High-Tech Manufacturing: Debunking Automation Myths

High-tech manufacturing stands as a pivotal force in industrial growth, driving both the quality and quantity of output. Despite its significance, misconceptions about automation abound, clouding its true impact. This blog aims to dispel these myths and shed light on the transformative power of automation in high-tech manufacturing.

Myth 1: Automation Replaces Jobs

The Reality of Job Displacement

Automation Creates New Jobs

In the realm of high-tech manufacturing, the fear that automation will lead to widespread job loss is a common misconception. World Economic Forum, an expert in economic analysis, dispels this myth by highlighting that automation is set to create a significant number of new jobs. Contrary to popular belief, the implementation of automated systems in manufacturing processes does not equate to human workers being replaced entirely. Instead, it opens up avenues for individuals to take on new roles that complement and enhance automated technologies.

As Vecna Robotics aptly puts it, "Just as ghosts are often misunderstood in spooky tales, the idea that automation will eliminate all human jobs is a misconception." This analogy underscores the fact that automation serves as a tool for augmenting human capabilities rather than rendering them obsolete. By streamlining repetitive tasks and optimizing efficiency, automation paves the way for the emergence of novel job opportunities within high-tech manufacturing industries.

Skill Enhancement and Training

Moreover, the integration of automation in manufacturing processes necessitates a shift in skill requirements rather than a reduction in workforce. As traditional manual tasks become automated, there arises a demand for individuals with expertise in operating and maintaining these advanced systems. Consequently, employees have the opportunity to upskill and reskill themselves to align with the evolving technological landscape.

The Brookings Institution, known for its economic analysis, emphasizes that throughout history, technological advancements have led to initial concerns about job displacement. However, these concerns have been consistently proven wrong as innovation drives the creation of new employment opportunities. In essence, automation acts as a catalyst for skill development and continuous learning among workers in high-tech manufacturing sectors.

