Key Innovations Driving Logistics Automation Forward

Logistics automation changes the industry in 2025. More than 65% of companies use artificial intelligence and robotics. These help them work better and faster. The main innovation areas are AI, IoT, blockchain, and sustainability. These areas help companies see real improvements. JUSDA is a leader in these trends. They set new rules for innovation and automation around the world.

Key Takeaways

Logistics automation uses AI, robotics, IoT, and blockchain to help supply chains work faster. These tools also make supply chains smarter and more reliable.

Real-time data and AI tools help companies guess what people will want. They help companies plan better. They also help companies react fast to changes. This saves time and money.

Sustainable practices like green warehousing and electric vehicles help lower emissions. They also support eco-friendly logistics for the future.

Logistics Trends 2025

Digital Transformation

Digital transformation is very important in logistics for 2025. Companies use AI, blockchain, cloud computing, big data analytics, and IoT. These help them collect and share data much faster. They make work easier and connect the supply chain better. Many companies now move goods faster and with better quality. They can also change plans quickly when needed. Inventory tracking is more exact, and data is shared right away. Digital tools like warehouse management systems and cloud platforms help with planning. They also help guess what customers will want. Automation in warehouses and route planning cuts down on mistakes and saves money. Robots and drones help put orders together and check inventory. This is very helpful when business is busy. B2B e-commerce is growing and brings new ideas. Digital tools and CRM integration help make logistics smarter. JUSDA is a leader in these changes. They give advanced digital supply chain solutions all over the world.

Globalization and Resilience

Globalization and resilience are big trends in logistics for 2025. Companies face new risks from world events, trade rules, and climate problems. They answer by using more suppliers and making supply chains flexible. The table below shows important points:

Aspect | Evidence Supporting Globalization and Resilience in Logistics for 2025 |

|---|---|

Global Trade Expansion | Global trade hit $33 trillion in 2024. This shows globalization is still growing. |

Supply Chain Strategy | Companies use suppliers from many places to lower risk. |

Tariffs and protectionism make things unsure, so resilience is important. | |

Policy Recommendations | Working together worldwide helps growth and resilience last. |

Trade Imbalances and Risks | Complicated trade needs smart and flexible logistics plans. |

JUSDA’s global network has regular freight services and strong local links. This supports new technology and ways of working. Their leadership in digital supply chain management helps companies stay quick and strong in a changing world.

AI in Logistics Automation

Artificial intelligence and machine learning are changing how logistics works in 2025. Companies use these tools to make smarter choices and save money. AI-driven automation helps teams finish hard jobs faster and with fewer errors. Real-time data and predictive analytics let managers plan ahead. They can also react quickly to changes in the supply chain.

Predictive Analytics

Predictive analytics is very important in logistics. It uses artificial intelligence and machine learning to study lots of data. This data includes weather, traffic, and market trends. Companies use predictive models to:

Make better guesses about what customers will want.

Find the best delivery routes to save time and fuel.

Know when machines need fixing, so they break less.

Automate warehouse jobs like sorting and scanning packages.

Keep track of inventory by guessing what will sell and restocking.

Plan for risks by looking at supplier data and market changes.

Help the environment by cutting extra trips and emissions.

Many logistics companies now use predictive analytics to get ready for busy times. These tools help balance inventory, lower costs, and make customers happier. AI-driven automation also helps with changing prices and cutting waste. About 55% of logistics companies want to use AI for demand forecasting and inventory management by the end of 2024. This shows that more companies are using data to make decisions.

Predictive analytics also helps manage risks. It lets managers find problems early, like weather delays or broken machines. Companies can use real-time alerts to change plans and stop problems. Predictive models also give better delivery times and help customers know when to expect their orders.

JusLink AI Solution by JUSDA

JUSDA’s JusLink AI solution brings smart automation to supply chain management. The platform uses artificial intelligence, IoT, and big data to connect all parts of the supply chain. JusLink gives managers real-time updates on shipments, inventory, and warehouse work. It helps teams share information fast and work together.

