Key Logistics Trends Shaping the Future of Supply Chains

The logistics supply chain is changing a lot in 2025. Many things are causing this change:

The market for supply chain tools may reach $31 billion by 2026. This shows more people are using digital tools and automation.

Most leaders say economic changes and cyber threats are big worries. Stronger networks are needed to handle these problems.

People want faster delivery, growing the same-day delivery market. In the US, it might go over $13 billion by 2025.

New technology like self-driving cars and drones is changing deliveries. At the same time, businesses are focusing on being eco-friendly. Over half of US shoppers are okay paying more for green options.

Key Takeaways

Being eco-friendly is important. Many US shoppers will pay extra for green products. Use eco-friendly logistics to draw in these buyers.

Robots and automation can improve work by 50%. Use these tools to make tasks easier and faster.

Online shopping needs flexible shipping. Businesses should use many delivery methods to meet customer needs quickly.

Key Trends Transforming Supply Chain Management in 2025

Sustainability and the Push for Green Logistics

Sustainability is changing how supply chains work. Companies are using eco-friendly methods to meet customer needs and follow rules. Examples include energy-saving tools, electric trucks, and green warehouses. Eco-friendly packaging is also popular, cutting waste and encouraging recycling.

🌱 Tip: Starting green logistics early can help your business compete and meet ESG goals.

More shoppers care about sustainability. About 55% of US buyers are okay with paying extra for eco-friendly items. This makes green logistics a must for businesses wanting to stay important.

Automation and Robotics in the Logistics Industry

Automation and robotics are changing logistics jobs. Machines cut manual work by up to 50%, letting workers focus on smarter tasks. Robots like AMRs improve production by 35%, while other robotics boost efficiency by 48%.

Metric | Improvement |

|---|---|

Less unplanned downtime | 20–40% |

Higher production | Up to 35% |

Less manual work | 30–50% |

These tools can make operations smoother, save money, and increase productivity. Automation is now a must-have to stay ahead in logistics.

AI and Big Data in Supply Chain Decision-Making

AI and big data are changing supply chain decisions. They give live updates, helping predict problems and avoid risks. For example, AI helps plan inventory and guess future demand.

The market for AI in supply chains is growing fast. By 2030, it may reach $40.53 billion, growing at 28.2% yearly. Businesses can use AI to switch from old systems to automated ones, improving work and decisions.

E-Commerce Growth and Omnichannel Logistics

E-commerce is causing big changes in supply chains. Online shopping sales worldwide may hit $8.1 trillion by 2026, up from $4.9 trillion in 2021. This growth needs omnichannel strategies for quick and flexible delivery.

The e-commerce logistics market was worth $315.82 billion in 2022 and is growing at 22.3% yearly. Companies should use tech to make operations smooth across different channels.

Blockchain for Supply Chain Transparency and Security

Blockchain improves supply chain safety and clarity. It creates secure records that can’t be changed, keeping data safe. Smart contracts allow safe deals, lowering risks when many groups are involved.

🔒 Note: Blockchain also helps track ESG goals, supporting sustainability efforts.

Studies by Deloitte show how blockchain makes supply chains safer and clearer. While there are challenges, the advantages of using this tech are clear.

Challenges Facing the Logistics Supply Chain in 2025

Geopolitical Risks and Trade Uncertainty

Global supply chains face risks from political problems. Trade wars, Brexit, and conflicts disrupt routes and raise costs. For instance, a 10% rise in geopolitical distance lowers trade by 2-3%. Many U.K. companies still see Brexit as a major issue. The Russia-Ukraine war has also hurt key exports. These problems make businesses change plans and spread out networks to stay strong.

