JUSDA's Role in Streamlining Warehouse Management

JUSDA plays a pivotal role in warehouse management, ensuring streamlined operations for companies worldwide. Efficient warehouse management is crucial for optimizing supply chain processes and reducing operational costs. By implementing advanced tracking systems and real-time visibility tools, JUSDA ensures precise stock control and minimizes excess inventory. Through its innovative strategies, including robust inventory management services and cutting-edge warehouse control system, JUSDA empowers businesses to enhance operational efficiency and streamline order fulfillment processes.

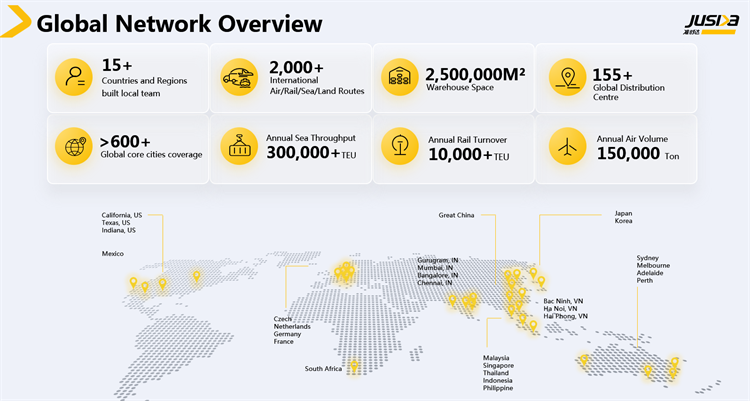

JUSDA operates warehouses across several global regions, as detailed below:

1. China: In China, JUSDA's warehouses are widespread, covering cities and regions such as Shenzhen, Shanghai, Wuxi, Zhengzhou, Taiyuan, Langfang, Hangzhou, Nanjing, Beijing, Hefei, Suzhou, Guangzhou, Wuhan, Changsha, Chongqing, Chengdu, among others. The total warehouse area in China alone spans 2.7 million square meters, with 870,000 square meters of space and capacities for 450,000 pallets and 300,000 carton slots.

2. Hong Kong: In Hong Kong, there are three warehouse locations with a total area of 106,000 square meters, offering Finished Goods Distribution Centers, Vendor Managed Inventory (VMI) hubs for raw materials, returns and inspection services, as well as B2C e-commerce services.

3. Taiwan: In Taiwan, one warehouse is located in Taoyuan, covering 10,000 square meters, providing finished goods distribution centers, raw material warehouses, and B2C e-commerce services.

4. Japan: JUSDA has a presence in 15 locations in Japan, including Ichikawa, Sapporo, Narita, Yamato, Nagoya, Kameyama, Yao, Suita, Sakai, Yamashirocho, Kitakyushu, and other cities, with a total area of 296,000 square meters.

5. Vietnam: Two warehouses are situated in Hanoi and Ho Chi Minh City, Vietnam, totaling 117,000 square meters, offering finished goods distribution centers, VMI for raw materials, Class 1000 cleanrooms, and sorting services.

6. India: There are three warehouses in Chennai, Ranjangaon, and Bhubaneswar, covering a total area of 10,700 square meters.

7. United States: Four warehouses are located in City of Industry, Los Angeles, Houston, and El Paso in the United States, with a combined area of 37,000 square meters.

8. Mexico: Two warehouses are based in Juarez and Guadalajara, Mexico, with a total area of 72,000 square meters.

Furthermore, JUSDA's global network extends to Europe (including the Czech Republic, Netherlands, Germany, France, etc.), India, Malaysia, Thailand, Indonesia, the Philippines, Australia, and other regions, signifying a comprehensive international footprint despite specific warehouse details not being listed in the provided content for these areas.

Inventory Optimization

Inventory optimization is a critical aspect of efficient warehouse management, ensuring that businesses maintain the right inventory levels to meet demand while minimizing excess stock. By prioritizing inventory based on demand patterns and sales velocity, companies can significantly reduce holding costs and enhance operational efficiency.

Importance of Inventory Optimization

Benefits for Businesses

Enhanced Supply Chain Visibility: By integrating demand forecasting with inventory optimization, businesses can achieve greater demand visibility, leading to improved inventory management and reduced carrying costs.

Improved Operational Efficiency: Prioritizing inventory levels through effective ABC analysis results in increased efficiency within the supply chain, ultimately enhancing customer service and satisfaction.

