The Future of Manufacturing Supply Chains: Trends to Watch

The manufacturing supply chain is evolving faster than ever. Technological advancements and shifting market demands are reshaping how you approach production and distribution. To stay competitive, you must adapt to these changes and anticipate the future of supply chains. Embracing innovation ensures your business remains resilient in a rapidly changing environment. The future holds immense potential for those who leverage emerging tools and strategies to optimize their supply chain operations.

Key Trends in the Future of Supply Chains

AI and Automation in Manufacturing Supply Chains

AI and automation are transforming supply chain management by enhancing efficiency and accuracy. AI improves supply chain visibility by analyzing historical data, enabling you to make data-driven decisions. It also enhances demand forecasting, helping you optimize inventory levels and reduce risks. For example, AI-powered logistics systems can optimize transportation routes, leading to faster deliveries and lower costs.

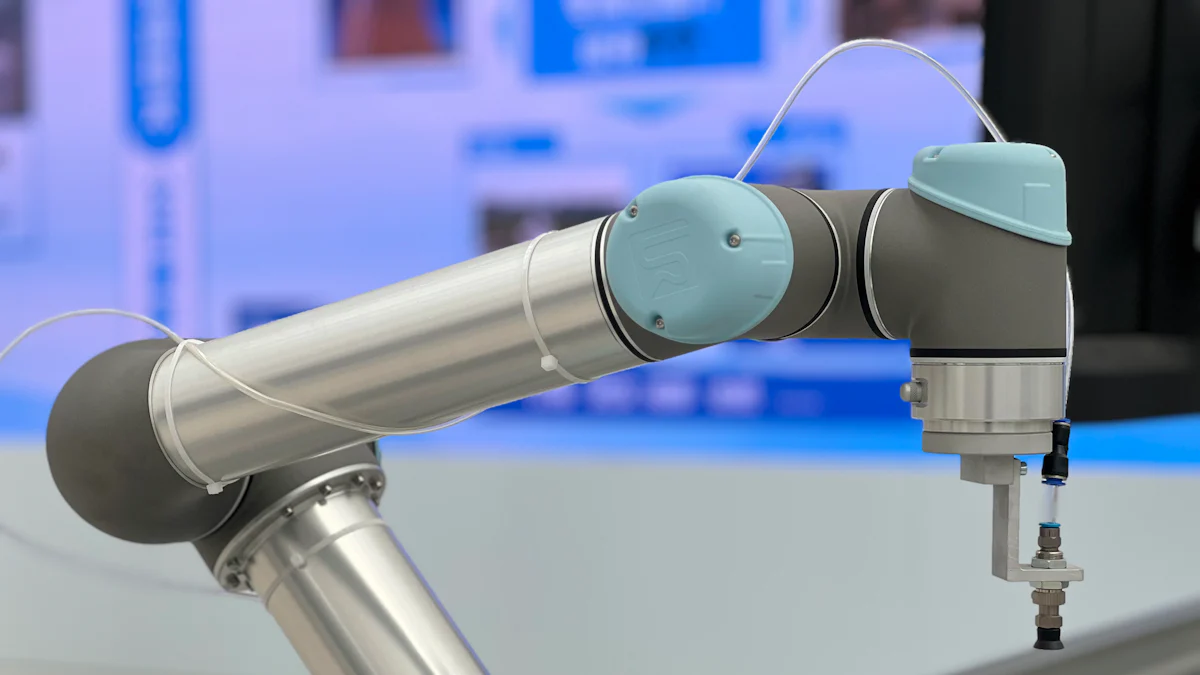

Automation reduces human intervention in repetitive tasks, improving operational efficiency. In warehouses, robotic systems handle picking and packing, increasing safety and productivity. Predictive maintenance, powered by AI, analyzes machinery data to predict failures before they occur, preventing costly downtime. Additionally, AI-controlled inventory systems automatically adjust stock levels based on real-time demand, minimizing excess inventory and carrying costs.

By adopting AI and automation, you can streamline workflows, improve decision-making, and stay competitive in the future of supply chains.

Reshoring and Localized Supply Chains

Reshoring and localized supply chains are gaining momentum as businesses seek to mitigate risks and improve resilience. By bringing production closer to home, you can reduce lead times, save costs, and enhance quality control. Localized supply chains also align with sustainability goals by reducing carbon footprints and supporting local economies.

Industries such as food and beverage, medical, and consumer goods are leading this trend. For example, localized supply chains foster greater collaboration with suppliers, ensuring better alignment with local market demands. This approach also strengthens supply chain resilience, allowing you to respond quickly to disruptions and maintain continuity.

Reshoring not only benefits your business but also contributes to the broader economy and environmental sustainability.

