Future Prospects of Digital Supply Chains: JUSDA's Engagement in Shaping Industry Trends

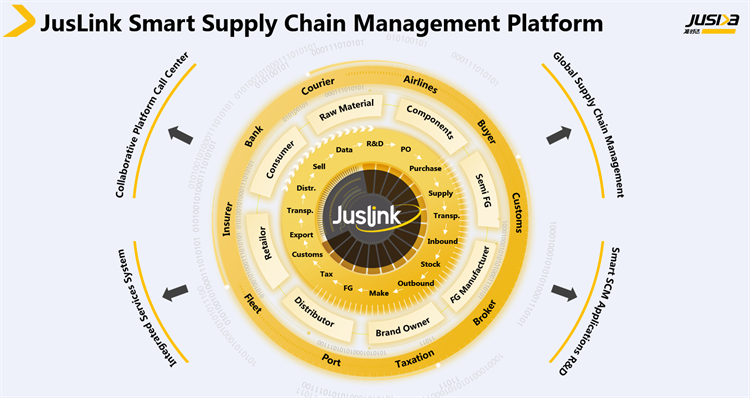

Digital supply chains represent a transformative shift in supply chain management. Companies that embrace digital transformation can expect significant benefits, including improved efficiency and reduced costs. According to McKinsey & Company, businesses that aggressively digitize their supply chains can boost annual growth of earnings before interest and taxes by 3.2% and annual revenue growth by 2.3%. JUSDA, a important participant in the industry, leverages advanced technologies such as IoT, cloud computing, and big data analytics through its smart supply chain platform, JusLink, to drive these advancements.

The Evolution of Digital Supply Chains

Historical Context

Traditional vs. Digital Supply Chains

Traditional supply chains relied heavily on manual processes and paper-based documentation. This approach often led to inefficiencies, delays, and errors. Digital supply chains emerged as a solution to these challenges by leveraging advanced technologies. The integration of IoT, big data analytics, and cloud computing transformed supply chain management into a more efficient and agile system.

Traditional supply chains lacked real-time visibility and faced significant disruptions during events like the COVID-19 pandemic. In contrast, digital supply chains offer real-time monitoring and predictive analytics, enabling companies to respond quickly to disruptions and maintain operational continuity.

Key Milestones in Digital Transformation

Several key milestones marked the evolution of digital supply chains:

1990s: Introduction of Enterprise Resource Planning (ERP) systems, which integrated various business processes.

2000s: Adoption of Radio Frequency Identification (RFID) technology for tracking inventory and assets.

2010s: Emergence of IoT and big data analytics, providing real-time insights and predictive capabilities.

2020s: Widespread implementation of AI and machine learning to automate decision-making and enhance efficiency.

Current State of Digital Supply Chains

Adoption Rates and Statistics

The adoption of digital supply chains has accelerated in recent years. According to Gartner, companies that embrace digital transformation can achieve a 20% increase in revenue and a 50% reduction in costs. A survey by McKinsey & Company revealed that 57% of businesses experienced serious disruptions during the COVID-19 pandemic, highlighting the importance of digital resilience.

Key statistics include:

80% of supply chain leaders plan to invest in digital technologies within the next five years.

60% of companies have already implemented IoT solutions in their supply chain operations.

45% of businesses use AI and machine learning for predictive analytics and forecasting.

Case Studies of Successful Implementations

Several companies have successfully implemented smart supply chain solutions:

Walmart: Utilized blockchain technology to enhance transparency and traceability in its food supply chain. This initiative reduced the time required to trace the origin of food products from seven days to just 2.2 seconds.

Amazon: Leveraged AI and machine learning to optimize inventory management and improve delivery times. The company's smart supply chain platform enables real-time tracking and predictive analytics.

JUSDA: Implemented the JusLink platform, which integrates IoT, big data, and cloud computing to provide end-to-end supply chain visibility. This smart supply chain solution enhances efficiency and reduces operational costs.

Key Technologies Driving Digital Supply Chains

Internet of Things (IoT)

IoT Applications in Supply Chain Management

The Internet of Things (IoT) revolutionizes supply chain management by enabling real-time data sharing across the entire network. IoT devices, such as sensors and RFID tags, collect and transmit data on inventory levels, transportation conditions, and equipment performance. This data helps companies monitor their supply chains more effectively and make informed decisions.

Inventory Management: IoT sensors provide real-time updates on stock levels, reducing the risk of overstocking or stockouts.

