Emerging Tech for more Efficient, Faster Supply Chain Operations

Supply chain efficiency holds immense importance in today's competitive market. Businesses must optimize operations to stay ahead. Technology plays a pivotal role in transforming supply chain processes. Innovations streamline activities, reduce costs, and improve accuracy. Various technologies contribute to these advancements. Automation, IoT, AI, blockchain, and advanced analytics enhance supply chain efficiency. These tools provide real-time data, predictive insights, and automated processes. Companies can achieve better performance and profitability through these technological solutions.

Enhancing Supply Chain Efficiency with Automation and Robotics

Automation and robotics revolutionize supply chain operations. These technologies streamline processes, reduce errors, and boost productivity. Businesses can achieve remarkable supply chain efficiency through automation and robotics.

Warehouse Automation

Warehouse automation transforms storage and retrieval processes. Automated systems handle tasks with precision and speed.

Automated Guided Vehicles (AGVs)

Automated Guided Vehicles (AGVs) navigate warehouses autonomously. AGVs transport goods efficiently, reducing manual labor. These vehicles follow pre-defined paths using sensors and software. AGVs enhance supply chain efficiency by minimizing human errors and increasing throughput.

Robotic Picking Systems

Robotic picking systems automate order fulfillment. Robots identify, pick, and place items accurately. These systems use advanced vision technology to locate products. Robotic picking systems improve supply chain efficiency by speeding up the picking process and reducing mistakes.

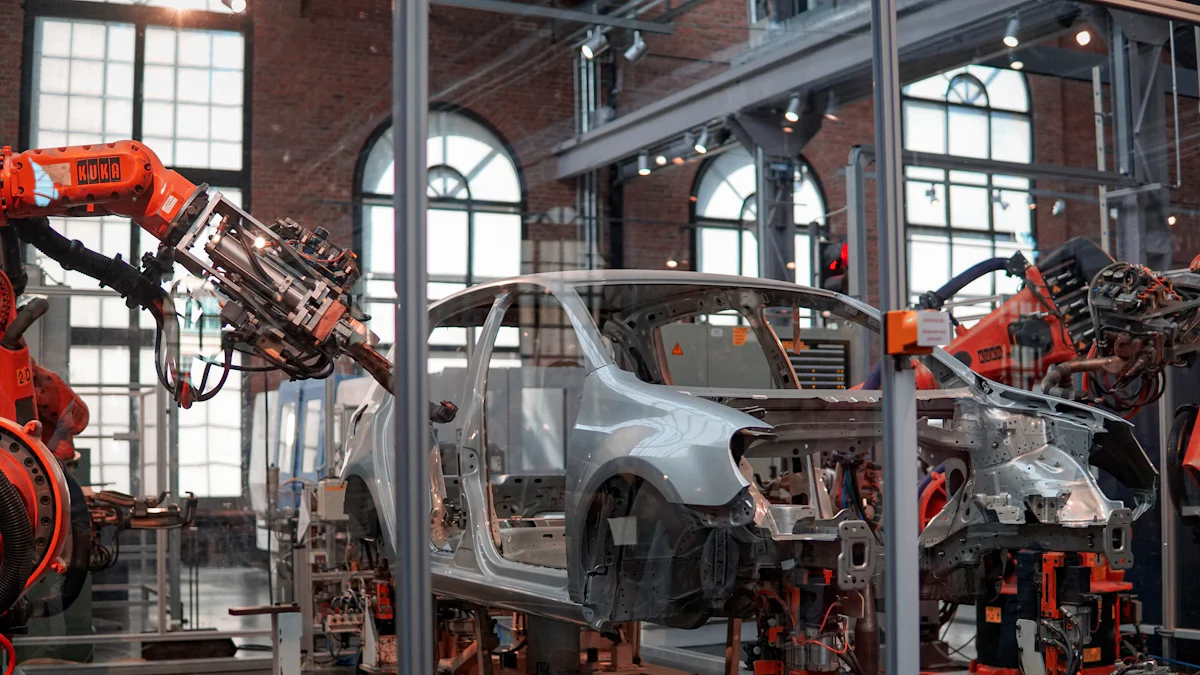

Manufacturing Automation

Manufacturing automation optimizes production lines. Automated systems perform repetitive tasks with consistency and accuracy.

Collaborative Robots (Cobots)

Collaborative robots, or cobots, work alongside humans. Cobots assist in tasks like assembly, packaging, and quality control. These robots enhance supply chain efficiency by increasing productivity and ensuring safety. Cobots adapt to various tasks, making them versatile in manufacturing environments.

Automated Production Lines

Automated production lines streamline manufacturing processes. Machines handle tasks such as welding, painting, and assembly. Automated lines operate continuously, reducing downtime. These systems boost supply chain efficiency by maintaining high production rates and consistent quality.

Leveraging the Internet of Things (IoT) for Supply Chain Efficiency

The Internet of Things (IoT) brings a new level of connectivity to supply chain operations. IoT devices collect and share data in real-time. This data helps businesses make informed decisions quickly. IoT technology enhances supply chain efficiency by providing visibility and control over various processes.

Real-time Tracking and Monitoring

Real-time tracking and monitoring improve supply chain efficiency. Businesses can track goods from production to delivery. This visibility reduces delays and ensures timely deliveries.

Smart Sensors

Smart sensors gather data on environmental conditions. These sensors monitor temperature, humidity, and other factors. Businesses use this data to ensure product quality. Smart sensors enhance supply chain efficiency by preventing spoilage and damage.

RFID Technology

RFID technology uses radio waves to identify and track items. RFID tags store information about products. These tags communicate with readers to provide real-time location data. RFID technology boosts supply chain efficiency by reducing manual tracking efforts and errors.

