Hidden Labor Costs in Supply Chain and Logistics Operations

Hidden labor costs in supply chain and logistics refer to expenses that remain unnoticed, such as wasted time, duplicated efforts, and errors in daily operations. These costs matter because they disrupt production, slow down warehousing, and increase transportation challenges. Industry reports show that hidden labor costs reduce profit margins and damage customer trust by causing delays and inefficiencies. Managers must examine their operations closely to find these hidden expenses. Innovative solutions from JUSDA use technology to help companies improve efficiency and protect profitability.

Key Takeaways

Hidden labor costs like turnover, human error, inefficiency, and poor management quietly increase expenses and reduce supply chain performance.

These costs lower productivity, raise payroll expenses, and hurt customer satisfaction by causing delays and mistakes.

Using technology such as automation, AI, and real-time tracking helps companies find and cut hidden labor costs effectively.

Investing in employee training and improving workflows boosts efficiency and reduces costly errors and turnover.

JUSDA’s JusLink platform offers smart solutions that automate tasks, improve scheduling, and provide real-time data to save labor costs and enhance operations.

Types of Hidden Labor Costs

Turnover

Turnover refers to the rate at which employees leave and new workers join a company. In supply chain and logistics, turnover rates are higher than in many other industries. When employees leave, companies spend money on recruiting, training, and onboarding replacements. New hires often need weeks or months to reach full productivity. This slows down operations and increases costs. High turnover also disrupts team cohesion and lowers morale, which can lead to more mistakes and safety issues. Staffing shortages force overtime or temporary labor, raising expenses. These hidden labor costs often go unnoticed but can reduce overall warehouse performance.

Turnover in logistics can cost between 50% to 200% of an employee’s annual salary, including lost productivity and workflow disruption.

Human Error

Human error includes mistakes such as mis-shipments, inventory inaccuracies, and incorrect order processing. These errors require extra labor to fix, like re-picking, packing, and recounting items. Companies may face compliance fines and lost sales due to delays or stockouts. The financial impact of human error can reach millions of dollars each year. For example, a medium-sized supplier with a 4% error rate may spend over $240,000 annually correcting mistakes. Advanced technologies help reduce these errors, but manual processes still create significant hidden labor costs.

Cost Category | Estimated Annual Cost Range | Explanation |

|---|---|---|

Manual Tasks | $2,625,000 | Labor costs tied to manual work. |

Error Correction & Rework | $240,000 - $1,500,000 | Costs from fixing mistakes and compliance issues. |

Lost Opportunities | $500,000 - $1,000,000 | Revenue lost due to delays and missed sales. |

Increased Operational Overhead | $100,000 - $300,000 | Extra staffing and overhead for error correction. |

Inefficiency

Inefficiency happens when workflows are poorly designed or rely too much on manual labor. Employees may spend too much time locating, handling, or packaging products. Disorganized warehouses and outdated processes slow down operations and increase payroll costs. Manual data entry and tracking raise error rates and require more staff. For example, an Order Operations Manager who spends hours on manual updates adds significant salary costs. Inefficiency leads to employee burnout and higher operational expenses. Automation and IoT-driven systems can help reduce these hidden labor costs by streamlining tasks and improving accuracy.

Productivity losses from inadequate labor management can reduce warehouse efficiency by up to 40%.

Inefficient inventory tracking increases labor and operational costs, often unnoticed until problems arise.

Poor Management

Poor management in logistics creates fragmented systems and disorganized warehouses. Employees spend extra time finding, picking, and packing products, which increases labor expenses. Delayed shipments and poor warehouse design slow order fulfillment and require overtime. Inefficient inventory management leads to overstocking or stockouts, causing rush orders and lost sales. These issues add to hidden labor costs and reduce profitability.

Impact on Labor Costs | |

|---|---|

More time spent on tasks, higher labor expenses. | |

Poor warehouse design | Slower fulfillment, more overtime needed. |

Delayed shipments | Extra labor to fix errors and delays. |

Streamlining workflows and using technology like Warehouse Management Systems can lower hidden labor costs and improve efficiency.

