How Technology is Redefining Inventory Management

Technology has revolutionized inventory management, transforming it into a more efficient and accurate process. Businesses now rely on tools like artificial intelligence and machine learning to predict demand and reduce stockouts. A 2023 Deloitte report highlights that reducing stock days by 10% can increase profitability by 5%. Automation and sensor-driven systems ensure real-time accuracy, minimizing errors and waste. These advancements not only streamline operations but also prepare businesses for the future of inventory management, where transparency and efficiency will define success.

Key Takeaways

Technology makes managing inventory easier and faster. Automation cuts down on manual work, so workers can focus on bigger goals.

AI tools help predict what customers will need. This lets businesses keep the right amount of stock, avoiding waste and shortages.

IoT gadgets show inventory updates instantly. This clear view reduces mistakes and keeps customers happy.

Cloud systems are flexible and grow with the business. They let companies check inventory from anywhere, helping them make better choices.

Using new technology can save a lot of money. Businesses spend less on operations and use resources more wisely.

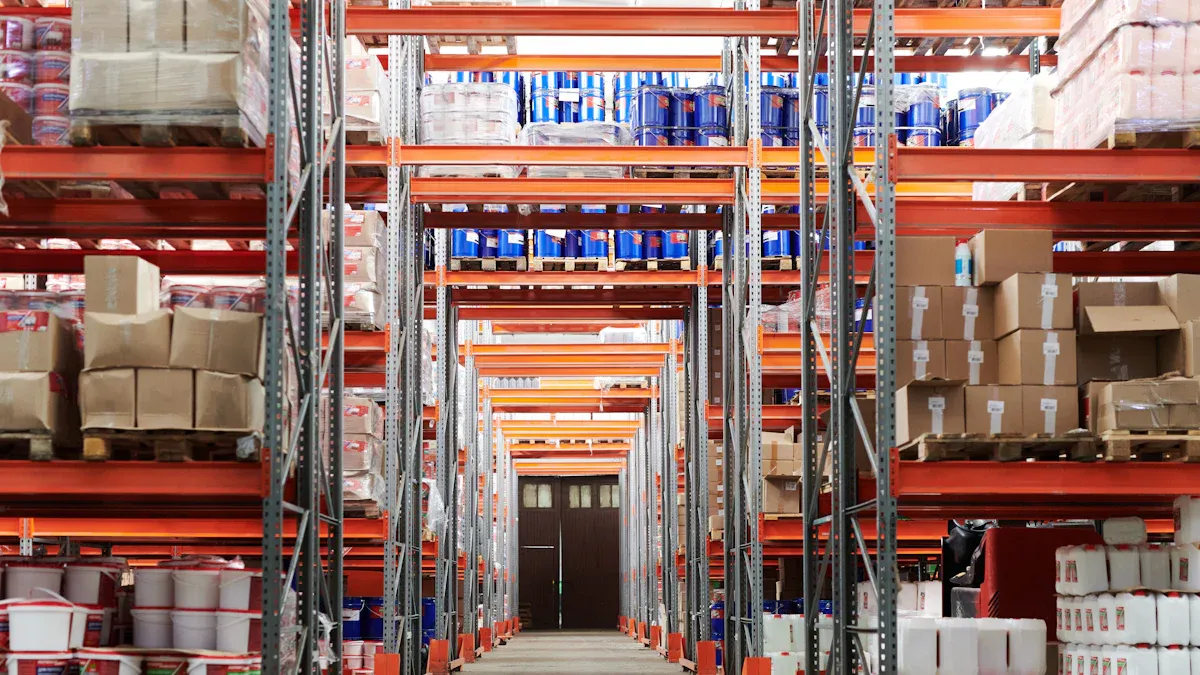

Key Technologies Shaping the Future of Inventory Management

Artificial Intelligence for Predictive Analytics

Artificial intelligence (AI) is transforming inventory management by enabling predictive analytics. AI algorithms analyze historical sales data, market trends, and seasonal patterns to forecast demand with remarkable accuracy. This predictive capability helps businesses maintain optimal stock levels, reducing the risk of overstocking or stockouts. For instance, AI-powered systems can identify slow-moving inventory and recommend adjustments to avoid unnecessary storage costs. Additionally, AI enhances decision-making by providing actionable insights, allowing businesses to respond proactively to changes in customer demand.

AI-driven predictive analytics empowers businesses to anticipate challenges and seize opportunities, making it a cornerstone of the future of inventory management.

