India's Auto Supply Chain Revolution: Embracing Localization

India's automotive industry stands as a significant player in the global market. In 2021, India produced around 4.4 million vehicles, ranking as the fourth largest automotive market worldwide. The industry contributes 7.1 percent to India's GDP and accounts for 49 percent of the country's manufacturing GDP. A turnover of ₹8.7 lakh-crore ($108 billion) was achieved by producing 2.7 crore vehicles in FY23. The Automotive Supply Chain in India is undergoing a revolution. Localization has emerged as a critical strategy. This approach reduces dependency on imports and enhances cost competitiveness.

Industry Events and Developments

Key Industry Events

Major conferences and summits

The Indian automotive sector has witnessed significant gatherings that shape its future. Major conferences and summits play a pivotal role in discussing the latest trends and challenges. The Automotive Component Manufacturers Association of India (ACMA) hosts annual events that bring together industry leaders. These events focus on localization strategies and technological advancements. Participants explore new opportunities for growth within the Automotive Supply Chain in India. Such gatherings foster collaboration and innovation among stakeholders.

Government initiatives and policies

Government initiatives have become crucial in driving the localization agenda. The 'Make in India' initiative encourages domestic manufacturing. This policy aims to reduce import dependency and enhance local production capabilities. The Ministry of Steel introduced the Steel Import Monitoring System (SIMS). This system provides real-time data on steel imports, aiding manufacturers in planning their sourcing strategies. These efforts align with the government's vision to strengthen the Automotive Supply Chain in India.

Recent Developments

Technological advancements

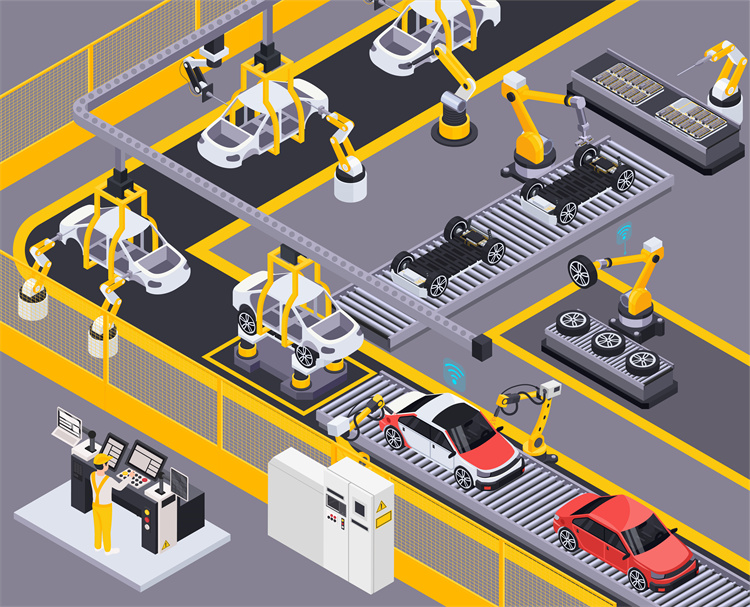

Technological advancements have transformed the Indian automotive landscape. The industry embraces digital technologies to improve efficiency and competitiveness. Comprehensive digital infrastructure supports standardization and data management. Collaboration with different industries enhances innovation. Electric mobility gains momentum, prompting structural shifts in the sector. Manufacturers adapt to these changes by investing in research and development. The focus remains on producing advanced components like electric motors and automatic transmissions.

Collaborations and partnerships

Collaborations and partnerships drive progress in the automotive sector. Companies join forces to leverage each other's strengths. The Society of Indian Automobile Manufacturers (SIAM) collaborates with global partners. These alliances facilitate knowledge exchange and technology transfer. Partnerships with South Korean firms boost engine production capabilities. The industry invests $7 billion over five years to deepen parts localization. This investment strengthens the Automotive Supply Chain in India and promotes sustainable growth.

Economic Impacts

Benefits of Localization

Cost reduction

Localization in India's automotive sector significantly reduces costs. Local sourcing eliminates long-distance transportation expenses. This approach minimizes carbon emissions by up to 50%. The reduction in transportation costs enhances the overall cost competitiveness of the industry. Local sourcing allows manufacturers to adopt just-in-time service models. This model improves efficiency and reduces inventory costs. The focus on local resources ensures a consistent supply chain. Manufacturers benefit from reduced lead times and increased production stability.

Job creation

Localization creates numerous job opportunities in India. The emphasis on local manufacturing boosts employment in various sectors. Increased production activities require a skilled workforce. The demand for local labor rises as companies expand operations. Localization supports the development of specialized skills. Training programs equip workers with the necessary expertise. The automotive industry contributes to economic growth through job creation. Local communities benefit from increased employment prospects.

Challenges Faced

Infrastructure limitations

India's automotive sector faces infrastructure challenges. Inadequate transportation networks hinder efficient logistics. Poor road conditions increase transportation time and costs. The lack of modern warehousing facilities affects supply chain efficiency. Manufacturers struggle with inconsistent power supply. These limitations impact production schedules and delivery timelines. The government recognizes the need for infrastructure improvements. Investments in transportation and energy sectors aim to address these issues.

Regulatory hurdles

Regulatory hurdles pose significant challenges to localization efforts. Complex trade regulations affect the import of raw materials. Manufacturers face delays due to bureaucratic processes. Compliance with environmental standards requires additional investments. The industry navigates varying state-level regulations. These inconsistencies create obstacles for seamless operations. The government works towards streamlining regulatory frameworks. Simplified policies aim to facilitate smoother localization processes.