JusLink’s AI-driven automation includes:

Looking at supply chain trends and guessing freight rates.

A risk control tower for real-time checks and early warnings.

JusElsa, a smart helper that uses natural language processing for easy talking.

JUSDA’s customer stories show how JusLink changes logistics management. Electronics makers use JusLink to handle global supply chains, work better, and save money. Car companies use JusLink for better warehouse management and different ways to move goods. The platform helps make supply chains greener by working more efficiently and cutting waste.

JusLink’s AI solution helps companies switch from manual work to using data for decisions. This means better planning, faster reactions, and stronger supply chains.

Scenario Planning

Scenario planning with AI gives logistics managers a strong tool for making choices. Old planning methods take weeks or months to test ideas. AI-driven automation can test thousands of scenarios in just minutes. This helps managers see how changes in weather, demand, or supply affect everything.

With scenario planning, companies can:

Get ready for surprises like port strikes or natural disasters.

Try out different logistics plans and pick the best one.

Change plans quickly when new risks or trends show up.

Balance things like space limits and special sales.

AI-driven scenario planning makes it easier to handle surprises in logistics. It helps teams work together, share data, and make clear choices. Companies use these predictions to manage risks, improve supply chains, and stay flexible in a changing world.

AI-driven automation in scenario planning helps managers act early. They can spot risks, change shipment routes, and use resources better. This leads to fewer delays, lower costs, and happier customers.

Logistics Automation and Robotics

Warehouse Robotics

Warehouse robotics are very important in logistics automation. Companies use robots for picking, packing, and sorting. These robots have AI and sensors to help them move. They avoid things in their way and find the best paths. Automation makes work faster and more accurate. This means fewer mistakes and less money spent. Robots do jobs that are boring or unsafe for people. This helps keep workers safe. Warehouse automation lets managers see inventory right away. It helps them make better choices. JUSDA uses advanced robotics and extra services in their warehouses. Their buildings have top security and reliability certifications. This shows they are serious about being a trusted partner.

Collaborative Robots (Cobots)

Cobots work with people in logistics automation and robotics. They help with sorting, picking orders, and loading trucks. Cobots have safety tools like force sensors and vision systems. These tools keep workers safe and help teams work together. Cobots can change to fit new warehouse needs. They also fit in small spaces. Using cobots makes orders go out faster and with fewer mistakes. JUSDA uses automation and robotics for safe and flexible warehouses.

Automated Storage Systems

Automated storage and retrieval systems are a big trend now. ASRS use AI and real-time data to store goods tightly. They also get items quickly when needed. These systems lower labor costs and cut down on mistakes. They use space better. ASRS can work all day without stopping. This helps get orders out faster and boosts productivity. JUSDA’s warehouse automation helps clients handle lots of goods and save money. This supports strong supply chain management.

IoT and Real-Time Visibility

Connected Supply Chains

The internet of things changes logistics by linking devices like sensors, RFID tags, GPS, and cameras. These devices gather and send live data about goods, vehicles, and storage. Companies use this data to track shipments and inventory in real time. This tracking helps managers see what is happening and make good choices.

Sensors check temperature, humidity, and location. They send updates to control centers right away.

RFID tags and GPS units track goods as they move through the supply chain.

Real-time data lets teams find delays, stop losses, and fix problems fast.

Automation with IoT means fewer manual checks and faster warehouse work.

Cloud platforms keep and study real-time data. This makes sharing and finding information easy.

Live tracking and clear data help companies plan well and serve customers quickly. With 5G and edge computing, data moves fast. This lets teams react right away. IoT also helps with predictive analytics. It lets companies guess demand and pick the best routes.

JUSDA’s JusLink Platform

JUSDA’s JusLink platform uses IoT for live tracking in global supply chains. The platform links partners from order to delivery. It gives updates and tracking at every step. JusLink’s cloud system shows managers all shipments, inventory, and warehouse work.