IoT and Smart Supply Chain Connectivity

IoT technology is revolutionizing supply chain management by providing real-time visibility into every stage of the process. IoT-enabled tracking devices optimize route monitoring and delivery efficiency, ensuring timely shipments. Smart inventory management uses sensors to monitor stock levels and conditions, reducing waste and improving accuracy.

Cold chain logistics, powered by IoT, preserves temperature-sensitive goods like pharmaceuticals and food. Predictive maintenance with IoT sensors minimizes downtime, enhancing overall supply chain reliability. Real-time data collection from IoT devices streamlines operations, automates processes, and reduces human errors.

By leveraging IoT, you can transform your supply chain into a connected network, enabling smarter decisions and improving efficiency. This technology is essential for building a digital supply chain that meets the demands of modern manufacturing trends.

Digitalization and data-Based Supply Chain Solutions

Digitalization is revolutionizing supply chain management by enabling you to harness the power of data for better decision-making. A digital supply chain integrates advanced technologies to streamline operations, improve efficiency, and enhance collaboration. By adopting digital tools, you can gain real-time visibility into your supply chain, enabling faster responses to challenges and opportunities.

One of the key benefits of digitalization lies in its ability to simplify coordination across the supply network. Using a single platform, you can ensure seamless communication between stakeholders. Standardized metrics and reporting reduce human errors, while advanced data analysis allows you to make data-driven decisions quickly. The table below highlights additional benefits of digitalization:

Benefit | Description |

|---|---|

Simple coordination | Enables seamless communication across the supply network using a single platform. |

Standardized metrics and reporting | Facilitates accurate and efficient data collection, reducing human errors. |

More advanced data analysis | Allows for efficient information gathering and quick decision-making based on comprehensive data. |

Risk identification | Real-time updates help identify quality challenges early, allowing for proactive measures. |

Speed | Accelerates processes, enabling quick responses to quality and compliance issues. |

Data-driven approaches are transforming supply chain management. Companies now use data analytics to optimize operations and reduce costs. Predictive analytics and real-time data monitoring allow you to anticipate disruptions and take proactive measures. These strategies not only enhance customer satisfaction but also position your business for long-term success.

By embracing digitalization, you can stay ahead of manufacturing trends and leverage supply chain technology to achieve supply chain optimization. This foresight ensures your business remains competitive in the future of supply chains.

Supply Chain Sustainability and Green Practices

Sustainability has become a cornerstone of modern supply chain management. With growing consumer demand for eco-friendly practices, integrating green initiatives into your supply chain is no longer optional. Sustainable supply chain practices reduce waste, improve energy efficiency, and lower costs. These measures not only benefit the environment but also enhance your brand image and operational efficiency.

To achieve supply chain sustainability, you can focus on innovating and collaborating with suppliers. Engaging suppliers in sustainable practices ensures that every stage of the supply chain aligns with environmental goals. Circular design, for instance, promotes products that can be disassembled, reused, or recycled. Minimalist design conserves resources and reduces waste, while modular design extends product lifespan by facilitating repairs.

Employee participation and customer feedback also play vital roles in sustainability efforts. Training employees in green practices fosters a culture of environmental responsibility. Involving customers in sustainability initiatives strengthens their connection to your brand and builds trust.

Retailers are increasingly adopting sustainable sourcing and energy-efficient technologies to reduce their carbon footprint. These innovations contribute to a greener future while providing strategic foresight for navigating market demands. By prioritizing sustainability, you can align your supply chain with global environmental goals and position your business as a leader in supply chain innovation.

Innovations Transforming the Manufacturing Supply Chain

Blockchain for Transparency and Trust

Blockchain technology is revolutionizing supply chain management by enhancing transparency and trust. It creates a tamperproof record of transactions, inventory, and financial flows, ensuring all stakeholders have access to a single source of truth. This shared ledger improves coordination and reduces risks, even among participants who may not fully trust each other. For example, blockchain ensures the authenticity of information during upstream transactions, fostering seamless collaboration.

The benefits of blockchain extend beyond trust. It accelerates product delivery, improves traceability, and integrates with existing systems without replacing them. By adopting blockchain, you can enhance efficiency and provide strategic foresight for your supply chain operations.

Blockchain Benefits |

|---|

Tamper-evident shared ledger enhances trust among stakeholders. |

Ensures transparency and authenticity of information during transactions. |

Facilitates seamless value exchange with a single source of truth. |

Digital Twins for Supply Chain Optimization

Digital twins are virtual replicas of physical supply chain processes. They provide real-time visibility into inventory, production, and logistics, enabling you to make informed decisions quickly. These tools excel in supply chain optimization by identifying inefficiencies and suggesting solutions to reduce costs and improve performance.

Digital twins also allow you to simulate disruptions, such as supplier delays or transportation issues. This capability helps you mitigate risks proactively. Additionally, they support strategic scenario planning by predicting demand shifts and preparing your business for potential disruptions. By leveraging digital twins, you can innovate and collaborate with suppliers more effectively, ensuring your supply chain remains resilient.

