AI and Data-Driven Excellence Shine in Today’s Lighthouse Factories

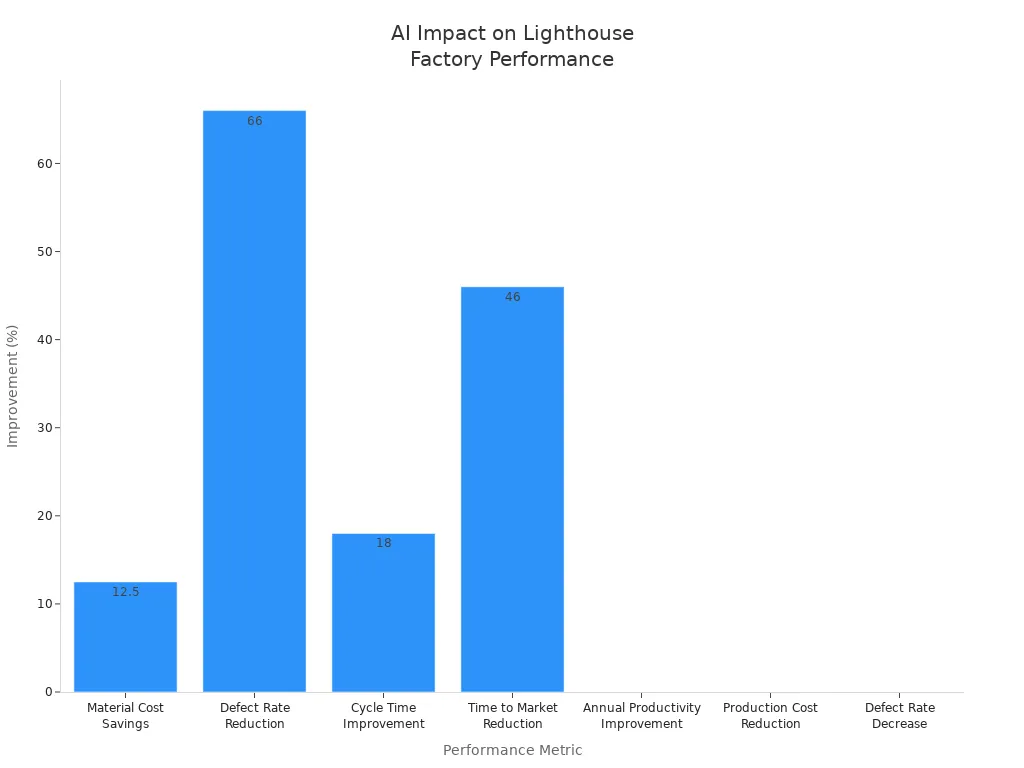

Lighthouse Factory operations are being transformed by data-driven strategies empowered by AI. The World Economic Forum’s Global Lighthouse Network highlights how digital tools, especially those empowered by AI, deliver outstanding results in every Lighthouse Factory. Factories that are data-driven and empowered by AI see major improvements:

Metric | Improvement (%) | Description |

|---|---|---|

Material Cost Savings | Data-driven AI reduces waste and mistakes in sheet metal forming. | |

Defect Rate Reduction | 66 | AI-powered decision tree models help prevent clinching failures. |

Cycle Time Improvement | 18 | Data-driven valve gate control checks over 150,000 data points. |

Time to Market Reduction | 46 | Machine learning, empowered by AI, speeds up cleaning cycle design. |

Michael Carroll says, “Companies that do not use digital tools may lose their assets to other companies in five years.” Stories from Lighthouse Factory environments show why data-driven and empowered by AI digital tools are essential today. Working together with data is now the key to excellence in manufacturing.

Key Takeaways

Lighthouse Factories use AI and data to work better. This helps them save money and make fewer mistakes. Real-time data and machine learning help make things faster. Teams can fix problems quickly and make products better. Predictive maintenance stops machines from breaking down. This saves money and helps people work more. Humans and machines work together in these factories. This makes workers happier and helps them finish jobs faster. Lighthouse Factories also care about the environment. They use AI to cut down on waste and use less energy. This helps make factories greener.

Global Lighthouse Factory Overview

Defining Lighthouse Factory

A global lighthouse factory is a leader in smart manufacturing. The World Economic Forum’s network picks these factories for using new technology. Factories get this name when they improve money, work, and the environment. Experts from many countries and industries choose which factories become digital lighthouses. These factories use AI, automation, cloud computing, and the Internet of Things. They create a system where data moves through every step. Teams can make quick choices because of this data. The main part of a global lighthouse factory is a value chain that uses data and smart planning. Every part of the process connects, from getting supplies to making products to sending them out. This system uses digital tools and teamwork to help factories do well.