Challenges and Opportunities

Overcoming Challenges

Strategies for improvement

The Indian automotive industry faces various challenges in its localization efforts. Manufacturers must adopt effective strategies to overcome these hurdles. A focus on enhancing supply chain efficiency can lead to significant improvements. Companies should invest in advanced logistics solutions. These solutions streamline operations and reduce costs. Local suppliers need support to meet quality standards. Training programs can equip them with necessary skills. Collaboration with technology providers can drive innovation.

Role of government support

Government support plays a crucial role in overcoming challenges. Policies that encourage investment in infrastructure are essential. The government should prioritize the development of transportation networks. Improved roads and railways enhance logistics efficiency. Incentives for local manufacturers can boost production capabilities. Financial assistance for research and development promotes innovation. Simplified regulatory frameworks facilitate smoother operations. Government initiatives align with the vision of a robust automotive supply chain.

Opportunities for Growth

Expansion into new markets

The localization of the automotive supply chain presents growth opportunities. Companies can explore expansion into new markets. Emerging economies offer potential for increased sales. Localized production reduces costs and enhances competitiveness. Exporting value-added products strengthens market presence. Partnerships with international firms facilitate market entry. Knowledge exchange improves product offerings. Expansion strategies contribute to the industry's global footprint.

Innovation and R&D

Innovation and research and development (R&D) drive growth in the automotive sector. Investment in R&D leads to the creation of advanced components. Electric vehicles and autonomous technologies gain prominence. Manufacturers focus on developing sustainable solutions. Collaboration with academic institutions fosters innovation. Research initiatives address industry-specific challenges. The emphasis on R&D enhances the industry's technological capabilities. Innovation positions India as a leader in the global automotive market.

Role of Electrification

Impact on Automotive Supply Chain in India

Changes in component sourcing

Electrification transforms the Automotive Supply Chain in India. Electric vehicles (EVs) require different components compared to traditional vehicles. Manufacturers need to source batteries, electric motors, and power electronics. Local suppliers must adapt to these new requirements. The demand for lithium-ion batteries increases significantly. India lacks sufficient local production of these batteries. Companies rely on imports to meet demand. The government encourages local production through incentives. Investments in battery manufacturing facilities rise. This shift impacts the entire supply chain.

Influence on manufacturing processes

Electrification influences manufacturing processes in the automotive industry. Traditional internal combustion engines require complex assembly lines. EVs simplify production with fewer moving parts. Manufacturers invest in new technologies for EV production. Automation plays a crucial role in this transition. Robotics and artificial intelligence enhance efficiency. Factories require skilled workers to operate advanced machinery. Training programs equip employees with necessary skills. The focus on electrification drives innovation in manufacturing techniques.

Future Prospects

Growth of electric vehicles

The growth of electric vehicles presents significant opportunities. The Indian government promotes EV adoption through policies. Incentives reduce the cost of purchasing EVs. Consumers show increasing interest in sustainable transportation. The demand for EVs rises steadily. Automakers expand their EV offerings to meet this demand. Local production of EVs enhances cost competitiveness. India aims to become a global hub for EV manufacturing. The focus on electrification aligns with environmental goals.

Investment in charging infrastructure

Investment in charging infrastructure supports the growth of EVs. A robust network of charging stations is essential. Public and private sectors collaborate to build this infrastructure. The government provides incentives for charging station installation. Companies invest in fast-charging technology. Urban areas see rapid growth in charging facilities. Rural regions require further development. Reliable charging infrastructure boosts consumer confidence. The expansion of charging networks accelerates EV adoption.

Importance of Raw Materials

Sourcing Local Materials

Benefits of local sourcing

Local sourcing in the Indian automotive industry provides numerous advantages. Manufacturers reduce transportation costs by obtaining materials locally. This approach decreases carbon emissions, benefiting the environment. Local sourcing supports the economy by creating job opportunities. Workers gain employment in manufacturing and supply chain sectors. The industry strengthens its supply chain by relying on local resources. Consistent material availability ensures stable production schedules.

Challenges in raw material procurement

The procurement of raw materials presents several challenges. Manufacturers face difficulties in securing high-quality local materials. The industry requires significant investment in infrastructure to support local sourcing. Inconsistent supply chains disrupt production timelines. Companies encounter regulatory hurdles when importing essential raw materials. The government must streamline regulations to facilitate smoother operations. Investments in local production capabilities can address these challenges.

Sustainable Practices

Environmental considerations

Sustainable practices in the automotive industry focus on environmental considerations. Manufacturers aim to reduce carbon footprints through efficient processes. The industry invests in renewable energy sources to power production facilities. Waste management systems minimize environmental impact. Recycling initiatives promote the reuse of materials. The adoption of electric vehicles contributes to cleaner air quality. These efforts align with global environmental goals.

Long-term sustainability

Long-term sustainability remains a priority for the automotive sector. Companies invest in research and development to create sustainable solutions. Innovations in materials lead to more eco-friendly products. The industry collaborates with academic institutions to drive sustainability research. Government incentives encourage the adoption of sustainable practices. The focus on sustainability enhances the industry's global competitiveness. Long-term strategies ensure the industry's continued growth and success.

India's automotive supply chain revolution highlights the strategic importance of localization. This approach enhances cost competitiveness and reduces dependency on imports. Localization allows for backward integration and protects against exchange rate fluctuations. Bridging the skills gap is crucial for successful localization, particularly in automatic transmission systems. India has the potential to become a key player in this sector. The future outlook remains promising as the industry embraces innovation and sustainability. Localization stands as a primary long-term strategy for original equipment manufacturers (OEMs) in India.

See Also

Unlocking Your Automotive Supply Chain's Full Potential

Artificial Intelligence in Supply Chain: Transforming Future Logistics

Expert Guidance for Overcoming Automotive Supply Chain Hurdles

Diving into Robotics: Revolutionizing the Supply Chain Industry

Addressing Global Supply Chain Growth Challenges Effectively