Innovations in Global Supply Chain Management: Insights from the Manufacturing Sector

Manufacturing plays a vital role in the global economy, driving innovation and economic growth. JUSDA stands at the forefront of this industry, providing unparalleled supply chain management services. It offers an invaluable platform for discussing the Future of Manufacturing and exploring cutting-edge trends.

Future of Manufacturing: Global Trends

Technological Advancements

Automation and Robotics

Automation and robotics have revolutionized the manufacturing landscape. These technologies enhance productivity and precision while reducing operational costs. AI-driven robotics streamline processes and minimize human error. Manufacturers benefit from increased efficiency and safety in their operations.

Internet of Things (IoT)

The Internet of Things (IoT) connects devices and systems, creating smart factories. IoT technology provides real-time insights and visibility into manufacturing processes. This connectivity improves decision-making and optimizes resource utilization. IoT applications enhance operational efficiency and open new revenue streams for manufacturers.

Artificial Intelligence (AI)

Artificial Intelligence (AI) transforms manufacturing by enabling advanced data analytics. AI identifies patterns in data generated by IoT devices, enhancing operational efficiency. AI-driven solutions bring innovation and precision to manufacturing processes. These technologies reduce costs and improve overall productivity.

Sustainable Manufacturing

Green Technologies

Green technologies promote sustainability in manufacturing. Renewable energy sources and energy-efficient practices reduce the environmental impact. Manufacturers adopt green technologies to meet regulatory requirements and consumer demands. These practices contribute to a more sustainable future for the industry.

Circular Economy

The circular economy focuses on resource efficiency and waste reduction. Manufacturers implement recycling and reuse strategies to minimize waste. This approach extends the lifecycle of products and materials. The circular economy supports sustainable manufacturing and reduces environmental impact.

Global Supply Chain Dynamics

Trade Policies

Trade policies influence global supply chain dynamics. Changes in tariffs and trade agreements impact manufacturing operations. Manufacturers must adapt to evolving trade policies to remain competitive. Understanding these policies helps companies navigate the global market effectively.

Geopolitical Factors

Geopolitical factors shape the future of manufacturing. Political stability and international relations affect supply chain reliability. Manufacturers must consider geopolitical risks when planning operations. Adapting to these factors ensures resilience and continuity in the global supply chain.

Future of Manufacturing: Impact on the Automotive Industry

Lean Manufacturing Principles

Just-In-Time (JIT) Production

Just-In-Time (JIT) Production revolutionizes the automotive industry. Manufacturers produce only what is needed, reducing waste and inventory costs. This method improves efficiency and responsiveness to market demands. JIT ensures that parts arrive exactly when required, minimizing storage needs.

Kaizen (Continuous Improvement)

Kaizen emphasizes continuous improvement in all aspects of manufacturing. Employees at all levels contribute to incremental changes. This philosophy fosters a culture of constant innovation and efficiency. Kaizen leads to higher quality products and reduced operational costs.

Supply Chain Optimization

Inventory Management

Effective inventory management is crucial for automotive manufacturers. Accurate forecasting and real-time tracking optimize stock levels. This practice reduces excess inventory and minimizes shortages. Efficient inventory management enhances overall supply chain performance.

Supplier Relationships

Strong supplier relationships are essential for a robust supply chain. Collaboration with suppliers ensures timely delivery of high-quality materials. Long-term partnerships foster trust and reliability. These relationships contribute to smoother operations and better product quality.

Technological Integration

Electric Vehicles (EVs)

Electric Vehicles (EVs) represent the future of the automotive industry. EVs offer a sustainable alternative to traditional combustion engines. Manufacturers invest in advanced battery technology and charging infrastructure. The rise of EVs drives innovation and reduces environmental impact.

Autonomous Vehicles

Autonomous Vehicles are transforming transportation. These self-driving cars rely on AI and sensor technology. Autonomous vehicles promise increased safety and efficiency on the roads. The development of autonomous vehicles marks a significant shift in the automotive landscape.

Future Trends and Predictions

Emerging Technologies

3D Printing

3D printing, also known as additive manufacturing, is revolutionizing the Future of Manufacturing. This technology creates objects by adding material layer by layer, allowing for complex shapes and designs that traditional methods cannot achieve. Manufacturers can produce parts on demand, reducing inventory costs and waste. Rapid prototyping with 3D printing accelerates innovation, enabling faster product development cycles. The agility offered by 3D printing enhances supply chain efficiency and responsiveness.

Blockchain in Supply Chain

Blockchain technology promises to transform supply chain management. By providing a decentralized and immutable ledger, blockchain enhances trust and transparency among supply chain participants. Real-time tracking of goods and verification of transactions become possible, reducing fraud and errors. Blockchain improves efficiency by streamlining processes and eliminating intermediaries. The speed and reliability of blockchain technology support the Future of Manufacturing by ensuring secure and efficient supply chains.