Dynamic dashboards show live data and tracking for every shipment.

Big data tools guess problems and help teams fix them early.

One-stop solutions mix main and extra services for better automation.

Security is very important in IoT logistics. Some problems are weak device security, data leaks, and old systems not working with new devices. The table below shows these problems and ways to fix them:

Cybersecurity Challenge | Description | Example / Solution |

|---|---|---|

Weak IoT Security | Devices may not have good protection. Hackers can attack them. | Use strong encryption and safe protocols. |

Data Exposure | Live data can be stolen or changed. | Use many layers of security and update often. |

Integration with Legacy Systems | Old systems may not work with new IoT devices. | Use middleware to connect systems safely. |

Connectivity Issues | Remote places may have bad network coverage. This causes tracking gaps. | Use satellite or LoRaWAN for good live tracking. |

Investment Costs | High costs can slow down using automation and live tracking. | Pick scalable solutions and spend money wisely. |

JUSDA’s JusLink platform solves these problems with strong security, easy data sharing, and steady live tracking. This keeps supply chains safe and running well.

Blockchain in Logistics

Secure Transactions

Blockchain technology makes logistics much safer. Companies use blockchain to keep a record of every transaction. This record cannot be changed unless the network agrees. This makes fraud and tampering much harder. Logistics teams use blockchain to:

Stop fraud, like fake delivery times, by keeping a clear history.

Use special tools to check digital documents and track things live.

Automate work with smart contracts to lower invoice fraud risks.

Make fast, safe payments across borders without extra middlemen.

Release money only when contract rules are met, making deals safer.

Blockchain uses codes to keep data safe. Once a transaction is added, it stays for everyone to see. This helps logistics companies work faster and use more automation.

Transparency and Trust

Transparency and trust are very important in logistics. Blockchain gives everyone a shared record that cannot be changed. This record shows every step, from where a product starts to where it ends. Companies get many benefits:

See shipments and inventory live, so no one is left out.

Track products from start to finish, with all checks recorded.

Use smart contracts to cut paperwork and stop mistakes.

No need for middlemen, so deals are safer and faster.

Better security to stop fraud and fake products.

Blockchain gives one true record. This helps everyone trust each other and work together better in the supply chain.

