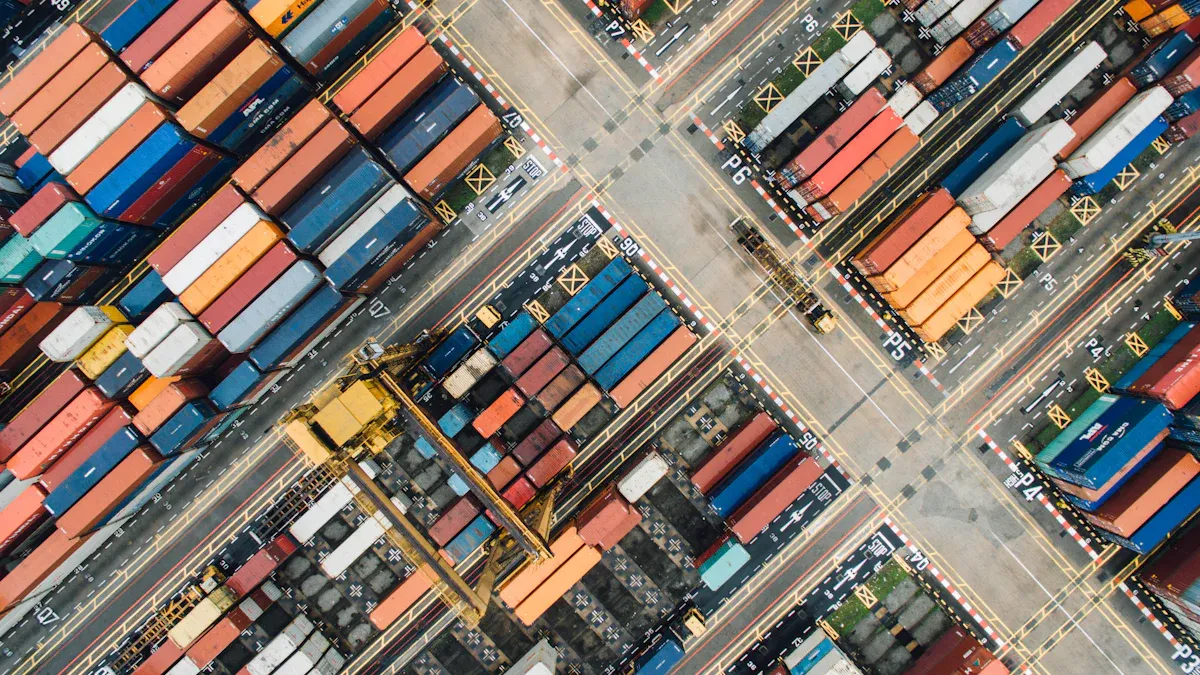

Lean Supply Chain Management: Streamlining Efficiency in Global Operations

Global supply chains are the backbone of modern commerce, yet they face mounting challenges. Many companies struggle with inefficiencies, such as spending 60% to 70% of their analytics teams’ time gathering data instead of analyzing it. Others lack the technology to monitor performance, with 63% of businesses falling into this category. These inefficiencies lead to higher costs and slower operations, making it harder to meet consumer demands.

Lean Supply Chain Management offers a solution. By focusing on reducing waste and optimizing resources, this approach transforms how businesses operate. It simplifies complex logistics networks, enabling companies to adapt quickly to disruptions and deliver value more effectively.

Benefits of Lean Supply Chain Management in Global Operations

Cost Reduction and Resource Optimization

Lean Supply Chain Management helps businesses cut costs and use resources more efficiently. By streamlining processes, companies can reduce lead times, lower inventory costs, and improve supplier relationships. For example, businesses with optimized supply chains experience 15% lower costs, hold less than 50% of the inventory, and achieve cash-to-cash cycles that are three times faster than those without optimization.

Here’s a breakdown of the quantitative improvements:

Improvement Type | Description |

|---|---|

Reduced Lead Times | Streamlining processes to deliver products faster, minimizing waiting times and production cycles. |

Lower Inventory Costs | Minimizing excess inventory to reduce holding costs and free up capital. |

Improved Quality | Ensuring high standards to reduce defects, returns, and rework, leading to higher quality. |

Enhanced Supplier Relationships | Fostering collaboration with suppliers for better cost management and reduced lead times. |

Cost Reduction | Overall reduction in transportation, holding, and operational costs, enhancing profitability. |

These benefits make Lean Supply Chain Management a powerful tool for companies looking to improve their bottom line.

Enhancing Quality and Predictability

Quality and predictability are essential for meeting customer expectations. Lean principles focus on eliminating defects and ensuring consistent performance. Studies show that implementing lean techniques improves service levels, customer satisfaction, and the quality of delivered goods.

