Improve Order Fulfillment with the Perfect Picking Strategy

Efficient order fulfillment plays a crucial role in the success of warehouse operations. It directly impacts customer satisfaction and operational costs. Picking strategies, such as batch picking and zone picking, can significantly enhance the efficiency of the picking process. These strategies streamline operations by optimizing picker routes and reducing bottlenecks. The concept of the perfect picking strategy aims to minimize operational costs, which can account for up to 55% of total warehouse expenses. By implementing an optimal picking strategy, warehouses can improve productivity and profitability.

Understanding Order Fulfillment

Order fulfillment encompasses several critical components that ensure the smooth operation of warehouse processes. Each component plays a vital role in delivering products to customers efficiently and accurately. order fulfillment encompasses

Key Components of Order Fulfillment

Receiving and Processing Orders

Receiving and processing orders form the foundation of order fulfillment. Warehouses must accurately record incoming orders to prevent errors. Efficient systems streamline this process, ensuring that orders move quickly from receipt to processing.

Inventory Management

Inventory management involves maintaining optimal stock levels to meet customer demand. Effective inventory management reduces the risk of stockouts and overstocking. Technologies like Warehouse Management Systems (WMS) enhance inventory accuracy and efficiency, leading to improved order fulfillment rates. inventory management involves

Picking and Packing

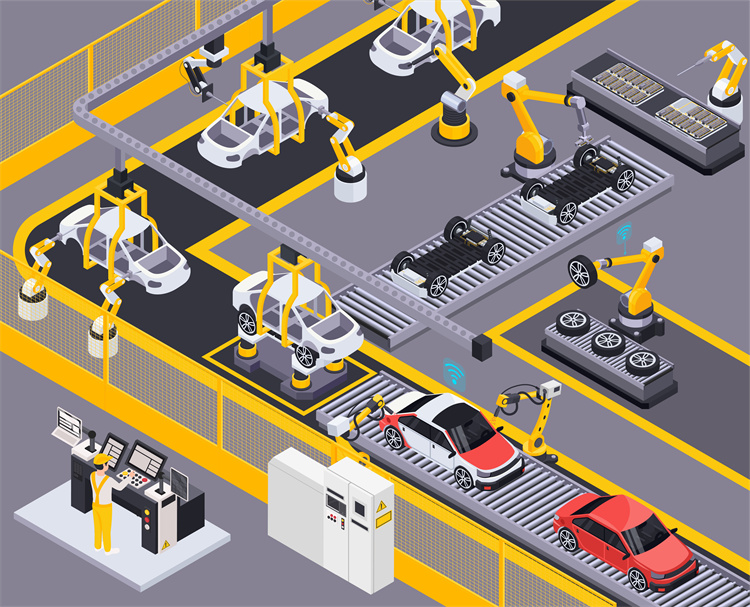

Picking and packing represent the core activities in order fulfillment. These processes require precision and speed. Utilizing technologies such as automated picking systems and collaborative robots can significantly enhance productivity. These innovations reduce manual errors and increase the speed of operations.

Shipping and Delivery

Shipping and delivery complete the order fulfillment cycle. Timely and accurate delivery ensures customer satisfaction. Implementing efficient logistics strategies and utilizing real-time tracking systems can optimize delivery processes, reducing lead times and improving overall service quality.

Challenges in Order Fulfillment

Despite the importance of order fulfillment, several challenges can hinder its efficiency.

Common Bottlenecks

Common bottlenecks include delays in order processing, inefficient picking routes, and inadequate inventory management. These issues can lead to increased operational costs and decreased customer satisfaction.

Impact of Inefficiencies

Inefficiencies in order fulfillment can have significant impacts. They may result in delayed shipments, increased labor costs, and dissatisfied customers. Automation and intelligent operations can mitigate these inefficiencies. For instance, Amazon's use of automation technologies has led to substantial cost reductions and efficiency improvements.

By understanding and addressing these components and challenges, warehouses can enhance their order fulfillment processes. Implementing advanced technologies and optimizing operations can lead to increased throughput, reduced lead times, and improved labor productivity.

