The Future is Automated: High-Tech Manufacturing Warehouse Benefits

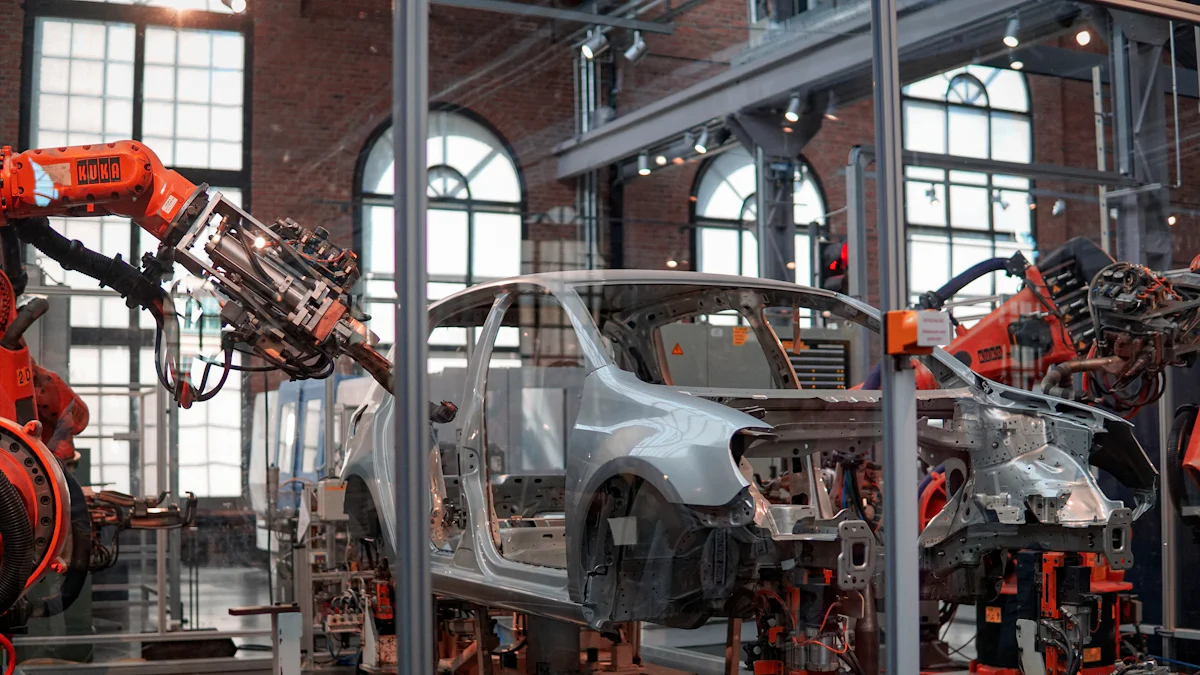

In the realm of high-tech manufacturing, Benefits of Automated Warehousing for High-Tech Manufacturing have revolutionized traditional warehouse operations. The shift towards automated warehousing is not just a trend but a necessity for businesses striving to enhance efficiency and competitiveness. With the increasing adoption of technology-driven solutions, warehouses are experiencing a significant transformation in their management practices. As companies embrace automation, robotics, and AI systems, the landscape of warehousing is undergoing a profound evolution.

Benefits of Automated Warehousing for High-Tech Manufacturing

In the realm of high-tech manufacturing, the implementation of automated warehousing systems brings forth a multitude of advantages that significantly enhance operational efficiency and productivity. Let's delve into the key benefits that these automated systems offer:

Increased Warehouse Throughput

Efficient Inventory Management

By utilizing automated warehousing solutions, companies can streamline their inventory management processes with precision and accuracy. The integration of advanced technologies allows for real-time tracking of stock levels, ensuring optimal inventory control.

Automated systems facilitate seamless inventory replenishment, reducing stockouts and overstock situations. This efficient management approach leads to improved order fulfillment rates and customer satisfaction.

Faster Order Fulfillment

With automated warehousing, orders are processed swiftly and accurately, minimizing delays in delivery timelines. The automation of order picking and packing operations accelerates the fulfillment process, enabling businesses to meet customer demands promptly.

The speed and accuracy achieved through automated order fulfillment not only enhance operational efficiency but also contribute to building a reputation for reliable service within the industry.

Better Resource Utilization

Optimized Space Usage

Automated warehouse systems maximize storage space utilization by strategically organizing inventory based on demand patterns. This optimized layout minimizes unnecessary movements within the warehouse, enhancing overall operational efficiency.

Through intelligent space utilization strategies enabled by automation, companies can store a larger volume of products in a compact area while maintaining accessibility for retrieval processes.

Reduced Waste

Automation plays a crucial role in minimizing waste generation within high-tech manufacturing warehouses. By implementing smart inventory control mechanisms, businesses can prevent excess stock accumulation and reduce instances of obsolete inventory.

The precise monitoring capabilities offered by automated systems enable proactive decision-making regarding inventory rotation and disposal, leading to reduced waste levels and improved sustainability practices.

Reduced Labor and Operational Costs

Lower Labor Expenses

Automated warehousing systems significantly decrease reliance on manual labor for routine tasks such as inventory counting and order processing. This reduction in labor-intensive activities translates to lower labor costs for businesses.

By automating repetitive operational functions, companies can allocate human resources more efficiently towards value-added tasks that require critical thinking and strategic decision-making capabilities.

