouse Productivity Through Advanced Logistics Robotics

The Importance Of Automating Warehouses For Business Growth

Benefits Of Automation In High-Tech Manufacturing Warehouses Today

Mastering Lean Logistics To Achieve Success In Manufacturing