Case Studies

Examples from Various Industries

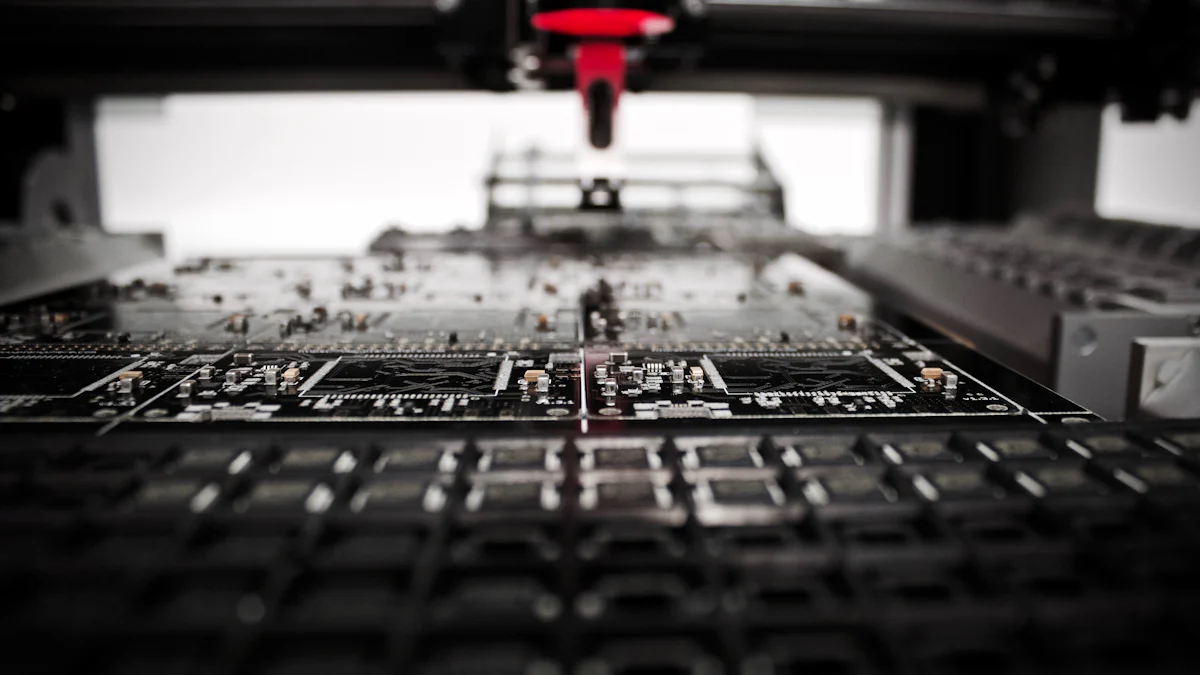

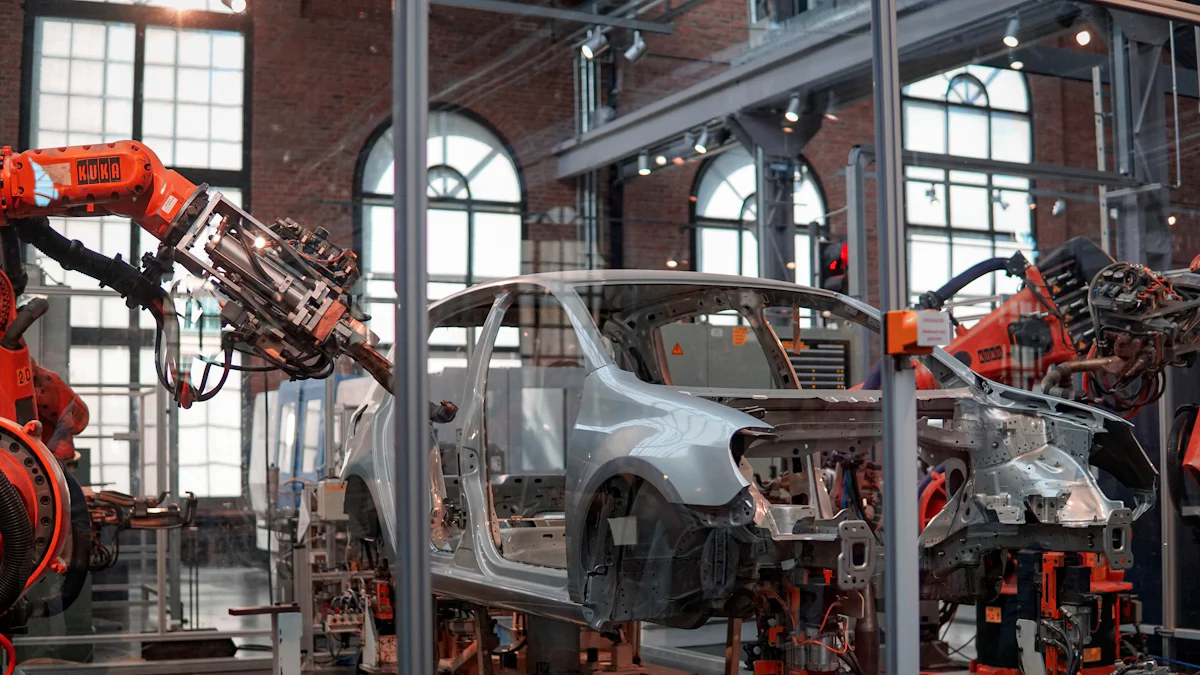

To further illustrate how automation contributes to job creation rather than replacement, consider the case studies across diverse industries such as pharmaceuticals, aerospace engineering, and electronics manufacturing. These sectors have embraced automation technologies to enhance precision and efficiency in their production processes while simultaneously expanding their workforce.

Myth 2: Automation is Too Expensive

Cost-Benefit Analysis

Initial Investment vs. Long-term Savings

When considering the integration of high-tech manufacturing automation systems, companies often face the initial concern of substantial investment requirements. However, a comprehensive cost-benefit analysis reveals that while there may be significant upfront costs, the long-term savings and efficiency gains outweigh these expenses. By strategically allocating resources towards automated technologies, businesses can optimize their production processes, reduce operational costs, and enhance overall productivity.

To illustrate this point further, let's delve into a case study from The Benefits and Risks of Automation in Manufacturing. In this study, it was found that companies that invested in automation witnessed a remarkable decrease in production lead times and an increase in product quality. This outcome underscores the notion that although automation may require a notable initial investment, the long-term benefits far surpass these costs.