Transportation Monitoring: GPS-enabled devices track the location and condition of shipments, ensuring timely deliveries and maintaining product quality.

Equipment Maintenance: IoT devices monitor machinery performance, predicting maintenance needs and preventing costly breakdowns.

Benefits and Challenges

The integration of IoT in smart supply chain management offers numerous benefits:

Enhanced Visibility: Real-time tracking provides a comprehensive view of the supply chain, improving transparency and accountability.

Improved Efficiency: Automated data collection reduces manual labor and minimizes errors.

Predictive Maintenance: IoT devices predict equipment failures, reducing downtime and maintenance costs.

However, IoT implementation also presents challenges:

Data Security: Protecting sensitive information from cyber threats remains a significant concern.

Integration Complexity: Integrating IoT devices with existing systems can be complex and costly.

Data Overload: Managing and analyzing vast amounts of data requires advanced analytics capabilities.

Artificial Intelligence and Machine Learning

Predictive Analytics and Forecasting

Artificial Intelligence (AI) and Machine Learning (ML) play crucial roles in smart supply chain management. These technologies analyze historical data to predict future trends and optimize decision-making processes.

Demand Forecasting: AI algorithms predict customer demand, helping companies adjust production schedules and inventory levels.

Risk Management: ML models identify potential risks and disruptions, allowing companies to develop contingency plans.

Supplier Selection: AI evaluates supplier performance, ensuring the selection of reliable partners.

Automation and Efficiency Improvements

AI and ML enhance efficiency by automating various supply chain processes:

Order Processing: AI-powered systems automate order processing, reducing manual intervention and speeding up delivery times.

Warehouse Management: ML algorithms optimize warehouse layouts and inventory placement, improving storage efficiency.

Quality Control: AI systems inspect products for defects, ensuring high-quality standards.

Blockchain Technology

Enhancing Transparency and Security

Blockchain technology enhances transparency and security in smart supply chain management by providing a decentralized and immutable ledger of transactions. Each transaction gets recorded in a block, which is then added to a chain of previous transactions. This process ensures that data cannot be altered or deleted.

Traceability: Blockchain enables end-to-end traceability of products, from raw materials to finished goods. This feature is particularly valuable in industries like food and pharmaceuticals, where product safety is critical.

Fraud Prevention: The immutable nature of blockchain records prevents fraud and ensures data integrity.

Compliance: Blockchain helps companies comply with regulatory requirements by providing a transparent and auditable record of transactions.

Real-world Examples and Use Cases

Several companies have successfully implemented blockchain technology in their smart supply chain operations:

Walmart: Utilized blockchain to track the origin of food products, enhancing food safety and reducing the time required for traceability.

Maersk: Partnered with IBM to develop a blockchain-based platform for tracking shipping containers, improving transparency and efficiency in global trade.

Industry Trends Led by JUSDA

JUSDA's Digital Initiatives

Overview of JUSDA's Digital Strategy

JUSDA has positioned itself as a leader in digital supply chain innovation. The company's strategy focuses on integrating advanced technologies to enhance supply chain efficiency and transparency. JUSDA leverages big data, IoT, and cloud computing to create a seamless supply chain experience.

The JusLink platform exemplifies JUSDA's commitment to digital transformation. This AI-driven system provides end-to-end visibility and real-time monitoring. Companies can use JusLink to manage their supply chains more effectively. The platform offers dynamic information visualization and risk prevention capabilities.

Image Source: unsplash

JUSDA's digital strategy also emphasizes collaboration. The company promotes a real-time collaborative supply chain ecosystem. This approach improves resource utilization and ensures supply chain stability. JUSDA's global network supports this strategy, with service points in key regions worldwide.

Key Projects and Innovations

JUSDA has spearheaded several key projects that showcase its innovative approach to supply chain management. These initiatives highlight the company's ability to integrate cutting-edge technology into practical solutions.

JusLink Intelligent System Platform:

JUSDA developed the JusLink platform to provide comprehensive supply chain visibility.

The platform integrates IoT, big data, and AI to offer real-time insights.

JusLink enhances decision-making by providing dynamic information visualization.

Blockchain Integration:

JUSDA integrated blockchain technology into its supply chain solutions.

Blockchain enhances transparency and security by providing an immutable ledger of transactions.

This technology ensures traceability and compliance, particularly in industries like food and pharmaceuticals.