Factories use AI-enabled systems to watch things in real time.

Digital tools connect all departments in end-to-end value chain lighthouse sites.

Digital lighthouses are setting new goals for smart manufacturing.

Industry 4.0 Impact

Industry 4.0 is changing manufacturing with digital tools. The global lighthouse network and McKinsey show how factories use digitalization to fix big problems. These factories are leaders in getting more done, helping the planet, and managing workers. They prove that smart manufacturing can make a big difference.

"Digital technologies are changing how we make things," said Kiva Allgood, Head of the Centre for Advanced Manufacturing and Supply Chains, World Economic Forum.

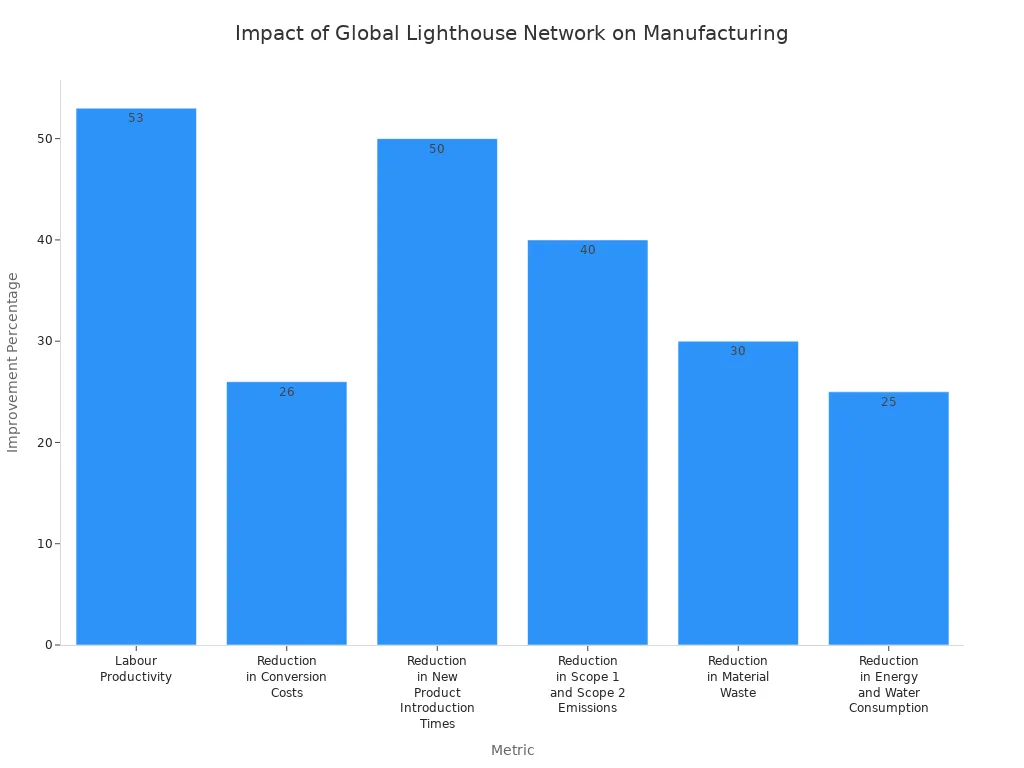

Factories in the network have great results:

Metric | Improvement Percentage |

|---|---|

Labour Productivity | 53% |

Reduction in Conversion Costs | 26% |

Reduction in New Product Introduction Times | 50% |

Reduction in Scope 1 and Scope 2 Emissions | 30%-50% |

Reduction in Material Waste | 30% |

Reduction in Energy and Water Consumption | 25% |

Digital lighthouses use AI-driven control towers and easy-to-use workflows. These tools help teams work together and react fast to changes. The closed-loop workflow makes each step smarter and more connected. The global lighthouse factory model encourages others to use digital and AI-powered tools for smart manufacturing.

Data-Driven Production Optimization

Lighthouse factories lead the way in digital change. These factories use data-driven strategies with AI to make manufacturing better. The workflow in a lighthouse factory is a closed loop. It uses real-time data and machine learning. Teams work together at every step, from getting supplies to sending products. This creates a value chain that gets better every day.

Real-Time Improvements

Production gets better with real-time data. Machine learning, automation, and AI watch every process. Teams get feedback right away and can act fast. This helps factories work better and make higher quality products.

"When factories use new technology, they improve every part of production," said a leader from the global lighthouse network.

The results are easy to see. Recent lighthouse factories saw labor productivity go up by 53%. Costs went down by 26%. Defects dropped by 99%. These numbers show how data-driven and AI-powered solutions help factories.

