The impact of JUSDA's global manufacturing trends on the automotive industry

JUSDA, a subsidiary of Foxconn Technology Group, revolutionizes global manufacturing through its advanced supply chain solutions. The automotive industry plays a crucial role in the global economy, driving innovation and employment. This blog explores how global manufacturing trends led by JUSDA impact the automotive sector, enhancing efficiency and resilience.

JUSDA's Global Manufacturing Trends

Technological Innovations

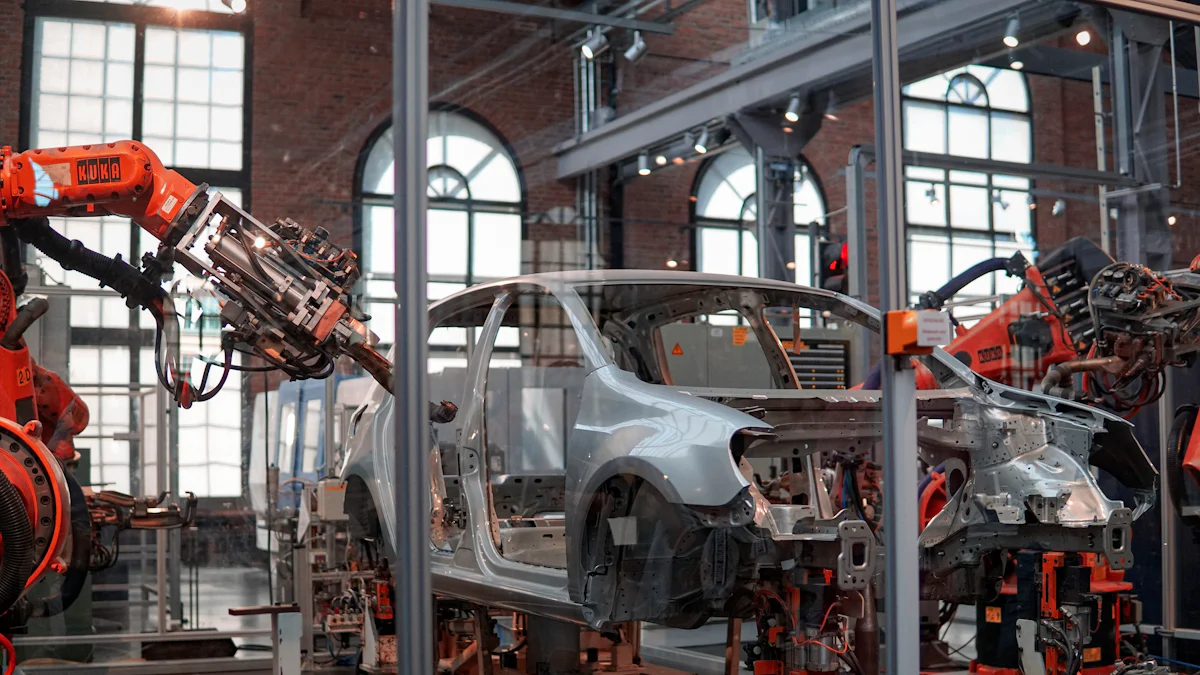

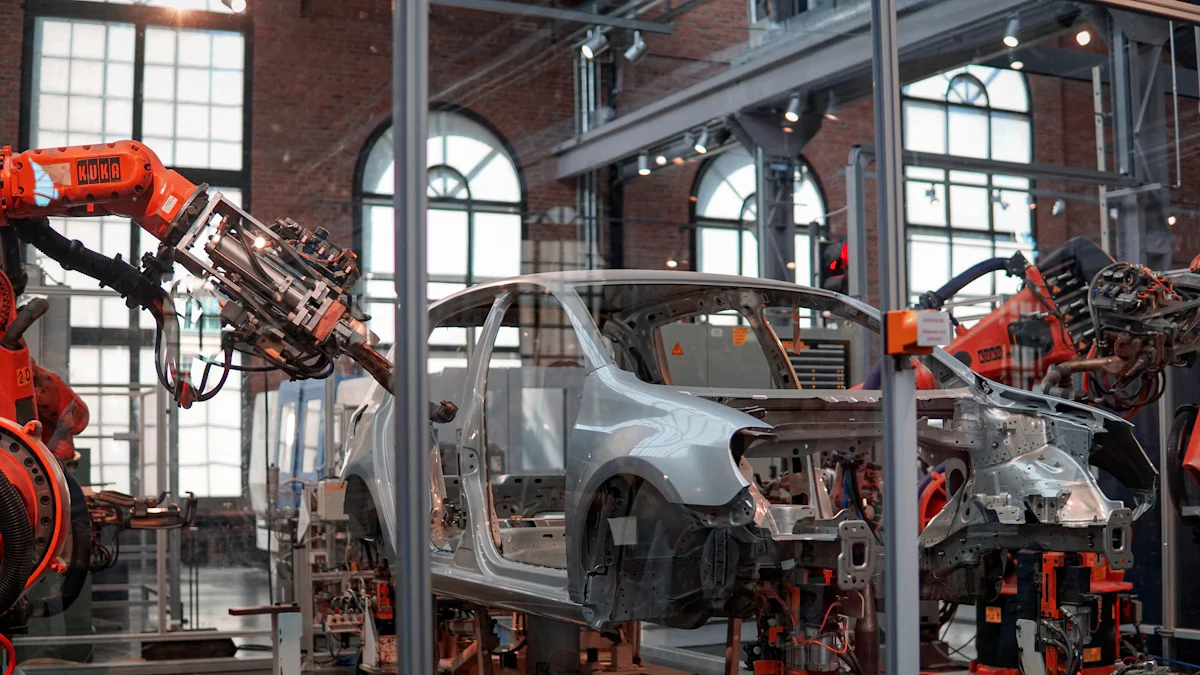

Automation and Robotics

JUSDA integrates global manufacturing trends by leveraging automation and robotics. These technologies streamline production processes, reducing human error and increasing efficiency. Automated systems handle repetitive tasks with precision, ensuring consistent quality. Robotics in manufacturing enhances productivity by operating continuously without fatigue. This integration allows automotive manufacturers to meet high production demands while maintaining quality standards.

Advanced Manufacturing Techniques

Advanced manufacturing techniques play a crucial role in JUSDA's strategy. Techniques such as additive manufacturing and precision machining enable the creation of complex components with high accuracy. Additive manufacturing, or 3D printing, allows for rapid prototyping and customization, reducing lead times. Precision machining ensures that each part meets exact specifications, enhancing the overall reliability of automotive products. These techniques contribute to cost savings and improved product performance.

Supply Chain Management

Just-In-Time (JIT) Manufacturing

JUSDA employs Just-In-Time (JIT) manufacturing to optimize supply chain efficiency. JIT reduces inventory costs by delivering materials only when needed for production. This approach minimizes waste and storage requirements, leading to significant cost savings. Automotive manufacturers benefit from JIT by maintaining lean inventories and reducing excess stock. JIT ensures that production schedules align with market demand, enhancing responsiveness.

Integrated Logistics Solutions

Integrated logistics solutions form the backbone of JUSDA's supply chain management. These solutions encompass transportation, warehousing, and distribution, ensuring seamless coordination. JUSDA's platform optimizes transportation routes and schedules, reducing operational costs. Effective production scheduling aligns with logistics, ensuring timely delivery of components. Integrated logistics enhance supply chain visibility, allowing manufacturers to track shipments in real-time.

