How Automotive Market Trends Are Shaping Global Manufacturing

Automotive market trends have significantly influenced the global manufacturing landscape. The automotive industry leads in technological advancements, focusing on sustainability and eco-friendly processes. The steady growth of the global automotive parts market over the past twenty years highlights this impact. JUSDA plays a crucial role in supply chain management within the automotive sector. The company leverages advanced technologies to optimize manufacturing and distribution processes, meeting complex customer demands efficiently.

Overview of Current Automotive Market Trends

Rise of Electric Vehicles (EVs)

Electric vehicles have become a significant focus within the automotive market trends. Manufacturers now prioritize the development and production of EVs due to their environmental benefits. The shift towards electric vehicles impacts traditional manufacturing processes. Factories must adapt to new technologies and materials specific to EV production. This transition requires significant investment in research and development.

The influence on supply chain dynamics is profound. The demand for lithium-ion batteries and other specialized components has increased. Suppliers must adjust to meet these new requirements. The supply chain must become more agile and responsive to changes in demand and technology.

Advancements in Autonomous Driving Technology

Autonomous driving technology represents another pivotal trend in the automotive market. Vehicle design and production undergo significant changes to accommodate self-driving capabilities. Manufacturers integrate advanced sensors, cameras, and software systems into vehicles. These additions require new manufacturing techniques and expertise.

Regulatory challenges and opportunities arise with autonomous vehicles. Governments must establish safety standards and regulations. Manufacturers see opportunities to innovate and lead in this emerging field. The balance between regulation and innovation becomes crucial for success.

Shift Towards Sustainable Practices

Sustainability has emerged as a key focus in automotive market trends. The adoption of eco-friendly materials is now a priority for manufacturers. Companies seek materials that reduce environmental impact while maintaining quality and performance. This shift influences material sourcing and production methods.

Energy-efficient manufacturing techniques gain importance. Factories implement processes that minimize energy consumption and waste. These practices align with global sustainability goals and enhance operational efficiency. The commitment to sustainability drives innovation across the industry.

Impact of Automotive Market Trends on Global Manufacturing

Changes in Production Techniques

The automotive market trends have led to significant changes in production techniques. The integration of smart manufacturing technologies has become a cornerstone in modern automotive production. Factories now utilize digitalization and additive manufacturing to enhance efficiency. These technologies enable on-demand and customized production, catering to individual customer preferences. This shift contrasts with traditional manufacturing techniques that focused on mass production with limited customization options.

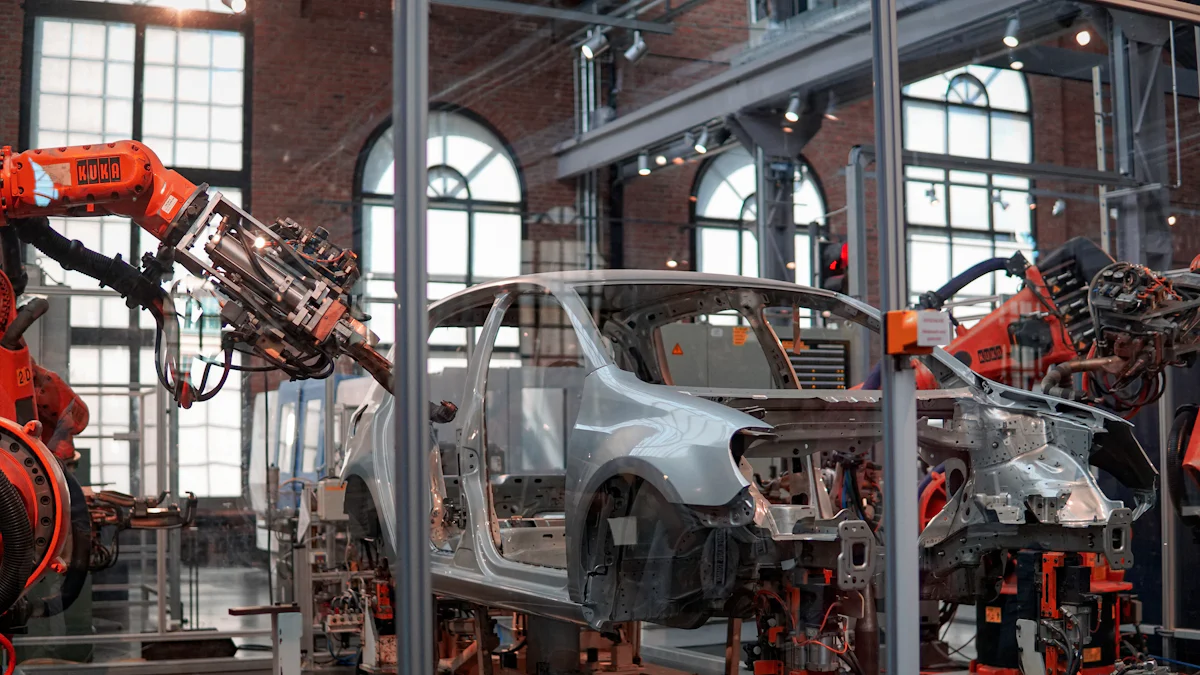

Automation and robotics in assembly lines have revolutionized the automotive industry. Robots perform repetitive tasks with precision and speed. This automation reduces human error and increases productivity. Modern manufacturing technologies incorporate sustainable practices, aligning with global sustainability goals. The adoption of these technologies reflects the industry's commitment to innovation and efficiency.