Statistic Description | Impact |

|---|---|

Revenue loss from supply chain problems | |

Companies with reputational damage | 60-65% |

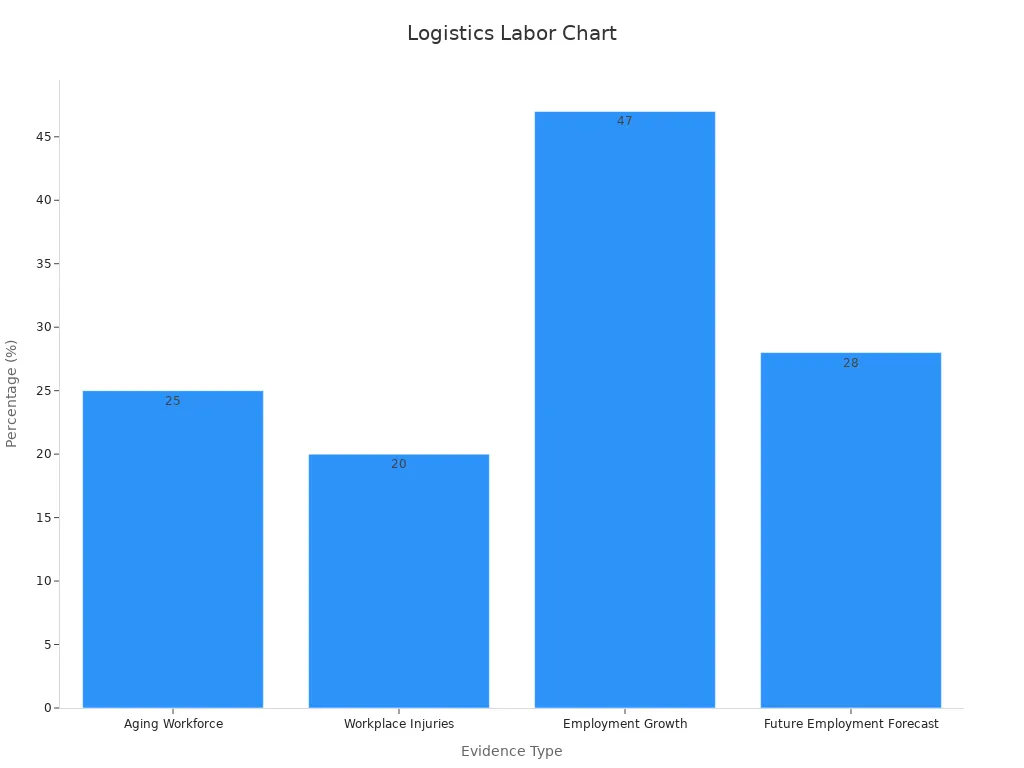

Labor Shortages and Workforce Transformation

Labor shortages are a big problem in logistics. The workforce is aging, with 25% more older workers in transport jobs. Also, 80% of dock workers have less than two years' experience. This lack of skilled workers hurts efficiency and visibility. Companies need to train workers and use automation to stay strong.

Regulatory Changes Impacting Supply Chain Management

New rules make managing supply chains harder. Laws like the Slave-Free Business Certification Act require forced labor checks. SEC cybersecurity rules demand better reporting of cyber incidents. These rules raise costs but improve risk management. Following these rules helps avoid problems and keeps operations smooth.

Regulatory Change | Description |

|---|---|

Slave-Free Business Certification Act | Requires big companies to check for forced labor and report it. |

SEC Amendments on Cybersecurity | Adds new rules for reporting cyber problems to reduce risks. |

Supply Chain Disruptions and the Need for Resilience

Disruptions like chip shortages and COVID-19 shutdowns show the need for resilience. These issues caused delays, higher costs, and bad reputations. For example, the global PPE shortage showed weak spots in healthcare supply chains. Companies can prepare by using more suppliers and digital tools to handle future problems.

Chip shortages made automakers use unreliable chips, causing returns.

The China–U.S. Trade War raised costs by disrupting material supplies.

The pandemic delayed shipments, helping competitors take market share.

📌 Tip: Use digital tools and predictive analytics to spot risks early and strengthen supply chains.

Strategies for Adapting to Logistics Industry Trends

Using JUSDA’s Warehouse Solutions for Better Supply Chains

Good warehouses are key for smooth supply chains. JUSDA uses smart tools like IoT, cloud systems, and big data to improve work. These tools help manage stock better and save money. For example, in electronics, JUSDA boosts work speed and cuts costs. In cars, it meets changing customer needs with custom plans. For bulk goods, lean methods make processes faster and better.

Industry | Key Features | Benefits |

|---|---|---|

Electronics | Uses IoT, cloud, and big data | Better work speed and lower costs |

Automotive | Custom plans for changing customer needs | Smarter use of resources and production |

Bulk Materials | Lean methods for better resource use | Faster and smoother supply chain work |

Using these tools can make your business faster and more competitive.

Building Strong and Flexible Supply Chains with JusLink

JusLink helps connect all parts of your supply chain. It uses IoT, cloud systems, and big data to make decisions easier. This system adjusts to customer needs and uses resources wisely. Working together across the supply chain makes it stronger and more efficient. JusLink’s tech helps you handle problems fast and keep things running smoothly.

JusLink uses IoT and big data for better links.

It offers flexible solutions for changing needs.

Teamwork improves strength and efficiency.

Focusing on Sustainability with Circular Supply Chains

Circular supply chains cut waste and reuse materials. This saves resources and lowers pollution. Recycling and reusing help the planet and save energy. Many people now want eco-friendly products, so this is important for staying popular.

They support recycling and green packaging.

Shoppers will pay more for eco-friendly items.

By going green, you can attract more eco-conscious customers.

Improving Teamwork Across the Supply Chain

Teamwork makes supply chains faster and cheaper. Digital tools can boost work speed by 30% and cut costs by 35%. Sharing info with suppliers builds better partnerships. Clear contracts also make relationships stronger.

Digital tools make work 30% faster.

Costs drop 35% with better teamwork.

Clear contracts improve supplier relationships.

Better teamwork leads to smoother and stronger supply chains.

Putting Customers First in Logistics

Customer-focused plans make people happier and improve deliveries. Tools like real-time tracking ensure fast deliveries. Feedback helps find problems and improve service. Meeting customer needs builds loyalty and keeps you ahead.

Indicator | Description |

|---|---|

Perfect Order Rate | Tracks orders with no mistakes, showing how well the supply chain works. |

Inventory to Sales Ratio | Measures how well stock matches customer demand. |

Delivery Time | Tracks how fast items go from warehouse to customer. |

Customer Satisfaction | Shows how happy customers are and if they’ll pay more for better service. |

Order Tracking | Lets businesses see where orders are in real-time, meeting customer expectations. |

By focusing on customers, you can keep them happy and stay ahead of competitors.

JUSDA Solutions

To provide you with professional solutions and quotations.

The logistics supply chain in 2025 offers many chances to grow. Using trends like sustainability, automation, and data strategies can help businesses improve.

Using digital tools makes decisions faster and work smoother.

Seeing the whole process clearly helps meet customer needs.

JUSDA’s smart warehouse services and JusLink system use IoT, cloud, and big data. These tools make work easier and give custom solutions for industries like electronics and cars.

🚀 Pro Tip: Using JUSDA’s tools helps your business stay strong and handle challenges better.

FAQ

What does IoT do in supply chain management?

IoT links devices to share live data. It helps track inventory, avoids delays, and improves decisions for smoother operations.

How does JUSDA help with green logistics?

JUSDA uses eco-friendly warehouses, green packaging, and recycling systems. These cut waste and help meet eco-friendly goals.

Why is blockchain useful for supply chain clarity?

Blockchain keeps data safe and unchangeable. It builds trust, tracks items, and supports ethical and green standards.