Internet of Things for Real-Time Visibility

The Internet of Things (IoT) is revolutionizing inventory tracking by providing real-time visibility into stock levels and movement. IoT devices, such as RFID tags and smart sensors, collect and transmit data about inventory location, condition, and quantity. This data enables businesses to monitor their supply chain with unparalleled precision. For example, IoT sensors can detect temperature fluctuations in perishable goods, ensuring product quality throughout the supply chain. Real-time updates also improve inventory accuracy, reducing errors and enhancing customer satisfaction.

By leveraging IoT, businesses gain a competitive edge through improved transparency and operational efficiency.

Cloud-Based Systems for Operational Flexibility

Cloud-based inventory management systems offer businesses the flexibility to adapt to changing demands. These systems provide real-time access to inventory data from any location with internet connectivity. This capability allows businesses to make informed decisions quickly, even in dynamic market conditions. Cloud solutions also eliminate the need for costly IT infrastructure, reducing maintenance expenses. Furthermore, they enable businesses to scale operations seamlessly without significant upfront investments.

Cloud-based systems are becoming a leading trend in the supply chain sector. Their ability to enhance operational flexibility makes them indispensable for businesses aiming to stay competitive in the future of inventory management.

Robotics and Automation in Warehousing

Robotics and automation are transforming warehousing operations by improving efficiency and reducing costs. Automated Guided Vehicles (AGVs) and robotic picking systems streamline material handling and order fulfillment. These technologies minimize human intervention, leading to faster and more accurate processes. For example, AGVs transport materials 30% faster, while robotic picking systems increase picking speed by 200%.

Warehouses also benefit from smart inventory management systems. These systems optimize space utilization and reduce inventory holding costs. Improved layout designs and resource allocation further enhance operational performance. The table below highlights the quantified benefits of robotics and automation in warehousing:

Improvement Area | Quantified Benefit |

|---|---|

Operational Performance | |

Space Utilization | Improved layout design and resource allocation |

Technology | Efficiency Gain | Cost Reduction |

|---|---|---|

AGVs | 30% faster material transport | 20% labor cost savings |

Robotic Picking | 200% increase in picking speed | 15% reduction in fulfillment costs |

Smart Inventory Management | 40% improved space utilization | 25% decrease in inventory holding costs |

Robotics and automation not only enhance productivity but also create safer working environments by reducing the need for manual labor in hazardous tasks.

Blockchain for Supply Chain Transparency

Blockchain technology is revolutionizing supply chain transparency by providing a tamper-evident shared ledger. This ledger enhances the authenticity of information and builds trust among stakeholders. Businesses can track products at every stage of the supply chain, ensuring traceability and accountability. For instance, blockchain enables environmental, social, and governance (ESG) tracking, helping companies meet sustainability goals.

Key benefits of blockchain in supply chains include:

Enhanced visibility through proactive risk detection.

Integration with IoT and AI for better security.

Support for smart contracts to automate transactions.

By leveraging blockchain, businesses can mitigate risks and ensure the authenticity of their supply chain data. This technology fosters transparency, which is critical for maintaining customer trust and meeting regulatory requirements.

Emerging Trends: Drones and Digital Warehousing

Drones and digital warehousing represent the next frontier in inventory management. Drones are increasingly used for inventory audits and deliveries. They can scan barcodes and RFID tags in hard-to-reach areas, significantly reducing the time required for stocktaking. In addition, drones enable faster last-mile deliveries, improving customer satisfaction.

Digital warehousing integrates advanced technologies like IoT, AI, and robotics to create smart warehouses. These warehouses use real-time data to optimize operations, from inventory tracking to order fulfillment. For example, digital twins—virtual replicas of physical warehouses—allow businesses to simulate and improve processes without disrupting operations.

The adoption of drones and digital warehousing is reshaping the logistics landscape, offering unprecedented speed, accuracy, and efficiency.

Challenges in Adopting Advanced Technologies

High Initial Costs and Implementation Barriers

Adopting advanced technologies often requires significant upfront investment. Businesses must allocate funds for purchasing hardware, software, and infrastructure upgrades. For example, implementing robotics or IoT devices involves not only the cost of equipment but also installation and maintenance expenses. Small and medium-sized enterprises (SMEs) face greater challenges due to limited budgets.

Note: A 2023 report by McKinsey highlights that 45% of SMEs delay technology adoption due to financial constraints.

Additionally, implementation barriers such as downtime during system upgrades can disrupt operations. Companies must carefully plan and allocate resources to minimize these disruptions. While the long-term benefits of technology adoption are undeniable, the initial financial burden remains a significant hurdle for many organizations.

Integration with Legacy Systems

Legacy systems, often outdated and incompatible with modern technologies, pose another challenge. Businesses relying on older software or hardware struggle to integrate new solutions seamlessly. For instance, cloud-based inventory systems may not communicate effectively with on-premise databases, leading to data silos.