Impact on Supply Chain

Efficient inventory optimization techniques play a crucial role in reducing overstocking and under-stocking scenarios, ensuring that businesses operate at optimal levels.

By implementing robust inventory optimization strategies, companies can streamline their operations, reduce costs associated with inventory management, and improve overall supply chain performance.

Enhancing Efficiency through Inventory Optimization

Cost Savings

Implementing efficient inventory optimization practices leads to significant cost savings for businesses by minimizing excess stock and reducing holding costs.

By aligning inventory levels with actual demand patterns, companies can optimize their resources effectively, resulting in improved financial performance.

Improved Customer Satisfaction

Enhanced supply chain visibility through advanced inventory optimization strategies enables businesses to meet customer demands promptly and accurately.

By ensuring products are readily available when needed, companies can boost customer satisfaction levels and build long-term relationships with their clientele.

JUSDA's Inventory Optimization Strategies

Use of Technology

Leveraging cutting-edge technology tools allows JUSDA to provide innovative solutions for optimizing warehouse operations.

Through the integration of advanced software platforms like a Warehouse Control System (WCS), JUSDA enhances supply chain visibility and streamlines order fulfillment processes effectively.

Data-Driven Decisions

JUSDA relies on data-driven insights to make informed decisions regarding inventory management and order fulfillment.

By analyzing real-time data trends and demand patterns, JUSDA optimizes its clients' warehouse operations for maximum efficiency.

Warehouse Management

Warehouse management is a critical component of efficient operations, encompassing various aspects such as space utilization and labor management. Maximizing the use of available space within a warehouse ensures optimal storage capacity, while effective labor management enhances productivity and workflow efficiency.

Key Aspects of Effective Warehouse Management

Space Utilization

Strategic Layout Design: Organizing the warehouse layout strategically allows for efficient movement of goods, reducing unnecessary travel time and optimizing storage space.

Shelving Systems: Implementing shelving systems based on product demand and frequency of access maximizes storage capacity and facilitates quick retrieval of items.

Labor Management

Training Programs: Providing comprehensive training programs for warehouse staff improves operational proficiency, leading to enhanced productivity and reduced errors in handling inventory.

Workflow Optimization: Streamlining workflow processes through clear task assignments and efficient communication channels boosts overall efficiency and minimizes delays in order fulfillment.

JUSDA's Warehouse Management Solutions

Advanced Systems and Technologies

Leveraging cutting-edge technologies such as Warehouse Management Systems (WMS) enhances inventory tracking accuracy, real-time monitoring capabilities, and streamlined order processing.

Implementing automated systems like barcode scanners and RFID technology ensures precise inventory control, reduces manual errors, and accelerates picking processes.

Real-Time Monitoring

Continuous Monitoring: Real-time monitoring tools enable constant surveillance of warehouse activities, allowing immediate identification of any discrepancies or inefficiencies in operations.

Performance Tracking: Tracking key performance indicators (KPIs) in real-time provides valuable insights into warehouse productivity levels, enabling prompt adjustments to optimize workflow processes.

Benefits of JUSDA's Warehouse Management

Enhanced Efficiency

By integrating advanced technologies into warehouse operations, JUSDA enhances operational efficiency by streamlining processes, reducing lead times, and increasing overall productivity levels.

Optimized Inventory Control: Through precise inventory tracking mechanisms and automated replenishment systems, JUSDA ensures optimal stock levels are maintained at all times to meet customer demands effectively.

Reduced Costs

Cost-Efficient Operations: Implementing efficient warehouse management solutions results in cost savings through minimized labor expenses, reduced carrying costs from excess inventory, and improved resource allocation strategies.

Improved Resource Utilization: By optimizing space usage and labor allocation efficiently, JUSDA helps businesses reduce operational costs while maximizing their overall profitability.

Warehouse Optimization

Efficient warehouse optimization is essential for businesses to maximize operational efficiency and minimize costs. By strategically optimizing warehouse space and streamlining processes, companies can significantly enhance their overall supply chain performance.

Types of Warehouse Optimization

Space Optimization

Maximizing warehouse space utilization is crucial for ensuring optimal storage capacity. Through strategic layout design and efficient shelving systems, businesses can enhance inventory control and facilitate quick retrieval of items.

