How JUSDA Addresses Automotive Supply Chain Issues

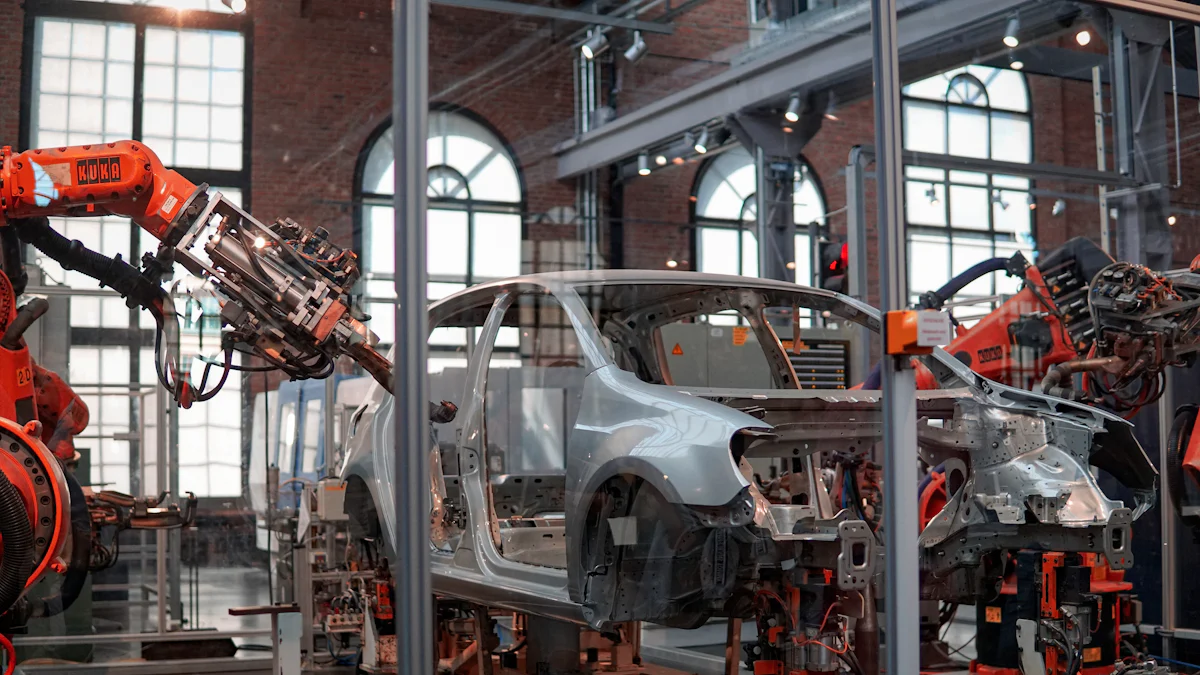

Fixing automotive supply chain problems is very important today. The industry changes fast. Electric cars and chip shortages are big issues. JUSDA leads with smart solutions to handle these problems. They are experts in supply chains. JUSDA works hard to make customers happy with custom plans. Let's see how JUSDA's skills improve the automotive supply chain for growth and success.

Challenges in the Automotive Supply Chain

Global Automotive Supply Chains

Global automotive supply chains have special problems based on where they are. Different places face issues like not enough workers, needing eco-friendly practices, changing old systems to electric car parts, and competition from Chinese car companies. These problems need new ideas to keep things running smoothly.

Facing Global Automotive Supply Issues

The car industry is changing fast. Global factors affect supply chains a lot. Delays in getting important parts, price changes due to high demand and low supply, and big impacts on the industry are common issues. It's important for car companies to adapt to these changes to succeed.

Key Challenges in the Automotive Industry

Car part suppliers are very important in the industry. They face problems like slow car sales, moving towards electric cars, making new tech for electric vehicles (EVs), and cutting costs by changing production or laying off workers. Solving these problems is key for growth and staying competitive.

Automotive Supply Chain Issues

The automotive supply chain has many challenges that affect how well it works. Managing parts from many suppliers, global influences, changing customer needs, unclear cost changes, and worries about making good quality products are main issues that need fixing for smooth operations.

Risk and Resilience

Managing risks is crucial for auto companies to handle unexpected events well. By using strong plans to reduce risks from supply chain disruptions, businesses can better deal with uncertainties.

Impact on Auto Companies

Supply chain problems affect more than just operations; they impact overall business performance too. Delays in production, higher costs, fewer cars available, and relying on advanced software show why it's important to fix these issues quickly.

Supply Chain Disruptions

Having plans ready for unexpected disruptions is vital in the automotive supply chain. Setting up quick response measures and good supplier management helps keep things running during tough times.

Crisis Response

Fast actions during a crisis help reduce disruptions in the supply chain. Using flexible strategies allows quick decisions and resource use which can lessen bad effects on production schedules and customer happiness.