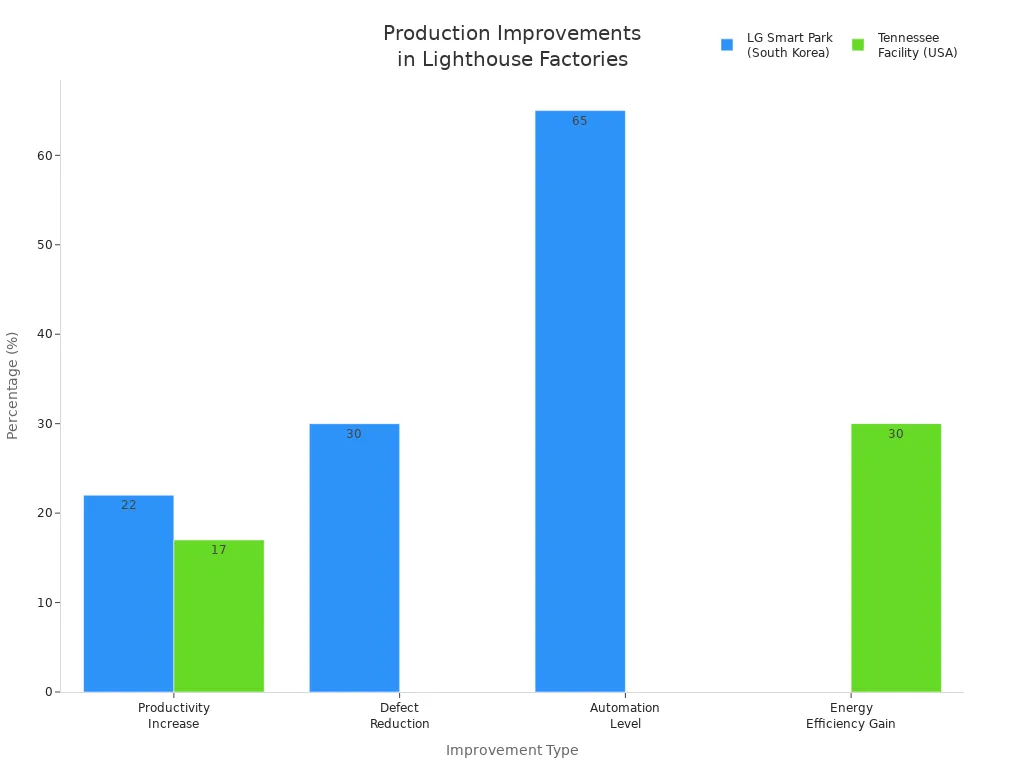

Here is how real-time improvements look in different places:

Improvement Type | LG Smart Park (South Korea) | Tennessee Facility (USA) |

|---|---|---|

Productivity Increase | 22% | 17% |

Defect Reduction | 30% | N/A |

Automation Level | 65% | N/A |

Energy Efficiency Gain | N/A | 30% |

Factories like Tinsukia use AI-powered vision systems to make changeovers faster by 85%. Labor productivity goes up by almost 400% when machine learning helps with workforce planning. The frozen period drops from 14 days to just one day. This means products get to market much faster. Teams use digital planning tools to check over 10,000 product choices for real-time demand. These AI tools help find problems and keep production smooth.

Predictive Maintenance

Predictive maintenance is a big part of digital factories. Machine learning checks equipment and finds problems before they happen. Condition-based maintenance lets teams spot trouble early and stop breakdowns. Predictive maintenance helps machines last longer and saves money by only changing worn parts.

Condition-based maintenance helps teams find failures early and stop breakdowns.

Predictive maintenance lowers big damage and saves on costs.

Watching machines all the time makes production smoother and keeps things running.

Factories cut down on extra maintenance costs from surprise breakdowns. Predictive maintenance means more output and less space needed for repairs. Teams have better schedules and fewer stops.

AI-Enabled Use Cases in Leading Factories

Companies like Siemens, LG, and Fujitsu show how AI use cases help factories work better. Their ways set new goals for the industry.

Company | AI Implementation Description |

|---|---|

Siemens | AI-driven IT automation and smart performance analytics. |

LG | AI-driven IT management and cloud monitoring tools. |

Fujitsu | AI-based performance management and cloud-security analytics. |

These companies use digital tools and machine learning to make production better. Siemens uses smart analytics to boost performance. LG uses cloud monitoring to keep systems working well. Fujitsu uses performance management and cloud-security analytics to protect and improve operations.