ROI in High-Tech Manufacturing

One crucial aspect of evaluating the affordability of automation in high-tech manufacturing is analyzing the return on investment (ROI) that these technologies offer. By implementing automated systems, businesses can streamline their operations, minimize errors, and achieve higher levels of precision in product manufacturing. This enhanced efficiency not only leads to cost reductions but also contributes to improved working conditions for employees.

An insightful example from *Automated Testing Cost Savings* showcases how test automation can significantly reduce testing time and costs while improving overall software quality. This success story highlights the tangible benefits that automation brings to manufacturing processes by optimizing resource allocation and enhancing operational efficiency.

Financial Accessibility

Options for Small and Medium Enterprises

While it is commonly believed that automation is exclusively reserved for large corporations with substantial financial capabilities, advancements in technology have made automated solutions increasingly accessible to small and medium enterprises (SMEs). Today, SMEs have a myriad of options available to them when seeking to implement automation technologies within their manufacturing operations.

A notable success story from A Success Story of Business Process Automation features Coca-Cola's implementation of Robotic Process Automation (RPA) to streamline their accounts payable and receivable processes. This initiative not only improved operational efficiency but also underscored how even industry giants can benefit from cost-effective automation solutions.

By exploring various avenues for financial accessibility in automation adoption, businesses across all scales can harness the transformative power of automated technologies to drive growth and innovation within the realm of high-tech manufacturing.

Myth 3: Automation is Only for Large Companies

Scalability of Automation Solutions

In the realm of high-tech manufacturing, the notion that automation is exclusively tailored for large corporations is a prevailing misconception. The scalability of automation solutions transcends the boundaries of business size, offering a myriad of benefits to enterprises across various scales. By embracing customizable automation systems, businesses can tailor their automated technologies to suit their specific production needs and operational requirements.

Customizable Automation Systems offer flexibility in adapting automated processes to unique manufacturing environments.

Small and medium-sized businesses implementing automation witness a reduction in labor costs, an increase in efficiency, and substantial savings in the long run.

Coca-Cola's successful integration of Robotic Process Automation (RPA) exemplifies how scalable automation solutions streamline financial operations with precision and speed.

Success Stories of Small Businesses

Small businesses stand as testament to the transformative power of automation, showcasing how these technologies drive growth and innovation irrespective of company size. Through success stories from various sectors, it becomes evident that automation fosters operational excellence and propels businesses towards heightened productivity and competitiveness.

"Automation can reduce labor costs, increase efficiency, save money in the long run, and provide more accurate data for decision-making." - Industry Expert

Small businesses leveraging affordable automation technologies witness enhanced operational efficiency and cost-effectiveness.

The implementation of scalable automation solutions enables SMEs to optimize their production processes while maintaining financial viability.

Coca-Cola's adoption of Robotic Process Automation (RPA) streamlined accounts payable and receivable processes, improving efficiency and accuracy in financial operations.

Technological Advancements

The landscape of high-tech manufacturing is continually evolving with advancements in affordable automation technologies. These technological innovations democratize access to automated solutions, making them accessible to businesses across all scales. By capitalizing on these advancements, companies can revolutionize their manufacturing processes and drive sustainable growth through enhanced productivity.

Affordable Automation Technologies empower small businesses to enhance their competitive edge by optimizing production workflows.

The integration of advanced automation tools facilitates precision engineering and quality assurance within high-tech manufacturing industries.

Coca-Cola's implementation of Robotic Process Automation (RPA) exemplifies how technological advancements enable even industry giants to achieve operational excellence through cost-effective automated solutions.

Automation ensures high-quality products and enables companies to consistently meet customer expectations.

Small businesses benefit from automation by reducing labor costs and increasing efficiency.

Automation tools enhance efficiency, quality, productivity, and competitiveness across various industries.

Humans remain essential for tasks requiring judgment, creativity, and complex decision-making.

Companies can make faster decisions based on the latest information provided by automated systems.

Workflow automation allows businesses to focus on more complex tasks, fostering growth and innovation.

See Also

Simplifying Strategies for Supply Chain Challenges in High-Tech Manufacturing

Innovative Advances in Logistics: Exploring Tomorrow's Path

Revealing AI Integration Insights for the Future of Supply Chains

Transforming Logistics: How Supply Chain Innovation is Changing the Game