Impact on Business Performance

Operational Efficiency

Hidden labor costs quietly drain productivity from supply chain operations. Companies lose up to 60% of potential productivity because of unproductive time and inefficient workflows. Workers often wait for equipment or tasks, which adds up to thousands of lost hours each year. In a warehouse with 50 employees, nearly 3,000 hours of productivity can disappear annually. Inefficient movements, such as unnecessary steps or circuitous routes, may account for half of total labor costs in some facilities. Unbalanced workloads create bottlenecks, leaving some workers overburdened and others idle. These silent inefficiencies reduce operational efficiency and make it harder for companies to meet demand.

Unproductive time and inefficient workflows can waste over 10% of performance potential each year.

Employee movements alone may represent 60-70% of labor costs in manual storage operations.

Research from IDC shows labor-related productivity losses of 30% to 40% in warehouse operations.

Financial Results

Hidden labor costs also impact the financial health of logistics companies. Excessive paperwork, manual workarounds, and outdated systems slow down operations and increase workforce dissatisfaction. Workers spend valuable time retyping invoices or entering data by hand when technology fails. These hidden tasks increase labor inefficiencies and cause operational delays. Companies face reduced profitability because of understaffing or overstaffing, which leads to delays, backlogs, and idle labor. High employee turnover raises hiring and training expenses. Advanced workforce management software can help reduce labor costs by up to 10% by optimizing schedules and capturing attendance data.

Financial Impact Area | Effect on Business |

|---|---|

Manual workarounds | Increased labor expenses |

Poor workforce planning | Higher overtime costs |

High turnover | More recruitment spending |

Inefficient processes | Lower profit margins |

Customer Satisfaction

Customer satisfaction suffers when hidden labor costs go unchecked. Extra labor hours spent searching for products, repacking, or correcting errors increase payroll expenses and slow deliveries. Poor logistics lead to more returns and damaged goods, which harm a company’s reputation. A PWC survey found that 73% of consumers consider a good delivery experience crucial for future purchases. Automation and AI-driven processes reduce manual labor, improve accuracy, and cut labor expenses. Reliable and transparent supply chain operations build customer trust and loyalty, leading to repeat business and higher profits.

Inefficient labor use leads to higher operating costs and employee burnout.

Automation frees staff to focus on strategic work and improves customer service.

Addressing inefficiencies lowers costs and builds more resilient operations.

JUSDA Solutions for Hidden Labor Costs

JUSDA stands as a leader in global supply chain management. The company focuses on innovation and efficiency, helping businesses uncover and reduce hidden labor costs. JUSDA’s JusLink platform uses advanced technology to transform supply chain operations.

JusLink AI Solution

JusLink’s AI Solution tackles hidden labor costs by automating repetitive tasks and using predictive analytics. The platform shifts manual work to automated systems, which lowers errors and frees employees for higher-value activities. JusLink’s predictive analytics help companies forecast demand, manage inventory, and evaluate employee performance. This optimization improves scheduling and reduces overtime.

JusLink automates time-consuming tasks, reducing manual workload and errors.

Predictive analytics enable accurate demand forecasting and inventory management.

AI-driven workforce management improves scheduling and lowers overtime costs.

Real-time performance analysis helps companies reallocate labor and reduce idle time.

AI supports employee well-being by predicting stress patterns and suggesting interventions.

Companies using AI solutions have seen impressive results. DHL improved delivery efficiency by 20% with AI-driven route optimization. IBM reduced training time by 30% using predictive analytics. Amazon cut overtime costs by 25% through real-time employee performance analysis. Deloitte reported annual savings of $2 million on personnel costs with AI-powered workforce management. These examples show how JusLink’s AI Solution uncovers hidden labor costs and boosts operational efficiency.

JUSDA Solutions

To provide you with professional solutions and quotations.

Real-Time Visibility

JusLink provides real-time visibility across the supply chain. This feature allows companies to track assets, shipments, and labor activities instantly. Real-time data helps managers respond quickly to delays and disruptions, improving labor utilization.

Faster gate check-ins and asset tracking reduce time spent searching for trailers and waiting for dock assignments.

Optimized yard management lowers detention fees and labor costs by improving truck and trailer movements.

AI-powered yard vision systems automate vehicle access control, eliminating manual logging and reducing errors.

