Key Logistics Trends Driving Industry Evolution in 2025

The logistics trends in 2025 are transforming the industry significantly. New technology and eco-friendly ideas are at the forefront of this evolution. For example:

About 80% of businesses will utilize robots and machines.

AI enhances inventory management by 35% and reduces costs by 15%.

Over 40% of companies attract customers through green initiatives.

Understanding these logistics trends is essential for thriving in this rapidly changing landscape.

Key Takeaways

Use tools like AI and IoT to make supply chains faster and cheaper.

Use green methods like electric cars and recycling to protect the planet.

Work with many suppliers to make supply chains stronger and safer.

Technology-Driven Logistics Innovations

The logistics world is changing fast because of new technology. These changes are making supply chains better, faster, and easier to track. Below are some key technologies shaping logistics in 2025.

Artificial Intelligence (AI) Improving Supply Chains

AI is a big part of these changes. It helps supply chains work better by improving decisions and cutting problems. AI tools study lots of data to predict needs and manage inventory. For example:

It helps keep supplies steady and avoids disruptions.

Robots using AI make work faster and more accurate.

AI also helps the environment by lowering carbon emissions. Over 75% of companies plan to use AI in new ways. Using AI makes your logistics faster, smarter, and more competitive.

Internet of Things (IoT) for Tracking and Updates

IoT is changing logistics by giving real-time updates. Devices like sensors and GPS trackers show where items are and how they’re doing. This helps you track shipments and fix problems quickly.

Here’s how IoT use has grown over time:

Year | Shipments (Million Tons) | Value (Billion USD) |

|---|---|---|

2017 | 19,786 | 18,907 |

2023 | 20,302 | 20,328 |

IoT keeps you updated on your supply chain. This helps you make better choices and keep customers happy.

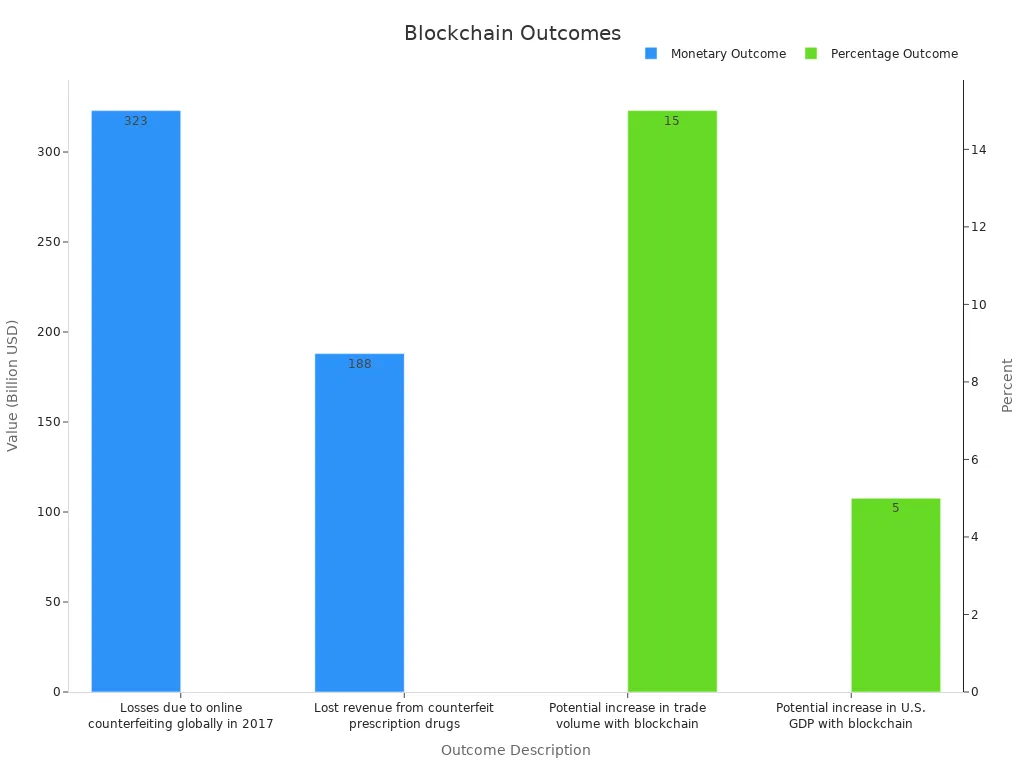

Blockchain for Safer Supply Chains

Blockchain makes supply chains safer and clearer. It records every transaction in a way that can’t be changed. This stops problems like fake goods and fraud, which cost a lot of money.