Evolving Business Models

Servitization

Servitization represents a shift from selling products to offering services. Manufacturers provide value-added services such as maintenance, upgrades, and customization. This model fosters long-term customer relationships and generates recurring revenue streams. Servitization encourages manufacturers to innovate continuously and improve service quality. The Future of Manufacturing will see more companies adopting servitization to differentiate themselves in competitive markets.

Customization and Personalization

Customization and personalization cater to individual customer preferences. Advances in technology enable manufacturers to offer tailored products without compromising efficiency. Mass customization allows for the production of unique items at scale, meeting diverse consumer demands. Personalization enhances customer satisfaction and loyalty by providing products that align with specific needs and tastes. The Future of Manufacturing will increasingly focus on delivering personalized experiences to consumers.

Workforce Transformation

Skills Development

The Future of Manufacturing requires a skilled workforce adept at handling advanced technologies. Continuous skills development programs ensure employees stay updated with the latest innovations. Training in areas such as robotics, AI, and IoT equips workers to operate and maintain sophisticated equipment. Investing in employee education fosters a culture of learning and adaptability. A skilled workforce drives productivity and innovation in manufacturing.

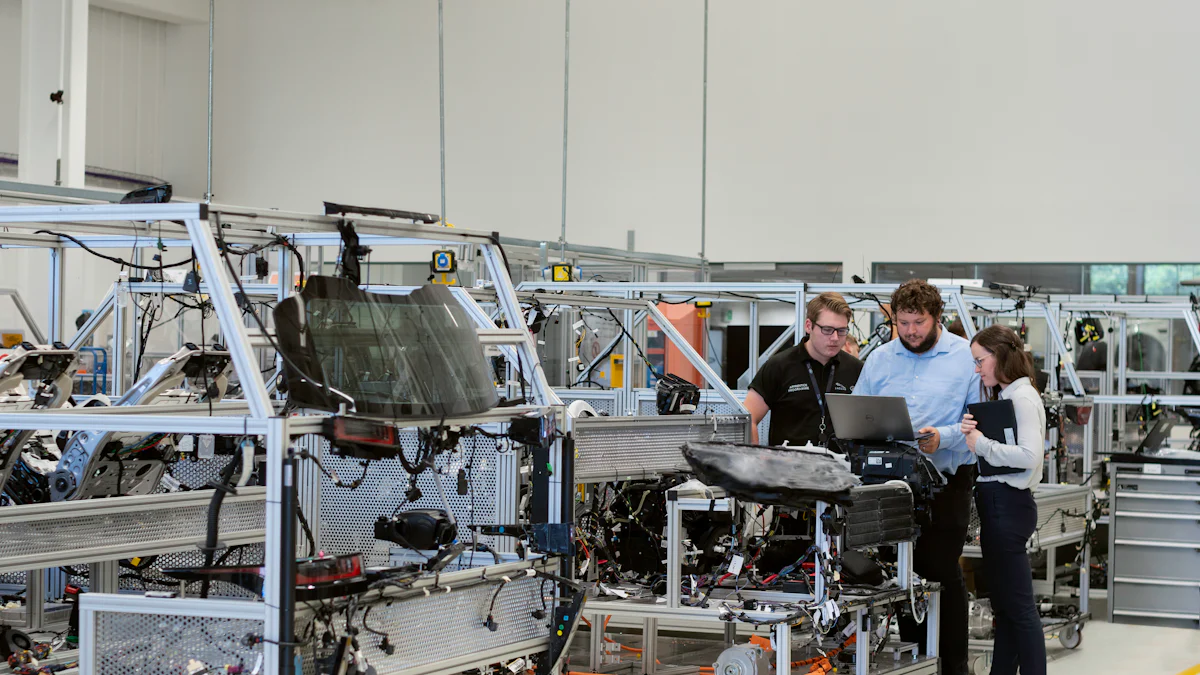

Human-Machine Collaboration

Human-machine collaboration combines the strengths of humans and machines. Workers use advanced tools and technologies to enhance their capabilities and efficiency. Collaborative robots, or cobots, work alongside humans, performing repetitive tasks while allowing workers to focus on complex problem-solving. This synergy between humans and machines boosts productivity and safety in manufacturing environments. The Future of Manufacturing will see increased integration of human-machine collaboration, leading to more efficient and innovative production processes.

See Also

Efficient Strategies for Supply Chain Challenges in High-Tech Manufacturing

Guiding Efficient Logistics for High-Tech Manufacturing Triumph

Unlocking High-Tech Manufacturing Consulting for Success

Understanding JUSDA's Logistics Solutions for High-Tech Manufacturing