Overcoming Challenges

Manufacturers face problems when using data-driven and AI-powered solutions. Bad data and hard-to-reach data can slow things down. Old systems can block automation and AI. Teams need to move to cloud platforms to grow. Changing rules need attention all the time. Companies must invest in new tools and skilled people to do well.

Tip: Teams that use digital change and invest in machine learning build a strong base for growth.

Lighthouse factories show that with the right tools and mindset, any factory can reach manufacturing excellence. Their closed-loop workflows and teamwork set a new standard for everyone.

AI Quality Control

Lighthouse Factories use AI and digital tools to improve quality control. They have a closed-loop workflow. Data moves easily from one step to the next. Teams work together across the value chain. This helps every product meet high standards. AI-powered systems and machine learning make these changes possible. Quality control is now faster, smarter, and more dependable.

Automated Defect Detection

Factories in the global lighthouse network use advanced AI to find defects early. Machine learning models check thousands of data points right away. These models get better with each inspection. They learn and improve their accuracy every time. AI-powered technology can spot tiny flaws that people might not see. This is very helpful during fast production.

"AI-driven quality control can find up to 99% of defects and cut inspection time from one minute to just 2.2 seconds."

Here is what AI-enabled defect detection can do:

Metric | Value |

|---|---|

Defect Detection Accuracy | 99% |

Inspection Time Reduction | From 1 minute to 2.2 seconds |

Defect Rate Reduction | 30% |

Cost Reduction | 30-fold |

Factories use different automated systems to get these results:

AI-enabled cameras check important connection points and catch small mistakes.

Smart equipment plug-ins use deep learning to warn technicians about possible problems.

Product tracing systems follow each item from the factory to the customer, so it is easy to act if a defect is found.

BMW’s AI plan helped cut defects by 60%. Proactive AI solutions save more money than old ways. Siemens uses machine learning to make testing better. Their AI-guided robots have lowered automation costs by 90%. Workers now get help from AI-guided systems, which raises both productivity and quality.

Valeo’s Shenzhen plant shows how strong AI can be. The team started 42 Fourth Industrial Revolution projects. They put AI into every part of their work. They cut lead time by 34.5% and raised productivity by 60.2%. The defect rate for smart front camera products dropped a lot. This proves digital transformation works.

Product Consistency

Consistency is very important in manufacturing. AI-powered quality control uses computer vision and machine learning to check every product in real time. These systems find visual mistakes, size errors, or material problems that people might miss, especially when things move fast.

AI-driven visual inspection systems use fast cameras and deep learning to spot flaws right away.

These tools make sure every product meets strict quality rules, lowering human error and catching even small problems.

AI learns from old defects, so it gets more accurate and reliable over time.

Siemens and Valeo both show how AI keeps quality high. Siemens uses machine learning to improve first-pass yield and efficiency. Valeo’s digital plan makes sure every smart camera meets what customers want. Teams work together across the value chain, using digital data and AI-powered systems to keep products consistent.

AI in Lighthouse Factories creates a closed-loop system. Data goes from inspection to production and back again. This lets teams act fast and stop problems. Automation and AI work with skilled workers. This builds a culture of always getting better. The result is higher efficiency, lower costs, and products customers can trust.

Empowered by AI: Workforce & Supply Chain

Human-Machine Collaboration

Lighthouse Factory teams do better when people and machines work together. Machine learning and automation help workers finish tasks faster and with fewer mistakes. Some factories in the Global Lighthouse Network have made productivity almost double. Lead times are much shorter, dropping by up to 80%. Many factories now use half as much energy as before.

Schneider Electric’s Monterrey factory uses the EcoStruxure platform. This helped them cut downtime by 25% and lower energy use by 29%.

Workers get help from AI-powered systems. These tools show new workers each step and give quick tips to experienced staff.

Generative AI assistants give real-time help. They solve problems fast so work does not stop.

A leader from the World Economic Forum said, “When people and machines work together, they become more skilled and efficient.”

Companies that use AI for training see workers become happier by 31%. Machine learning looks at what skills workers have and makes training that fits each person. Predictive analytics help teams get ready for new jobs, so they can handle changes better.

Digital Supply Chain

Digital change helps Lighthouse Factories make their supply chains more flexible. Machine learning and digital tools let companies react quickly to new problems. Generative AI is now used in real work, not just tests.

Use Case | Description |

|---|---|

Demand Forecasting | |

Inventory Optimization | Puts products in the best places to save time and money. |

Predictive Maintenance | Tells when machines need fixing to stop breakdowns. |

Route Optimization | Plans the best delivery routes to save fuel and time. |

Digital Twins | Copies factory steps to use resources smarter. |

Mass Personalization | Changes product designs fast for each customer. |

Workforce Training | Makes training for each worker’s job and skill. |

Sustainable Manufacturing | Finds ways to use less energy and make less waste. |

Walmart uses generative AI to guess what customers will buy. Amazon uses smart programs to manage inventory. Rolls-Royce uses machine learning to know when engines need fixing. UPS uses AI to plan delivery routes and save fuel.