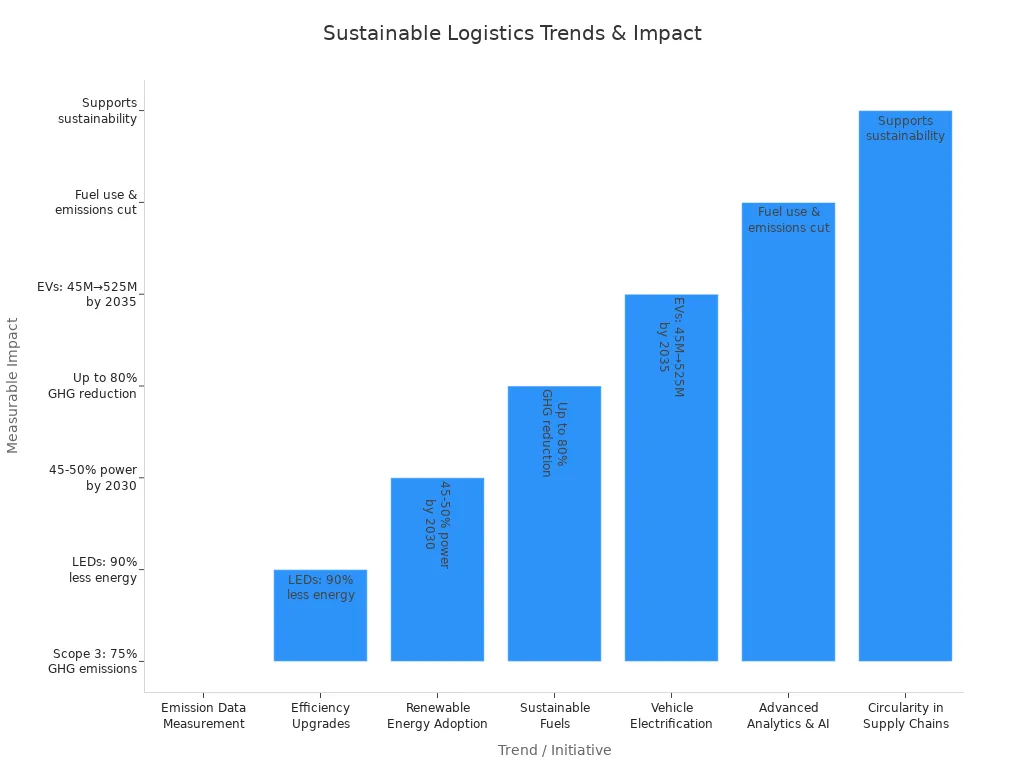

Sustainable Logistics Industry Trends

Sustainable logistics is changing how supply chains work. Companies want to lower emissions and use less energy. They also try to build supply chains that reuse and recycle. The table below shows new trends and how they help cut carbon emissions:

Trend / Initiative | Description | Measurable Impact / Data Points |

|---|---|---|

Decarbonization | Reducing carbon footprint by measuring emissions across Scope 1, 2, and 3 | Transport and logistics sector contributes ~24% of global CO2e emissions |

Electric Vehicle Fleets | Adoption of EVs in logistics, especially last-mile delivery | DHL aims for 60% of last-mile vehicles electric by 2030 |

Green Energy Solutions | Switching to renewable energy suppliers, installing solar panels | Over 30% of global electricity generated from renewables as of 2023; reduces carbon footprint |

AI Innovations | AI for demand forecasting, route optimization, and energy efficiency | Reduces fuel consumption and emissions by optimizing logistics operations |

Circularity | Closed-loop reuse and recycling systems in supply chains | 55% of large businesses committed; supports long-term sustainability |

Green Warehousing

Green warehousing means using eco-friendly ways to save energy. Companies add LED lights and motion sensors to warehouses. They use smart HVAC systems to control temperature. Solar panels and electric forklifts help use less fossil fuel. Warehouse management systems stop overstocking and save energy. Using better packaging and recycling helps too. Workers learn about saving energy and being green.

Electric and Autonomous Vehicles

Electric vehicles and self-driving trucks are changing delivery fleets. Over 100 cities test self-driving delivery vehicles now. More than 70% of big stores want to work with self-driving truck companies. These trucks can lower carbon emissions by about 30%. Experts think self-driving trucks will be normal by 2035. Using automation in transport helps the planet and company goals.

JUSDA’s Sustainability Initiatives

JUSDA is a leader in eco-friendly actions around the world. The company spends money on green warehouses and energy-saving automation. JUSDA uses LED lights, smart climate control, and solar panels in its buildings. They use recyclable packaging and make reverse logistics better. JUSDA’s digital tools use AI to plan routes and cut emissions. These steps help lower carbon footprints and support green logistics everywhere.

JUSDA Solutions

To provide you with professional solutions and quotations.

Logistics automation and robotics help companies work faster and save money. They also make jobs more accurate. JUSDA is a leader in these new solutions. They help businesses all over the world.

The main benefits are:

Tasks get done quicker

There are less mistakes

Work runs more smoothly

Customers are happier

Companies need to use new technology. They should teach their teams and watch for new trends. This helps them stay ahead of others.

See Also

Transforming Supply Chains Through Innovative Logistics Solutions

Artificial Intelligence Driving The Future Of Supply Chains

Digital Technologies Paving The Way For Future Logistics

Exploring Cutting-Edge Technology Advancements In Logistics

Robotic Innovations Boosting Efficiency In Warehouse Operations