Future of Automotive Supply Chain Management

Automotive supply chain management involves the coordination of various processes to ensure the efficient production and delivery of vehicles. The industry faces significant challenges, such as managing thousands of component parts and international logistics. Emerging trends and technologies, like artificial intelligence (AI) and green supply chain management, are transforming operations. AI provides real-time vehicle location data and analytics, reducing costs and errors. Green supply chain practices enhance sustainability, making operations more environmentally friendly. These advancements highlight the evolving landscape and the future of automotive supply chain management.

Future of Automotive: The Role of Artificial Intelligence in Supply Chain Management

Artificial intelligence (AI) is transforming automotive supply chain management. AI enhances efficiency, reduces risks, and improves decision-making processes. The integration of AI into the supply chain marks a significant shift in the industry.

Future of Automotive: Predictive Analytics

Demand Forecasting

AI-driven predictive analytics enables accurate demand forecasting. AI algorithms analyze vast amounts of historical data. These insights help manufacturers anticipate market demands. Accurate forecasts reduce stockouts and minimize excess inventory. Companies can plan production schedules more effectively.

Inventory Management

AI optimizes inventory management by predicting future demand. Real-time data analysis ensures dynamic inventory adjustments. This capability prevents overstocking and understocking issues. AI systems provide real-time replenishment suggestions. Companies can maintain optimal inventory levels.

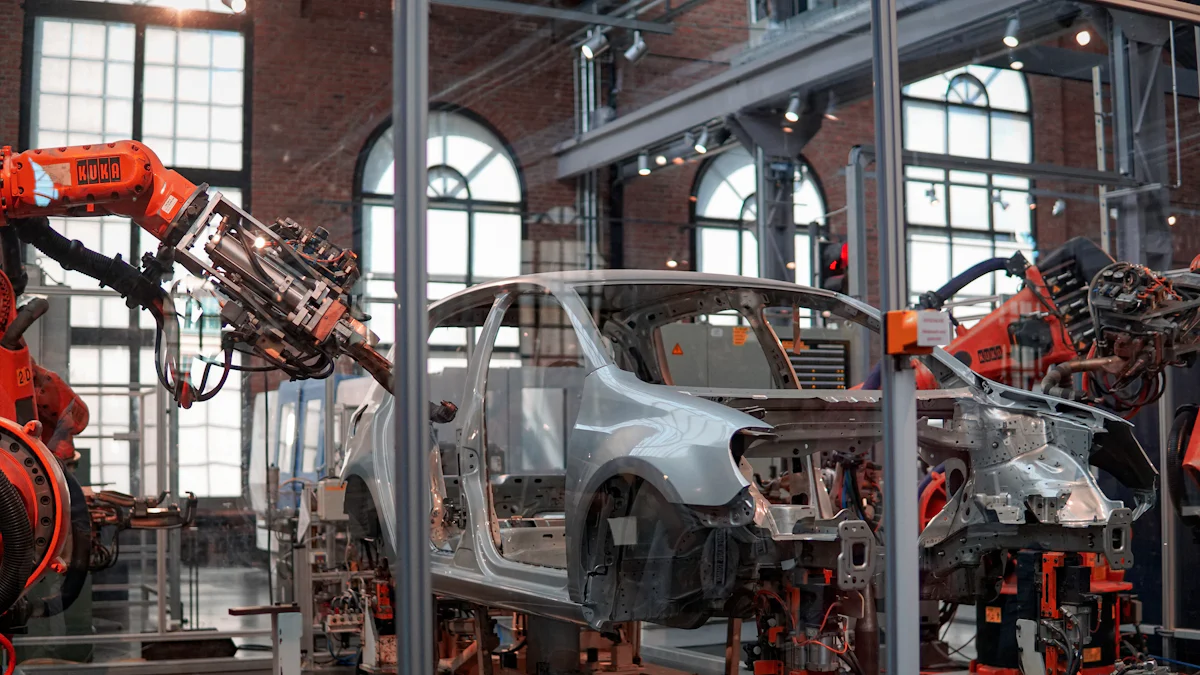

Automation and Robotics

Autonomous Vehicles

Autonomous vehicles play a crucial role in supply chain automation. These vehicles transport goods without human intervention. AI enhances navigation and route optimization. Autonomous vehicles reduce transportation costs and improve delivery times. The future of automotive logistics relies on these innovations.

Automated Warehousing

Automated warehousing revolutionizes storage and retrieval processes. AI-powered robots handle tasks traditionally performed by humans. These robots increase efficiency and accuracy in warehouses. Automated systems streamline order fulfillment and inventory management. The future of warehousing will see widespread adoption of these technologies.

AI-Driven Decision Making

Real-Time Data Analysis

AI enables real-time data analysis for informed decision-making. Supply chain managers receive up-to-date information on various metrics. This data includes production rates, inventory levels, and shipment statuses. Real-time analysis allows quick responses to changing conditions. Companies can make proactive adjustments to optimize operations.

Risk Management

AI enhances risk management in the supply chain. Predictive analytics identify potential disruptions before they occur. AI models assess risks related to suppliers, logistics, and market fluctuations. Companies can implement mitigation strategies to minimize impacts. Effective risk management ensures supply chain resilience.

Importance of Supply Chain Resilience and Localization

Building Resilient Supply Chains

Risk Mitigation Strategies

Supply chain resilience ensures that automotive companies can withstand disruptions. Risk mitigation strategies play a crucial role in this process. Companies must identify potential risks, such as semiconductor shortages and geopolitical concerns. These risks can impact production timelines and procurement processes. By understanding these risks, companies can develop contingency plans. These plans may include alternative sourcing options and flexible production schedules.