Decreased Operational Overheads

The adoption of automated warehouse solutions results in decreased operational overheads associated with manual handling processes. Automation minimizes errors in tasks such as picking, packing, and shipping, thereby reducing rework costs.

With streamlined operational workflows driven by automation technologies, businesses can achieve cost savings through enhanced process efficiency and error reduction across various warehouse operations.

The integration of automated warehousing systems revolutionizes traditional warehouse practices in high-tech manufacturing environments by offering unparalleled benefits in throughput enhancement, resource optimization, labor cost reduction, and operational efficiency improvement.

Key Advantages

In the realm of high-tech manufacturing, the implementation of automated warehousing systems not only enhances operational efficiency but also elevates customer service standards. Let's explore the key advantages that automated warehouse systems bring to the forefront:

Improved Customer Service

Faster Delivery Times

Automated warehouse systems expedite order processing and fulfillment, leading to swift delivery times that meet customer expectations promptly.

By leveraging advanced technologies, businesses can ensure timely deliveries, enhancing overall customer satisfaction and loyalty.

Enhanced Accuracy

The integration of automated quality control mechanisms minimizes errors in product handling and shipment processes, guaranteeing precision and consistency in every order.

Consistent performance driven by automation translates into enhanced accuracy levels throughout the supply chain, reinforcing trust and reliability with customers.

Minimized Human Errors

Automated Quality Control

Automated systems work tirelessly to maintain quality standards by conducting thorough inspections and assessments without human intervention.

By implementing automated quality control measures, businesses can uphold product integrity and reliability, mitigating risks associated with manual errors.

Consistent Performance

The continuous operation of automated warehouse systems ensures consistent performance levels across all tasks, from inventory management to order processing.

With consistent performance as a hallmark of automation, businesses can deliver reliable services consistently, fostering long-term relationships with customers.

Increased Productivity and Efficiency

Streamlined Processes

Automation streamlines warehouse processes by optimizing workflows and minimizing bottlenecks, resulting in seamless operations from receiving to shipping.

Through streamlined processes facilitated by automation technologies, businesses can achieve higher productivity rates while maintaining operational efficiency.

Higher Output Rates

Automated warehouse systems enhance output rates by accelerating task completion times and maximizing resource utilization for increased productivity.

By achieving higher output rates through automation, companies can meet growing demands effectively while ensuring operational excellence.

The adoption of automated warehousing solutions in high-tech manufacturing not only transforms internal operations but also elevates customer service standards through faster delivery times, enhanced accuracy, minimized human errors, increased productivity levels.

Future Trends

In the ever-evolving landscape of high-tech manufacturing, the integration of AI and IoT technologies is paving the way for groundbreaking advancements in warehouse operations. These cutting-edge innovations are reshaping traditional practices and setting new standards for efficiency and sustainability.

Integration with AI and IoT

Predictive Maintenance

AI-powered analytics have emerged as a game-changer in predictive maintenance strategies within high-tech manufacturing warehouses. By harnessing the power of artificial intelligence, companies can proactively identify equipment failures before they occur, minimizing downtime and optimizing operational continuity. Through real-time data analysis, predictive maintenance not only enhances equipment reliability but also streamlines maintenance schedules for maximum efficiency.

Smart Inventory Systems

The implementation of IoT-enabled smart inventory systems revolutionizes inventory management practices by providing real-time visibility into stock levels, location tracking, and demand forecasting. With interconnected sensors and devices, businesses can monitor inventory movements seamlessly, ensuring accurate stock replenishment and reducing instances of stockouts. Smart inventory systems empower companies to make data-driven decisions that enhance supply chain responsiveness and optimize storage utilization.

Sustainability and Green Warehousing

Energy-Efficient Solutions

Embracing energy-efficient solutions is paramount in fostering sustainable warehouse practices within high-tech manufacturing environments. By leveraging renewable energy sources, implementing LED lighting systems, and optimizing heating/cooling mechanisms, companies can significantly reduce their carbon footprint while lowering operational costs. Energy-efficient initiatives not only contribute to environmental conservation but also position businesses as responsible corporate citizens committed to eco-friendly operations.

Eco-Friendly Practices

Adopting eco-friendly practices such as waste recycling, packaging optimization, and green logistics further reinforces the commitment to sustainable warehousing in high-tech manufacturing settings. By minimizing waste generation through recycling programs and adopting biodegradable materials, companies can mitigate environmental impact while promoting circular economy principles. Eco-friendly practices extend beyond internal operations to encompass supplier partnerships that prioritize sustainability throughout the supply chain network.

As high-tech manufacturing warehouses embrace the future trends of AI integration, IoT connectivity, sustainability initiatives, and eco-conscious practices, they are poised to redefine industry standards for operational excellence and environmental stewardship.

Investing in automated warehousing solutions is a strategic move for high-tech manufacturing companies seeking operational excellence. Automation significantly enhances efficiency by reducing errors and optimizing processes, ultimately leading to increased productivity and cost savings. The transformative impact of automation on warehouse management is undeniable, with benefits ranging from improved accuracy to streamlined workflows. As the industry evolves, embracing AI integration and sustainable practices will be key for staying ahead. To thrive in the future landscape of high-tech manufacturing, businesses must prioritize innovation and continuous improvement in their warehouse operations.

See Also

Exploring the Future of Supply Chain: AI Integration Perspectives

Advancements in Logistics Tech: Exploring Future Trends

Efficient Strategies for High-Tech Manufacturing Supply Chain Challenges

Transforming Logistics: The Influence of Supply Chain Advancements