Advantage | Description |

|---|---|

Real-time visibility | Offers a live view of inventory and logistics for quick decision-making. |

Process optimization | Identifies inefficiencies and suggests cost-saving solutions. |

Scenario planning | Simulates future disruptions to prepare for demand shifts. |

Enhanced collaboration | Improves coordination across departments for better decision-making. |

Predictive Analytics for Proactive Decision-Making

Predictive analytics is a game-changer in supply chain technology. It uses historical data and real-time insights to forecast demand, optimize inventory, and streamline logistics. For example, predictive analytics can recommend optimal stock levels, reducing carrying costs and avoiding stockouts. It also enhances delivery schedules by analyzing traffic and weather data, ensuring timely shipments.

This technology helps you mitigate risks by identifying vulnerabilities and developing contingency plans. It also improves supplier relationship management by evaluating performance metrics and addressing issues proactively. By adopting predictive analytics, you can align production schedules with demand forecasts, minimize waste, and enhance customer satisfaction.

Key Applications of Predictive Analytics:

Demand forecasting to anticipate future needs.

Inventory management to optimize stock levels.

Logistics optimization for efficient delivery routes.

Risk mitigation through proactive planning.

Supplier performance evaluation for better collaboration.

Predictive analytics empowers you to make proactive decisions, ensuring your supply chain remains agile and competitive in the future.

Challenges and Strategies for the Future of Supply Chains

Addressing Cybersecurity Risks in Supply Chains

Cybersecurity risks pose significant challenges to supply chain management. Cybercriminals often exploit vulnerabilities to disrupt operations or steal sensitive data. Common threats include:

Malware attacks that infect systems to steal information or halt operations.

Phishing scams that trick employees into revealing confidential details.

Supply chain attacks targeting third-party vendors to inject malicious code.

Man-in-the-middle attacks intercepting communications to access sensitive data.

Denial-of-service (DoS) attacks overwhelming systems to disrupt normal activities.

To protect your supply chain, you must adopt robust cybersecurity strategies. Regular audits and vulnerability assessments help identify weak points. Multi-factor authentication secures access to critical systems. Keeping software updated ensures protection against the latest threats. Employee training builds awareness, reducing the risk of human error. Limiting access to sensitive data minimizes potential exposure. By implementing these measures, you can safeguard your supply chain and maintain operational continuity.

Overcoming Labor Shortages with Technology

Labor shortages challenge the efficiency of manufacturing supply chains. Technology offers solutions to bridge this gap. For example:

Robotic process automation (RPA) handles repetitive tasks, reducing the need for additional staff.

IoT sensors enable remote facility monitoring, minimizing the demand for on-site personnel.

Digital twins also serve as cost-effective training tools for less-experienced workers. Mobile hiring apps streamline recruitment and onboarding processes. However, while technology addresses many challenges, human skills remain essential. Combining automation enhancements with workforce development ensures a balanced approach to overcoming labor shortages.

Managing Geopolitical and Economic Uncertainty

Geopolitical and economic uncertainties disrupt supply chains worldwide. Trade tensions, sanctions, and conflicts force businesses to reevaluate sourcing and logistics strategies. For instance, U.S.-China trade disputes and Brexit have increased the complexity of navigating tariffs and regulations. Conflicts in Eastern Europe and the Middle East further complicate operations with sanctions and rising costs.

To adapt, you can diversify suppliers and source locally. Producing goods closer to target markets reduces risks and transportation costs. Risk assessment and reduction strategies help you prepare for potential disruptions. Rapid response plans ensure agility in addressing unforeseen challenges. As one expert noted, "Being well-prepared to deal with a ‘Black Swan’ event is, at the very least, comforting." By innovating and collaborating with suppliers, you can build a resilient and future-ready supply chain.

The future of supply chains will revolve around innovation, sustainability, and resilience. To thrive, you must embrace digital transformation and adopt end-to-end ecosystems that enable proactive planning. Building collaborative resilience through real-time data sharing and partnerships strengthens your ability to handle disruptions. Designing flexible, sustainable supply chains ensures adaptability to dynamic conditions. Proactive strategies, such as optimizing processes and investing in technology, prevent inefficiencies and enhance productivity. By integrating advanced tools and fostering collaboration, you can align with supply chain innovation and position your business for long-term success in a smart and evolving landscape.

See Also

Key Trends Shaping Future Efficiency In Supply Chains

Transforming Logistics With AI Innovations For The Future

Sustainable Practices: Robotics Trends In Supply Chain Management

The Supply Chain Revolution Driven By Robotics Technology

Effective Solutions To Tackle Supply Chain Challenges In Manufacturing