Challenge | Impact |

|---|---|

System Incompatibility | Delays in data synchronization and reduced operational efficiency. |

High Integration Costs | Additional expenses for custom APIs or middleware solutions. |

Risk of Data Loss | Potential errors during migration from legacy systems. |

To overcome these issues, companies must invest in integration tools or hire experts to bridge the gap. However, these solutions add to the overall cost and complexity of technology adoption.

Workforce Training and Adaptation

Advanced technologies require employees to learn new skills and adapt to changing workflows. For example, workers in warehouses must understand how to operate robotic systems or interpret data from IoT devices. Without proper training, employees may feel overwhelmed, leading to resistance or reduced productivity.

Tip: Companies can address this challenge by offering hands-on training sessions and continuous learning opportunities.

Investing in workforce development ensures employees feel confident and capable of using new tools. This approach not only improves adoption rates but also fosters a culture of innovation within the organization.

Cybersecurity and Data Privacy Risks

The adoption of advanced technologies in inventory management introduces significant cybersecurity and data privacy risks. As businesses increasingly rely on cloud-based systems, IoT devices, and AI-driven platforms, they expose themselves to potential vulnerabilities. Cyberattacks targeting these systems can disrupt operations, compromise sensitive data, and damage reputations.

Large-scale data breaches have become more frequent, compromising sensitive information and exposing individuals to identity theft. These incidents also harm company reputations and lead to compliance violations. For example, regulations like the General Data Protection Regulation (GDPR) in the EU and the California Consumer Privacy Act (CCPA) in the United States impose strict penalties for data mishandling. This global trend toward stricter data privacy laws underscores the need for robust cybersecurity measures.

Evidence Type | Description |

|---|---|

Breach Frequency | Increasing number of data breaches reported, indicating a growing threat. |

Human Error | A significant percentage of breaches are caused by human mistakes. |

Compliance Costs | Rising costs associated with breaches prompt companies to invest in security. |

Human error remains a major contributor to cybersecurity incidents. Employees may inadvertently expose systems to threats through weak passwords or phishing scams. Training programs and strict protocols can mitigate these risks, ensuring employees understand their role in maintaining data security.

Investing in cybersecurity measures is no longer optional. Businesses must implement encryption, multi-factor authentication, and regular system audits to protect sensitive information. Additionally, integrating cybersecurity into inventory management systems ensures that data remains secure throughout the supply chain.

Tip: Companies should prioritize cybersecurity to safeguard their operations and comply with evolving data privacy regulations. Proactive measures not only reduce risks but also build trust with customers and stakeholders.

By addressing cybersecurity and data privacy risks, businesses can protect their assets, maintain compliance, and foster long-term success in an increasingly digital landscape.

The future of inventory management is being reshaped by groundbreaking technologies that promise to revolutionize the industry. Businesses adopting innovations like AI, IoT, and blockchain gain a competitive edge by enhancing efficiency, accuracy, and sustainability. For example, AI-driven analytics improve demand forecasting, while IoT devices enable real-time tracking of stock levels. Automation reduces repetitive tasks, allowing employees to focus on strategic goals.

Key advancements include:

Hyper-personalized inventory tailored to customer preferences.

Autonomous operations with robots optimizing warehouse efficiency.

Decentralized inventory systems improving delivery speed.

These trends highlight the importance of embracing innovation to remain competitive. By leveraging technology, businesses can prepare for disruptions, meet customer demands, and contribute to sustainable practices. The journey toward a connected, efficient, and transparent supply chain is not just a possibility—it is an imperative for long-term success.

FAQ

Are cloud-based systems secure for inventory management?

Cloud-based systems offer robust security features, including encryption and multi-factor authentication. Regular updates and backups protect data from breaches. Businesses must follow best practices, such as using strong passwords and monitoring access, to ensure data remains secure.

What are the benefits of using robotics in warehouses?

Robotics improves warehouse efficiency by automating repetitive tasks like picking and packing. Automated Guided Vehicles (AGVs) transport materials faster, while robotic arms enhance accuracy. These technologies reduce labor costs, increase productivity, and create safer working environments.

How can blockchain enhance supply chain transparency?

Blockchain creates a tamper-proof ledger that tracks products at every stage of the supply chain. It ensures data authenticity, builds trust among stakeholders, and supports compliance with regulations. Businesses can use blockchain to verify product origins and meet sustainability goals.

See Also

Enhance Your Business Using Innovative Inventory Strategies

Revolutionizing Supply Chain Management Through Cloud Solutions

Embracing Change: Adjusting to Technology-Driven Supply Chains

Transforming Future Logistics with AI in Supply Chains

The Next Generation of Supply Chain Management with Digital Twins