Real-time shipment updates allow labor scheduling to match actual arrivals, cutting idle labor time and overtime costs.

Digital workflows replace paper-based processes, speeding up billing and reducing administrative labor.

These improvements help companies reduce labor inefficiencies and overtime expenses. Real-time visibility leads to measurable labor cost savings and better workforce management.

Case Study: SHARP

SHARP, a global household appliances manufacturer, faced complex supply chain challenges. After partnering with JUSDA, Sharp transformed its logistics operations using JusLink’s intelligent platform. The company implemented automated procurement, vendor-managed inventory, and just-in-time strategies.

The results were significant:

Improvement Area | Measurable Result |

|---|---|

Labor Cost Reduction | 70% decrease |

Logistics Cost Savings | 20% reduction |

Order Delivery Times | 30% faster, near-perfect accuracy |

Communication Efficiency | 50% increase |

SHARP shortened order processing cycles and improved inventory management. The company reduced unnecessary inventory and streamlined distribution. JusLink’s real-time visibility allowed SHARP to coordinate supply chain activities across multiple countries.

JusLink’s intelligent platform helped SHARP uncover hidden labor costs, improve delivery times, and boost operational efficiency.

JUSDA’s solutions show the value of integrating technology and intelligent platforms in modern supply chains. Companies gain better control, reduce costs, and build more resilient operations.

Managing and Reducing Hidden Labor Costs

Effectively managing and reducing hidden labor costs requires a proactive approach. Supply chain leaders can use technology, invest in workforce development, and optimize processes to uncover and eliminate these expenses.

Technology Adoption

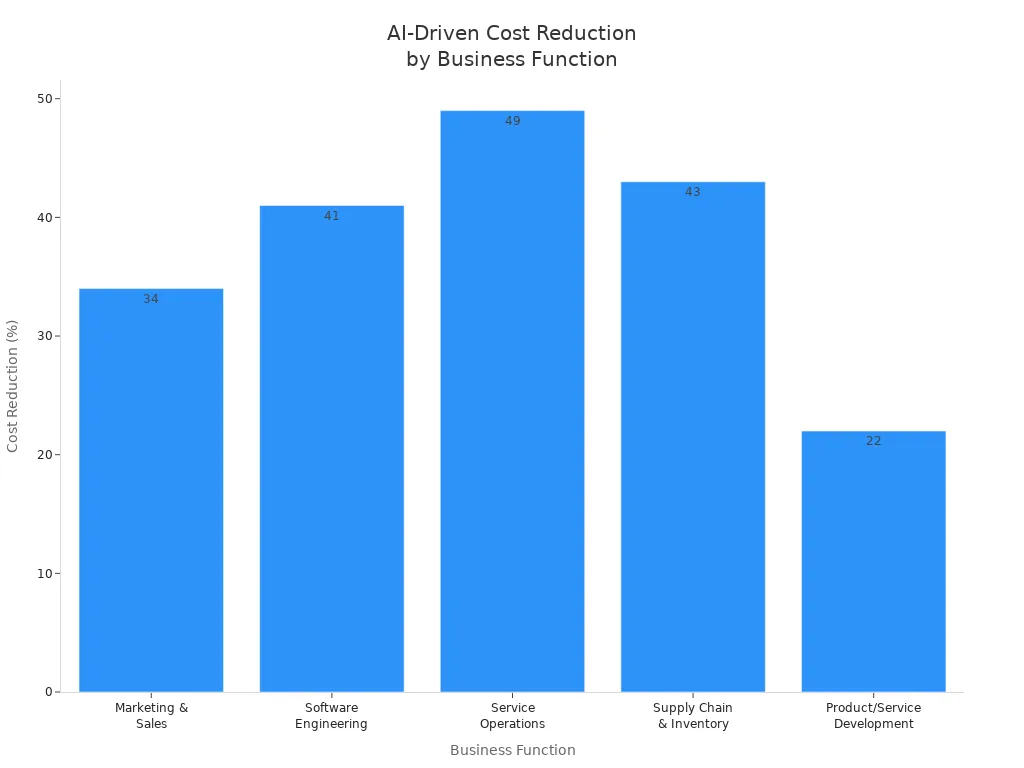

Companies that adopt automation and AI gain a clear advantage. Automation handles repetitive tasks like data entry and invoice processing, which reduces manual labor and payroll expenses. AI-driven systems improve decision-making by analyzing data, optimizing resource allocation, and predicting maintenance needs. These tools help prevent costly downtime and errors. For example, AI and automation can reduce costs in supply chain and inventory management by about 43%, as shown below:

Business Function | Approximate Cost Reduction (%) | Revenue Increase (%) |

|---|---|---|

Supply Chain & Inventory | Around 43% | Up to 63% |

Service Operations | Around 49% | Up to 57% |

Marketing & Sales | Around 34% | Up to 67% |

Warehouse management systems and barcoding also improve productivity and accuracy. Companies should conduct ROI analysis before investing in automation to ensure cost-effectiveness.

Training and Retention

Employee training and retention play a key role in reducing hidden labor costs. Strong onboarding and ongoing training help new hires become productive faster and reduce early turnover. Recognizing talent, offering career growth, and maintaining open communication keep employees engaged. Digital training platforms make learning flexible and track progress in real time. These efforts lower turnover, prevent shipment delays, and protect valuable knowledge within the team.

Process Optimization

Process optimization uncovers and removes inefficiencies that drive up hidden labor costs. Leaders can:

Assess current workflows using data analysis and benchmarking to find wasted time and underused labor.

Reconfigure facility layouts to reduce unnecessary movement and speed up tasks.

Implement automation and lean principles to eliminate non-value-added activities.

Foster a culture of continuous improvement by encouraging employees to suggest changes.

Collaborate with suppliers for just-in-time inventory and better communication.

Use quality control systems to catch errors early and avoid costly rework.

Regular internal audits using technology-driven tools help managers compare planned and actual labor hours, spot productivity gaps, and implement improvements.

Partnering with third-party logistics providers (3PLs) offers flexible labor solutions. 3PLs handle recruitment, training, and workforce management, which reduces fixed costs and allows companies to pay only for the services they use. This approach helps manage seasonal spikes and variable workloads without increasing hidden labor costs.

Continuous improvement practices, such as process mining and predictive analytics, help maintain low hidden labor costs over time. Empowering frontline workers to suggest small changes leads to big savings when repeated across the organization.

Uncovering and addressing hidden labor costs strengthens supply chain transparency, supports sustainability, and improves risk management. Companies using intelligent platforms like JUSDA’s JusLink see measurable gains, such as up to 50% fewer forecasting errors and a 15% reduction in supply-chain costs.

Managers should review workflows, consult supply chain experts, and adopt automation tools to optimize labor. These steps help organizations build resilient operations and achieve long-term success.

FAQ

What are hidden labor costs in supply chain operations?

Hidden labor costs include wasted time, duplicated tasks, and errors that do not appear on standard financial reports. These costs reduce efficiency and profitability. Managers often overlook them during daily operations.

Tip: Regular workflow audits help identify hidden labor costs.

How can companies identify hidden labor costs?

Managers can track labor hours, review error rates, and analyze workflow bottlenecks. Technology platforms like JusLink provide real-time data and performance metrics. These tools help companies spot inefficiencies and areas for improvement.

What role does automation play in reducing hidden labor costs?

Automation replaces manual tasks with digital processes. Companies use AI to optimize scheduling, inventory management, and error correction. Automated systems lower payroll expenses and improve accuracy.

Example: Automated order processing reduces rework and speeds up fulfillment.

How does JUSDA’s JusLink platform help manage labor costs?

JusLink uses AI and real-time visibility to streamline supply chain tasks. The platform automates repetitive work, predicts demand, and monitors labor performance. Companies see faster deliveries, fewer errors, and lower labor expenses.

Note: JusLink helped Sharp reduce labor costs by 70%.

See Also

Understanding Financial Strategies To Reduce Supply Chain Costs

Unlocking Hidden Logistics Tips To Boost Supply Chain Savings

Effective Approaches To Solve Supply Chain Challenges In Tech

How To Identify And Cut Excess Supply Chain Spending

The Critical Role Of Security In Modern Supply Chain Management