Problem or Benefit | Amount | Source |

|---|---|---|

323 Billion USD | ||

Lost money from fake prescription drugs | 188 Billion USD | |

Trade growth possible with blockchain | 15% | |

U.S. GDP growth possible with blockchain | Up to 5% |

Blockchain builds trust by showing clear records. Using it can reduce risks and improve partnerships.

Robots and Automation in Warehouses

Robots and automation are making warehouses faster and more accurate. They handle tasks like packing and sorting, so less manual work is needed. Benefits include:

Better accuracy for orders and shipping.

Smarter inventory placement to avoid running out or overstocking.

Real-time tracking for quicker responses.

In early 2021, North America ordered 9,972 robots worth $485 million. This was a 19.6% rise from early 2020. Robots are becoming more common in warehouses. Using them saves money and meets customer needs faster.

Sustainability and Green Logistics Trends

Sustainability is changing how logistics works. Companies are finding new ways to help the planet and work better. Here are some important trends shaping green logistics in 2025.

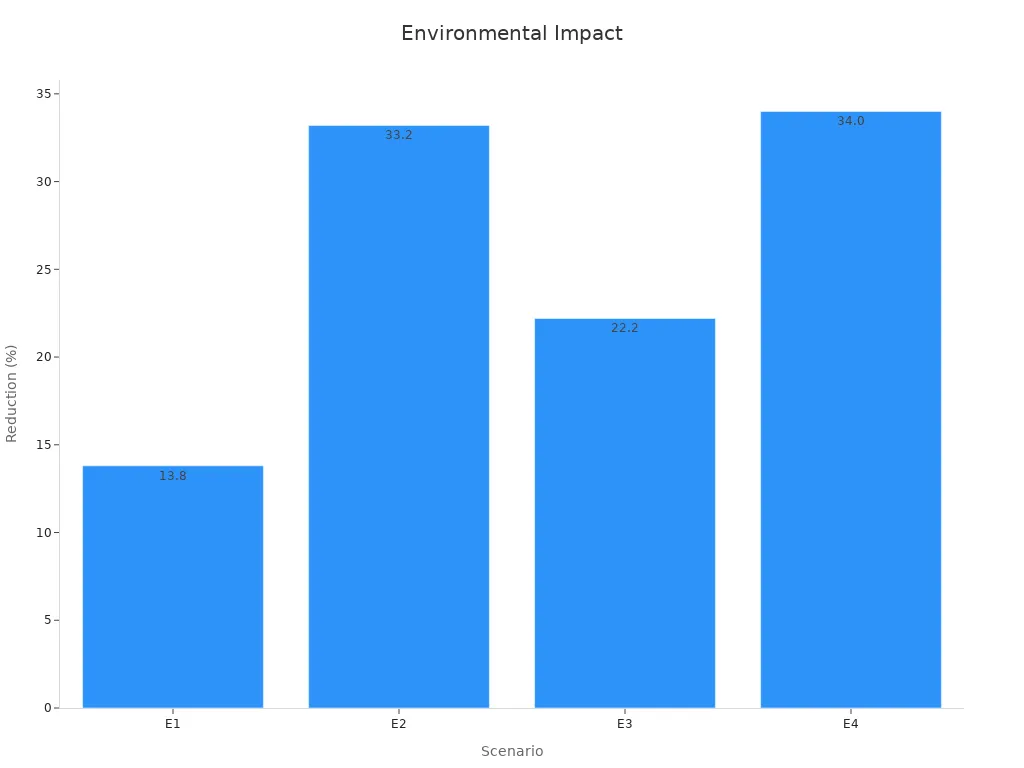

Electric and Self-Driving Vehicles in Logistics

Electric and self-driving vehicles are improving logistics. They plan better routes and cut traffic, which lowers pollution. Electric vehicles go further by having no harmful emissions. This helps fight climate change and makes the air cleaner.

Main benefits include:

Better control of vehicle fleets.

Tracking locations and performance in real time.

Saving resources and reducing wasted time.

Shared electric self-driving vehicles cut pollution a lot. For example, in one case, PM2.5 pollution dropped by 34%, and CO2 fell by 30%. These changes show how electric vehicles can make logistics greener.