Source | Quality Metric Improvements | Notes |

|---|---|---|

Moyano-Fuentes and Sacristán-Díaz (2012) | Service level, customer satisfaction | Emphasizes importance in lean supply chain |

Naylor et al. (1999) | Cost and quality | Highlights the relationship between cost and quality in lean supply chains |

Arif-Uz-Zaman et al. (2014) | Quality of delivered goods, customer satisfaction | Discusses quality in terms of customer satisfaction and forecasting accuracy |

By enhancing predictability, businesses can avoid costly disruptions and maintain a competitive edge. Lean Supply Chain Management ensures that operations run smoothly, delivering consistent results every time.

Improving Responsiveness to Market Demands

In today’s fast-paced world, businesses must adapt quickly to changing market conditions. Lean Supply Chain Management enables companies to respond faster by reducing inefficiencies and leveraging analytics. For instance, 79% of companies with high-performing supply chains achieve greater revenue growth, while 73% feel pressure to improve delivery capabilities.

Analytics play a crucial role in responsiveness. Supply chain professionals believe analytics can reduce costs and improve delivery times. By adopting lean principles, businesses can meet customer demands more effectively and stay ahead of competitors.

Leveraging JusLink for Intelligent Supply Chain Efficiency

JusLink stands out as a game-changer in modern supply chain management. This intelligent platform empowers businesses to tackle inefficiencies and adapt to the complexities of global trade. By integrating advanced technologies like AI, IoT, and big data, JusLink transforms supply chains into streamlined, responsive networks.

One of JusLink’s key strengths lies in its ability to provide real-time visibility across the entire supply chain. This transparency helps businesses identify bottlenecks, predict demand fluctuations, and adapt to market changes. For example:

It pinpoints inefficiencies, enabling swift corrective actions.

It forecasts demand shifts, ensuring inventory levels align with market needs.

It enhances resilience by allowing quick responses to disruptions.

JusLink also fosters collaboration by sharing data across the supply chain network. This shared insight improves decision-making, reduces transportation costs, and lowers inventory levels. Companies using JusLink report smoother operations and better customer service due to this enhanced visibility.

The platform’s AI-driven tools further optimize operations. Features like intelligent risk management and automated application tracking ensure that shipments stay on schedule and risks are mitigated. These capabilities make JusLink an essential tool for businesses aiming to implement Lean Supply Chain Management principles effectively.

Tip: Businesses leveraging JusLink often experience significant efficiency gains, including reduced costs and improved responsiveness.

JusLink doesn’t just simplify supply chain management; it redefines it. By combining cutting-edge technology with lean principles, it helps businesses stay competitive in an ever-changing global market.

Real-World Applications of Lean Supply Chain Management

Toyota: A Pioneer in Lean Supply Chains

Toyota has long been recognized as a leader in Lean Supply Chain Management. The company’s innovative practices, such as the Toyota Production System (TPS), have set the standard for efficiency and waste reduction. TPS focuses on delivering value by eliminating unnecessary steps in production. This approach ensures that every process adds value to the final product.

Toyota’s success also stems from its Just-In-Time (JIT) system. JIT ensures materials arrive exactly when needed, reducing inventory costs and waste. The company’s strong relationships with suppliers further enhance efficiency. By fostering long-term partnerships, Toyota creates a collaborative environment that benefits all parties.

The integration of digital technologies like IoT and AI has taken Toyota’s supply chain to the next level. These tools provide real-time monitoring and predictive analytics, enabling better decision-making. The table below highlights key performance metrics that showcase Toyota’s lean effectiveness:

Performance Metric | Description |

|---|---|

Just-In-Time (JIT) | Reduces waste by ensuring on-demand delivery of materials. |

Supplier Relationships | Builds long-term partnerships for enhanced collaboration. |

Toyota Production System | Maximizes efficiency while minimizing overproduction and waste. |

Demand Forecasting Systems | Aligns production schedules with market demand. |

Digital Technologies | Uses IoT and AI for improved monitoring and predictive analytics. |

Toyota’s commitment to lean principles has made it a global benchmark for supply chain excellence.

Lean Practices in the Automotive and FMCG Industries

Lean Supply Chain Management plays a vital role in both the automotive and FMCG sectors. These industries rely on lean principles to improve efficiency and meet consumer demands.

The automotive industry excels in logistics precision. Delivery times are optimized to within 15 minutes, ensuring smooth operations.

The FMCG sector faces unique challenges, especially with perishables. Companies must maintain agility to deliver fresh products to consumers.

Both industries prioritize safety and cost efficiency. By adopting lean practices, they reduce waste and enhance overall performance. This approach helps them stay competitive in fast-paced markets.

JUSDA’s Role in Optimizing Global Supply Chains

JUSDA has emerged as a key player in global supply chain optimization. The company leverages lean principles to address the complexities of modern logistics. Its JusLink platform integrates advanced technologies like AI and IoT to streamline operations.

JUSDA’s solutions focus on reducing costs, improving efficiency, and enhancing collaboration. For example, JusLink provides real-time visibility across the supply chain. This transparency helps businesses identify bottlenecks and adapt quickly to disruptions.

The company’s impact extends across industries. From automotive to FMCG, JUSDA tailors its services to meet specific needs. By combining lean principles with cutting-edge technology, JUSDA empowers businesses to achieve operational excellence.