JUSDA Supply Chain Management International Co., Ltd. provides end-to-end lean supply chain management services for various industries, including the automotive sector. Leveraging its extensive global network and advanced technology platforms, JUSDA offers comprehensive solutions that cover raw material procurement, manufacturing, distribution, and delivery to end consumers. The company's services include multimodal transportation, warehousing, e-commerce, cross-border logistics, and supply chain finance, all integrated into a collaborative production model.

JUSDA's expertise in lean supply chain management, combined with its JusLink intelligent system platform, enables real-time collaboration and precise business decision analysis. This makes JUSDA a valuable partner for automotive companies looking to optimize their supply chain operations and achieve greater efficiency and competitiveness in the global market.

SMART JUSLINK

Supply Chain Management Solution

Diversification of Suppliers

Diversifying suppliers strengthens the supply chain. Relying on a single supplier increases vulnerability to disruptions. Multiple suppliers provide a buffer against unforeseen events. For example, the pandemic highlighted the need for supplier diversification. Disruptions in one region affected global production. Companies with diverse supplier networks managed these disruptions more effectively. Supplier diversification enhances overall supply chain resilience.

Localization Strategies

Nearshoring

Nearshoring involves relocating production closer to primary markets. This strategy reduces dependency on distant suppliers. Nearshoring shortens supply chain distances and mitigates geopolitical risks. Countries like Mexico benefit from nearshore production. Proximity to major markets improves logistics efficiency. Nearshoring also supports regional economic growth. Automotive companies adopting nearshoring can respond more quickly to market demands.

Regional Manufacturing Hubs

Establishing regional manufacturing hubs enhances supply chain localization. These hubs serve as centralized points for production and distribution. Regional hubs reduce transportation costs and lead times. Governments worldwide encourage the creation of these hubs. Policies promoting reshoring and local manufacturing support this trend. Regional hubs increase supply chain agility and resilience. Automotive companies investing in these hubs gain a competitive advantage.

Case Studies

Examples from Leading Automotive Companies

Leading automotive companies provide valuable insights into resilient supply chains. For instance, Toyota's approach to supplier diversification sets a benchmark. Toyota maintains relationships with multiple suppliers for critical components. This strategy minimizes the impact of disruptions. Another example is Ford's investment in regional manufacturing hubs. Ford's facilities in North America and Europe enhance supply chain localization. These examples highlight effective resilience and localization strategies.

Lessons Learned

Lessons from these companies emphasize the importance of proactive measures. Identifying risks and diversifying suppliers are essential steps. Investing in nearshoring and regional hubs strengthens supply chains. Continuous evaluation and adaptation ensure long-term resilience. The automotive industry must prioritize these strategies. Future of Automotive supply chains depends on resilience and localization.

Sustainable Supply Chain Practices

Green Logistics

Reducing Carbon Footprint

Automotive companies focus on reducing carbon footprints to enhance sustainability. Companies implement energy-efficient manufacturing processes. Optimizing logistics reduces emissions from transportation. AI-driven systems improve route planning for delivery vehicles. This optimization minimizes fuel consumption and greenhouse gas emissions. Companies also adopt renewable energy sources in production facilities.

Eco-Friendly Transportation

Eco-friendly transportation methods play a crucial role in green logistics. Electric and hybrid vehicles reduce reliance on fossil fuels. These vehicles produce fewer emissions compared to traditional internal combustion engines. Companies invest in electric vehicle (EV) fleets for deliveries. Charging infrastructure development supports the widespread use of EVs. Public transportation and carpooling initiatives further reduce environmental impact.

Circular Economy

Recycling and Reuse

The circular economy model emphasizes recycling and reuse. Automotive companies design products for easy disassembly and recycling. Materials from end-of-life vehicles find new applications. Recycling reduces the need for raw material extraction. This practice conserves natural resources and lowers environmental impact. Companies also refurbish and remanufacture components to extend product life cycles.

Sustainable Materials

Sustainable materials play a vital role in the circular economy. Companies prioritize sourcing materials with minimal environmental impact. Bio-based plastics and recycled metals replace traditional materials. These sustainable options reduce the carbon footprint of automotive production. Companies also explore innovative materials like biodegradable composites. Sustainable materials contribute to a greener supply chain.

Regulatory Compliance

Environmental Regulations

Compliance with environmental regulations ensures sustainable practices. Governments worldwide enforce strict emission standards. Automotive companies must adhere to these regulations to avoid penalties. Regulations drive the adoption of cleaner technologies and processes. Companies invest in research and development to meet regulatory requirements. Compliance enhances the industry's overall environmental performance.

Industry Standards

Industry standards guide sustainable supply chain practices. Organizations like the International Organization for Standardization (ISO) set benchmarks. ISO 14001 certification focuses on environmental management systems. Companies achieve certification by implementing sustainable practices. Adherence to industry standards demonstrates a commitment to sustainability. Standards also promote continuous improvement in environmental performance.

The blog highlights the transformative impact of AI on automotive supply chain management. AI enhances efficiency, reduces risks, and improves decision-making processes. Supply chain resilience and localization strategies ensure companies withstand disruptions. Sustainable practices, such as green logistics and circular economy models, promote environmental responsibility.

Continuous innovation and collaboration remain crucial for future advancements. Automotive suppliers must work with tech players to develop new solutions. The industry must adapt to digitization and Industry 4.0 trends. The future of automotive supply chain management promises increased innovation, resilience, and sustainability.

See Also

Unlocking Your Automotive Supply Chain's Full Potential

Artificial Intelligence in Supply Chain: Transforming Logistics Ahead

Virtual Replicas: Revolutionizing Supply Chain Management Tomorrow

Diving into Robotics: Transforming the Supply Chain Landscape

Tomorrow's Supply Chain: A Route to Professional Advancement