Global Supply Chain Adjustments

Automotive market trends have necessitated adjustments in the global supply chain. The sourcing of raw materials has become more strategic. Manufacturers seek eco-friendly materials to reduce environmental impact. This shift influences material sourcing and production methods. Suppliers must adapt to meet these new requirements.

Logistics and distribution challenges arise from these adjustments. The demand for specialized components like lithium-ion batteries has increased. Supply chains must become more agile and responsive to changes in demand and technology. Efficient logistics solutions are essential to meet complex customer demands. The automotive industry relies on advanced technologies to optimize supply chain management.

Workforce Implications

The evolving automotive market trends have significant implications for the workforce. The need for skilled labor in new technologies has increased. Workers must possess expertise in digitalization, automation, and sustainable practices. The demand for skilled labor reflects the industry's focus on innovation and efficiency.

Training and development programs play a crucial role in addressing this need. Companies invest in programs that equip workers with the necessary skills. These programs ensure that the workforce can adapt to new manufacturing techniques. The commitment to training and development supports the industry's growth and competitiveness.

JUSDA's Role in Navigating Automotive Market Trends

Leveraging Advanced Technologies

Use of Big Data and IoT in Supply Chain Management

JUSDA employs big data and the Internet of Things (IoT) to revolutionize supply chain management. Big data analytics allows JUSDA to process vast amounts of information, providing insights into market trends and customer preferences. This data-driven approach enhances decision-making and optimizes operations. IoT technology connects devices and systems, enabling real-time tracking and monitoring of goods throughout the supply chain. This connectivity ensures transparency and efficiency, reducing delays and improving service quality.

Cloud Platforms for Real-Time Collaboration

Cloud platforms play a crucial role in JUSDA's strategy for real-time collaboration. These platforms facilitate seamless communication among manufacturers, suppliers, and customers. Real-time data sharing enhances coordination and reduces the risk of errors. Cloud-based solutions allow stakeholders to access information from anywhere, fostering flexibility and responsiveness. This approach supports JUSDA's commitment to delivering efficient and reliable supply chain services.

Enhancing Supply Chain Efficiency

JusLink Platform for Intelligent Supply Chain Systems

The JusLink platform represents a significant advancement in intelligent supply chain systems. This platform integrates modern technologies such as IoT, cloud computing, and big data. JusLink breaks down information silos, promoting enterprise information sharing across the entire supply chain. This integration connects manufacturers, dealers, and car owners, enhancing profitability and reducing product loss. JusLink enables the orderly development and redistribution of benefits within the automotive industry.

Multimodal Transportation and Warehousing Solutions

JUSDA offers comprehensive multimodal transportation and warehousing solutions. These services ensure the efficient movement of goods across various modes of transport. JUSDA's warehousing facilities provide secure storage and handling of products. The company's global presence supports logistics operations, ensuring timely delivery to customers worldwide. These solutions reflect JUSDA's dedication to optimizing supply chain processes and meeting the diverse needs of the automotive market.

JUSDA Solutions

To provide you with professional solutions and quotations.

Future Predictions and Implications

Long-term Effects on Manufacturing Industries

Potential for New Market Entrants

The automotive industry presents opportunities for new market entrants. Emerging trends such as electric vehicles and autonomous technology create a demand for innovative solutions. Companies with expertise in these areas can enter the market and compete with established manufacturers. The rise of startups and tech companies in the automotive sector highlights this potential. These new players bring fresh ideas and technologies, driving competition and innovation.

Evolution of Existing Manufacturing Hubs

Existing manufacturing hubs face evolution due to changing automotive trends. Traditional centers must adapt to new production techniques and technologies. The shift towards smart manufacturing requires investment in digitalization and automation. Manufacturing hubs that embrace these changes can maintain competitiveness. Regions that fail to adapt may lose their status as industry leaders. The evolution of manufacturing hubs reflects the dynamic nature of the automotive industry.

Emerging Opportunities and Challenges

Innovations in Manufacturing Processes

Innovations in manufacturing processes offer significant opportunities. Advanced robotics and artificial intelligence enhance precision and efficiency. Human-robot collaboration allows for high-quality production with reduced injury risk. The integration of these technologies transforms traditional manufacturing methods. Companies that adopt these innovations can improve productivity and product quality. The automotive industry continues to explore new ways to optimize manufacturing processes.

Economic and Geopolitical Factors

Economic and geopolitical factors present challenges for the automotive industry. Trade policies and tariffs impact global supply chains. Manufacturers must navigate these complexities to ensure efficient operations. Economic fluctuations influence consumer demand and production costs. Geopolitical tensions can disrupt supply chains and affect market stability. Companies must develop strategies to mitigate these risks. The ability to adapt to economic and geopolitical changes is crucial for success in the automotive industry.

Automotive market trends reshape global manufacturing. The rise of electric vehicles and autonomous technology drives innovation. Smart manufacturing and Industry 4.0 enhance production efficiency. AI and machine learning optimize operations and improve customer experiences. The future of the automotive industry promises growth through luxury car sales. Challenges and opportunities coexist in this evolving landscape. JUSDA remains committed to supporting the automotive market with advanced supply chain solutions. The company's dedication ensures efficient adaptation to emerging trends.

See Also

Unlocking the Power of Your Automotive Supply Chain

Harnessing Data for Enhanced Automotive Demand Forecasting

Mastering Automotive Supply Chain Hurdles: Expert Advice

The Blueprint for Manufacturing Excellence: Essential Tactics