Predictive Maintenance

Predictive maintenance prevents equipment failures. IoT devices monitor machinery and predict issues before they occur. This approach minimizes downtime and extends equipment life.

IoT-enabled Equipment Monitoring

IoT-enabled equipment monitoring tracks machine performance. Sensors collect data on usage, wear, and tear. This data helps businesses schedule maintenance proactively. IoT-enabled monitoring improves supply chain efficiency by avoiding unexpected breakdowns.

Data Analytics for Predictive Insights

Data analytics for predictive insights analyzes collected data. Advanced algorithms identify patterns and predict future issues. Businesses use these insights to plan maintenance activities. Predictive analytics enhances supply chain efficiency by optimizing equipment performance and reducing costs.

Artificial Intelligence and Machine Learning in Supply Chain Efficiency

Artificial Intelligence (AI) and Machine Learning (ML) transform supply chain operations. These technologies provide valuable insights and automate complex tasks. AI and ML enhance supply chain efficiency by predicting demand and optimizing inventory.

Demand Forecasting

Demand forecasting becomes more accurate with AI and ML. Businesses can predict future demand patterns and adjust operations accordingly.

AI-driven Predictive Analytics

AI-driven predictive analytics analyze historical data. These tools identify trends and forecast future demand. Businesses use these insights to plan production and inventory levels. AI-driven predictive analytics improve supply chain efficiency by reducing overstock and stockouts.

Machine Learning Algorithms

Machine learning algorithms learn from data. These algorithms adapt to changing market conditions. Businesses use machine learning to refine demand forecasts continuously. Machine learning algorithms boost supply chain efficiency by providing real-time adjustments.

Inventory Management

Inventory management benefits greatly from AI and ML. These technologies optimize stock levels and automate replenishment processes.

AI-based Inventory Optimization

AI-based inventory optimization analyzes sales data. These systems determine optimal stock levels for each product. Businesses use AI to minimize holding costs and avoid shortages. AI-based inventory optimization enhances supply chain efficiency by maintaining balanced inventory levels.

Automated Replenishment Systems

Automated replenishment systems use AI and ML. These systems monitor inventory levels and trigger reorders automatically. Businesses ensure timely restocking without manual intervention. Automated replenishment systems improve supply chain efficiency by preventing stockouts and reducing labor costs.

Blockchain Technology for Supply Chain Efficiency

Blockchain technology revolutionizes supply chain efficiency. Businesses gain transparency and traceability through blockchain. This technology ensures secure and immutable records.

Enhanced Transparency and Traceability

Blockchain enhances transparency in supply chain operations. Every transaction gets recorded on a decentralized ledger. This process provides a clear view of the entire supply chain.

Blockchain for Supply Chain Provenance

Blockchain tracks the origin of products. Each step from production to delivery gets documented. This documentation ensures product authenticity. Consumers trust the provenance of goods, boosting supply chain efficiency.

Secure and Immutable Records

Blockchain creates secure records. No one can alter these records once they get added. This immutability prevents fraud and errors. Businesses rely on accurate data, enhancing supply chain efficiency.

Smart Contracts

Smart contracts automate agreements. These contracts execute automatically when conditions get met. Automation reduces delays and disputes.

Automated Contract Execution

Smart contracts handle contract execution. Pre-defined rules trigger actions without human intervention. This automation speeds up processes. Businesses achieve higher supply chain efficiency through timely contract fulfillment.

Reducing Fraud and Disputes

Smart contracts reduce fraud. Transparent terms and automated execution leave no room for manipulation. Disputes decrease as contracts get executed precisely. This reliability boosts supply chain efficiency by fostering trust.

Advanced Analytics and Big Data in Supply Chain Efficiency

Advanced analytics and big data transform supply chain operations. These tools provide insights that drive better decisions. Businesses can optimize processes and enhance supply chain efficiency.

Data-driven Decision Making

Data-driven decision making relies on real-time data analysis. Businesses use this approach to make informed choices quickly.

Real-time Data Analysis

Real-time data analysis monitors supply chain activities. Sensors and systems gather data continuously. This information helps businesses track performance and identify issues immediately. Real-time analysis boosts supply chain efficiency by enabling quick responses to problems.

Predictive Analytics for Supply Chain Optimization

Predictive analytics uses historical data to forecast future trends. Businesses apply these insights to optimize supply chain operations. Predictive models help plan inventory levels, production schedules, and transportation routes. This proactive approach enhances supply chain efficiency by reducing waste and improving accuracy.

Risk Management

Risk management identifies and mitigates potential threats. Businesses use advanced analytics to anticipate and address risks.

Identifying and Mitigating Risks

Identifying risks involves analyzing data from various sources. Businesses look for patterns that indicate potential problems. Once identified, companies develop strategies to mitigate these risks. Effective risk management improves supply chain efficiency by preventing disruptions.

Scenario Planning and Simulation

Scenario planning and simulation test different strategies. Businesses create models to simulate various scenarios. These simulations help companies understand the impact of different decisions. Scenario planning enhances supply chain efficiency by preparing businesses for unexpected events.

The discussed technologies significantly enhance supply chain efficiency. Automation, IoT, AI, blockchain, and advanced analytics streamline operations and reduce costs. The future looks promising for the adoption of these innovations. Businesses should explore and implement these technologies to stay competitive. Embracing these advancements will lead to improved performance and profitability.

See Also

AI Supply Chain Innovations: Unlocking Operational Efficiency

Supply Chain Innovation Impact: Logistics Revolutionized

Cloud Technology Solutions: Enhancing Supply Chain Operations

Revealed: 5 Techniques for Optimizing Supply Chain

High-Tech Manufacturing: Solutions for Streamlined Supply Chains