Big Data Analytics:

JUSDA utilizes big data analytics to optimize supply chain operations.

The company analyzes vast amounts of data to predict trends and identify potential disruptions.

Big data analytics supports precise business decision-making and improves overall efficiency.

IoT Applications:

JUSDA employs IoT devices to monitor inventory levels, transportation conditions, and equipment performance.

IoT sensors provide real-time updates, reducing the risk of overstocking or stockouts.

GPS-enabled devices track shipments, ensuring timely deliveries and maintaining product quality.

AI and Machine Learning:

JUSDA uses AI and machine learning to automate various supply chain processes.

AI algorithms predict customer demand and optimize production schedules.

Machine learning models identify potential risks and develop contingency plans.

Case Studies:

Semiconductor Supply Chains:

JUSDA's digital strategies offer unparalleled efficiency and security in semiconductor logistics.

The company's state-of-the-art solutions help businesses integrate technology seamlessly.

Embracing digital solutions is essential for sustainable growth and competitiveness.

Client Success Stories:

JUSDA's commitment to innovation and client collaboration sets the company apart.

Real-world success stories exemplify excellence in streamlining operations and enhancing efficiency.

Transformative solutions elevate supply chain performance and meet evolving market demands.

JUSDA's digital initiatives demonstrate the company's leadership in the industry. By leveraging advanced technologies, JUSDA continues to drive future trends in supply chain management.

Future Projections and Opportunities

Emerging Trends

Integration of Advanced Technologies

The future of smart supply chain management will see the integration of more advanced technologies. Companies will adopt AI, IoT, and blockchain to enhance efficiency and transparency. AI will predict customer demand and optimize inventory levels. IoT devices will provide real-time updates on stock levels and transportation conditions. Blockchain will ensure data integrity and traceability.

A report by Gartner predicts that digital transformation in supply chains can lead to a 20% increase in revenue and a 50% reduction in costs. Companies will leverage these technologies to gain a competitive advantage. The majority of organizations expect to have access to most of the data and analytics from the extended supply chain by 2024. This trend will continue to grow, offering significant benefits.

Sustainability and Green Supply Chains

Sustainability will become a key focus in smart supply chain management. Companies will adopt green practices to reduce their environmental impact. This includes using renewable energy sources and optimizing transportation routes to minimize carbon emissions. Sustainable supply chains will not only benefit the environment but also enhance brand reputation.

Digital transformation will play a crucial role in achieving sustainability goals. IoT sensors will monitor energy consumption and waste production. AI algorithms will optimize resource utilization. Blockchain will ensure transparency in sustainable practices. Companies that embrace these technologies will lead the way in creating green supply chains.

Challenges and Considerations

Data Privacy and Security Concerns

As companies integrate advanced technologies into their smart supply chain, data privacy and security will become major concerns. IoT devices and AI systems will collect vast amounts of data. Protecting this data from cyber threats will be crucial. Companies will need to invest in robust cybersecurity measures to safeguard sensitive information.

Data breaches can have severe consequences. They can lead to financial losses and damage to brand reputation. Ensuring data privacy and security will require continuous monitoring and updating of security protocols. Companies must stay vigilant to protect their smart supply chain operations.

Regulatory and Compliance Issues

Regulatory and compliance issues will pose challenges for smart supply chain management. Different regions have varying regulations regarding data privacy and environmental standards. Companies will need to navigate these regulations to ensure compliance. Non-compliance can result in legal penalties and reputational damage.

Staying updated with regulatory changes will be essential. Companies will need to implement systems that ensure compliance with local and international laws. Blockchain technology can help by providing transparent and auditable records of transactions. This will simplify compliance and reduce the risk of legal issues.

Digital supply chains offer transparency, reliability, and visibility. These features prevent inventory shortages and streamline deliveries. JUSDA's contributions have significantly impacted the industry. The JusLink platform integrates IoT, big data, and AI to enhance efficiency. Future prospects for digital supply chains include advanced technology integration and sustainability. Organizations can better adapt to market changes and improve efficiency. Digital transformation remains essential for staying competitive in the global market.

See Also

Revolutionizing Supply Chain Sustainability with JUSDA

Industry-Leading Solutions: JUSDA's Supply Chain Success

Achieving Success in Supply Chain Resilience with Jusda

Exploring Global Consumer Demands: Jusda's Supply Chain Insights

Enhancing Efficiency: JUSDA's Comprehensive Supply Chain Visibility