Exploring Picking Strategies

Order picking strategies play a pivotal role in enhancing warehouse efficiency and accuracy. By selecting the right method, warehouses can streamline operations, reduce costs, and improve customer satisfaction.

Types of Picking Methods

Single Order Picking

Single order picking involves picking items for one order at a time. This method suits warehouses with low order volumes or specialized orders. It ensures high accuracy, as workers focus on one order, minimizing errors. However, it may not be the most efficient for high-volume operations due to increased travel time.

Batch Picking

Batch picking allows workers to pick items for multiple orders simultaneously. This method reduces travel time by consolidating similar items from different orders into a single pick run. It is ideal for warehouses with high order volumes and similar product types. By grouping orders, batch picking optimizes labor efficiency and speeds up the fulfillment process.

Zone Picking

Zone picking divides the warehouse into specific zones, with workers assigned to each zone. Each worker picks items only within their designated area, reducing travel time and increasing efficiency. This method works well in large warehouses with diverse product ranges. Zone picking minimizes congestion and enhances productivity by allowing simultaneous picking in different zones.

Wave Picking

Wave picking combines elements of batch and zone picking. Workers pick items for multiple orders within a specific time frame or "wave." This method coordinates picking activities with shipping schedules, ensuring timely order fulfillment. Wave picking suits warehouses with fluctuating order volumes and tight delivery deadlines. It maximizes efficiency by aligning picking with downstream processes.

Factors Influencing Picking Strategy Choice

Selecting the right picking strategy depends on several factors that impact warehouse operations.

Order Volume and Frequency

Order volume and frequency significantly influence the choice of picking method. High-volume warehouses benefit from batch or wave picking to optimize efficiency. In contrast, low-volume operations may find single order picking more suitable for maintaining accuracy.

Warehouse Layout and Design

The layout and design of a warehouse play a crucial role in determining the most effective picking strategy. A well-organized layout minimizes travel distances and enhances picking speed. Zone picking works best in large, complex warehouses, while smaller facilities may benefit from simpler methods like single order picking.

Product Characteristics

Product characteristics, such as size, weight, and fragility, affect the choice of picking strategy. For instance, fragile items may require careful handling through single order picking to prevent damage. Conversely, durable products can be efficiently picked using batch or wave methods.

Key Insight: A smart Warehouse Management System (WMS) can analyze order processing information, warehouse layout, and inventory location to optimize order picking routes for floor workers.

By understanding these picking methods and factors, warehouses can tailor their strategies to meet specific operational needs. Implementing the right picking strategy enhances efficiency, reduces costs, and ultimately improves customer satisfaction.

Implementing the Perfect Picking Strategy

Steps to Develop an Optimal Picking Strategy

Analyzing Current Processes

To develop an optimal picking strategy, warehouses must first analyze their current processes. This involves evaluating existing workflows, identifying inefficiencies, and understanding the unique requirements of the operation. By conducting a thorough analysis, warehouses can pinpoint areas that need improvement and set the foundation for a more efficient picking strategy.

Identifying Areas for Improvement

Once the analysis is complete, the next step involves identifying specific areas for improvement. Warehouses should focus on reducing travel times, minimizing errors, and enhancing overall productivity. Implementing smarter slotting strategies and visually scanning orders can significantly optimize picking processes. These improvements not only reduce operating costs but also enhance the accuracy and speed of order fulfillment.

Selecting Appropriate Technologies

Choosing the right technologies is crucial for implementing an effective picking strategy. Warehouse Management Systems (WMS) play a vital role in optimizing operations by managing inventory locations, picking routes, and labor allocation. Technologies like voice-picking systems, pick-to-light systems, and automated mobile robots (AMRs) can further enhance efficiency and accuracy. These systems provide real-time updates and ensure that pickers have accurate information, ultimately boosting productivity.