Note: JUSDA’s commitment to innovation makes it a trusted partner for companies seeking efficient supply chain solutions.

Case Study: JusLink’s Impact on Supply Chain Efficiency

JusLink has revolutionized how businesses manage their supply chains. Its intelligent platform combines advanced technologies like AI, IoT, and big data to tackle inefficiencies and improve operational performance. Companies using JusLink have reported significant improvements in cost savings, responsiveness, and overall efficiency.

One notable example involves a global electronics manufacturer struggling with high inventory costs and delayed shipments. By implementing JusLink, the company gained real-time visibility into its supply chain. This transparency allowed them to identify bottlenecks and optimize inventory levels. As a result, they reduced holding costs by 25% and improved delivery times by 30%.

JusLink’s AI-driven tools also played a crucial role. The platform’s demand forecasting feature helped the manufacturer predict market trends with greater accuracy. This capability ensured that production schedules aligned with customer demand, minimizing waste and overproduction. Additionally, JusLink’s intelligent risk management system provided early warnings about potential disruptions, enabling swift corrective actions.

Another success story comes from the FMCG sector. A leading company faced challenges in managing perishable goods across multiple regions. JusLink’s automated application management streamlined their logistics operations. It tracked shipments in real time and flagged anomalies, ensuring products reached consumers fresh and on time.

JusLink Solutions

To provide you with professional solutions and quotations.

These examples highlight JusLink’s ability to support Lean Supply Chain Management principles. By reducing waste, enhancing visibility, and improving decision-making, JusLink empowers businesses to stay competitive in today’s fast-paced market.

Insight: Companies leveraging JusLink often experience faster cash-to-cash cycles and improved customer satisfaction, making it a vital tool for modern supply chains.

Comparing Lean, Agile, and Hybrid Supply Chain Models

Key Differences Between Lean and Agile Supply Chains

Lean and Agile supply chains serve different purposes, each excelling in specific environments. Lean models prioritize efficiency by reducing waste and streamlining processes. They work best in stable demand scenarios where predictability is high. On the other hand, Agile supply chains focus on flexibility, enabling businesses to adapt quickly to market changes. This approach suits industries with volatile demand and shorter product life cycles.

Here’s a quick comparison:

Lean Supply Chains:

Focus on cost efficiency and waste reduction.

Ideal for environments with low variety and predictable demand.

Emphasize long product life cycles.

Agile Supply Chains:

Prioritize responsiveness and adaptability.

Designed for dynamic markets with unpredictable demand.

Support innovative products with shorter life cycles.

Both models have their strengths, but businesses must choose based on their operational needs and market conditions.

When to Choose Lean Over Agile or Hybrid Models

Selecting the right supply chain model depends on several factors. Lean models shine in stable environments where demand predictability is high. For example, industries like automotive manufacturing often benefit from Lean Supply Chain Management due to their focus on cost efficiency and long production cycles.

The table below highlights key decision criteria:

Criteria | Lean Supply Chain | Agile Supply Chain |

|---|---|---|

Demand Predictability | Stable and predictable demand | Volatile and unpredictable demand |

Market Conditions | Stable environments | Dynamic and rapidly changing markets |

Focus | Cost efficiency and waste reduction | Flexibility and quick response |

Example Companies | N/A | H&M, Zara |

Hybrid models, which combine lean and agile principles, are gaining popularity. They balance efficiency with adaptability, making them suitable for businesses operating in diverse markets.

Combining Lean Principles with Digital Solutions Like JusLink

Digital solutions like JusLink enhance Lean Supply Chain Management by integrating advanced technologies such as AI and IoT. These tools improve efficiency and visibility across the supply chain. For instance, JusLink’s real-time monitoring capabilities help businesses identify and eliminate nonvalue-adding activities, aligning perfectly with lean principles.

Research shows that combining lean practices with Industry 4.0 technologies boosts operational efficiency. Digital tools enhance quality management and waste reduction, which are core to lean strategies. The table below illustrates this synergy:

Evidence Type | Description |

|---|---|

Synergistic Support | Lean supply chain management and Industry 4.0 technologies enhance each other. |

Quality Management | Digital solutions improve quality management practices in lean systems. |

Waste Reduction | Lean principles eliminate nonvalue-adding activities, enabling better use of digital tools. |

By leveraging platforms like JusLink, businesses can achieve the best of both worlds—cost efficiency and technological innovation. This integration ensures they remain competitive in today’s fast-paced global market.

Lean Supply Chain Management offers businesses a clear path to cost savings, better quality, and smoother operations. Companies can reduce waste, improve predictability, and respond faster to market changes. JUSDA stands out as a leader in this space, combining lean principles with cutting-edge tools like JusLink. Their commitment to innovation helps businesses tackle global supply chain challenges with ease. By adopting lean strategies and leveraging intelligent platforms, companies can stay competitive and thrive in today’s fast-paced global market.

Takeaway: Lean principles and tools like JusLink are essential for businesses aiming to succeed in a globalized economy.