Strategic Layout Design: Organizing the warehouse layout strategically allows for efficient movement of goods, reducing unnecessary travel time and optimizing storage space.

Shelving Systems: Implementing shelving systems based on product demand and frequency of access maximizes storage capacity and facilitates quick retrieval of items.

Process Optimization

Optimizing warehouse processes plays a key role in enhancing workflow efficiency and productivity. By implementing streamlined workflow processes and providing comprehensive training programs for staff, businesses can achieve operational excellence.

Training Programs: Providing comprehensive training programs for warehouse staff improves operational proficiency, leading to enhanced productivity and reduced errors in handling inventory.

Workflow Optimization: Streamlining workflow processes through clear task assignments and efficient communication channels boosts overall efficiency and minimizes delays in order fulfillment.

JUSDA's Warehouse Optimization Techniques

Use of Robotics

JUSDA leverages cutting-edge robotics technology to automate repetitive tasks within warehouses. By incorporating robotics into daily operations, JUSDA enhances efficiency, accuracy, and speed in handling inventory.

Process Re-engineering

Through continuous process re-engineering initiatives, JUSDA optimizes end-to-end warehouse processes to eliminate bottlenecks and enhance overall operational flow. By re-evaluating existing workflows and implementing innovative solutions, JUSDA ensures seamless operations within warehouses.

Impact on Operational Efficiency

Increased Throughput

Warehouse optimization directly contributes to increased throughput by streamlining processes, reducing lead times, and improving overall productivity levels. By optimizing inventory management practices and workflow efficiency, businesses can achieve higher throughput rates while meeting customer demands effectively.

Minimized Costs

Efficient warehouse optimization results in minimized costs associated with labor expenses, excess inventory holding costs, and resource allocation inefficiencies. By maximizing space utilization, automating tasks through robotics, and re-engineering processes for greater efficiency, businesses can reduce operational costs significantly while maintaining high service standards.

Warehousing Facilities

When it comes to Warehousing Facilities, JUSDA stands out with its global network of strategically located warehouses designed to optimize supply chain efficiency and enhance customer satisfaction. These facilities represent a significant leap towards enhanced efficiency and streamlined operations in the realm of supply chain management.

Overview of JUSDA's Global Warehousing Facilities

Locations and Capacities

With a presence in key regions worldwide, including China, Hong Kong, Taiwan, Japan, Vietnam, India, the United States, Mexico, Europe, Malaysia, Thailand, Indonesia, the Philippines, Australia, and more.

Total warehouse area spans over 250 millions of square meters globally.

Offering specialized services such as Finished Goods Distribution Centers and Vendor Managed Inventory (VMI) hubs for raw materials.

Specialized Services

Finished Goods Distribution: Ensuring timely delivery of products to end customers.

Vendor Managed Inventory (VMI): Enhancing collaboration between vendors and buyers for efficient inventory management.

Importance of Strategic Locations

Supply Chain Efficiency

By strategically locating warehouses near key transportation hubs and manufacturing centers.

Ensuring swift movement of goods across the supply chain network for optimized operations.

Customer Satisfaction

Proximity to end customers ensures faster order fulfillment and reduced lead times.

Meeting customer demands promptly leads to increased satisfaction levels and fosters long-term relationships.

JUSDA's Advanced Warehousing Technologies

Smart Systems

Leveraging smart systems for automated inventory tracking and real-time monitoring.

Enhancing visibility into warehouse operations for improved decision-making processes.

Real-Time Data

Utilizing real-time data analytics to optimize inventory levels based on demand patterns.

Ensuring accurate stock control through continuous monitoring and data-driven insights.

JUSDA stands as a beacon of efficiency and innovation in the realm of warehouse management, ensuring that every aspect of the manufacturing industry's needs is met and exceeded. The commitment to enhanced efficiency translates into faster distribution processes, optimizing supply chain workflows, and leveraging strategic warehousing locations for swift delivery of goods. At the core of JUSDA's new facilities are intelligent operations that leverage data-driven insights to optimize workflows continuously. Through real-time monitoring and predictive analytics, operational processes are refined to meet evolving demands effectively.

See Also

Revolutionizing Efficiency: JUSDA's Logistics Optimization

Maximizing Efficiency: JUSDA's Cutting-Edge Logistics Technology

Exploring JUSDA's Smart Logistic Systems Implementation Case Study