Sustainability Practices

Green Manufacturing

Green manufacturing is a key focus in JUSDA's global manufacturing trends. This practice involves using eco-friendly materials and processes to reduce environmental impact. JUSDA implements energy-efficient technologies and renewable resources in manufacturing. Automotive manufacturers adopting green practices benefit from reduced carbon footprints and compliance with environmental regulations. Green manufacturing also appeals to environmentally conscious consumers, enhancing brand reputation.

Waste Reduction Strategies

Waste reduction strategies are integral to JUSDA's sustainability efforts. These strategies involve minimizing waste generation and maximizing resource utilization. JUSDA employs lean manufacturing principles to identify and eliminate waste in production processes. Recycling and reusing materials further contribute to waste reduction. Automotive manufacturers implementing these strategies achieve cost savings and promote sustainability. Efficient waste management enhances operational efficiency and supports environmental conservation.

Impact on the Automotive Industry

Production Efficiency

Cost Reduction

JUSDA's global manufacturing trends have led to significant cost reductions in the automotive industry. The integration of advanced supply chain solutions has optimized transportation routes and production scheduling. This optimization reduces operational costs and minimizes waste. Automotive manufacturers benefit from lower logistics expenses and improved resource utilization. The implementation of Just-In-Time (JIT) manufacturing further decreases inventory costs by delivering materials only when needed.

Time-to-Market Improvements

Time-to-market improvements represent another critical impact of JUSDA's trends. The use of real-time data and analytics enhances demand forecasting accuracy. This accuracy allows manufacturers to align production schedules with market demands. Rapid prototyping through additive manufacturing accelerates the development process. Automotive companies can introduce new models faster, gaining a competitive edge. Efficient supply chain management ensures timely delivery of components, reducing lead times.