Carbon-Free Supply Chain Practices

Carbon-free supply chains are now a big focus for companies. These methods aim to cut carbon pollution while staying fast and flexible. Proven data shows big improvements:

Metric | Improvement |

|---|---|

Total Savings | |

Carbon Pollution Cut | 30% |

Average Carbon Footprint Drop | 25-40% in five years |

Logistics Cost Savings | 15-20% |

Using these methods lowers costs and makes operations clearer. This helps the planet and gives businesses an advantage.

Recycling and Less Waste in Logistics

Recycling and reusing materials are key to reducing waste. In logistics, this means building systems that use resources wisely. For example, companies are:

Switching to packaging that breaks down naturally.

Recycling returned items through reverse logistics.

Working with suppliers to reuse materials in loops.

These actions lower harm to the environment and support long-term goals. By following these trends, companies can meet global sustainability targets.

Supply Chain Strength and Risk Control

In 2025, logistics faces more challenges than before. Companies focus on staying strong and reducing risks. Here are key trends shaping these changes.

Using Many Suppliers for Safer Supply Chains

Depending on one supplier can cause big problems. Using many suppliers helps avoid risks and find new chances. Companies now choose suppliers that follow eco-friendly and fair practices.

Two suppliers for key materials make supply chains stronger.

Different suppliers add flexibility and lower risks.

A study shows 57% of Chinese manufacturers use a "supplier + 1" plan. This reduces reliance on one supplier or country during global issues.

Predicting Problems with Smart Tools

Smart tools study data to predict risks before they happen. This helps companies prepare for problems early. For example, these tools can spot delays or guess future needs.

With predictive tools, you can:

Avoid delays by spotting problems early.

Keep the right amount of stock to avoid shortages.

Make better choices using real-time data.

This trend helps companies stay ready and run smoothly.

Moving Production Closer to Home

Making products closer to home lowers risks and costs. It also helps companies understand local rules and markets better. Here’s a comparison of far-away and nearby production:

Aspect | Far-Away Risks | Nearby Benefits |

|---|---|---|

Political Stability | High risk from different governments | Lower risk with similar systems |

Trade Disruptions | More problems from global events | Fewer issues due to closeness |

Transportation Costs | Higher costs for long distances | Lower costs for short distances |

Cultural Affinity | Hard to understand local needs | Easier to meet local needs |

Moving production closer fits today’s logistics trends. It makes supply chains faster and keeps customers happy.

Customer-Focused Logistics Trends

Customer-focused logistics is all about meeting your needs. In 2025, companies are finding new ways to deliver faster and easier. These changes are improving how logistics works.

New Ideas for Last-Mile Delivery

Last-mile delivery is how items get to you. Companies now use smart tools to make this step quicker and better. For example, GPS finds delays, and smart systems change routes to avoid problems. You also get real-time updates, so you know where your package is.

Here’s a simple look at the improvements:

Improvement Type | What It Does |

|---|---|

Spots delays and helps deliveries stay on time. | |

Real-Time Updates | Gives you accurate info, so you trust the process. |

Smart Route Planning | Predicts problems and picks better paths. |

Live Tracking and Alerts | Shows where your package is and when it will arrive. |

Smart Lockers | Lets you pick up packages anytime, avoiding missed deliveries. |

High-Tech Tools | Drones and sensors make deliveries faster, even in busy cities. |

These tools make last-mile delivery faster and easier for everyone.

Personal Touch for Better Service

Personalized service makes logistics feel more special. When companies adjust to your needs, you feel happier. For example, choosing your delivery time or getting updates your way makes things smoother. Studies show that personal touches make customers more satisfied.

By focusing on what you like, companies build stronger connections. This keeps you coming back for more.

Fast Delivery for Online Shopping

Online shopping now demands super-fast delivery. You want your orders quickly and without trouble. Companies are using new tech to make this happen.

Same-day delivery gets your items fast.

Smart tools like AI make deliveries run smoothly.

Cities get faster service with better systems.

These changes show how logistics is keeping up with what you need. Fast delivery makes online shopping even better for you.

Global Challenges and Opportunities in Logistics

The logistics industry in 2025 has both problems and chances. By solving worker shortages, handling trade rules, and exploring new markets, businesses can grow and succeed.