Role of Technology in Picking

Automated Picking Systems

Automated picking systems revolutionize warehouse operations by streamlining processes and reducing manual errors. These systems generate and manage picking lists, provide real-time updates, and ensure that pickers have accurate information. By automating repetitive tasks, warehouses can significantly enhance productivity and reduce labor costs.

Use of Robotics and AI

Robotics and AI have become integral components of modern warehouse operations. Automated mobile robots (AMRs) work alongside human workers to boost productivity and worker satisfaction. These robots assist in tasks such as picking, packing, and transporting goods, allowing human workers to focus on more complex tasks. The integration of AI enables intelligent order batching and dynamic picking strategies, further optimizing warehouse efficiency.

JUSDA Solutions for Picking Optimization

JUSDA offers comprehensive solutions for picking, leveraging advanced technologies to enhance warehouse operations. Their services include consultation to identify the best picking strategies tailored to specific requirements. By embracing JUSDA's solutions, warehouses can boost fulfillment capabilities and achieve seamless operations. The company's commitment to innovation and efficiency positions it as a key player in the global logistics and supply chain industry.

Key Insight: Embracing technology and innovation is essential for developing the perfect picking strategy. By analyzing current processes, identifying areas for improvement, and selecting appropriate technologies, warehouses can achieve significant enhancements in efficiency and accuracy.

Overcoming Challenges in Picking

Order fulfillment often encounters challenges that can hinder efficiency and accuracy. Addressing these issues requires a strategic approach to enhance the picking process.

Addressing Common Issues

Reducing Picking Errors

Errors in picking can lead to significant setbacks in order fulfillment. They result in incorrect shipments, increased returns, and dissatisfied customers. To reduce these errors, warehouses should implement scan verification systems. These systems ensure that pickers select the correct items by scanning barcodes, which minimizes human error. Additionally, integrating light-directed technology can guide pickers visually, further enhancing accuracy.

Enhancing Speed and Efficiency

Speed and efficiency are crucial for effective order fulfillment. Warehouses can achieve this by optimizing picker routes and utilizing automated systems. Automated Storage and Retrieval Systems (ASRS) streamline the picking process by reducing travel time and increasing throughput. Real-time visibility into inventory levels also allows for timely replenishment, ensuring that popular items remain in stock and ready for picking.

Solutions and Best Practices

Training and Workforce Management

A well-trained workforce is essential for efficient picking operations. Regular training sessions equip workers with the skills needed to handle advanced technologies and adapt to new processes. Workforce management tools can help allocate tasks effectively, ensuring that each worker operates at peak efficiency. By fostering a culture of continuous learning, warehouses can maintain high standards of accuracy and productivity.

Continuous Process Improvement

Continuous improvement is vital for overcoming challenges in picking. Warehouses should regularly assess their processes to identify areas for enhancement. Implementing performance monitoring systems provides valuable insights into operational efficiency. These systems track key metrics, allowing managers to make informed decisions and implement changes that drive improvement. By embracing a mindset of constant refinement, warehouses can stay ahead of industry demands and maintain optimal order fulfillment.

Key Insight: Leveraging technology, such as warehouse automation and real-time visibility, significantly boosts picker productivity. Performance monitoring further aids in identifying bottlenecks and optimizing processes.

A perfect picking strategy is vital for enhancing warehouse productivity and profitability. By optimizing order fulfillment processes, businesses can achieve significant cost savings and improve customer satisfaction. Efficient picking and packing strategies reduce order processing time, providing a competitive edge. Implementing the discussed strategies and technologies, such as a smart Warehouse Management System (WMS), can streamline operations and boost efficiency. Warehouses should embrace these advancements to stay ahead in the industry and ensure seamless order fulfillment.

See Also

Maximizing Warehouse Efficiency with Robotic Automation Technology

Logistics Robotics: Driving Warehouse Productivity to New Heights

Ensuring Success: Deploying Leading Supply Chain Optimization Strategies

Unveiling 5 Cutting-Edge Supply Chain Optimization Approaches

Mastering Lean Logistics for Success in High-Tech Manufacturing