Quality and Reliability

Enhanced Product Quality

Enhanced product quality stands as a hallmark of JUSDA's influence on the automotive sector. Advanced manufacturing techniques such as precision machining ensure that each component meets exact specifications. Automation and robotics reduce human error, maintaining consistent quality standards. The use of eco-friendly materials and processes also contributes to superior product performance. Automotive manufacturers achieve higher reliability and customer satisfaction through these innovations.

Consistency in Manufacturing

Consistency in manufacturing processes has improved due to JUSDA's technological integration. Automated systems handle repetitive tasks with precision, ensuring uniformity. Real-time collaboration platforms provide visibility across the supply chain. This visibility allows manufacturers to monitor and control production stages effectively. Consistent manufacturing processes lead to fewer defects and higher overall efficiency. Automotive companies can maintain high production volumes without compromising quality.

Market Dynamics

Competitive Advantage

JUSDA's global manufacturing trends offer a substantial competitive advantage to automotive manufacturers. The ability to reduce costs and improve efficiency positions companies favorably in the market. Advanced supply chain solutions enable rapid response to market changes. Manufacturers can adapt quickly to shifting consumer preferences and regulatory requirements. The adoption of green manufacturing practices also enhances brand reputation, appealing to environmentally conscious consumers.

Consumer Preferences

Consumer preferences in the automotive industry have evolved with JUSDA's trends. The focus on sustainability resonates with eco-friendly consumers. Green manufacturing practices reduce carbon footprints and promote environmental conservation. Enhanced product quality and reliability meet the demands of discerning customers. The ability to introduce new models quickly aligns with consumer expectations for innovation. Automotive companies leveraging JUSDA's solutions can better cater to these evolving preferences.

Future Trends and Predictions

Emerging Technologies

AI and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) will revolutionize manufacturing. AI algorithms can analyze vast amounts of data to optimize production processes. Machine Learning models can predict equipment failures, reducing downtime. These technologies enable predictive maintenance, enhancing operational efficiency. Automotive manufacturers will benefit from improved decision-making capabilities. AI and ML will drive innovation in product design and development.

IoT in Manufacturing

The Internet of Things (IoT) will transform the manufacturing landscape. IoT devices can monitor and control machinery in real-time. This connectivity ensures seamless communication between different production stages. IoT integration enhances supply chain visibility, allowing for better inventory management. Manufacturers can track components from production to delivery. The use of IoT will lead to smarter factories with higher efficiency.

Global Market Shifts

Regional Manufacturing Hubs

Regional manufacturing hubs will gain prominence. Companies will establish production facilities closer to key markets. This shift reduces transportation costs and delivery times. Localized manufacturing hubs enhance responsiveness to market demands. Automotive manufacturers will benefit from reduced supply chain complexities. Regional hubs will foster economic growth in their respective areas.

Trade Policies and Regulations

Trade policies and regulations will shape the global manufacturing landscape. Governments will implement policies to protect domestic industries. Tariffs and trade barriers will influence supply chain strategies. Manufacturers must navigate these regulations to remain competitive. Compliance with environmental and labor standards will become crucial. Trade policies will impact the cost and availability of raw materials.

Challenges and Opportunities

Adapting to Rapid Changes

Manufacturers must adapt to rapid technological advancements. The integration of new technologies requires significant investment. Training the workforce to handle advanced machinery is essential. Companies must stay updated with evolving global manufacturing trends. Failure to adapt can result in loss of competitiveness. Continuous innovation will be key to thriving in a dynamic market.

Leveraging New Opportunities

New opportunities will arise from technological advancements. Automation and digitization will optimize resource usage. Manufacturers can reduce human error and increase precision. Sustainable practices will attract environmentally conscious consumers. Companies can leverage data analytics to enhance product quality. Embracing new technologies will unlock growth potential in the automotive industry.

JUSDA's global manufacturing trends have significantly influenced the automotive industry. Key advancements include automation, robotics, and advanced manufacturing techniques. These innovations enhance production efficiency and product quality. Supply chain management practices like Just-In-Time (JIT) and integrated logistics solutions optimize operations. Sustainability practices, including green manufacturing and waste reduction strategies, promote environmental responsibility.

The future of the automotive industry looks promising with JUSDA's continued influence. Emerging technologies such as AI, Machine Learning, and IoT will further transform manufacturing processes. Industry stakeholders should embrace these trends to stay competitive and drive innovation.

See Also

Revolutionizing Supply Chain Sustainability with JUSDA

Driving Market Trends via Customer Demands with JUSDA

Exploring Global Consumer Demands in Jusda's Supply Chains