How Integrated Logistics Solutions Drive Business Success

Integrated logistics change the way companies achieve success. Businesses that use integrated logistics see real improvements in cost, efficiency, and customer satisfaction. Studies show digital logistics solutions can reduce supply chain costs by up to 15% and boost efficiency by 10-15%.

McKinsey reports inventory levels drop by 20-50% with integrated logistics.

Gartner finds real-time visibility cuts operational costs by 15% and increases on-time delivery by 25%.

A major retailer improved customer satisfaction by 32% after using integrated logistics to reroute shipments. Integrated logistics make every step, from shipping to inventory, work together for better results. Companies that rely on integrated logistics solutions gain a clear advantage in today’s fast-paced markets.

Key Takeaways

Integrated logistics connect all parts of the supply chain, using technology and teamwork to improve efficiency and reduce costs.

Advanced tools like AI, IoT, and real-time data help companies save money, respond quickly to changes, and lower risks in their logistics operations.

Better logistics lead to faster, more reliable deliveries that boost customer satisfaction and loyalty, giving businesses a strong competitive edge.

Integrated Logistics Solutions

Definition and Key Elements

Integrated logistics connects every part of the supply chain into one seamless system. Companies use this approach to merge procurement, production, storage, distribution, and transportation. Each step works together, supported by technology and teamwork.

Key elements include:

Transportation: Moves goods efficiently using road, rail, air, and sea.

Warehousing: Stores products with real-time inventory tracking.

IT Integration: Uses systems like Warehouse Management Systems (WMS) and Transportation Management Systems (TMS) for data sharing and visibility.

Collaboration: Encourages communication among teams, suppliers, and partners.

Integrated logistics relies on advanced technology to link departments and manage activities. Real-time data helps companies spot problems and make quick decisions. Collaboration across the supply chain improves efficiency and reduces costs. Research shows that companies with integrated logistics see better performance, lower costs, and higher customer satisfaction compared to those with fragmented systems.

JUSDA’s Approach

JUSDA stands out as a global leader in supply chain management. The company uses innovation and technology to deliver top-tier logistics solutions. Its JusLink intelligent platform connects every part of the supply chain, offering real-time insights and seamless coordination.

JUSDA’s eight core products cover all major logistics needs:

Air, land, ocean, and rail transport

Cloud warehousing

Consolidation and distribution

Comprehensive foreign trade services

JusLink intelligent supply chain platform

These products work together to create integrated logistics solutions for industries like electronics, automotive, and FMCG. JUSDA’s approach ensures efficiency, cost savings, and reliable service for businesses worldwide.

Business Benefits

Cost Savings and Efficiency

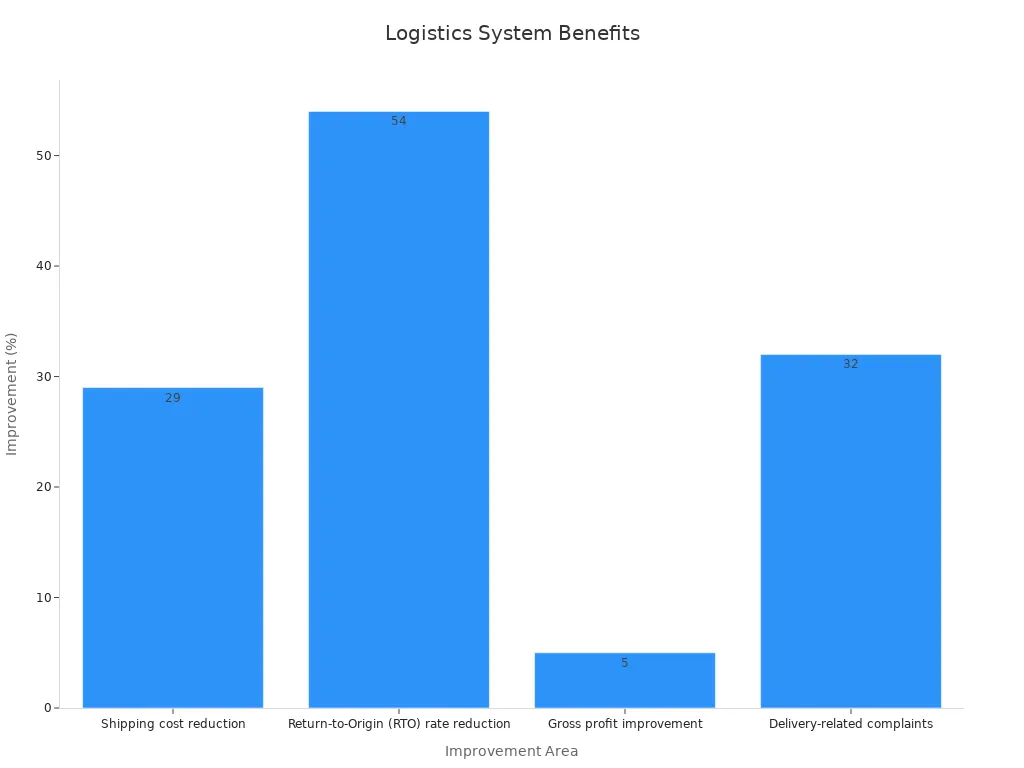

Integrated logistics help companies save money and work faster. Businesses that use advanced technology, such as AI and big data, can optimize routes and reduce costs. For example, Walmart increased productivity by over 40% and reduced errors by using VR and AR technologies. Automation and robotics can lower logistics costs by 15%, improve inventory by 35%, and boost service levels by 65%. Companies like FedEx use AI to predict maintenance needs, which keeps fleets running smoothly and reduces downtime.