Supplier Management

Good supplier management ensures smooth operations in the automotive supply chain. Working closely with suppliers, having clear communication channels, and making backup plans can strengthen resilience against possible disruptions while improving overall performance.

JUSDA's Solutions for Supply Chain Issues

Digital Transformation

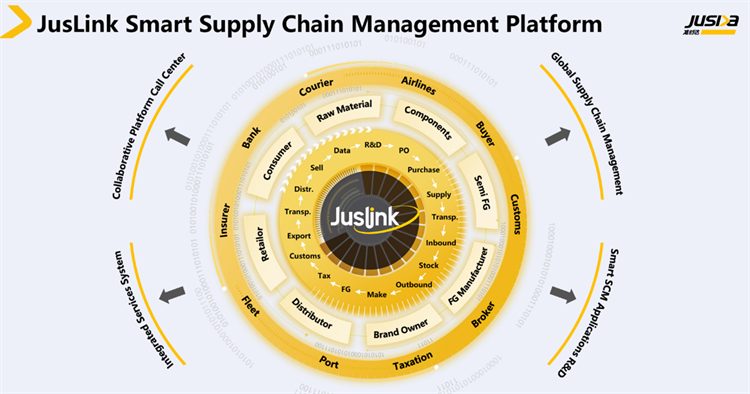

Jusda leads in supply chain management with digital changes. They use JusLink to improve logistics. This makes tasks easier and cheaper. Better supply chain visibility helps businesses decide quickly. Through Juslink, clients gain full visibility into their supply chains, real-time monitoring of all nodes, and risk prevention, achieving dynamic management and total control over global supply chain dynamics.

JusLink and AI Integration

With JusLink's AI tool, JusAI, they make logistics better. AI helps users get fast and accurate services, changing supply chains smartly.

Enhancing Supply Chain Visibility

Seeing the whole supply chain is key for good work. Jusda's solutions give real-time checks at every step. This helps stop risks and manage global chains well.

Resilience and Risk Management

Being strong is important in the car industry. Jusda gives plans to protect supply chains from problems. They help auto supply chains be ready for surprises.

Business Resilience Strategies

Jusda knows a lot about supply chain management. With 20 years of experience, they offer plans that make work smooth.

Preparing Auto Supply Chains

Working with over 3,000 parts makers worldwide, Jusda leads in global supply chains. Businesses should choose Jusda to strengthen their supply chains.

Supplier Collaboration

Working with car suppliers is key for success. Suppliers must keep up with new trends to stay effective.

Automotive Suppliers Respond

Car suppliers shape the industry by reacting to market changes. Their actions affect how well the whole supply chain works.

Supply Chain Trends

Knowing new trends is crucial to compete well. From higher worker pay to more transparency and AI use, these trends help businesses handle the changing car supply chain world.

Case Study: JusLink in Action

Overview of JusLink

JusLink is a smart tool by JUSDA.It makes work easier, faster, and better. The tool fits the needs of car makers, helping with smooth logistics.

How JusLink Supports Global Automotive Supply Chains

JusLink helps global automotive supply chains by giving real-time info, better routes, and easy talks between people. Its simple design makes hard tasks easy, making it very useful for companies everywhere.

Benefits for Auto Companies

Car companies using JusLink get many benefits. They save money with better logistics and make smarter choices with data insights. The tool gives clear views and smooth work, helping them win in the market.

Real-World Impact

Many success stories show how it has changed supply chain management for car companies worldwide. By using data and new ideas, businesses have grown a lot.

Success Stories

Companies using JusLink have seen great results in their supply chains. They work better, spend less money, and keep customers happy. The tool's ability to change with the market helps businesses grow steadily.

Data-Driven Decisions

Data is key to JusLink's help for car companies. With data insights, businesses can make smart choices that boost profits and efficiency. The tool's analytics help firms solve problems and grab chances in the fast-changing car world.

JUSDA is great at giving top services that make customers happy. They know what clients need very well. For almost 20 years, they have focused on smart waste management and special solutions. JUSDA leads the way in making things better and growing sustainably. Their unique ways of managing supply chains make them different from others. They help businesses run smoothly and work better. JUSDA's goal to cut down waste shows they care about the environment. This helps create a greener and more efficient supply chain system. With JUSDA, companies can expect better operations and higher productivity for a brighter future in global supply chains.

To sum up, JUSDA is great at fixing automotive supply chain problems. They use smart ideas and always aim to make customers happy. Their special plans are made to meet customer needs. By working closely with partners, JUSDA makes sure supply chains run well. With almost 20 years of experience and over 3,000 global parts makers, they lead the industry. For businesses wanting to be strong and compete better, checking out JUSDA's services is a good idea.

See Also

The Superiority of JUSDA's Industry-Leading Supply Chain Solutions

JUSDA's Innovation in Sustainable Supply Chain Transformation

The Definitive Guide to JUSDA's Supply Chain Quality Management

Expert Strategies for Overcoming Automotive Supply Chain Challenges