A Lighthouse Factory’s workflow is a closed loop. Data-driven choices and empowered by AI systems link every part of the value chain. Teams work together from start to finish, making supply chains strong and able to change quickly.

Sustainability in Lighthouse Factories

Energy Efficiency

Lighthouse Factories are leaders in green manufacturing. They use smart ways to save energy and money. Teams work to cut waste and make production better. They also use more renewable energy. Data and AI help guide every step in the process. This closed-loop system helps others want to do the same.

Strategy | Description |

|---|---|

Waste Reduction | Less waste in each step saves money and resources. |

Production Optimization | Smarter steps help use less energy and work better. |

Renewable Energy Integration | Solar and wind power lower costs and cut pollution. |

Automation and Digitization | Machines and AI work together to boost output and need fewer workers. |

Sustainable Production | Green actions help factories grow and protect the earth. |

Factories in the Global Lighthouse Network have big wins: They work 30% more efficiently. Costs are 15% lower. There are 37% fewer complaints from customers. Some factories have zero-carbon goals and green awards.

Novelis is a top company in aluminum. Its Ohio plant uses 97% recycled content. This cuts energy use and helps the circular economy. Unilever’s Tinsukia factory in India uses digital twin technology and AI. This helps them reach new sustainability goals.

Smart Resource Management

AI changes how factories use resources. Teams use data-driven systems to watch energy, water, and materials. This helps give better service, make fewer mistakes, and keep the environment clean.

AI use in the Global Lighthouse Network grew from under 20% in 2018 to almost 60% by 2023.

Many sites doubled or tripled their productivity.

Energy use dropped by 30%.

64% of lighthouses show good results for the environment from AI.

Fujitsu is a strong example. Its logistics data service uses government rules and cloud tech to keep data the same. The Virtual Watch Tower project uses advanced AI to watch supply chains and lower greenhouse gas emissions. Foxconn and Midea Hefei use AI and IoT to track carbon and recycle more. They cut emissions by over 40%.

🌱 “Sustainability is not just a goal. It is a journey powered by data, AI, and teamwork,” says a leader from the Global Lighthouse Network.

Lighthouse Factory leaders notice big changes with data-driven and empowered by AI solutions. They make work faster, save money, and help teams get better.

CITIC Dicastal in Morocco taught workers new skills. They kept more workers and filled more top jobs with local people.

Continental made an AI logistics center. They lowered scrap costs by almost half and made machines work better.

Haitian Flavouring & Food in China used a smart nose system. It checked more products and did it four times quicker.

Trend Description | Prediction | Year |

|---|---|---|

Production Efficiency | By 2027, 30% of Asia’s top factories will use smart planning to keep PO rates above 95%. | 2027 |

Quality Management | By 2028, 40% will use GenAI to check quality. This will save time and money by 10%. | 2028 |

Supply Chain Optimization | By 2028, 40% will add more spare parts partners to help fix things worldwide. | 2028 |

Industry leaders say everyone should learn digital skills, make strong teams, and use green ideas in every step. The future will be better for those who start now.

FAQ

What makes a Lighthouse Factory different from a regular factory?

A Lighthouse Factory connects all steps with data and AI. Teams work together at every stage. This teamwork helps them make more products and better quality.

How does AI help workers in Lighthouse Factories?

AI gives workers tips and training right away. Teams fix problems quickly and learn new things. Machine learning helps everyone do their jobs better and stay safe.

Why is end-to-end collaboration important in Lighthouse Factories?

End-to-end teamwork connects each part of the value chain. Teams share data and ideas with each other. This helps them create new things and keep work moving well.

Can Lighthouse Factories help the environment?

Yes! Lighthouse Factories use smart tools to save energy and resources. AI helps teams waste less and lower pollution. 🌱 They are leaders in green manufacturing.

What is a closed-loop workflow in a Lighthouse Factory?

A closed-loop workflow lets data move through every step. AI checks each part and gives advice. Teams use this to make things faster and better every day.

See Also

Mastering Lean Logistics for Success in High-Tech Production

Transforming Future Logistics Through AI Supply Chain Solutions

Enhancing Efficiency With Innovative AI Supply Chain Strategies

Automated Solutions: Advantages for High-Tech Manufacturing Warehouses

Seamless Success: Ensuring Continuity in Supply Chain Operations