Fixing Worker Shortages with Automation

Worker shortages are causing problems in logistics. Automation helps by doing jobs faster and filling empty roles. For example:

In December 2023, the U.S. had 9.5 million job openings but only 6.5 million people looking for work.

In early 2024, 600,000 manufacturing jobs were unfilled, and this could grow to 2.1 million by 2030.

Baby Boomers are retiring quickly, with 10,000 leaving work every day.

Using robots and smart machines reduces the need for human workers. Tasks like packing, sorting, and managing inventory become easier. This not only solves worker shortages but also saves money and boosts productivity.

Adapting to Changing Trade Rules

Trade rules are always changing and affecting logistics. Higher taxes, stricter environmental laws, and new trade deals mean businesses must adjust fast. Main challenges include:

More paperwork because of customs changes.

Rules that limit where goods can be sold.

Political problems that disrupt supply chains.

Following global rules and using more suppliers can help. By going green and using technology, businesses can turn these challenges into chances to grow.

Growing in New Markets

New markets bring big chances for logistics growth. Countries like India, Vietnam, and Mexico are improving roads, ports, and trade deals. Here’s a look at some opportunities:

Country | Key Opportunities for Supply Chain Growth |

|---|---|

India | Growing middle class, better roads, trade deals, and government programs like Make in India. |

Vietnam | Young workers, low wages, better infrastructure, and trade deals like RCEP. |

Mexico | Close to the U.S., skilled workers, USMCA benefits, and investments in ports and railroads. |

Kenya | Great location, better transport systems, and more city-based shoppers. |

Nigeria | Africa’s biggest economy, growing middle class, better infrastructure, and rising online shopping. |

Expanding into these areas helps businesses reach new customers. Using local resources and systems can lead to steady growth.

JUSDA’s Role in Shaping Logistics Trends

Using JusLink for Better Supply Chain Tracking

JUSDA’s JusLink platform changes logistics by improving tracking. It uses smart tools to give real-time updates, so you know what’s happening. This helps you make quick choices and avoid problems. JusLink also automates tasks from buying to delivery, saving time and effort.

Here’s how JusLink improves tracking:

Feature/Metric | What It Does |

|---|---|

Real-time updates | Gives instant changes and fixes in logistics. |

No extra inventory | Manages stock efficiently from start to finish. |

Full supply chain view | Shows every step of the process clearly. |

Smart inventory control | Adjusts stock levels quickly based on needs. |

Automated buying | Speeds up orders and reduces mistakes. |

Problem spotting | Finds and fixes supply chain issues early. |

Predicting needs | Plans for future logistics based on product stages. |

Rule-following growth | Makes sure new markets follow laws and taxes. |

With JusLink, you work faster and avoid risks. This tool keeps your logistics smooth and reliable.

JUSDA’s Warehouses for Better Stock Management

JUSDA’s warehouses make managing stock easier. They use machines and digital tools to improve logistics. You can track stock in real time and react to changes fast. This cuts down on extra items and speeds up sales.

Main features of JUSDA’s warehouses include:

Feature | How It Helps |

|---|---|

Technology use | Tracks logistics instantly, making supply chains faster. |

Smart stock movement | Moves items efficiently, reducing waste and improving sales. |

Digital tools | Simplifies supply chain tasks, making them more effective. |

These tools make your operations clear and cost-effective. They help you meet customer needs while saving money.

Custom Supply Chain Solutions by JUSDA

JUSDA creates special solutions for different industries. Whether it’s cars, electronics, or fast-moving goods, JUSDA has you covered. For example, blockchain makes supply chains safer and clearer, ensuring smooth work.

JUSDA’s innovations include:

AI tools to predict future needs.

Blockchain for safe and clear transactions.

Automation for quicker and more accurate logistics.

These solutions help you stay ahead and adjust to market changes.

JUSDA Solutions

To provide you with professional solutions and quotations.

The logistics field in 2025 relies on new technology and green ideas. Big changes mean businesses must adjust fast to stay ahead. Trends like live updates and strong supply chains are key. Reaching eco-friendly goals and solving problems will lead to success. Companies using smart tools can meet customer needs and stay on top.

See Also

Exploring Five Key Trends Shaping Supply Chain Efficiency

Transforming Logistics Through Artificial Intelligence Innovations

Innovative Technologies Paving The Way For Future Logistics

Enhancing Future Logistics Through Digital Technology Solutions

The Role Of Supply Chain Innovations In Logistics Transformation