A systematic review of Industry 4.0 technologies in sustainable logistics shows clear benefits. Smart transportation planning with AI and IoT reduces delays and fuel use. Green vehicle routing systems cut costs and energy use. Simulation models show fewer truck loads, less fuel, and lower emissions. These improvements help companies in many industries save money and work more efficiently.

Cost Reduction Aspect | Percentage Reduction / Change | Description |

|---|---|---|

Transportation Spend | Freight consolidation replaces LTL shipments with full truckload shipments | |

Cost per Case (packaging) | 50% reduction | Solving complex packaging challenges |

Cost per Pound | From $0.46 to $0.39 (approx. 15% reduction) | Freight optimization solution reduces LTL costs |

Delivery process efficiency can improve by up to 18% when companies adjust schedules based on data. Shorter delivery times help reduce extra inventory costs. Even a 5% reduction in delivery time can lead to a 12% improvement in supply chain responsiveness. Companies using AI, IoT, and big data analytics report up to a 25% increase in logistics efficiency.

JUSDA’s logistics solutions use these technologies to help clients cut costs and improve efficiency. Their JusLink platform connects every part of the supply chain, making it easier to spot problems and fix them quickly.

Flexibility and Risk Reduction

Integrated logistics make supply chains more flexible and less risky. Companies can respond faster to changes in demand or supply. Advanced modeling techniques, such as Bayesian belief networks and AI, help businesses plan for risks and handle uncertainty. These tools identify critical risks in logistics, such as delays or shortages, and suggest ways to avoid them.

Technology-based risk management tools, like IoT and blockchain, increase flexibility and reduce operational risks.

Integrated evaluation of all logistics steps gives better results than looking at each step alone.

New technologies help companies respond to demand changes and resource limits.

Decision-makers can prioritize risks more reliably, leading to better strategies.

In the automotive industry, integrated logistics planning with new technology reduces risks and increases flexibility.

JUSDA supports flexible supply chains by offering real-time tracking, demand forecasting, and dynamic inventory management. Their platform helps companies adjust quickly to market changes and avoid costly disruptions.

Customer Experience

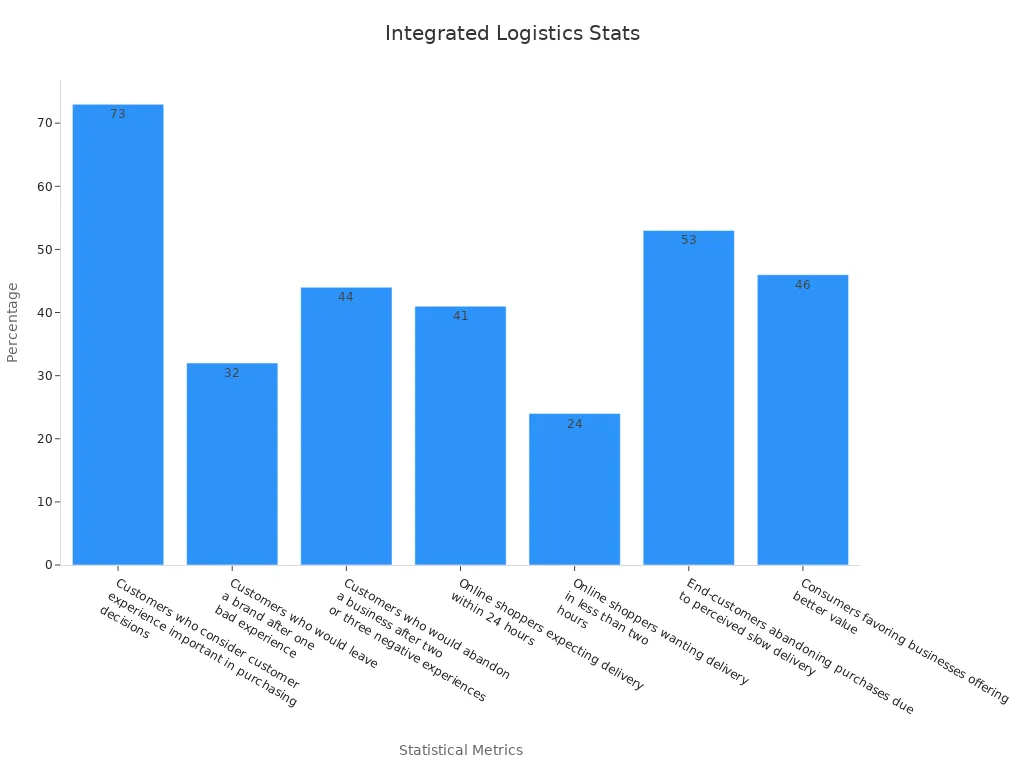

Integrated logistics improve customer experience by making deliveries faster and more reliable. Customers expect quick and accurate service. If companies fail to deliver, they risk losing business. The following table shows how important customer experience is:

Customer Satisfaction Statistic | Percentage | Explanation |

|---|---|---|

Customers who consider customer experience important in purchasing decisions | 73% | Customer experience shapes buying decisions. |

Customers who would leave a brand after one bad experience | 32% | Reliability matters for customer loyalty. |

Customers who would abandon a business after two or three negative experiences | 44% | Repeated poor service drives customers away. |

Online shoppers expecting delivery within 24 hours | 41% | Fast delivery is now a standard expectation. |

Online shoppers wanting delivery in less than two hours | 24% | Ultra-fast delivery demand is rising. |

End-customers abandoning purchases due to slow delivery | 53% | Delivery speed affects purchase completion. |

Consumers favoring businesses offering better value | 46% | Cost-effectiveness attracts customers. |

Automated order tracking reduces customer service tickets by 16%. Real-time tracking and accurate delivery information build trust and loyalty. Key metrics like CSAT, CES, and NPS show that integrated logistics lead to higher satisfaction and repeat business. JUSDA’s logistics solutions provide these features, helping clients meet customer expectations and stand out in the market.

Real-World Success: JUSDA Case Study

JUSDA’s work with global manufacturers shows the real benefits of integrated logistics. For example, Sharp, a leading electronics company, faced complex supply chain challenges as it expanded worldwide. JUSDA implemented its Supply Chain Management Collaboration Platform, powered by AI and cloud computing. This platform improved demand forecasting, delivery coordination, and inventory management.

As a result, Sharp reduced logistics costs by 20% and improved order processing cycles. The platform also helped Sharp standardize operations and reduce manual work. These changes made Sharp’s supply chain more efficient and cost-effective, supporting its global growth.

Other companies have seen similar results. UPS saved $50 million each year by optimizing delivery routes and cutting fuel use. Amazon improved decision-making and performance by using cloud-based data warehousing. These examples show how integrated logistics drive business success across different industries.

JUSDA’s logistics solutions support companies in electronics, automotive, FMCG, and more. Their approach helps businesses expand globally, reduce risks, and deliver better service to customers.

Implementing Integrated Logistics

Steps to Success

Companies achieve integrated logistics by following a clear set of steps. First, they audit their current logistics systems, such as TMS, WMS, and ERP, to understand data sources. Next, they set objectives and key performance indicators to measure progress. Building a centralized, cloud-based data hub helps consolidate information and remove redundancy. Real-time data synchronization through APIs and middleware increases visibility across the supply chain. Standardizing data management and automating processes with barcode scanners, RFID, and IoT sensors further streamlines operations. Cross-department teams and regular communication foster collaboration. Continuous monitoring and improvement ensure long-term success. Unilever’s use of routing optimization software improved efficiency and reduced environmental impact, showing the value of technology and teamwork in integrated logistics.

Technology and Collaboration

Technology adoption and collaboration drive integrated logistics success. Companies deploy IoT, GPS, and RFID for real-time tracking. Big data, AI, and analytics help identify inefficiencies and improve decision-making. Standardized processes and metrics keep performance consistent. Cross-functional teams and regular training build a culture of innovation. Collaboration extends beyond internal teams to include partners and technology providers. For example, logistics service providers who co-develop systems with carriers see faster payments and fewer delays. This approach creates a seamless supply chain model, improves supply chain coordination, and gives companies a competitive edge.

JUSDA’s Best Practices

JUSDA leads with an AI-powered platform that integrates data from every part of the supply chain. Their JusLink platform uses IoT, cloud computing, and big data to provide real-time insights. JUSDA’s industry-specific solutions help companies in electronics, automotive, and FMCG achieve better results. Statistical insights show that AI-powered logistics can reduce inventory costs by up to 32% and improve order fulfillment productivity by 32%. JUSDA’s focus on workforce training and process standardization ensures smooth adoption of new technologies. Businesses that partner with JUSDA benefit from improved efficiency, lower costs, and enhanced customer satisfaction.

JUSDA Solutions

To provide you with professional solutions and quotations.

Integrated logistics solutions transform business performance. Companies see higher customer satisfaction, improved supply chain efficiency, and stronger loyalty.

Studies show logistics integration boosts operational quality, trust, and cost-effectiveness.

Market trends reveal rapid growth in last-mile delivery, smart warehouses, and secure logistics platforms.

JUSDA offers innovation and global reach. Businesses should consider JUSDA for future-ready supply chains.

See Also

Mastering Efficient Logistics In Advanced Manufacturing Industries

How Artificial Intelligence Is Transforming Future Supply Chains

Innovative Supply Chain Strategies Changing The Logistics Landscape

Unlocking Cost Savings Through Expert Supply Chain Techniques

Exploring JUSDA’s Advanced Logistics For High-Tech Manufacturing